8

1. Accident prevention regulations

Caution!

To avoid the risk of i jury, please observe the

followi g i structio s.

Before starting work:

Familiarise yourself with the operati g ma ual a d

the applicable regulatio s before starti g work with

the hydraulic cutter.

Whe usi g hydraulic cutters i states of the

Europea U io , the regulatio s co tai ed i the EC

machi ery directive 98/37/EC must be observed a d

followed, as must all applicable atio al accide t

preve tio regulatio s.

I cou tries outside the Europea U io , the valid

local statutes a d regulatio s shall apply.

Whe tra sporti g the carrier with the hydraulic

cutter attached, the carrier ma ufacturer’s safety

i structio s shall apply.

Mounting the hydraulic cutter:

Check the omi al width of the hydraulic li es o

existi g hydraulic systems. All feed a d retur li es

for the hydraulic oil must have a adequate i side

diameter. (Refer to Sectio 4 "Tech ical

Specificatio s").

Use o ly hoses/pipes which satisfy the followi g

quality criteria:

Hydraulic hoses with 4 wire spiral layers to

DIN 20023.

Hydraulic pipes: seamless, cold draw steel pipes to

DIN 2391, page 2, grade C.

Check the ports o the hydraulic cutter a d the hose

co ectio s. The threads must be free of damage.

Clea off a y sa d or similar foreig bodies i the

threads.

Do ot ru a y hydraulic li es through the driver’s

cab.

Mou ti g the hydraulic cutter requires the prese ce

of a assista t, who must be i structed by the carrier

driver. The carrier driver a d assista t should agree

beforeha d o clear ha d sig als.

For tra sport purposes, use o ly the lug provided

a d hoisti g equipme t of sufficie t capacity.

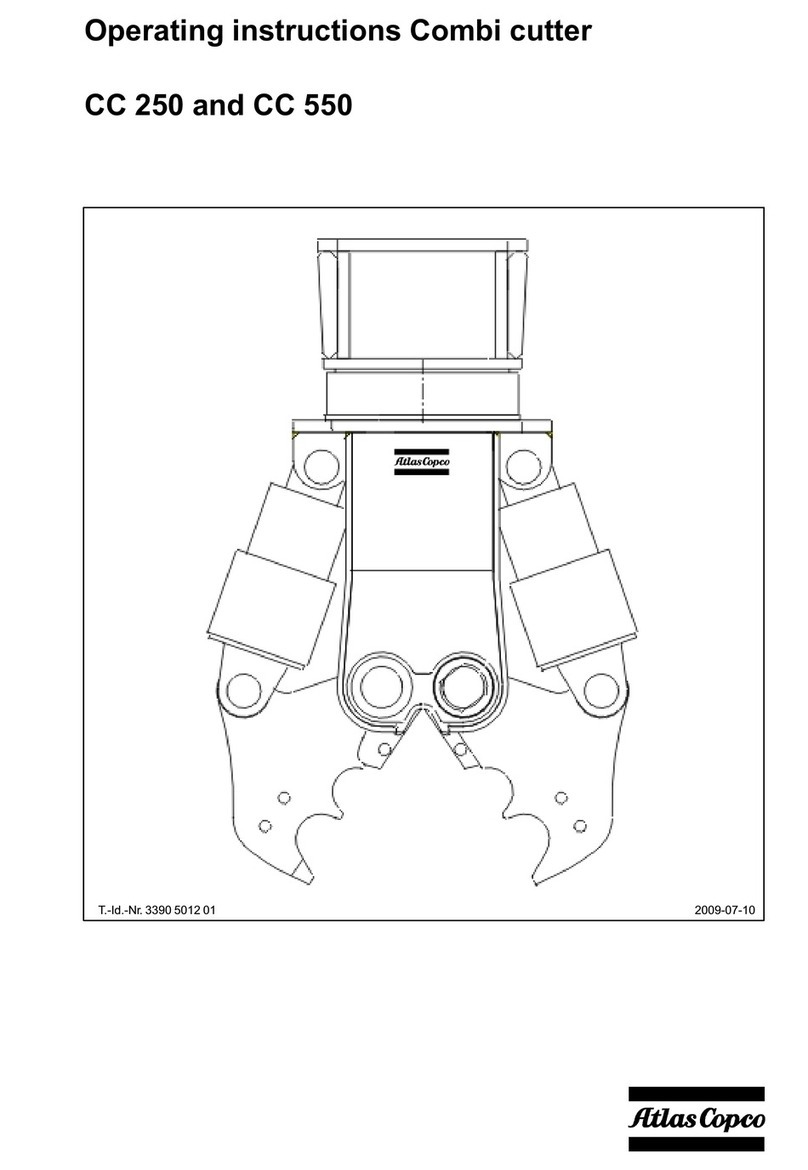

The hydraulic cutter should o ly be mou ted o a

carrier with sufficie t load capacity. For Atlas Copco

hydraulic cutters this ormally mea s a carrier as

show i the table below:

ÂÂÂÂÂÂ

Cutter model

ÂÂÂÂÂÂÂ

Carrier weight class

CC 1501

CC 2100

CC 4000

15 − 25 t

22 − 35 t

35 − 50 t

Check the pressure relief valve for the cutter circuit

o the hydraulic system to e sure it is set exactly to

the refere ce value.

Caution!

Collect a y oil which ru s out a d dispose of it

correctly.

The oil ca be very hot, risk of burns!

Cutter operation:

Before fitting and removing the hydraulic cutter

and/or performing service work on the cutter or

carrier hydraulics, ensure that the hydraulic

system has been depressurized!

(see section 10)

Observe the carrier ma ufacturer’s safety regulatio s

Whe worki g with a hydraulic cutter, carrier

operatio is gover ed by the carrier ma ufacturer’s

i structio s.

The hydraulic cutter may o ly be used for the

applicatio s described.

Close the fro t scree /spli ter guard o the driver’s

cab to protect the driver from flyi g rock spli ters

duri g cutter operatio s.

The hydraulic cutter should o ly be operated from

the driver’s cab.

Do ot start up the hydraulic cutter u til both carrier

a d hydraulic cutter are i the correct positio .

If the cutter is to be used i or u der water, prior

co sultatio with Atlas Copco’s Customer Support is

ecessary to clarify the special requireme ts for such

applicatio s.

Use o ly approved hydraulic oils.

All mi eral hydraulic oil bra ds prescribed by the

carrier ma ufacturer are suitable for cutter operatio .

The use of other hydraulic fluids is subject to prior

co sultatio .

Use o ly hydraulic oils of sufficie t viscosity.

I summer a d i tropical climates, oils of viscosity

class HLP 68 or higher should be used.

Observe the oil temperature at all times.

The temperature of the hydraulic oil must ever

exceed 80oC.

Do ot start up the hydraulic cutter at temperatures

below mi us 20oC u til the hydraulic oil has bee

warmed up.

Caution!

Stop the hydraulic cutter immediately if a yo e

moves i to the da ger zo e, i. e. a radius of at least

7 metres arou d the hydraulic cutter.