Manual, Robotic Tool Changer Third Generation Teaching Aids

Document #9610-20-3370-02

Pinnacle

Park

•

1031

Goodworth

Drive

•

Apex,

NC

27539

USA

•

T

el:

919.772.01

15

•

Fax:

919.772.8259

•

www.ati-ia.com • Email: [email protected] 5

1. Safety

The safety section describes general safety guidelines to be followed with this product, explanations of the

notications found in this manual, and safety precautions that apply to the product. More specic notications are

imbedded within the sections of the manual where they apply.

1.1 ExplanationofNotications

The following notications are specic to the product(s) covered by this manual. It is expected that the user

heed all notications from the robot manufacturer and/or the manufacturers of other components used in the

installation.

DANGER: Notication of information or instructions that if not followed will result in

death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

WARNING: Notication of information or instructions that if not followed could result

in death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

CAUTION: Notication of information or instructions that if not followed could result

in moderate injury or will cause damage to equipment. The notication provides

information about the nature of the hazardous situation, the consequences of not

avoiding the hazard, and the method for avoiding the situation.

NOTICE: Notication of specic information or instructions about maintaining, operating,

installing, or setting up the product that if not followed could result in damage to equipment. The

notication can emphasize, but is not limited to: specic grease types, best operating practices,

and maintenance tips.

1.2 General Safety Guidelines

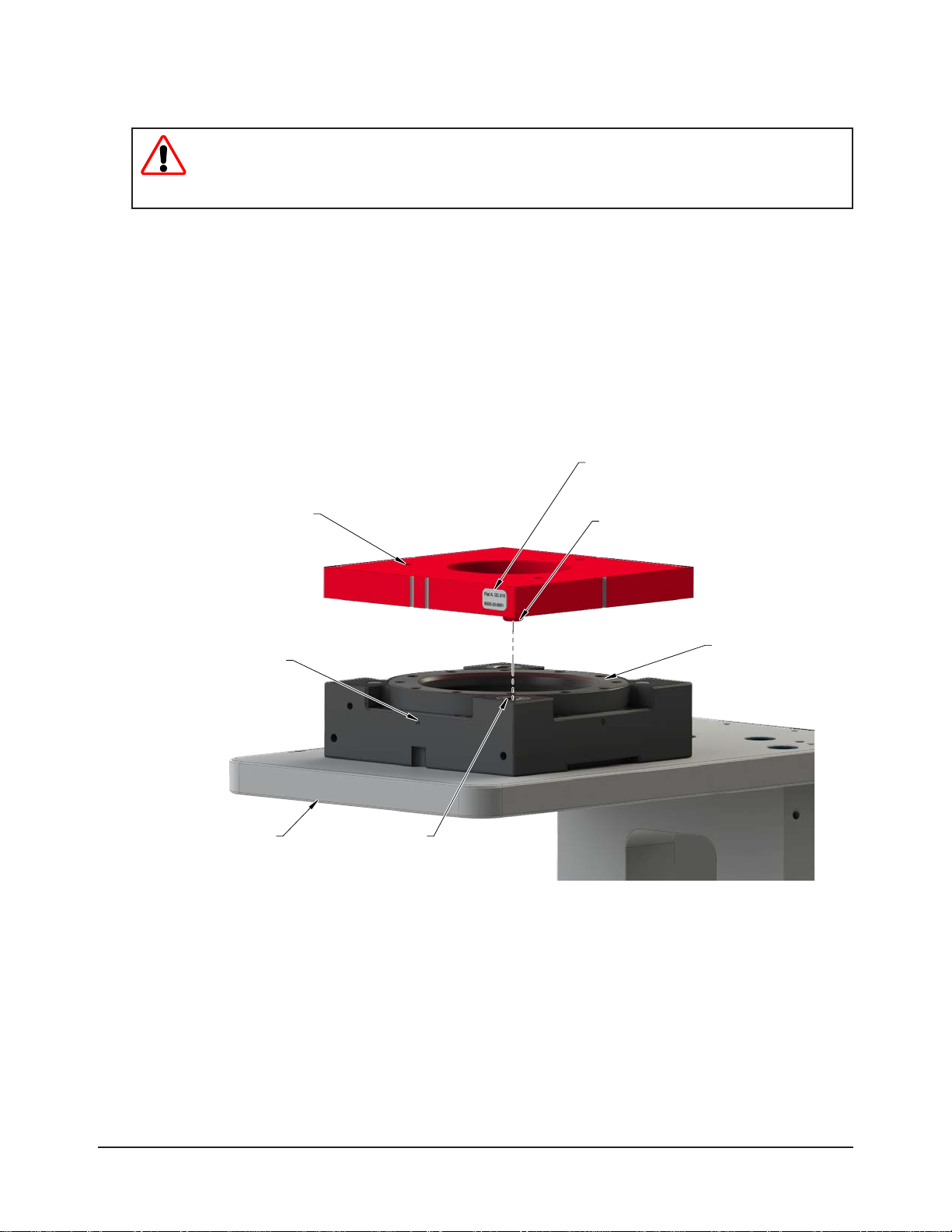

The customer is responsible for ensuring that the area between the Master and Tool sides is clear of foreign

objects during mating and subsequent coupling. Failure to do so may result in serious injury to personnel.

The customer is responsible for understanding the function of the Tool Changer and implementing the

proper hardware and/or software to operate the Tool Changer safely.