Model: Cyklop CX 85

Stand 11/2009

The semi-automatic strapping machine Cyklop CX 85 for the strapping of diverse packages and other products such as magazines.

The CX 85 can be used in many different branches of industry. It distinguishes itself through reliability, easy operation and low maintenance.

Great value was put into developing the operator panel.

Semi-automatic strapping

Features:

Automatic strap in-take

The strap is automatically guided from the

strap dispenser between guide rollers. After

pressing the start button threading begins

automatically. When the strap accumulator

is full the machine is ready to start opera-

tion.

Loop function

Unintentional blank strapping sequences are

ejected, the following strapping sequence

takes place undisturbed.

Strap end sensor

A sensor recognises when the strap coil is

empty. Strap surplus is automatically ejected

out of the machine and the machine is ready

for a new strap coil.

Operation

The strapping cycle may be started either

by push button, foot switch or a separate

switch on the table. The strapping cycle is

started as soon as the package is put into

the machine.

Strap tensioning

Pre-selection per potentiometer, continuous-

ly variable.

Lengthening the holding time

Seals snapping open belong to the past. The

seal holding time is automatically adapted

to the selected strap tension.

Flexible application

The CX 85 can be used almost anywhere

with its 4 castors and 230 V supply voltage.

Interior strapping coil

The coil is integrated in the machine which

results in a compact construction. The coil is

simply pulled out of the machine, changed

and pushed back.

Technical data:

Strapping capacity:

Up to 40 Cycles/min. Frame size 600 x 400

mm

depending on the pre-selected strapping

tension

and package size.

Small package: 80 mm x 30 mm (WxH)

Max. package weight: 30 kg.

Strapping material: Polystrap 5 x 0,45 mm

Strap coil:

Core diameter: 200 mm

Outer diameter: 420 mm

Width: 190 mm

Strap tension: 0 – 400 N

Noise: 74 dB(A)

Heating time: Approx. 30 sec.

Supply voltage: 230 V, 50 Hz

Machine weight: Approx. 200 kg

Color: RAL 5003

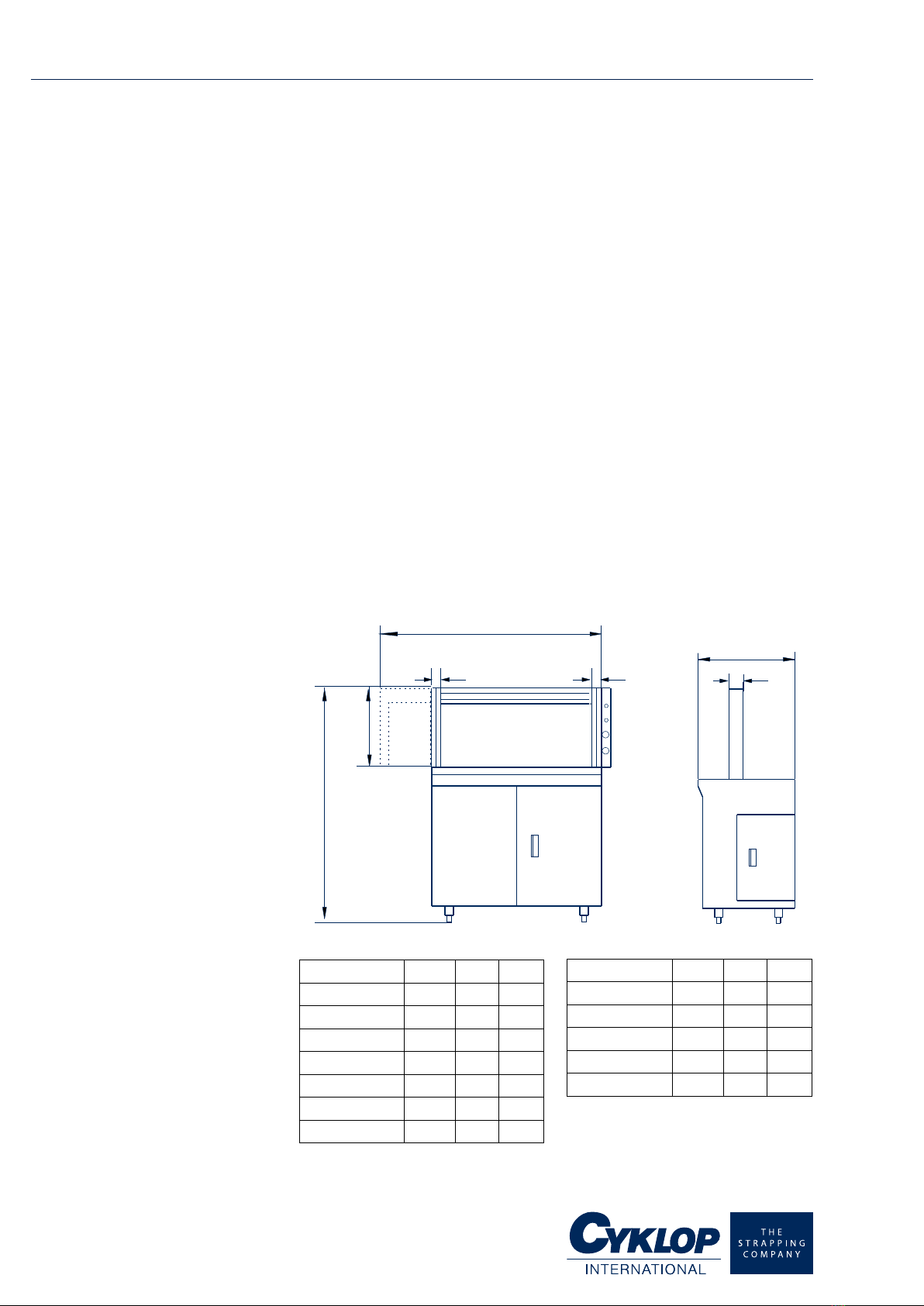

A

B

C

130 130

550

72

Frame size A B C

600 x 400 900 495 1315

800 x 400 1100 495 1315

1000 x 400 1300 495 1315

1200 x 400 1500 495 1315

1400 x 400 1700 495 1315

600 x 600 900 695 1515

800 x 600 1100 695 1515

Frame size A B C

1000 x 600 1300 695 1515

1200 x 600 1500 695 1515

600 x 800 900 895 1715

800 x 800 1100 895 1715

1000 x 800 1300 895 1715

PackSolutions

Post Box 78618-00507

Nairobi, KENYA

Phone: ++ 254 / 733 / 670 937

www.packsolutions.biz

info@packsolutions.biz

Subject to Modification.

Copyright 2009 by Cyklop GmbH

Protectory notice persuant to ISO 16016 to be observed

e