Qualification

Transporting the hydraulic attachment is only

permitted if carried out by people who:

•are authorised to operate a crane or a forklift

truck according to the applicable national

provisions,

•know all the relevant national/regional safety

provisions and accident prevention rules,

•have read and understood the safety and

transport chapter of these Safety and operating

instructions.

First installation and commissioning of the

hydraulic attachment is only permitted if carried out

by people who:

•are authorised by Construction Tools GmbH,

•know all the relevant national/regional safety

provisions and accident prevention rules,

•have read and understood these Safety and

operating instructions.

Installing, maintaining, storing and disposing of

the hydraulic attachment are only permitted if

carried out by people who:

•know all the relevant national/regional safety

provisions and accident prevention rules,

•have read and understood these Safety and

operating instructions.

Operating the hydraulic attachment is only

permitted if carried out by qualified carrier drivers.

Carrier drivers are qualified if they:

•have been trained to operate a carrier

according to the national regulations,

•know all the relevant national/regional safety

provisions and accident prevention rules,

•have read and understood these Safety and

operating instructions.

Testing the hydraulic installation is only

permitted if carried out by professionals.

Professionals are people who are authorised to

approve a hydraulic installation for operation

according to the national regulations.

Repairing the hydraulic attachment is only

permitted if carried out by professionals trained by

Construction Tools GmbH. These professionals

must have read and understood these Safety and

operating instructions. They must follow all safety

instructions and guidelines for repair. Otherwise

the operational safety of the hydraulic attachment

is not guaranteed.

Personnel (carrier operator, maintenance

personnel) must receive instructions from the

operator regularly. For the purpose of improved

traceability, the provision of instructions must be

recorded.

Intended use

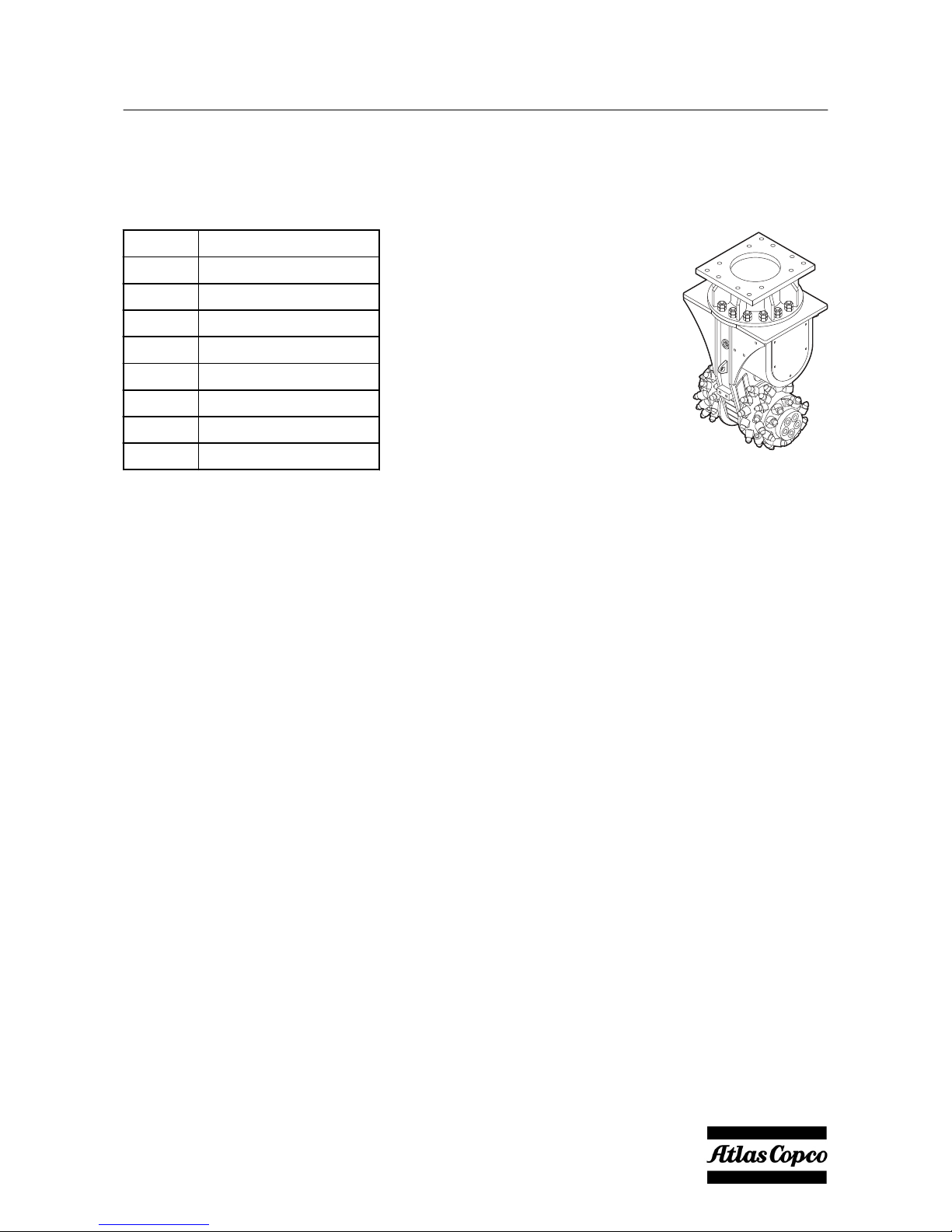

Only attach the transverse drum cutter to a

hydraulic carrier of a suitable load-bearing

capacity. Read the carrier manufacturer's Safety

and operating instructions before attaching the

transverse drum cutter to the carrier and operating

it. Observe all instructions.

The transverse drum cutter is intended exclusively

for mounting on a hydraulic excavator or, following

agreement with the Atlas Copco Customer Center/

dealer in your area, with another carrier.

The transverse drum cutter serves exclusively to

cut:

•Rock

•Concrete (reinforced and non-reinforced)

•Asphalt

•Frozen soil

•Ice

Furthermore, the transverse drum cutter is suitable

for cutting ditches and tunnels. The transverse

drum cutter can be used to a depth of 30 m under

water.

When cutting with the transverse drum cutter,

check the compressive strengths of the rock to be

cut (see chapter Technical specifications).

Intended use also includes adhering to all

specifications contained in this manual.

Any further use which exceeds or is contrary to the

intended use is considered inappropriate use.

Use other than intended

Misusing the transverse drum cutter or the boom

can lead to dangerous situations.

•Do not use the transverse drum cutter in areas

with a risk for explosions.

•Do not cut any materials other than those

mentioned in chapter Intended use.

•Do not carry out any impacting work.

•Do not operate the transverse drum cutter if

picks are broken.

•Do not use the transverse drum cutter as a

device for lifting people or materials.

•Do not use the transverse drum cutter as a

surface for carrying or transporting machines,

materials or tools.

•Do not use the transverse drum cutter to take

the weight of the carrier.

Claims of any kind as a result of damages arising

from misuse are excluded.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

9