Set the tool in AC Voltage mode, using the probe tip with

chassis ground or the auxiliary ground lead.

Connect vacuum pump to MAP sensor.

Contact the probe tip to the MAP sensor positive

terminal and observe the LCD readings which should be

a sine wave in normal condition.

Apply vacuum.

Release vacuum and observe the LCD readings.

If the LCD readings are abnormal, there is a problem with

this sensor.

•

•

•

•

•

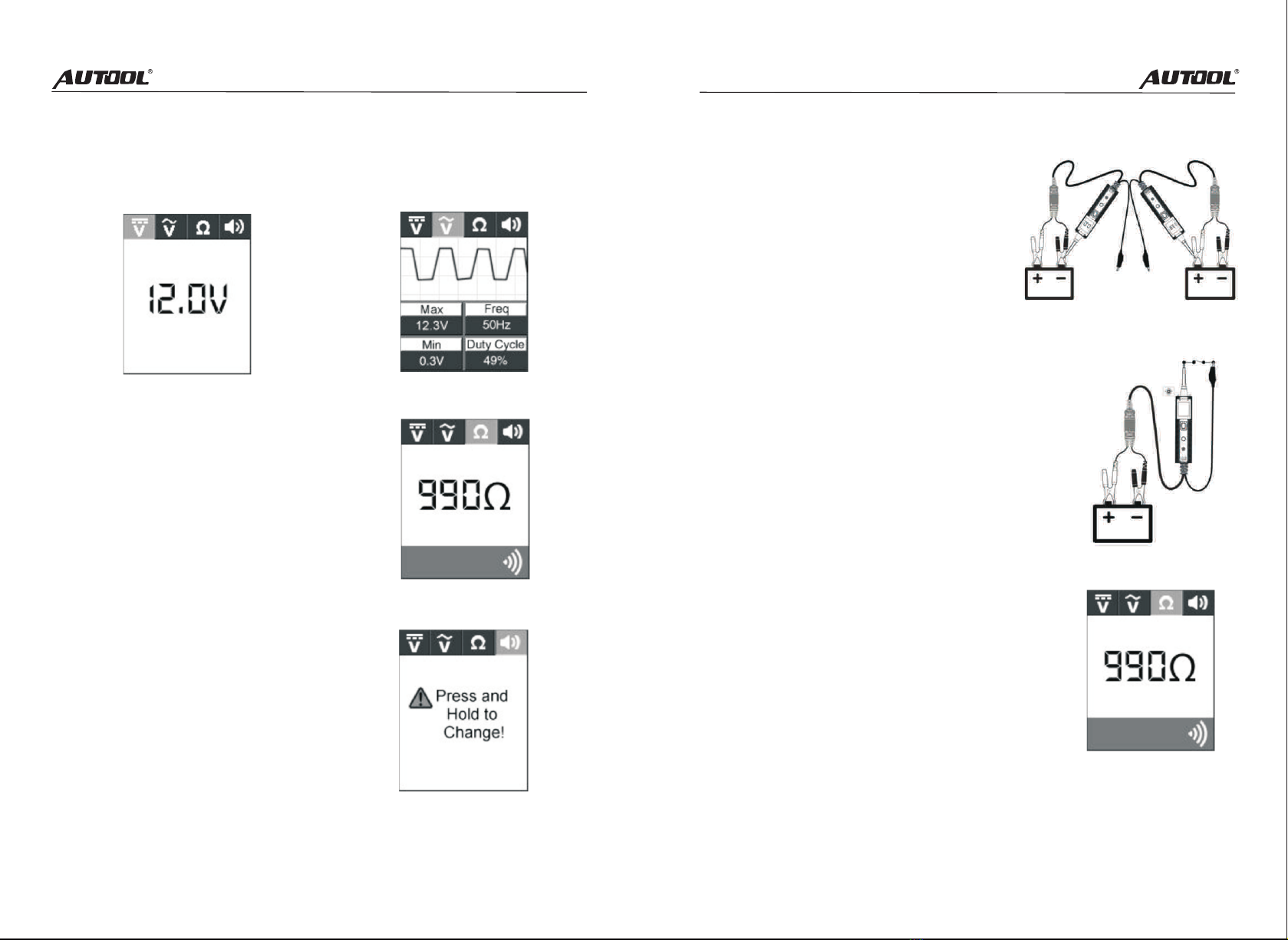

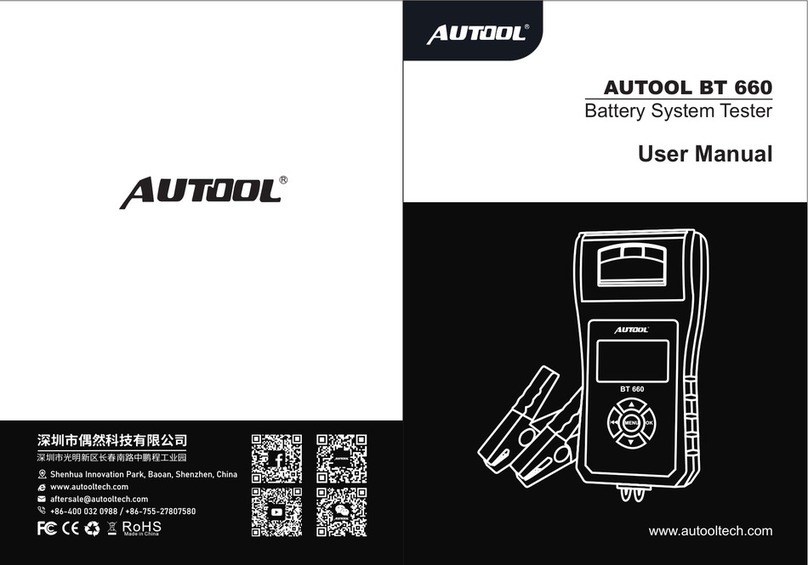

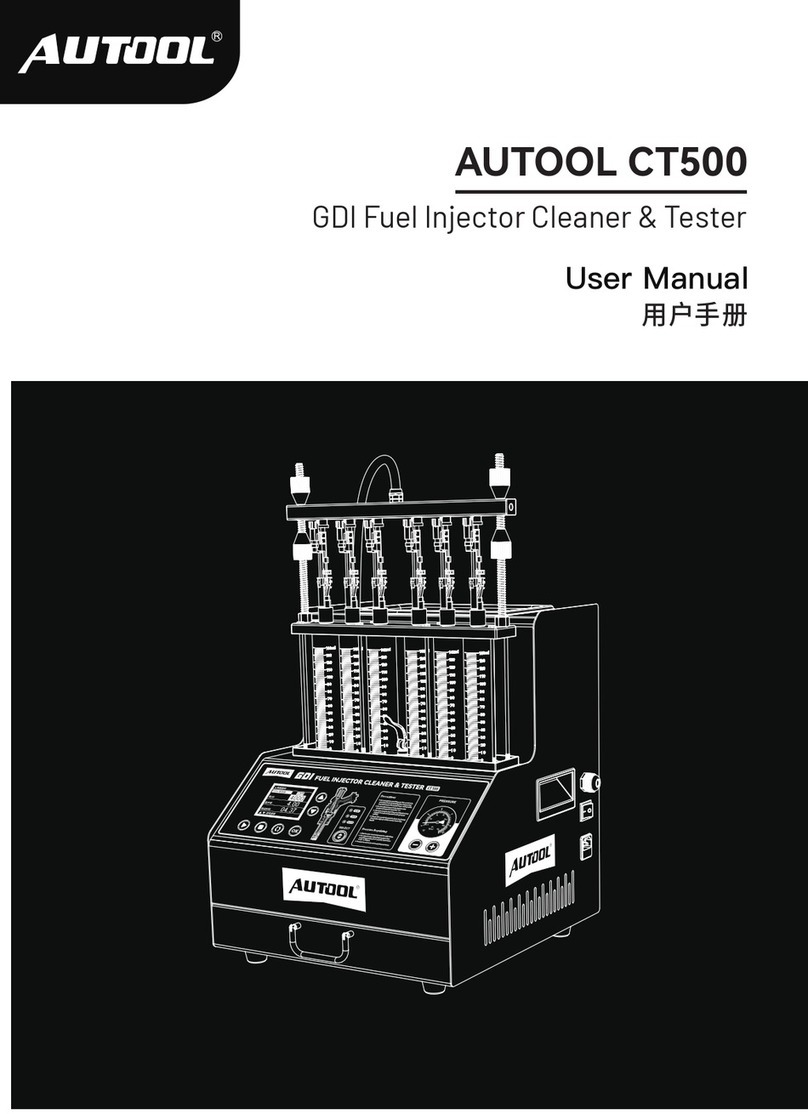

While the tool is in DC Voltage mode, by

using the probe tip in connection with the

auxiliary ground lead, components can be

activated right in your hand, thereby testing

their functions.

Connect the auxiliary ground lead to the

negative terminal or ground side of the

component being tested. Then contact the

probe tip to the positive terminal of the

component, the green LED should light,

indicating continuity through the component.

Activating Components in Your Hand

While keeping an eye on the green LED, quickly press and release the power switch forward.

If the green LED went out and the red LED came on, you may proceed with further activation.

Rock the power switch forward and hold it down to provide power to your component. With

the power switch rocked forward, power will flow from the positive lead on the battery into the

probe tip, through the tip into the component ’ s positive terminal, into the component and out

of the component, through the auxiliary ground lead and back into the tool, and back to the

vehicle battery ’ s ground.

If the green LED went off at that instant or if the circuit breaker tripped, the tool has been

overloaded. This could happen for the following reasons:

The contact you are probing is a direct ground or negative voltage.

The component you are testing is short-circuited.

The component is a very high current component (i.e., starter motor).

If the circuit breaker is tripped, reset it by waiting for it to cool down (15 sec.) and then

depressing the reset button.

•

•

•

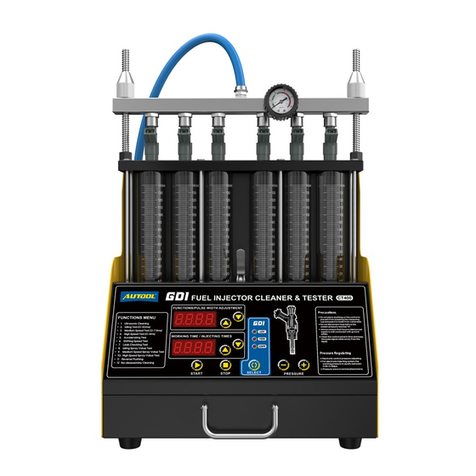

While the tool in DC Voltage mode, clip the

auxiliary ground lead to the trailer ground,

probe the contacts at the jack and then apply

voltage to the probe tip. This lets you check

the function and orientation of the connector

and trailer lights.

If the circuit breaker tripped, that contact is

likely a ground. Reset the circuit breaker by

letting it cool down for 15 seconds and

depressing the reset button until it clicks into

Place.

Testing Trailer Lights and Connections

7 8

If the circuit breaker is tripped, reset it by

waiting for it to cool down (15 sec.) and then

depressing the reset button.

WARNING: Haphazardly applying voltage to

certain circuits can cause damage to a

vehicle’s electronic components. Therefore, it

is strongly advised to use the vehicle

manufacturer’s schematic and diagnosing

procedure while testing.

Activating Components in The Vehicle

While the tool in DC Voltage mode, contact the probe tip to the positive terminal of the

component, the green LED should light, indicating continuity to ground. While observing the

green LED, quickly depress and release the power switch forward. If the green LED went out

and the red LED came on, you may proceed with further activation.

If the green LED went off at that instant or if the circuit breaker tripped, the tool has been

overloaded. This could happen for the following reasons:

The contact you are probing is a direct ground.

The component you are testing is short-circuited.

The component is a very high current component(i.e., starter motor).

•

•

•

NOTE : When powering up components, you can increase the life of power switch if you first

press the switch, then contact the tip to the component. The arcing will take place at the tip

instead of the contacts of the switch.