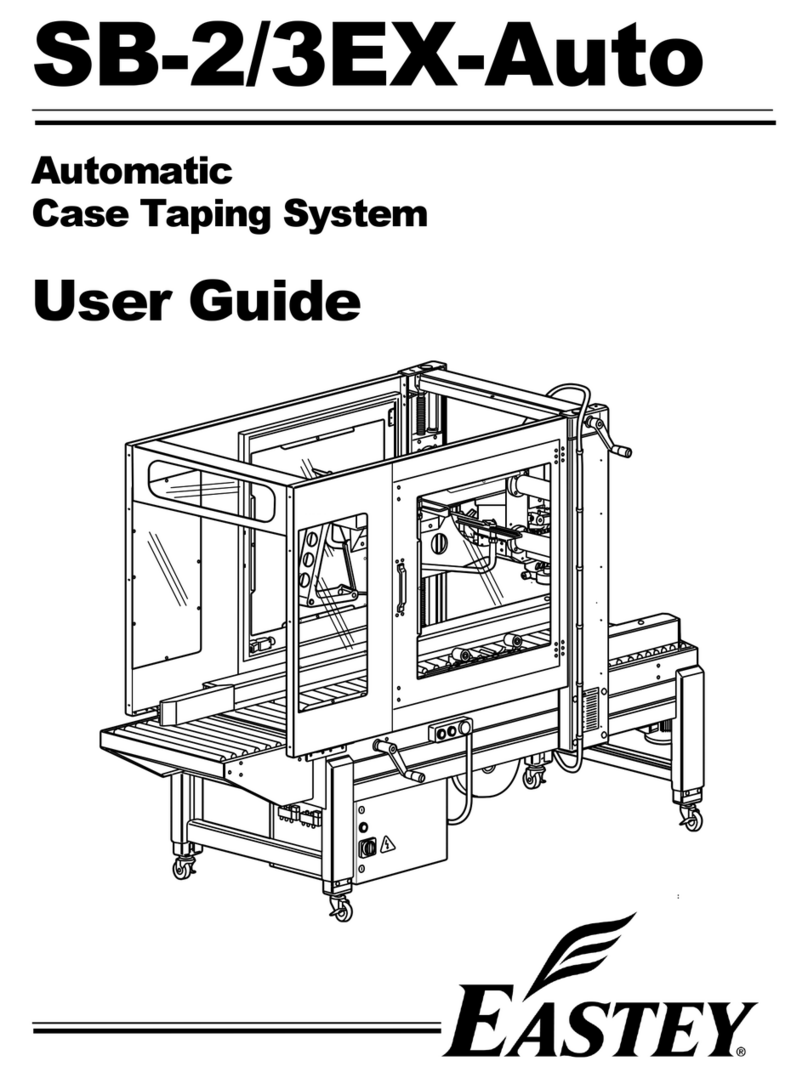

Audion Elektro D 552 AVT User manual

Continuous Sealer

D 552 AVT

D 552 AVT ENG Rev.01

User manual

www.audion.com

2

'translation of the original instructions'

All rights reserved.

No part of this publication may be reproduced and/or published by means of print, photocopy,

or in any other way, without prior written permission from Audion Elektro BV.

Audion Elektro BV reserves the right to modify the machine and/or change the operating manual

without prior notice.

Audion Elektro BV is not liable for any damage caused by specifications deviating from the

standard version.

Although this operating manual was compiled with the utmost care, Audion Elektro BV does not

accept any liability for any mistakes it may contain and/or the consequences of any incorrect

interpretation of its contents.

Audion Elektro BV is not liable for any damage or problems resulting from the use of parts other

than original parts. If this operating manual does not provide instructions for certain repairs,

settings or maintenance, please contact your dealer or Audion Elektro BV.

Please read this operating

manual carefully before using

the sealer or carrying out

maintenance on it.

The sealer is part of the Audion

product range. We also provide:

- Impulse sealers.

- Heat sealers.

- Continuous sealers.

- Vacuum sealers.

- Vacuum chambers.

- Crimping machines.

- Validatable sealers.

- Form, fill and seal machines.

Since its inception in 1947,

Audion has gained a lot of

experience and expertise with a

wide variety of sealing and

packaging machines. Our

solutions for packaging

problems are unique. Our many

years of experience together

with our modern production,

assembly and testing methods

ensure that our packaging

machines meet the highest

quality standards. We can also

customise the machines

according to your specific

requirements.

Audion is the right supplier for

a packaging machine that is

geared to your requirements.

Continuous Sealer

D 552 AVT

Contents

4

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Machine type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Warranty conditions and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Symbols used in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Operating personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Maintenance personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.2 What to do in case of fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.3 Use for special applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Safety provisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Safety symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Unpacking the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Placing the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Connecting the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Adjusting the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 Adjusting the height of the sealing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.2 Adjusting the horizontal position of the conveyor belt . . . . . . . . . . . . . . . . . . . 15

3.4.3 Adjusting the height of the conveyor belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Description of the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Overview of the sealer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Preparing the sealer for production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.1 Switching on the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.2 Setting the sealing temperature and speed. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.3 Switching on the heating, the cooling and the blower . . . . . . . . . . . . . . . . . . . 21

5.1.4 Starting the sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Stopping the sealer (STANDBY mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Continuous Sealer

D 552 AVT

Contents 5

5.4.1 Restarting after an emergency stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5 Switching off the sealer completely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.1 Daily maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.2 Weekly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.3 Annual maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 Switching off the sealer and opening the protective cover . . . . . . . . . . . . . . . . . . 29

7.3 Replacing the PTFE belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4 Replacing the V belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.5 Adjusting the V belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.6 Replacing the heating elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.7 Adjusting the pressing force of the heating blocks. . . . . . . . . . . . . . . . . . . . . . . . 35

7.8 Adjusting the pressing force of the press rollers . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.9 Adjusting the pressing force of the cooling plates . . . . . . . . . . . . . . . . . . . . . . . . 36

7.10 Adjusting the pressing force of the after-press rollers. . . . . . . . . . . . . . . . . . . . . . 36

7.11 Adjusting the tension of the conveyor belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8 Disposing of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.1 Directive 2002/96/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2 Correct disposal for reuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Annex 1 Technical information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A1.1 Dimensional drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A1.2 Technical information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Annex 2 Electrical Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Annex 3 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A3.1 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A3.2 Exploded views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Annex 4 Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A4.1 Maintenance log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Annex 5 CE declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Introduction

6

1 Introduction

1.1 Manufacturer

The Continuous Sealer was manufactured by:

1.2 Machine type plate

The sealer has an EC mark. This means that the sealer meets the fundamental

health and safety requirements of the European Communities.

Audion Elektro BV

Hogeweyselaan 235

1382 JL Weesp

The Netherlands

Telephone: +31 (0)294 491717

Fax: +31 (0)294 491755

Email: [email protected]

Web: www.audion.com

Figure 1-1: Machine type plate of the Continuous Sealer

Continuous Sealer

D 552 AVT

Introduction 7

1.3 Warranty conditions and liability

Subject to the restrictions stated below, we provide a 12-month warranty

regarding the products delivered by us. This warranty is limited to manufacturing

defects and therefore does not cover any malfunctions caused by any form of

wear, or any part of the delivered product that is subject to wear.

•The warranty we provide for parts or accessories purchased from third parties

is limited to the warranty the third-party provides to us.

•If the other party, and/or any third parties engaged by them, makes unskilled

use of the product delivered, the warranty becomes void.

•The warranty is also void if the other party and/or any third parties engaged by

them carries out work and/or modifications on the delivered product.

•Any parts we replace in order to meet our warranty obligations become our

property.

•Should the other party not meet obligations resulting from the agreement

entered into between the parties in whole or in part or in a timely manner, we

are not obliged to provide warranty for as long as that situation continues.

We exclude all liability to the extent that the liability is not regulated by law. Our

liability will never exceed the total amount of the order in question.

Subject to the generally applicable legal rules of public order and good faith, we

are not obliged to pay compensation to the other party or any third party for

damages of any nature whatsoever, incurred directly or indirectly, including trading

loss, damage to movable or immovable property or persons.

In any case, we are not liable for any damage resulting from or caused by using

the delivered product or its unsuitability for the purpose for which the other party

purchased it.

Safety

8

2 Safety

2.1 Symbols used in this manual

The following symbols are used in this user manual:

A tip on how a task can be carried out more efficiently.

Instructions for carrying out a task in the correct manner.

Danger of injury to the user or damage to the sealer if the

instructions are not observed.

Continuous Sealer

D 552 AVT

Safety 9

2.2 User

The sealer should only be operated by authorised personnel.

Improper use of the sealer may lead to serious personal injury and

considerable material damage.

Keep bystanders at a distance. Do NOT allow unauthorised

personnel to operate the sealer.

2.2.1 Operating personnel

The company using the machine has organized a training to inform its operating

personnel of the potential risks of unskilled behaviour while carrying out their

tasks.

Installation, maintenance and repair require specialised knowledge,

which is why these tasks should only be performed by

maintenance personnel.

Observe the safety instructions in this user manual. Failure to

observe the safety instructions may cause unacceptable risks.

The operating personnel must be familiar with all chapters of this user manual with

the exception of ’Installation’ and ’Maintenance’. Always observe the following

safety instructions before using the sealer or carrying out any maintenance work.

2.2.2 Maintenance personnel

This personnel's professional training, knowledge and experience, and knowledge

of the manufacturer's terms enable them to carry out the assigned work and

immediately recognize any risks that may arise.

Observe the safety instructions in this user manual. Failure to

observe the safety instructions may cause unacceptable risks.

Maintenance personnel must be familiar with all chapters of this user manual.

Always observe the following safety instructions before using the sealer or

carrying out any maintenance work on it.

Safety

10

2.3 Safety instructions

The sealer meets the fundamental health and safety requirements of the European

Community. This means that the sealer can be operated and maintained safely if

all safety instructions are carefully observed. However, improper or careless use

can create dangerous situations.

Observe the safety instructions in this user manual. Always

remain alert to dangerous situations and avoid any improper or

careless use.

2.3.1 General safety instructions

Observe the following general safety instructions:

•Tie back long hair.

•Do not wear loose clothing or jewellery.

•Always wear the personal protective equipment (PPE) prescribed by the

company, such as safety shoes, gloves, and goggles.

Use the PPE required on the shop floor, such as safety shoes,

gloves and goggles and/or hearing protection, in particular when

carrying out maintenance work.

•Check the operation of the sealer every day.

•Keep your hands away from dangerous parts of the sealer.

•Always leave protective covers in place during production.

•Never bypass or deactivate any safety provisions.

•The sealer should never be operated or maintained by people who are under

the influence of alcohol, medication and/or drugs.

•Only use sealable material that is suitable for the sealer.

•The user is obliged to observe the normally applicable hygienic measures

•If you are in doubt about the correct functioning of the machine, switch it off

and consult the maintenance personnel.

•Both the user and the sealer must be supervised while the sealer is in use.

Continuous Sealer

D 552 AVT

Safety 11

•Do not switch the sealer back on until the malfunction has been repaired.

•Should any liquid or foreign object enter the machine, switch off the sealer

and immediately remove the plug from the wallsocket and have the sealer

checked by maintenance personnel before using it again.

•Should an unusual event occur, such as the development of smoke, remove

the plug from the socket immediately and have the sealer checked by

maintenance personnel before using it again.

•Remove the plug from the socket before carrying out any maintenance work.

•Never open the sealer's housing while it is connected to the mains power.

•Do not use any water, abrasive cleaning agents, chemical solvents or other

liquids when cleaning the sealer.

2.3.2 What to do in case of fire

NEVER use water to extinguish a fire. This may result in life-

threatening situations because the sealer may be live.

Should the sealer catch fire, never use water to extinguish the fire. Because the

machine is live, this may result in life-threatening situations. During use, you are

obliged to have a fire extinguisher within reach of the machine. The following

types of fire extinguishers are suitable to extinguish fires occurring to this

machine:

•Powder extinguisher.

•Foam extinguisher.

2.3.3 Use for special applications

If the machine is used in a specialised environment, the company

using the machine is responsible for making sure any specific

instructions that apply are observed.

•If the machine is used in a medically sterile environment or cleanroom, the

company using the machine is responsible for making sure any specific

instructions that apply there are observed.

•If the machine is used for the packaging of medical instruments, the company

using the machine is responsible for making sure any specific instructions that

apply are observed.

•If the machine is used for the packaging of food, the company using the

machine is responsible for making sure any specific instructions that apply are

observed.

Safety

12

2.4 Safety provisions

The sealer has the following safety provisions:

1. Safety covers.

-Electrical and mechanical parts in the housing are protected.

2. Metal parts are earthed.

-No dangerous voltage can develop between (external) metal parts and the

earth.

3. Fuse in 230 V circuit.

-If the voltage gets too high, the fuse will blow, cutting off the power sup-

ply.

4. Emergency stop button

-In case of a hazard, this will immediately and completely switch off the

sealer.

2.5 Safety symbols

The following safety symbols are applied to the Continuous Sealer:

•’Hot surfaces’.

On the front of the Continuous Sealer on the

cover. It may get hot because of the heating

elements.

Continuous Sealer

D 552 AVT

Installation 13

3 Installation

3.1 Unpacking the sealer

Check the following when unpacking the sealer:

1. Are all parts and accessories present?

-Sealer

-User manual

The sealer is packaged in environmentally friendly material that

can be disposed of as ordinary household waste.

Keep the crate and the packaging material so the sealer can be

safely transported, should such be necessary.

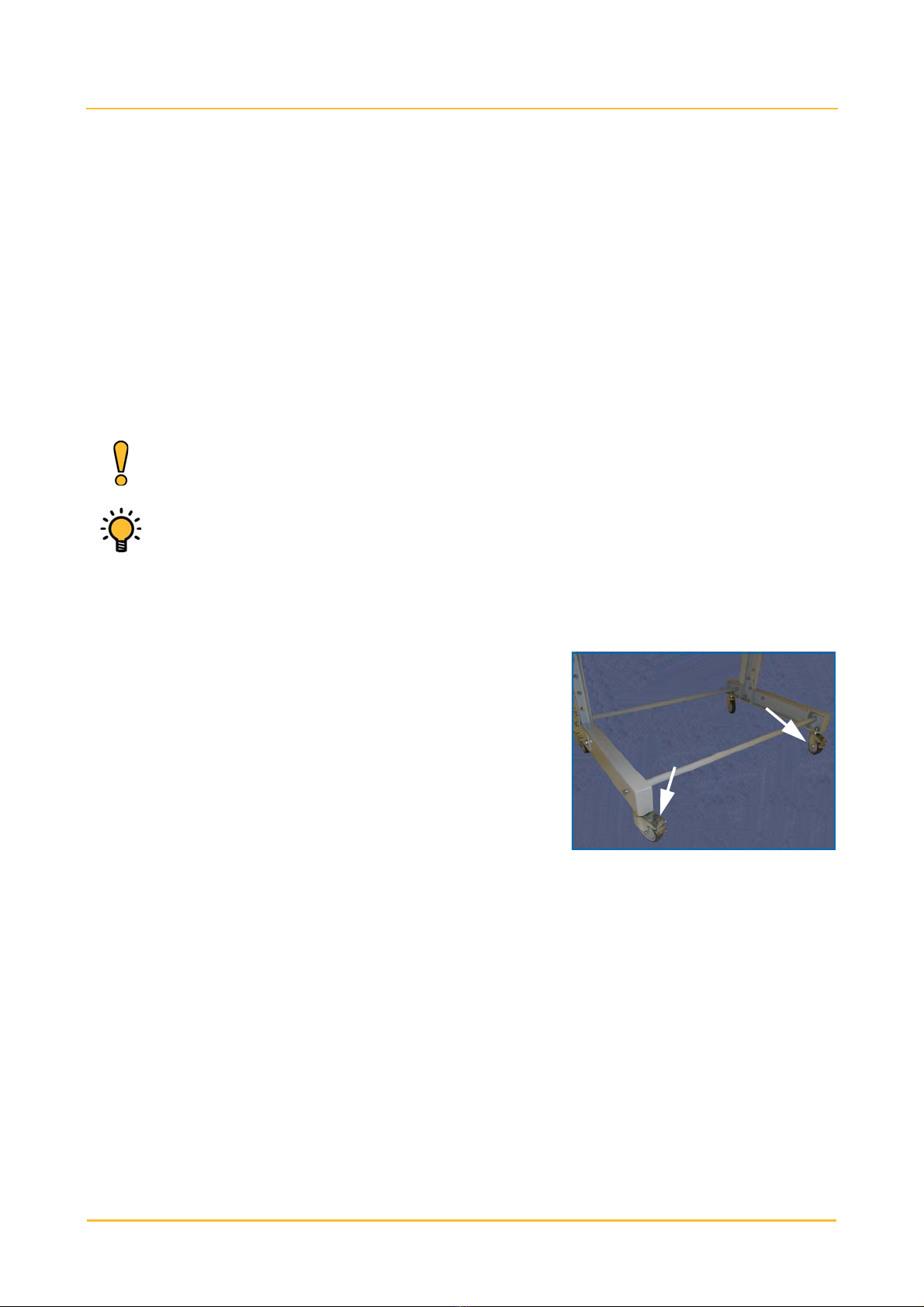

3.2 Placing the sealer

1. Place the sealer in the desired location.

2. Lock the castors by depressing the

brakes.

Installation

14

3.3 Connecting the sealer

1. Check whether the main switch is in the

’0’ position.

2. Put the plug in the socket.

Continuous Sealer

D 552 AVT

Installation 15

3.4 Adjusting the sealer

You can make the following adjustments:

•Height of sealing unit in relation to the conveyor belt; to adjust the length of

the bags.

•Horizontal distance between conveyor belt and sealing unit; to adjust the

position of the bags on the conveyor belt.

•Height of conveyor belt in relation to the floor; to adjust the working height.

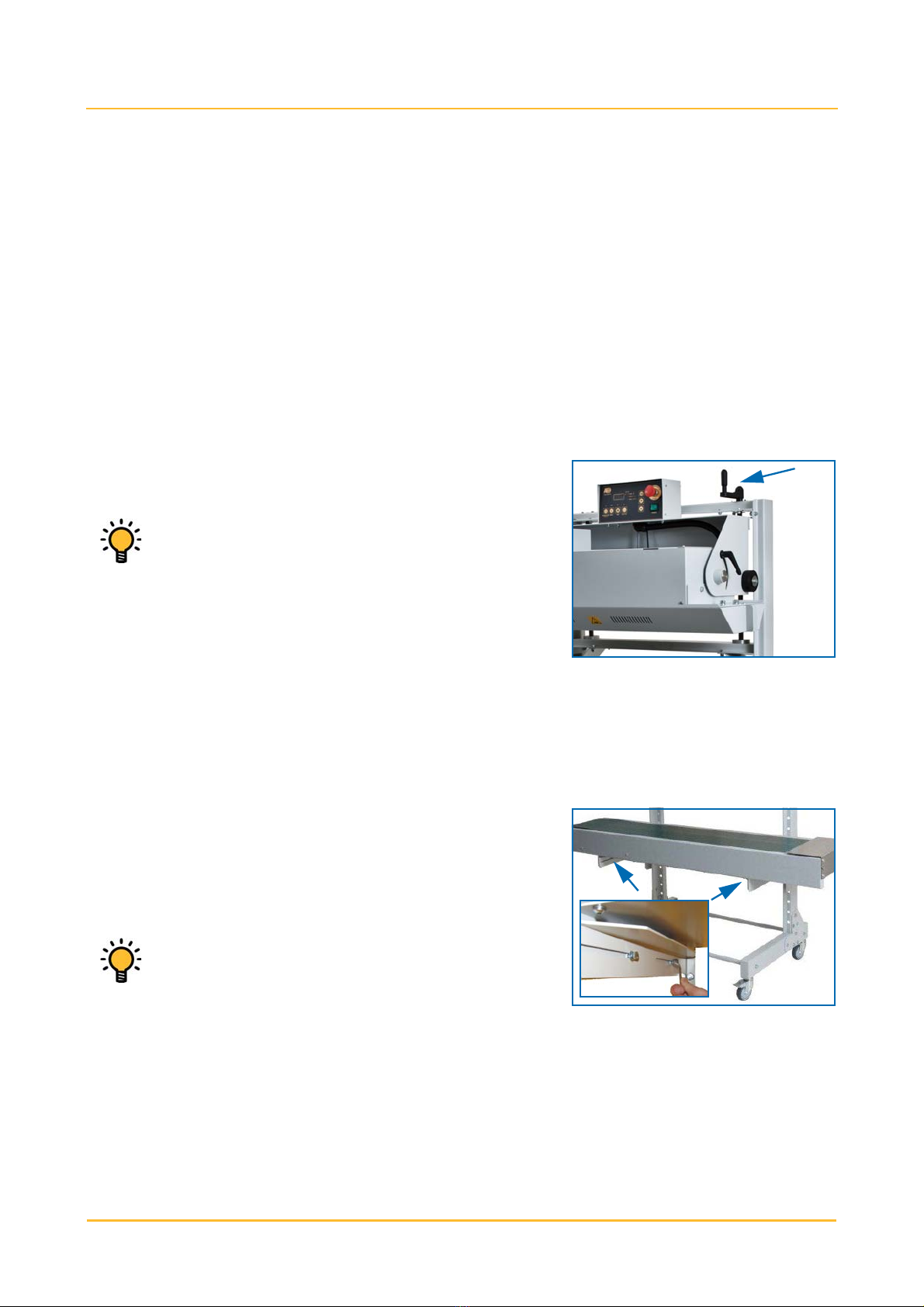

3.4.1 Adjusting the height of the sealing unit

The height of the sealing unit in relation to the conveyor belt is adjusted as

follows:

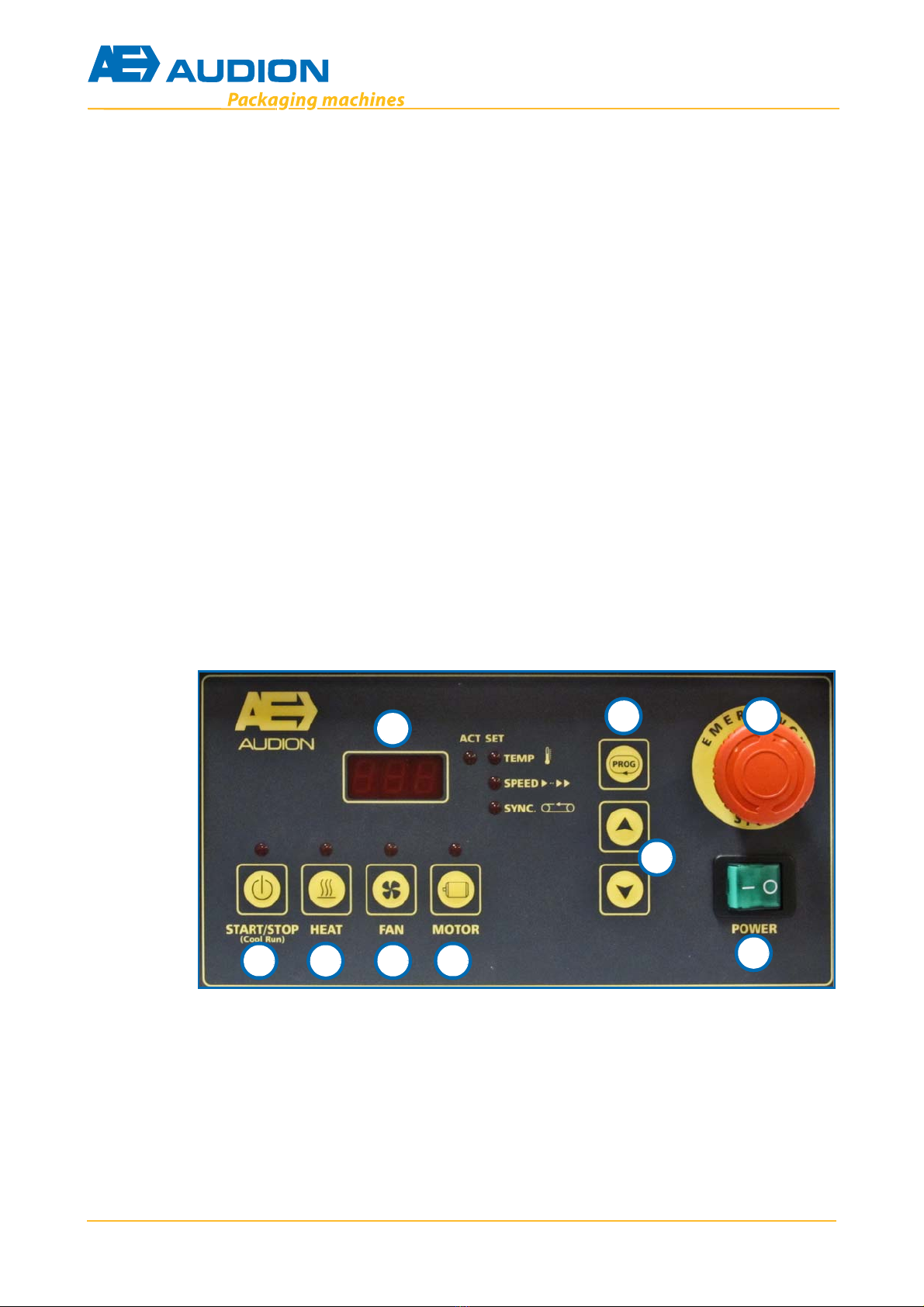

3.4.2 Adjusting the horizontal position of the conveyor belt

The horizontal distance of the conveyor belt in relation to the sealing unit is

adjusted as follows:

1. Set the height of the sealing unit by

rotating the crank.

The top of the bag to be sealed

should be able to move freely along

the top of the infeed guide.

1. Loosen the four locking bolts a number

of turns.

2. Adjust the position of the conveyor belt

in relation to the sealing unit by shifting

the conveyor belt.

The position of the conveyor belt is

to be adjusted in such a way that

the bag to be sealed is in the centre

of the conveyor belt as far as

possible.

3. Tighten the locking bolts again.

Installation

16

3.4.3 Adjusting the height of the conveyor belt

The height of the conveyor belt is adjusted as follows:

1. Loosen the 2 mounting nuts at the back

of the conveyor-belt brackets.

2. Take the conveyor belt from the

frame.

Always make sure two people lift

the conveyor belt from the frame

together.

3. Position the conveyor belt on the

frame at the desired height.

The height of the conveyor belt is

to match the infeed and outfeed

belts.

Always make sure two people

position the conveyor belt on the

frame together.

4. Tighten the mounting nuts again.

Continuous Sealer

D 552 AVT

Description of the sealer 17

4 Description of the sealer

4.1 Function

The Continuous Sealer is a band sealer for the packaging of a wide variety of

products in larger quantities. The products are packaged in ready-to-use bags and

subsequently sealed. The sealer is suitable for the sealing of ready-to-use bags

made of polyethylene (PE), polypropylene (PP), thin PVC, and various laminates

with a thickness of between 20μm and 150μm.

Do not use the Continuous Sealer for any other applications.

The sealer is not suitable for the following applications:

•Use in a clean room environment.

•Use in a medical, sterile environment.

•Use in an explosive environment.

•Use of toxic, asphyxiant or irritating gases.

•Use of the machine in a dusty environment.

4.2 Overview of the sealer

Figure 4-1: Overview of the sealer

1

5

24

3

Description of the sealer

18

1. Housing

2. Control panel

3. Conveyor belt

4. Setting of distance and height of the conveyor belt in relation to the sealing

unit

5. Frame with castors.

The sealer comprises a frame with castors onto which a conveyor belt and housing

are mounted. The housing comprises the electrical and drive components; the

operating panel is mounted on top of the housing. During maintenance work, the

housing can be tilted to make the interior easily accessible.

The conveyor belt will transport the bags to be sealed along the heating blocks,

the press rollers, the cooling plates, and the after-press rollers that are positioned

inside the housing.

The height of the conveyor belt is adjustable to make it seamlessly match the

infeed and outfeed belts. Also, the vertical distance between the conveyor belt

and the housing is adjustable so that bags of different heights can be sealed, and

the horizontal position of the conveyor belt in relation to the sealing unit is

adjustable so that the bags are in the centre of the conveyor belt as far as possible.

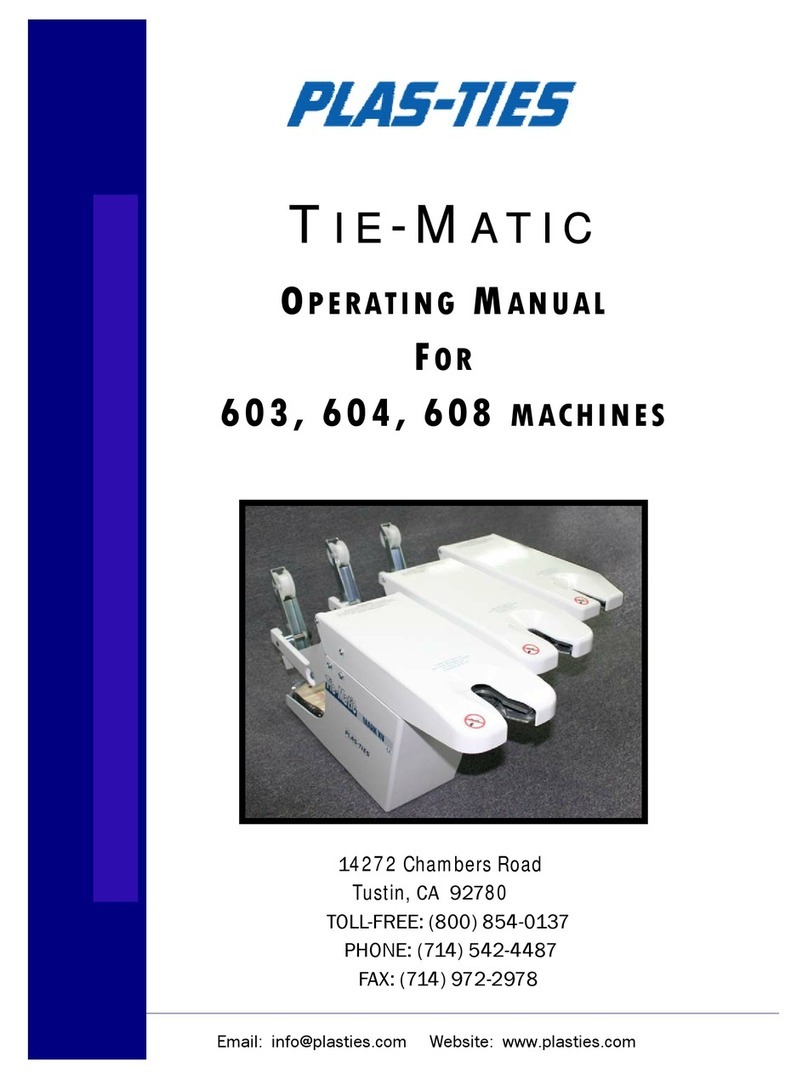

4.3 Control panel

Figure 4-2: Control panel

1

3

2

59

4

6 7 8

Continuous Sealer

D 552 AVT

Description of the sealer 19

Coolrun mode

The coolrun mode prevents burning of the PTFE belts. After the machine has been

stopped, the heater is switched off; however, the blower and the motor will

continue to run. When the sealing temperature has dropped to below 80°C, the

sealer is switched to stand-by mode and the blower and the motor will also be

switched off.

1. Display Indicates the actual sealing temperature, speed or a

malfunction notification. While adjusting the values,

the set value will be shown.

2. Prog Press to change the settings menu of the sealer. An

led next to the button will indicate which setting can

be adjusted:

Temp, the sealing temperature.

Speed, the sealing speed.

Sync., synchronising the sealing speed and the speed

of the conveyor belt.

3. Up/down Press to increase or reduce a setting.

4. Emergency

stop button

In case of a hazard, this will immediately and com-

pletely switch off the sealer.

5. Start/stop Press to start or stop the sealer. An led above the but-

ton indicates whether the sealer is switched on or off.

When the actual sealing temperature upon switching

off is over 80°C, the sealer will first switch to Coolrun

mode.

6. Heat Press to switch the heating on or off. An led above the

button indicates whether the function is switched on

or off.

7. Fan Press to switch the blower on or off. An led above the

button indicates whether the function is switched on

or off.

8. Motor Press to switch the motor on or off. An led above the

button indicates whether the function is switched on

or off.

9. Main switch Press to switch the sealer on or off.

Table of contents

Other Audion Elektro Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

Fieldpiece

Fieldpiece MG44 user manual

Plas-Ties

Plas-Ties TIE-MATIC 603 operating manual

FLOTER

FLOTER AirWave 2 Additional information

Polychem

Polychem PHT1401 Operation manual and spare parts list

ItaldibiPack

ItaldibiPack ESPERT 7555 EV Installation, use and maintenance

GRAPHTEC

GRAPHTEC F-MARK2 quick start guide

Advanced Poly-Packaging

Advanced Poly-Packaging T-375 instructions

Miller

Miller AG-BAG MX1012 Operator's manual

Rice Lake

Rice Lake 920i FlexWeigh Systems 201 Operation manual

U-Line

U-Line H-109 instructions

Loveshaw

Loveshaw LITTLE DAVID LDXCRS owner's manual

M. J. MAILLIS GROUP

M. J. MAILLIS GROUP SIAT GTH 19 user manual