[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

CONTENTS

Introduction.....................................

eee

semen

eessasennnansnn

1

TechnicalData....................................................

eee

6

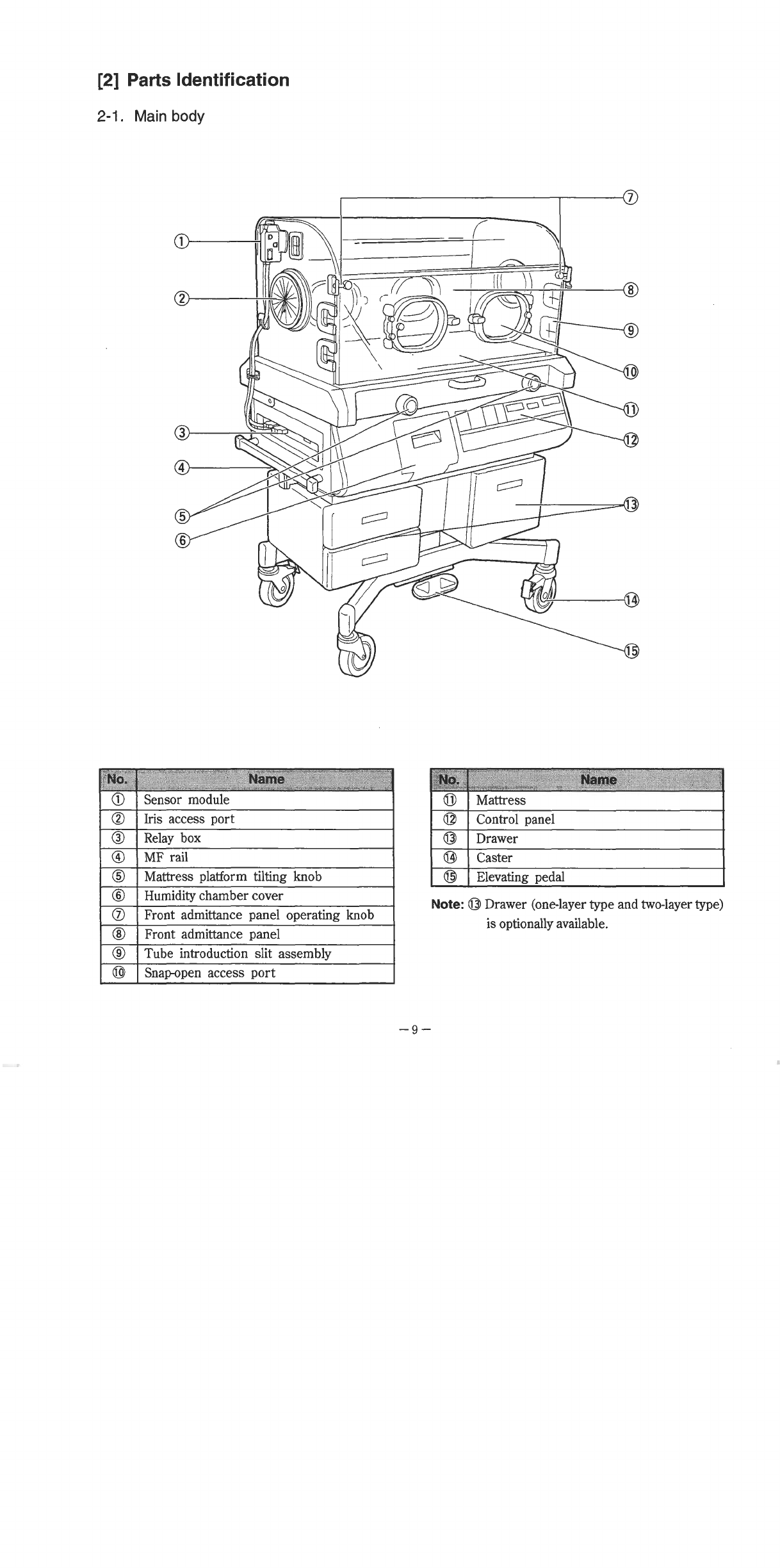

Parts

Identification

2-1.

Mainbody..................

eee

ere

eeezi

eee

cenere

ie

eee

eee

cei

re

nin

ezine

cazione

nere

9

2-2.

Control

Panel...

sise

11

Troubleshooting

3-1.

Troubleshooting

in

control

failure

rire

13

3-2.

Troubleshooting

in

system

malfunction

.............

irene

15

Cleaning,

Disinfection

and

Maintenance

4-1.

H00d

ennemies

20

4-2.

Mattress

Platform

and

Parts

Beneath

....................

rin

22

4-3,

Others

i...

ϱϱϱϱ”ϱ”ϱ-.--

24

4-4,

Humidity

Chamber

rire

iii

24

4-5.

Replacing

the

Filter

ss

26

4-6.

Replacing

the

Oxygen

Sensor

nn

27

Inspection

sn

29

Replacing

the

fuse

and

the

battery

.pe

36

SettingtheDIP

switch........................................................

emen

38

Periodical

replacement

partS

eee

39

Block

Diagram

and

Wiring

Diagram

.pe

41

Replacement

Parts

List...

ger

43