AU Tool CT500 User manual

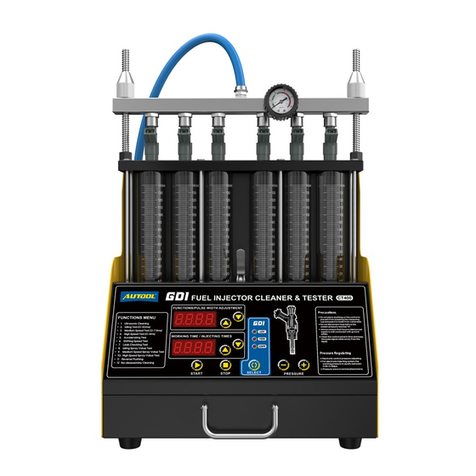

AUTOOL CT500

GDI Fuel Injector Cleaner & Tester

User Manual

用户手册

1

TABLE OF CONTENTS

Cautions .............................................................................................................. 2

Warning........................................................................................................... 2

Product Introduction.......................................................................................... 3

Overview ......................................................................................................... 3

Main functions ................................................................................................. 3

Main features .................................................................................................. 3

Working environment ...................................................................................... 4

Technical parameters ...................................................................................... 4

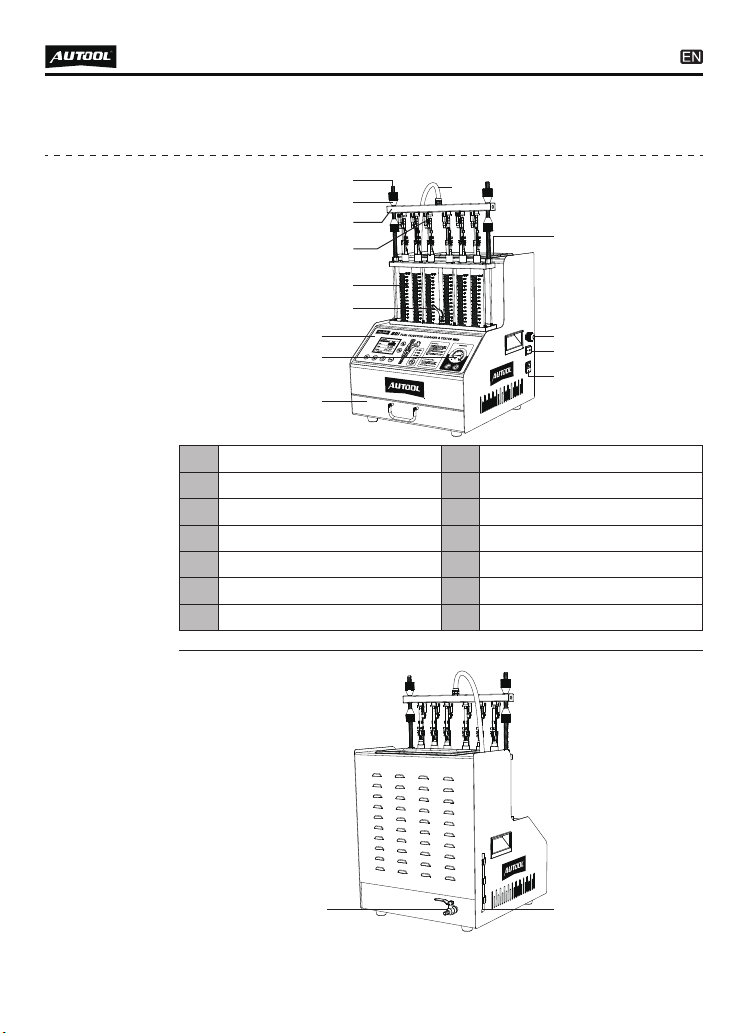

Product Structure............................................................................................... 5

Structure diagram............................................................................................ 5

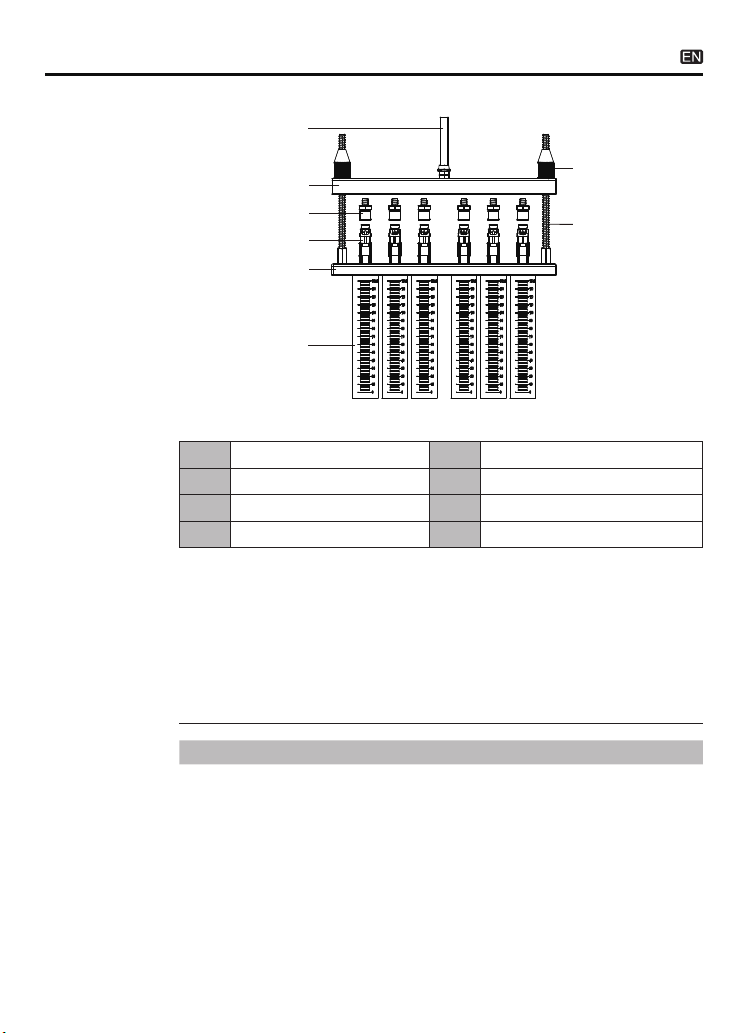

Operation panel diagram................................................................................. 6

Operation Process ............................................................................................. 7

Ultrasonic cleaning.......................................................................................... 7

Injector diagnostic ........................................................................................... 8

Storage And Maintenance ................................................................................. 13

Storage............................................................................................................ 13

Maintenance Service.......................................................................................... 14

Maintenance.................................................................................................... 14

Warranty .............................................................................................................. 15

Warranty access.............................................................................................. 15

Disclaimer ....................................................................................................... 15

Return & Exchange Service .............................................................................. 16

Return & Exchange ......................................................................................... 16

2

CAUTIONS

Warning

Since the test device is part of quartz glass, it is easy to break,

so do not place other objects around the equipment to avoid

bumping and breaking.

If there is no digital display after power on, please check

whether the power supply is powered; if so, check whether the

plug is connected firmly, or whether the fuse is blown. If it is not

broken, and the switch is still invalid after pressing the switch

several times intermittently, please contact the manufacturer

and must not disassemble it by yourself, otherwise our compa-

ny will not provide warranty.

When no cleaning agent is added to the ultrasonic tank, it is

strictly prohibited to open the ultrasonic cleaning item to avoid

damage to the ultrasonic system.

Every time the test solution is changed, it must be cleaned up,

and then 1L of new test solution should be added.

The use of unqualified testing agent will cause corrosion of the

oil pump, oil supply pipeline and failure of the pressure gauge.

Using other cleaning agent and testing agent will cause the

equipment surface coating to peel off.

It is strictly forbidden to use kerosene, gasoline or other testing

agent and cleaning agents as testing agent and cleaning

agents for this machine. Otherwise, the “O” ring and pipeline

rubber parts in the equipment will be damaged, causing

leakage.

The cleaning agent and testing agent should not be mixed up.

Before using the instrument, please read this manual careful-

ly for proper operation.

3

Fuel injector diagnostic and cleaning equipment is a mechatronics

product that combines ultrasonic cleaning technology and micro-

computer oil pressure closedloop control cleaning and detection

technology. This product simulates various operating conditions

of the engine, and cleans and inspects the fuel injectors of various

automobiles and motorcycles. This equipment is the necessary

and preferred equipment for the automobile and motorcycle repair

and maintenance industry, research and teaching and training

departments.

PRODUCT INTRODUCTION

Overview

Main

functions

Ultrasonic cleaning:

Ultrasonic cleaning can be performed on single or multiple

injectors at the same time, which can remove the attachments

and internal blockages on the injectors.

Uniformity detection:

To detect the uniformity of the injection volume of each injector.

Atomization observation:

Using the background light, you can observe the spray atomi-

zation situation of the nozzle in a comprehensive and careful

manner.

Tightness test:

It can detect the tightness and dripping of the fuel injector

under high pressure.

Fuel injection volume detection:

It can detect the fuel injection volume of the fuel injection

nozzle under specific working conditions (Such as the same

time and the same number of times).

●

●

●

●

●

Main features Using ultrasonic powerful cleaning technology, strong cleaning

ability.

Using electronic pressure regulating control technology, stable

oil pressure and wide adjustable range.

Use high-quality oil pump to ensure long-term stable use.

●

●

●

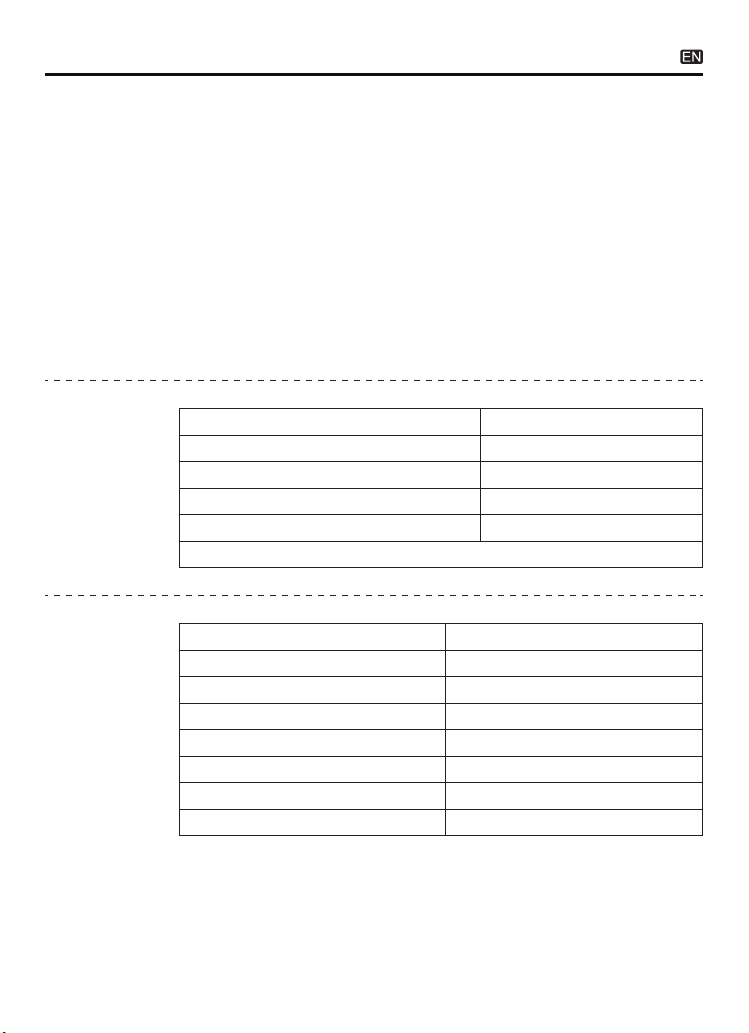

Power Supply

Frequency

Relative Humidity

Environment Temperature

AC 110 / 220V ±10%

50HZ ±0.5

<85%

0°C ~ +40°C

External Magnetic Field Strength

No open flames are allowed around

<400A/m

4

Working

environment

Fuel Tank Capacity

Range Of Rotation

PWM Pulse Width

Time Settings

2000ml

0-7500r/min

0~40ms, step 0.1ms

0~10min

Cylinder Volume

Injection Times

System Pressure

Ultrasonic Cleaning Power

140ml

0~9900times, step 100ms

0~0.8Mpa

70W

Technical

parameters

Design with HD color display, makes the operation clear and

easy to learn.

The oil tank liquid level is displayed visually, and the detection

liquid can be recycled.

Bright background light, you can clearly see the various

situations of the fuel injector when it is working.

It has replaceable composite joints suitable for a variety of

vehicle types.

Within the allowable adjustment range, the test time, working

frequency, fuel injection times, shortest switching period, etc.

of the fuel injector can be adjusted arbitrarily.

●

●

●

●

●

5

PRODUCT STRUCTURE

Structure

diagram

Operation panel

Portable drawer

7

9

Pressure gauge

Oil outlet pipe

8

10

Ultrasonic cleaning tank

11

Power switch

13

Lock pole

Oil rail

1

3

Lock nut

Top oil inlet connector

2

4

Oil drain handle

6

Signal wire

12

Power socket

14

Glass measuring cylinder

5

15 16

1

2

3

4

5

6

7

8

9

10

12

14

13

11

TFT color screen

Voltage selection

of injectors

1

3

Function buttons

Pressure adjustment

2

4

6

Operation

panel

diagram

Cleaning agent

drain valve

15 Testing agent liquid level

16

1 2 43

7

OPERATION PROCESS

Ultrasonic

cleaning

Ultrasonic cleaning is to use the penetrating and cavitation shock

waves generated when ultrasonic waves propagate in the medium,

and powerfully clean objects with complex shapes, cavities and

pores to completely remove stubborn carbon deposits on the fuel

injector.

Preparation

Remove the fuel injector from the vehicle and check whether

its rubber seal is damaged. If it is damaged, it should be

replaced in time before the cleaning test to avoid leakage

during the test. Then put the fuel injection nozzle into the

cleaning agent, carefully remove the external grease and wipe

it with a soft cloth.

Turn on the power and turn on the power switch on the side of

the main unit.

Put the cleaning bracket in the accessories into the ultrasonic

cleaning tank, and place the wiped fuel injector in the cleaning

bracket positioning hole of the ultrasonic tank.

●

●

●

Methods And Steps

Add an appropriate amount of cleaning agent to the ultrasonic

tank.

Insert the plugs of the drive wires into the injector sockets in

turn. (Special fuel injectors need to be connected with an

adapter cable)

Press the up or down key to select item 01 “Ultrasonic Clean-

ing” , and then press the function setting key to set the working

time.The default working time is 10 minutes, which can be

changed by up and down keys if needed.

Press START button, the system starts to feed pulse signal

and cleaning. After finishing cleaning, take out the injectors

from the ultrasonic bath, wipe the cleaning agent on them with

a soft cloth and prepare for the next item.

●

●

●

●

01 Ultrasonic Cleaning

8

NOTE

During the cleaning process, you can hear the intermittent

(approximately 5 seconds) vibrating sound when you take the

fuel injector out and put it to your ear, so you can judge whether

the fuel injector is working normally.

Ultrasonic cleaning is strictly prohibited when there is no

cleaning agent in the ultrasonic tank to avoid equipment

damage.

Only the ultrasonic cleaning agent dedicated to cleaning the

fuel injection nozzle can be added to the ultrasonic tank, and

other reagents cannot be used instead, otherwise any

malfunctions and damages caused will not be covered by the

warranty.

Injector

diagnostic

This function is to detect the atomization, dripping, blockage, fuel

injection angle status of the fuel injectors and the size and

balance of the fuel injection of each fuel injector at different

speeds.

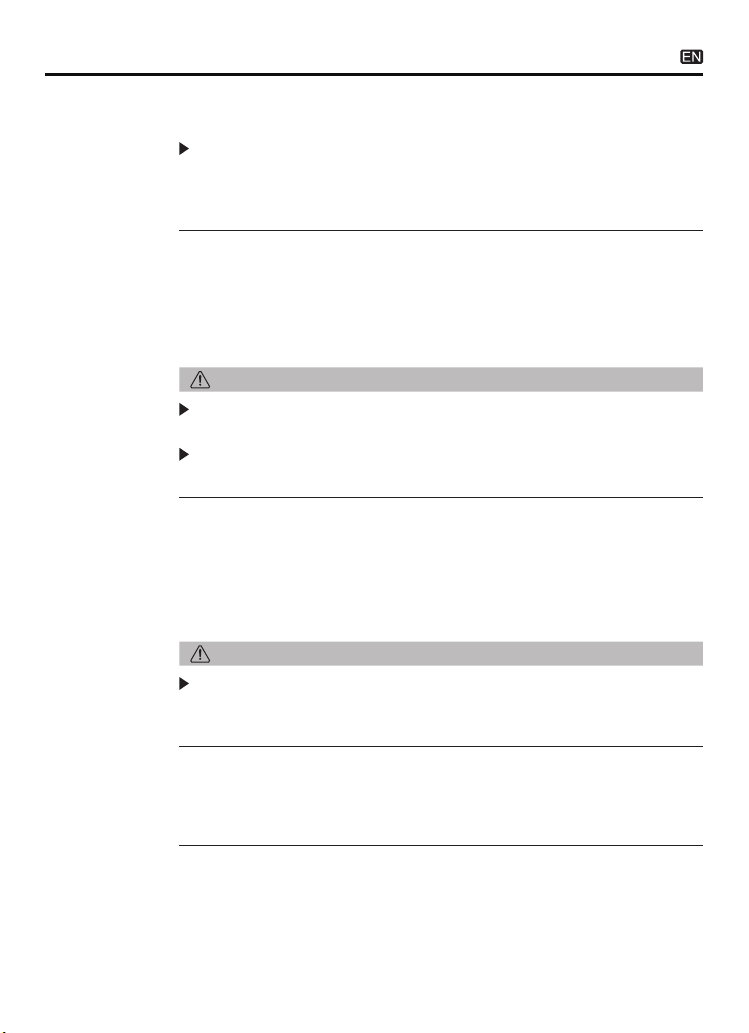

Preparation

Confirm that the oil drain handle is open, use the funnel in the

accessories to add the test liquid to the equipment through the

glass window, and pay attention to control the flow rate during

the addition to avoid overflow.

Add 1 bottle (about 1000ml) of testing agent each time.

Install the fuel injector.

●

●

●

9

Select the top oil inlet connector from the accessories and

install it into the oil separator.

Install the fuel injector in the forward direction (apply a little

grease on the “O” ring of the fuel injector)

Put the horizontal end of the oil separator and the fuel injector

on the upper plate seat, and tighten the two ends with the

locking rod. Ready to test.

●

●

●

Methods And Steps

02 Idle Speed Test

Confirm that the injector to be tested has been installed

properly and the signal wire has been plugged in.

Select “02 Idle Speed Test”.

Press the function setting key to set the working time and pulse

width.

Press the start button to start work.

●

●

●

●

Lock nut7Lock pole8

Oil outlet pipe

Top oil inlet connector

1

3

Oil rail

Injectors

2

4

Glass measuring cylinder

6

Upper plate seat

5

Top-in fuel injector installation diagram

①

②

③

④

⑤

⑥

⑦

⑧

10

Turn the pressure adjustment knob to adjust the pressure to

0.25 ~ 0.3MPa. (In the electronic injection system, the general

oil pressure works at 0.25~ 0.3MPa)

The working time gradually decreases. When it is 0, the system

automatically stops.

●

●

NOTE

The fuel pressure, working time and pulse width are automati-

cally set by the system. The time system defaults to 10s as a

cycle period, and the user does not need to set it separately.

The system will automatically and continuously cycle three

times to simulate the working condition and fuel injection

volume of the fuel injector when the engine is accelerating

uniformly.

03 Medium Speed Test

Select “03 Medium Speed Test”.

Press the start button.

The rest of the operation steps are consistent with item 02.

●

●

●

04 High Speed Test

Select “04 High Speed Test”.

Press the start button.

The rest of the operation steps are consistent with item 02.

●

●

●

05 Accelerating Test

Select “05 Accelerating Test”.

Press the start button.

●

●

06 Variable Speed Test

Select “06 Variable Speed Test”.

Press the start button.

●

●

NOTE

The fuel pressure, working time and pulse width are automati-

cally set by the system. The time system defaults to a cycle of

11

NOTE

The pulse width system defaults to 3ms, no need to set it

again.

Whether the fuel injection nozzle is dripping and leaking when

the simulated oil pressure is 0.3Mpa.

10s, and the user does not need to set it separately.

The system will automatically and continuously cycle three

times to simulate the working condition and fuel injection

volume of the fuel injector when the engine is idling, medium

speed, and high speed.

07 Leakage Test

Select “07 Leakage Test”.

Press the function setting key to set the working time. (Gener-

ally set to 1 minute)

The rest of the operation steps are consistent with item 02.

●

●

●

DESCRIPTION

Simulate the working conditions and fuel injection volume of

the engine when the fuel injection nozzle works for a certain

number of times when the engine is idling.

08 Idling Spray Value Test

Select “08 Idling Spray Value Test”.

Press the function setting key to set the pulse width and pulse

times. (Generally set to 2000 times)

The rest of the operation steps are consistent with item 02.

●

●

●

10 High Speed Spray Value Test

Select “10 High Speed Spray Value Test”.

The rest of the operation steps are consistent with item 08.

●

Select “09 Medium Speed Spray Value Test”.

The rest of the operation steps are consistent with item 08.

●

●

●

09 Medium Speed Spray Value Test

12

NOTE

Flow Balance Test

The flow balance test shall be carried out at different speeds.

When the liquid level in the measuring cylinder is 2/3 of the

measuring cylinder, pause or stop work to observe the balance

of the fuel injection volume. The deviation of the fuel injection

volume of all fuel injection nozzles on a vehicle should not

exceed 2%. Or refer to the relevant technical manual of the fuel

injector to judge the flow balance of the fuel injector.

Observation of Fuel Injection Shape

Observe whether the fuel injection shapes and angles of all

fuel injection nozzles on the same car are uniform at various

speeds. At the same time, you can adjust the opening pulse

width of the fuel injection nozzle to check whether the minimum

opening pulse width of the fuel injection nozzle is consistent.

Leak Detection Test

The leak detection test is to detect the tightness of the injector

needle valve under the high pressure of the system. (Observe

the tightness of the fuel injector, generally there should be no

leakage within one minute)

11 Reverse Flushing

Press the item selection up and down keys to select “11

Reverse Flushing”, and install the injectors in the opposite

direction for cleaning.

●

12 No-disassembly Cleaning

Select “12 No-disassembly Cleaning”.

Cleaning time can be set to a maximum of 20 minutes. Please

connect to various special parts that can clean the combustion

chamber or throttle.

●

●

13 Pulse Injection Test

Select “13 Pulse Injection Test”.

Press function setting key to set pulse width and pulse times.

Other steps are the same as in item 02.

●

●

●

13

STORAGE AND MAINTENANCE

Storage Turn off the power and unplug the power plug.

Put all connectors back into the accessory box for storage.

Drain the ultrasonic cleaning agent. Wipe the equipment clean

with a dry soft cloth.

If the machine needs to be stored for a long time, discharge the

testing agent into a bottle and seal it.

●

●

●

●

Replacement of Test Agent

When the test agent is used for a period of time, a lot of impuri-

ties will accumulate, and the agent containing dirt cannot be

used, otherwise it will easily block the fuel injector. When

replacing the agent, first open the testing agent drain valve to

empty the tank, and then inject a little testing agent to clean the

interior of the tank. After cleaning, drain the fuel tank again and

then pour 1L of new testing agent into the tank.

Fuse Replacement

There is a square box marked with a fuse on the power socket

on the left side of the device, and the fuse can be seen by

opening the box. If it is blown, replace it with a new one.

●

●

14 Wide Pulse Injection Test

Press the up or down key to select “Item 14 Wide Pulse Injec-

tion Test”.

Other steps are the same as in item 13.

●

●

15 Continuous Injection Test

Press the up or down key to select “Item 15 Continuous Injec-

tion Test”.

Press function setting key to set working time. (Recommended

working time is less than 30s)

Other steps are the same as in item 02.

●

●

●

14

Be careful not to rub the product against rough surfaces or

wear the product, especially the sheet metal housing.

Please regularly check the product parts that need to be

tightened and connected. If found loose, please tighten it in

time to ensure the safe operation of the equipment. The exter-

nal and internal parts of the equipment in contact with various

chemical media should be frequently treated with anti-corrosion

treatment such as rust removal and painting to improve the

corrosion resistance of the equipment and extend its service

life.

Comply with the safe operating procedures and do not

overload the equipment. The safety guards of the products

are complete and reliable.

Unsafe factors are to be eliminated in time. The circuit part

should be checked thoroughly and the aging wires should be

replaced in time.

Adjust the clearance of various parts and replace worn

(broken) parts. Avoid contact with corrosive liquids.

When not in use, please store the product in a dry place. Do

not store the product in hot, humid, or non-ventilated places.

Our products are made of long-lasting and durable materials, and

we insist on perfect production process. Each product leaves the

factory after 35 procedures and 12 times of testing and inspec-

tion work, which ensures that each product has excellent quality

and performance.

To maintain the performance and appearance of the product, it is

recommended that the following product care guidelines be read

carefully:

●

●

●

●

●

●

MAINTENANCE SERVICE

Maintenance

15

WARRANTY

The repair or replacement of products is determined by the

actual breakdown situation of product.

It is guaranteed that AUTOOL will use brand new component,

accessory or device in terms of repair or replacement.

If the product fails within 90 days after the customer receives

it, the buyer should provide both video and picture, and we will

bear the shipping cost and provide the accessories for the

customer to replace it free of charge. While the product is

received for more than 90 days, the customer will bear the

appropriate cost and we will provide the parts to the customer

for replacement free of charge.

The product is not purchased through official or authorized

channels.

The product breakdown because the user does not follow

product instructions to use or maintain the product.

From the date of receipt, we provide a three-year warranty for the

main unit and all the accessories included are covered by a

one-year warranty.

We AUTOOL pride ourselves on superb design and excellent

service. It would be our pleasure to provide you with any further

support or services.

All information, illustrations, and specifications contained in this

manual, AUTOOL resumes the right of modify this manual and the

machine itself with no prior notice. The physical appearance and

color may differ from what is shown in the manual, please refer to

the actual product. Every effort has been made to make all

descriptions in the book accurate, but inevitably there are still

inaccuracies, if in doubt, please contact your dealer or AUTOOL

after-service centre, we are not responsible for any consequences

arising from misunderstandings.

●

●

●

●

●

These conditions below shall not be in warranty range

Warranty

access

Disclaimer

16

If you are an AUTOOL user and are not satisfied with the

AUTOOL products purchased from the online authorized

shopping platform and offline authorized dealers, you can

return the products within seven days from the date of receipt;

or you may exchange it for another product of the same value

within 30 days from the date of delivery.

Returned and exchanged products must be in fully saleable

condition with documentation of the relevant bill of sale, all

relevant accessories and original packaging.

AUTOOL will inspect the returned items to ensure that they

are in good condition and eligible. Any item that does not pass

inspection will be returned to you and you will not receive a

refund for the item.

You can exchange the product through the customer service

center or AUTOOL authorized distributors; the policy of return

and exchange is to return the product from where it was

purchased. If there are difficulties or problems with your return

or exchange, please contact AUTOOL Customer Service.

●

●

●

●

RETURN & EXCHANGE SERVICE

Return &

Exchange

China

Oversea Zone

E-mail

Facebook

YouTube

400-032-0988

+86 0755 23304822

aftersale@autooltech.com

https://www.facebook.com/autool.vip

https://www.youtube.com/c/autooltech

Table of contents

Other AU Tool Test Equipment manuals

AU Tool

AU Tool CT400 User manual

AU Tool

AU Tool BT460 User manual

AU Tool

AU Tool BT 260 User manual

AU Tool

AU Tool SPT101 User manual

AU Tool

AU Tool BT760 User manual

AU Tool

AU Tool BT-660 User manual

AU Tool

AU Tool BT70 User manual

AU Tool

AU Tool BT360 User manual

AU Tool

AU Tool BT-660 User manual

AU Tool

AU Tool BT160 User manual

Popular Test Equipment manuals by other brands

Pace Technologies

Pace Technologies OMEGA SRT-15/150 instruction manual

Ripley

Ripley MILLER DLS 650 user guide

Gas Measurement Instruments

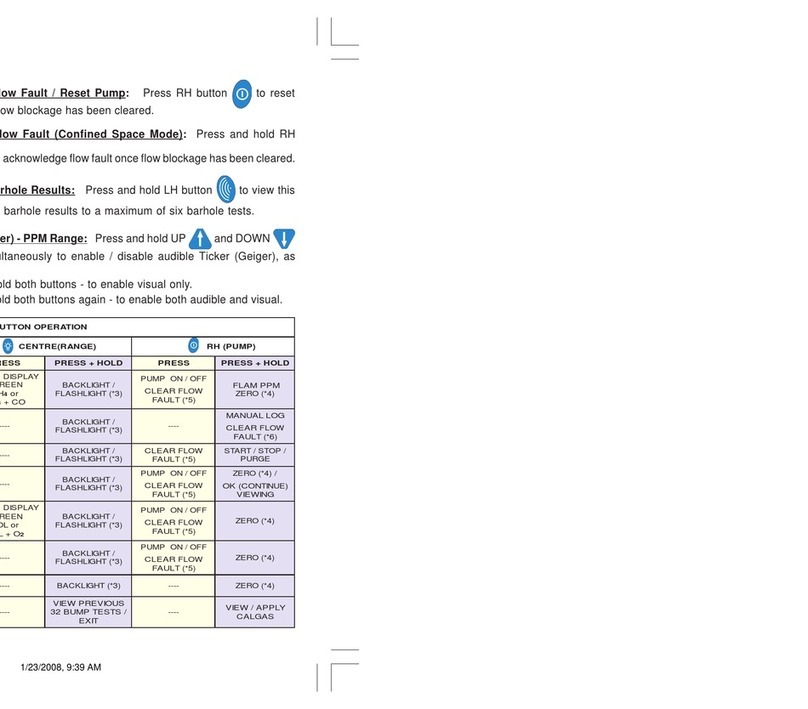

Gas Measurement Instruments 67130 Quick Operating Instructions

IDEAL Networks

IDEAL Networks SignalTEK NT manual

BTE Technologies

BTE Technologies Multi-Cervical Unit user manual

Ponovo

Ponovo T500 Series Hardware operation manual