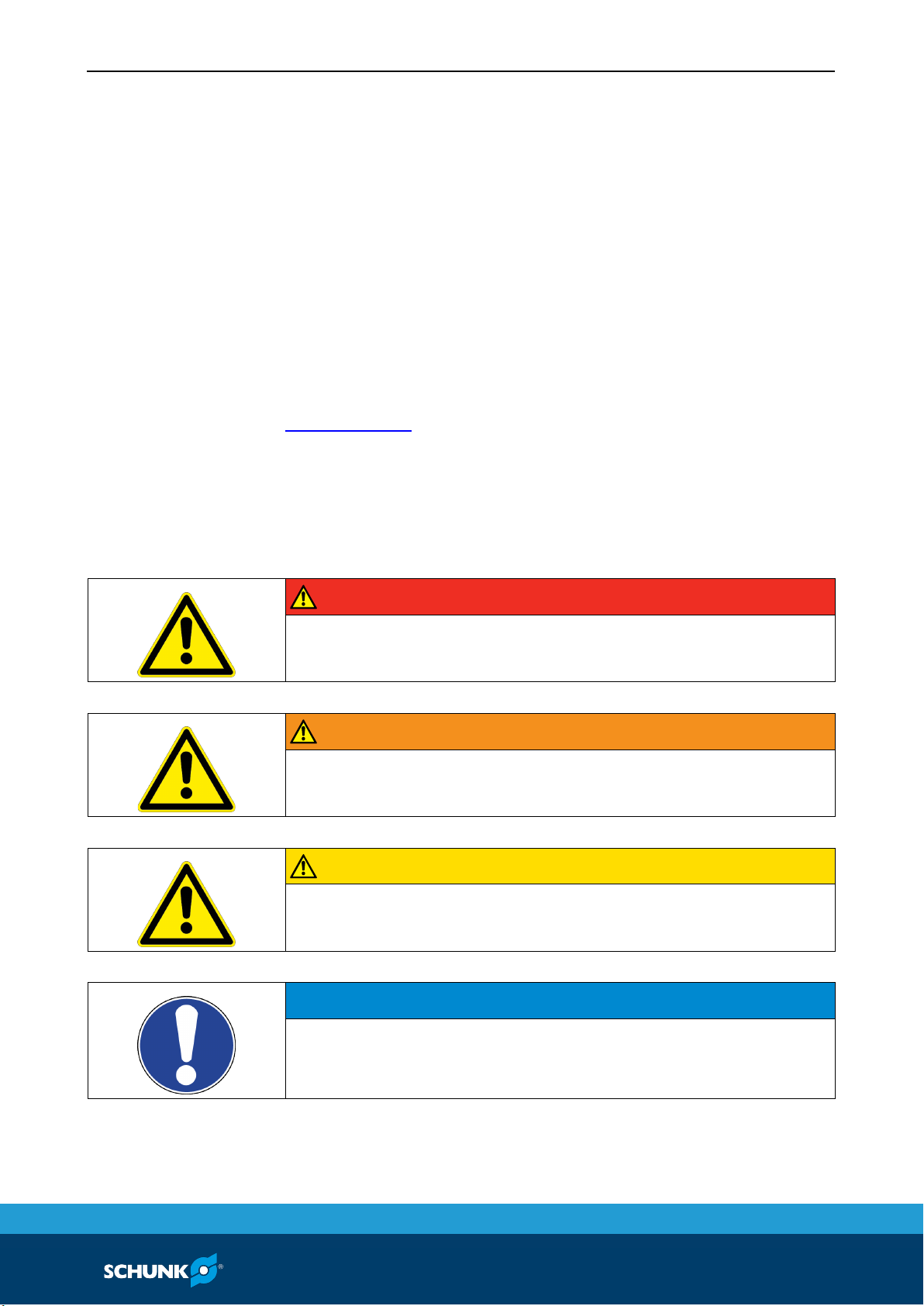

Basic safety instructions

02.00|0889073_ROTA TB-TBS-

7

Basic safety instructions

Improper handling, assembly and maintenance of this product may

result in risk to persons and equipment if this operating manual is

not observed.

Report any failures and damage immediately and repair without

delay to keep the extent of the damage to a minimum and prevent

compromising the safety of the product.

Only original SCHUNK spare parts may be used.

Intended use

The chuck is used to clamp workpieces on machine tools and other

suitable technical facilities, paying particular attention to the

technical data specified by the manufacturer. The technical data

specified by the manufacturer must never be exceeded.

The product is intended for industrial use.

Intended use also means that the user has read and understood

this operating manual in its entirety, especially the chapter “Basic

safety notes”.

The maximum RPM of the chuck and the required clamping force

must be determined by the user for the respective clamping task

based on the applicable standards and technical specifications of

the manufacturer.

(See also “Calculations for clamping force and RPM” in the chapter

“Technical data”). (6.1, Page 19)

Not intended use

A not intended use of the product is for example:

• It is used as a press, a punch, a toolholder, a load-handling

device or as lifting equipment.

• the product is used for unintended machines or workpieces.

• the technical data is exceeded when using the product.

(6.1, Page 19)

• if workpieces are not clamped properly, paying particular

attention to the clamping forces specified by the manufacturer.

• if it is used in working environments that are not permissible.

• if the product is operated without a protective cover.