AU Tool LM708 User manual

Table of contents

Other AU Tool Test Equipment manuals

AU Tool

AU Tool BT 260 User manual

AU Tool

AU Tool BT-660 User manual

AU Tool

AU Tool BT70 User manual

AU Tool

AU Tool BT360 User manual

AU Tool

AU Tool BST-100 User manual

AU Tool

AU Tool BT160 User manual

AU Tool

AU Tool BT760 User manual

AU Tool

AU Tool SPT360 User manual

AU Tool

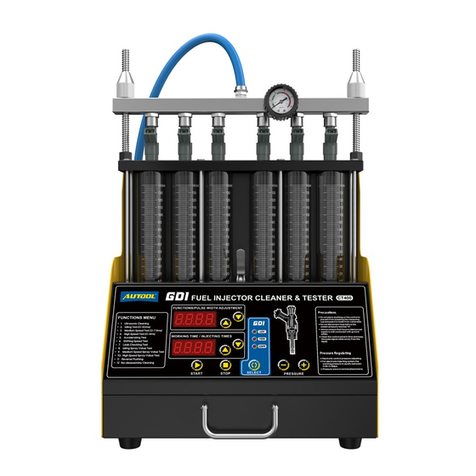

AU Tool CT400 User manual

AU Tool

AU Tool SPT101 User manual

Popular Test Equipment manuals by other brands

Tektronix

Tektronix P6133 instruction manual

Keysight Technologies

Keysight Technologies 16034E Operation and service manual

Testboy

Testboy TB 55 operating instructions

Chroma

Chroma 63200 Series Operation & programming manual

Apera Instruments

Apera Instruments PH60S user manual

ChemInstruments

ChemInstruments PT-1000 operating instructions

Tektronix

Tektronix DPO70000C/DX user manual

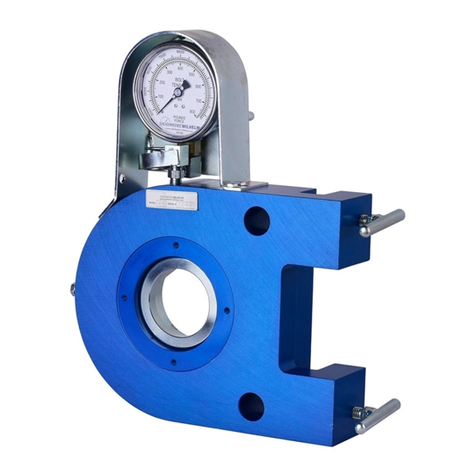

Skidmore-Wilhelm

Skidmore-Wilhelm MZ-100 user manual

Butts of Bawtry

Butts of Bawtry TBT0900 instruction manual

MULTI MEASURING INSTRUMENTS CO.,LTD.

MULTI MEASURING INSTRUMENTS CO.,LTD. MCL-800IRV instruction manual

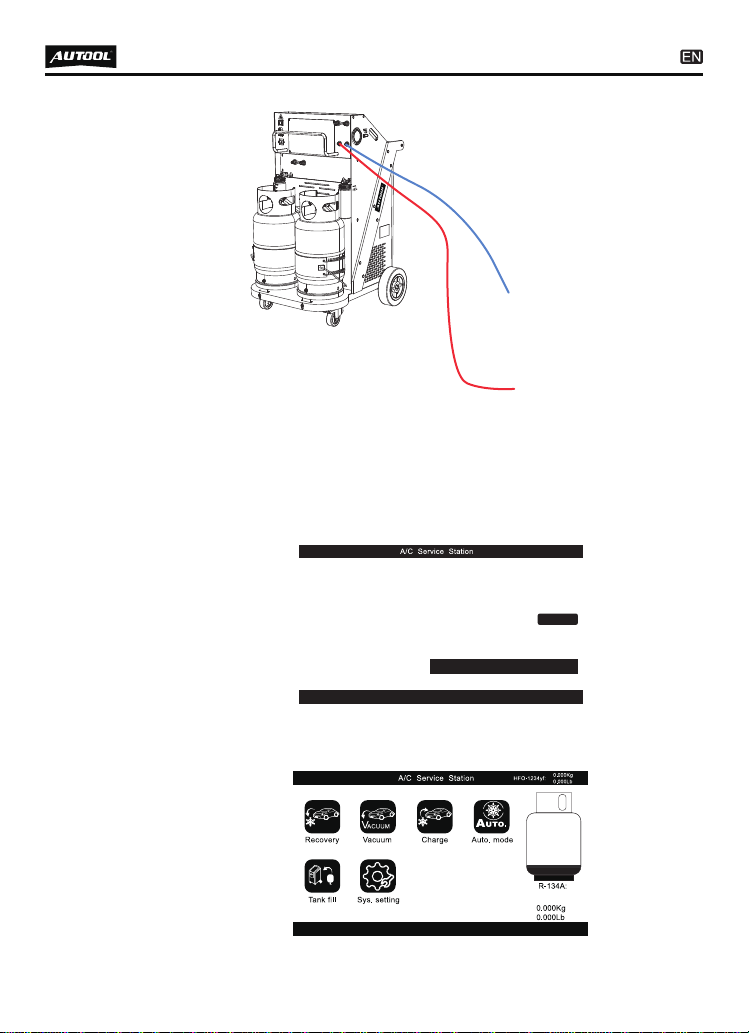

Johnson Controls

Johnson Controls YORK RECOVERY PAK LD17585 operation & maintenance

PeakTech

PeakTech P 3441 manual