AUMA AC 01.2 User manual

Control

→Parallel

Profibus

Modbus RTU

Modbus TCP/IP

Foundation Fieldbus

HART

Actuator controls

AC 01.2/ACExC 01.2

Operation and settingManual

Read operation instructions first.

●Observe safety instructions.

Purpose of the document:

This document contains information for the commissioning, operation and maintenance staff. It is intended to

support local device operation and setting modifications.

Reference documents:

●Operation instructions (Assembly, operation, commissioning) for actuator.

Reference documents can be downloaded from the Internet (www.auma.com) or ordered directly from AUMA

(refer to <Addresses>).

Table of contents Page

81. Safety instructions................................................................................................................. 81.1. Basic information on safety 81.2. Range of application 91.3. Warnings and notes 91.4. References and symbols

102. Identification........................................................................................................................... 102.1. Name plate 112.2. Short description

133. Operation................................................................................................................................ 133.1. Local actuator operation 143.2. Actuator operation from remote 143.3. Menu navigation via push buttons (for settings and indications) 153.3.1. Menu layout and navigation 163.4. User level, password 163.4.1. Password entry 173.4.2. Password change 173.5. Language in the display 173.5.1. Language change

194. Indications.............................................................................................................................. 194.1. Indications during commissioning 194.2. Indications in the display 204.2.1. Feedback indications from actuator and valve 234.2.2. Status indications according to AUMA classification 244.2.3. Status indications according to NAMUR recommendation 254.3. Indication lights of local controls 264.3.1. Indication lights: change colour

275. Signals (output signals)......................................................................................................... 275.1. Status signals via output contacts (digital outputs) 275.1.1. Assignment of outputs 275.1.2. Coding the outputs 275.2. Configurable status signals 295.3. Analogue signals (analogue outputs) 295.3.1. Assignment of analogue output 1 305.3.2. Signal range of analogue output 1 305.3.3. Adjustment of analogue output 1

2

Actuator controls

Table of contents AC 01.2/ACExC 01.2

305.3.4. Assignment of analogue output 2 305.3.5. Signal range of analogue output 2 315.3.6. Adjustment of analogue output 2

326. Operation ............................................................................................................................... 326.1. Operation mode Off 326.2. Operation mode Local 326.2.1. Push-to-run operation or self-retaining Local 336.3. Operation mode Remote 336.3.1. Push-to-run operation or self-retaining Remote 356.4. Operation mode EMERGENCY 356.5. Operation mode EMERGENCY stop 356.6. Operation mode Disabled 356.7. Operation mode Service

377. Basic settings for commissioning........................................................................................ 377.1. Type of seating for end positions 377.1.1. Type of seating: set 387.2. Torque switching 397.2.1. Torque switching: set 407.3. Limit switching 407.3.1. Limit switching: set 427.4. Date and time 427.5. Display formats 427.5.1. Date format 437.5.2. Time format 437.5.3. Number format 437.5.4. Torque unit 437.5.5. Temperature unit 437.5.6. Position units 447.5.7. Process factor units 457.5.8. Analogue working value units (AIN) 457.5.9. Analogue signal output units (AIN) 457.6. Contrast

468. Application functions............................................................................................................. 468.1. Intermediate positions (pivot points) 468.1.1. Intermediate positions (pivot points): define 468.1.2. Signal behaviour of intermediate positions: set 478.1.3. Hysteresis for intermediate positions: set 488.2. Operation profile (operation behaviour) for intermediate positions 488.2.1. Operation profile: activate 488.2.2. Operation behaviour for intermediate positions (pivot points):set 498.2.3. Off times for intermediate positions (pivot points):set 498.3. Two-wire control 508.4. Positioner (operation mode Remote SETPOINT) 508.4.1. Positioner: activate 508.4.2. Adaptive behaviour: switch on or off 518.4.3. Overrun (inner dead band): set manually 518.4.4. Max. error variable (outer dead band): set manually 528.4.5. Dead time: set 528.4.6. Hysteresis for positioner: set

3

Actuator controls

AC 01.2/ACExC 01.2 Table of contents

528.4.7. Closing fully/opening fully (end position tolerance for setpoint) 538.4.8. Setting range: limit 538.4.9. Change-over between OPEN - CLOSE control and setpoint control 548.4.10. Input of setpoint position 548.4.11. Input range of setpoint position 548.4.12. Split Range operation 558.5. Process controller 568.5.1. Process controller activation 568.5.2. Process controller: set modulating behaviour 578.5.3. Setpoint source (input for process setpoint) 588.5.4. Behaviour on loss of process setpoint 588.5.5. Inverse operation 588.5.6. Internal process setpoint 598.5.7. Setting procedure 598.5.8. Proportional amplification Kp: set 598.5.9. Reset time Ti: set 598.5.10. Rate time Td: set 608.5.11. Actual value source (input for actual process value) 608.6. Stepping mode 608.6.1. Stepping mode: activate 618.6.2. Operation mode for stepping mode 618.6.3. Start and end of stepping mode 618.6.4. On times and off times 628.7. By-pass function 638.7.1. Bypass function: activate 648.7.2. By-pass application: configure 648.8. Lift Plug Valve (LPV) 678.8.1. LPV function: activate 678.8.2. LPV actuator type: configure 678.8.3. Delay time of master LPV actuator: configure 688.8.4. Delay time of slave LPV actuator: configure 688.9. Multiport valve function (operation to position) 688.9.1. Multiport valve function: activate 698.9.2. Actuator type: set/check 698.9.3. Gear reduction ratio: set/check 698.9.4. Number of ports (positions) 708.9.5. Home port (zero position): set 708.9.6. Positions (of valve ports): define/check 718.9.7. Operate to position via push buttons of the local controls 728.9.8. Operate to position from Remote 728.9.9. Dead band 728.9.10. Backlash compensation 738.9.11. Signalling behaviour of positions:set/check 738.9.12. Hysteresis for signalling intermediate positions: set 748.10. Automatic deblocking 758.10.1. Automatic deblocking function: activate 758.10.2. Operation time for operation in opposite direction: set 758.10.3. Number of deblocking attempts: set 758.10.4. Tolerance range: set 758.11. Heater system and heaters

4

Actuator controls

Table of contents AC 01.2/ACExC 01.2

768.11.1. Heater system within the actuator controls 768.11.2. Heater on control unit (actuator) 768.11.3. Motor heater

779. Failure functions.................................................................................................................... 779.1. Reversing prevention time 779.2. Failure behaviour on loss of signal 779.2.1. Failure behaviour initiation on loss of signal 779.2.2. Failure source (failure reason) for a failure operation: set 789.2.3. Failure operation (reaction of the actuator) on loss of signal 789.2.4. Failure position: define 789.2.5. Failure position MPV:define 799.2.6. Delay time: set 799.3. EMERGENCY behaviour 809.3.1. EMERGENCY behaviour: activate 809.3.2. EMERGENCY failure behaviour 819.3.3. Failure source (failure reason) for an EMERGENCY operation: set 819.3.4. Operation mode for EMERGENCY behaviour 819.3.5. EMERGENCY operation 829.3.6. EMERGENCY position 829.3.7. EMERGENCY position MPV 829.3.8. Torque switching: by-pass 829.3.9. Motor protection: by-pass 839.3.10. Stepping mode: by-pass 839.3.11. Operation profile: by-pass 839.3.12. Interlock: by-pass 839.3.13. Local stop: by-pass 849.3.14. Delay time for EMERGENCY operation 849.4. Enabling local controls 849.4.1. Enabling function: activate 859.4.2. Enabling function behaviour 859.5. Priority REMOTE 869.5.1. Priority REMOTE: activate 869.5.2. Priority REMOTE behaviour 869.6. Interlock (enabling operation commands) 879.6.1. Interlock: activate 879.6.2. Failure source of Interlock enable signal: set 879.6.3. Operation mode for interlock 879.6.4. Interlock behaviour (running direction) 889.7. Local Stop 889.7.1. Behaviour 889.8. EMERGENCY stop function 899.9. Partial Valve Stroke Test (PVST) 909.9.1. PVST: activate 909.9.2. Operation mode for PVST 919.9.3. Behaviour for PVST: define 919.9.4. Partial stroke for PVST:set 919.9.5. PVST monitoring time: set 919.9.6. PVST operating time: set 919.9.7. PVST reverse time: set 929.9.8. PVST reminder

5

Actuator controls

AC 01.2/ACExC 01.2 Table of contents

9310. Monitoring functions.............................................................................................................. 9310.1. Torque monitoring 9410.2. Motor protection monitoring (thermal monitoring) 9510.3. Type of duty monitoring (motor starts and running time) 9610.4. Operating time monitoring 9710.5. Reaction monitoring 9710.6. Motion detector 9710.6.1. Motion detector: activate 9810.6.2. Detection time dt 9810.6.3. Travel difference dx 9810.6.4. Delay time 9810.7. Monitoring of electronics power supply 9910.8. Temperature monitoring 9910.9. Heater system/heater monitoring 10010.10. Verification of sub-assemblies 10110.11. Phase failure monitoring 10110.12. Phase sequence detection and correction of the direction of rotation

10211. Functions: activate and enable............................................................................................. 10211.1. Activate functions 10211.2. Enable functions

10412. Service functions................................................................................................................... 10412.1. Direction of rotation 10412.2. Factory setting 10512.3. Languages: reload 10512.4. Data export 10512.5. Data import 10612.6. Actual configuration: accept 10612.7. Firmware update 10612.8. Service software AUMA CDT (Bluetooth)

10813. Diagnostics............................................................................................................................. 10813.1. Electronic device ID 10813.2. Diagnostic Bluetooth connection 10913.3. Diagnostic Interface 11013.4. Diagnostic Position transmitter potentiometer 11013.5. Diagnostic Position transmitter RWG 11113.6. Diagnostic Position transmitter MWG 11113.7. Diagnostic positioner 11113.8. Diagnostic On time monitoring 11213.9. Diagnostic Process controller 11213.10. Diagnostic FQM (fail safe) 11213.11. Simulation (inspection and test function) 11213.11.1. Actuator signals 11313.11.2. Interface signals

11414. Plant Asset Management....................................................................................................... 11414.1. Operating data 11514.2. Event report 11614.3. Characteristics 11614.3.1. Torque-travel characteristic 11814.3.2. Position-time characteristic

6

Actuator controls

Table of contents AC 01.2/ACExC 01.2

11914.3.3. Temperature-time characteristic 11914.4. Histograms 11914.4.1. Motor running time-position (histogram) 12014.4.2. Motor running time-temperature (histogram) 12114.4.3. Acceleration-frequency (histogram) 12114.4.4. Motor running time-torque (histogram) 12214.5. Maintenance (information and signals) 12414.6. Operating times: display 12414.7. Device temperatures: display

12515. Corrective action.................................................................................................................... 12515.1. Primary fuses 12515.2. Fault indications and warning indications

13316. Appendix................................................................................................................................. 13316.1. Selection overview for output contacts and indication lights (digital outputs DOUT) 13516.2. Selection overview of binary signals for digital inputs (DIN)

137Index........................................................................................................................................

141Parameter index.....................................................................................................................

146Addresses...............................................................................................................................

7

Actuator controls

AC 01.2/ACExC 01.2 Table of contents

1. Safety instructions

1.1. Basic information on safety

Standards/directives AUMA products are designed and manufactured in compliance with recognised

standards and directives.This is certified in a Declaration of Incorporation and a EC

Declaration of Conformity.

The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

They include among others:

●Standards and directives such as:EN 60079“Electrical apparatus for explosive

gas atmospheres" –

- Part 14: Electrical installations in hazardous areas (other than mines).

-Part 17:Inspection and maintenance of electrical installations in hazardous

areas (other than mines).

Safetyinstructions/warn-

ings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out exclusively by suitably qualified personnel having been authorised by

the end user or contractor of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Work performed in potentially explosive atmospheres is subject to special regulations

which have to be observed.The end user or contractor of the plant are responsible

for respect and control of these regulations, standards, and laws.

Commissioning Prior to commissioning, it is important to check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage.Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe the national regulations.

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance Any device modification requires the consent of the manufacturer.

1.2. Range of application

AUMA actuator controls are exclusively designed for the operation of AUMA actuators.

Other applications require explicit (written) confirmation by the manufacturer.The

following applications are not permitted, e.g.:

●motor control

●pump control

No liability can be assumed for inappropriate or unintended use.

8

Actuator controls

Safety instructions AC 01.2/ACExC 01.2

Observance of these operation instructions is considered as part of the device's

designated use.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in these

operation instructions, each marked by the appropriate signal word (DANGER,

WARNING, CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level of risk. Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning may result in minor or moderate injury.May also be used

with property damage.

Potentially hazardous situation. Failure to observe this warning may result in

property damage. Is not used for personal injury.

Arrangement and typographic structure of the warnings

Type of hazard and respective source!

Potential consequence(s) in case of non-observance (option)

→Measures to avoid the danger

→Further measure(s)

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in these instructions:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Important information before the next step.This symbol indicates what is required

for the next step or what has to be prepared or observed.

Via the menu to parameter

Describes the path within the menu to the parameter. By using the push buttons of

the local controls you may quickly find the desired parameter in the display.

< > Reference to other sections

Terms in brackets shown above refer to other sections of the document which provide

further information on this topic.These terms are either listed in the index, a heading

or in the table of contents and may easily be located.

9

Actuator controls

AC 01.2/ACExC 01.2 Safety instructions

2. Identification

2.1. Name plate

Each device is equipped with a name plate.

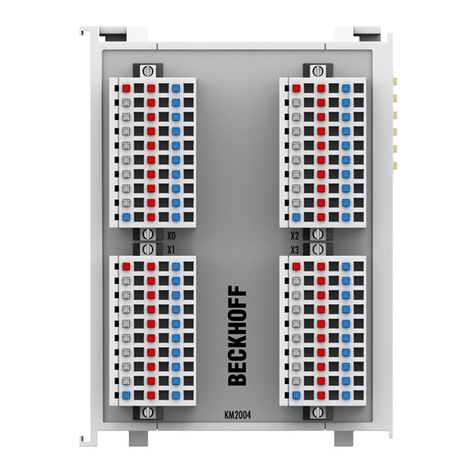

Figure 1: Arrangement of name plate

[1] Actuator controls name plate

Description of actuator controls name plate

Figure 2: Actuator controls name plate

[1] Type designation

[2] Order number

[3] Serial number

[4] Actuator terminal plan

[5] Actuator controls terminal plan

[6] Mains voltage

[7] AUMA power class for switchgear

[8] Permissible ambient temperature

[9] Enclosure protection

[10] Control

[11] Data Matrix code

Descriptions

Type designation Type and size

These instructions apply to the following devices types and sizes:

Types: AC/ACExC = AUMATIC actuator controls

Size: 01.2

Versions: Intrusive and Non-Intrusive

Order number The product can be identified using this number and the technical data as well as

order-related data pertaining to the device can be requested.

Please always state this number for any product inquiries.

On the Internet at http://www.auma.com, we offer a service allowing authorised

users to download order-related documents such as wiring diagrams and technical

data (both in German and English), inspection certificates and the operation

instructions when entering the order number.

10

Actuator controls

Identification AC 01.2/ACExC 01.2

Serial number Table 1: Description of serial number (with example)

MD123451405

Position 1+ 2: Assembly in week

Week 0505

Position 3 +4 :Year of production

Year of production: 201414

All other positions Internal number for unambiguous product identificationMD12345

Actuatorcontrolstermin-

al plan Position 9 in the TPA wiring diagram: Position transmitter (actuator):

Control unit: electromechanical:

0= Without position transmitter

A, B, J, K, L, N = Potentiometer

C, D, E, G, H, M, S = EWG/RWG (electronic position transmitter)

Control unit: electronic:

I= MWG (Magnetic limit and torque transmitter)

AUMA power class for

switchgear The switchgear used in the actuator controls (reversing contactors/thyristors) are

classified according to AUMA power classes (e.g.A1, B1, ....).The power class

defines the max. permissible rated power (of the motor) the switchgear has been

designed for.The rated power (nominal power) of the actuator motor is indicated in

kW on the motor name plate.For the assignment of the AUMA power classes to the

nominal power of the motor types, refer to the separate electrical data sheets.

For switchgear without assignment to any power classes, the actuator controls name

plate does not indicate the power class but the max. rated power in kW.

Control Table 2: Control examples (indications on controls name plate)

DescriptionInput signal Control voltage 24V DC for OPEN - CLOSE control via digital inputs

(OPEN, STOP, CLOSE)

24 V DC

Control voltage 115V AC for OPEN - CLOSE control via digital inputs

(OPEN, STOP, CLOSE)

115 V AC

Input current for setpoint control via analog input0/4 –20 mA

Data Matrix code When registered as authorised user, you may use the AUMA Support App to scan

the Data Matrix code and directly access the order-related product documents without

having to enter order number or serial number.

Figure 3: Link to the App store:

2.2. Short description

Actuator controls AUMATIC actuator controls are used to operate AUMA actuators and are supplied

ready for use.The controls may be mounted directly to the actuator or separately

on a wall bracket.

The functions of the AUMATIC controls include standard valve control in OPEN -

CLOSE duty, positioning, process control, logging of operating data right through to

diagnostic functions.

Local con-

trols/AUMA CDT Operation, setting, and display can be performed on site directly at the controls.

When set to local control, it is possible to

11

Actuator controls

AC 01.2/ACExC 01.2 Identification

●operate the actuator via the local controls (push buttons and display) and perform

settings (contents of these instructions).

●read in or out data or modify and save settings via the AUMA CDT software

(accessories), using a computer (laptop or PC).The connection between com-

puter and AUMATIC is wireless via Bluetooth interface (not included in these

instructions).

Intrusive - Non-Intrusive ●Intrusive version (control unit: electromechanical):

Limit and torque setting is performed via switches in the actuator.

●Non-Intrusive version (control unit: electronic):

Limit and torque setting is performed via the controls, actuator and controls

housings do not have to be opened.For this purpose, the actuator is equipped

with an MWG (magnetic limit and torque transmitter), also supplying analogue

torque feedback signals/torque indication and analogue position feedback sig-

nals/position indication.

12

Actuator controls

Identification AC 01.2/ACExC 01.2

3. Operation

Valve damage due to incorrect basic setting!

→Prior to electrical operation of the actuator, the basic settings i.e.type of seating,

torque and limit switching have to be completed.

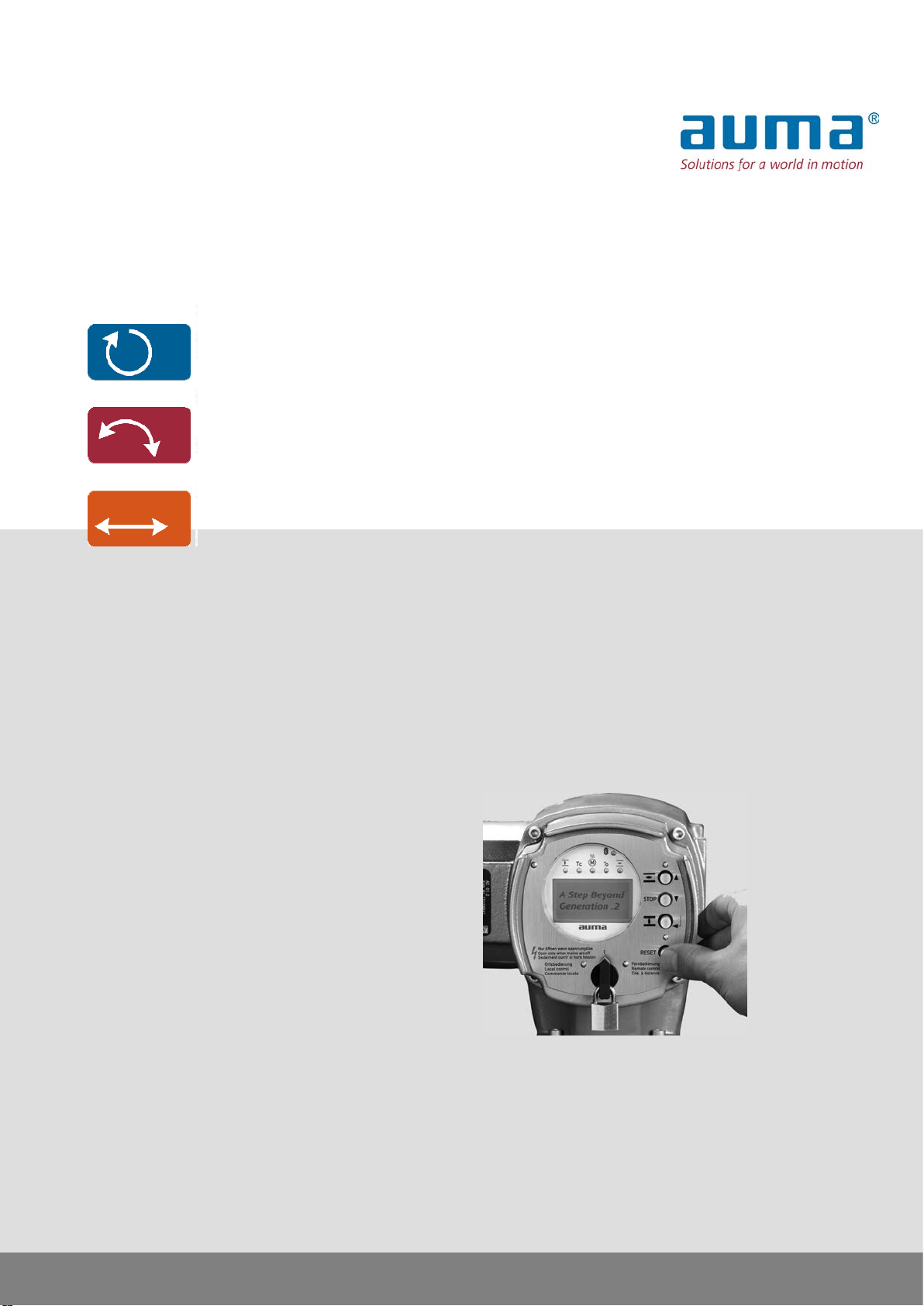

3.1. Local actuator operation

Local actuator operation is performed using the push buttons of the local controls of

the AC.

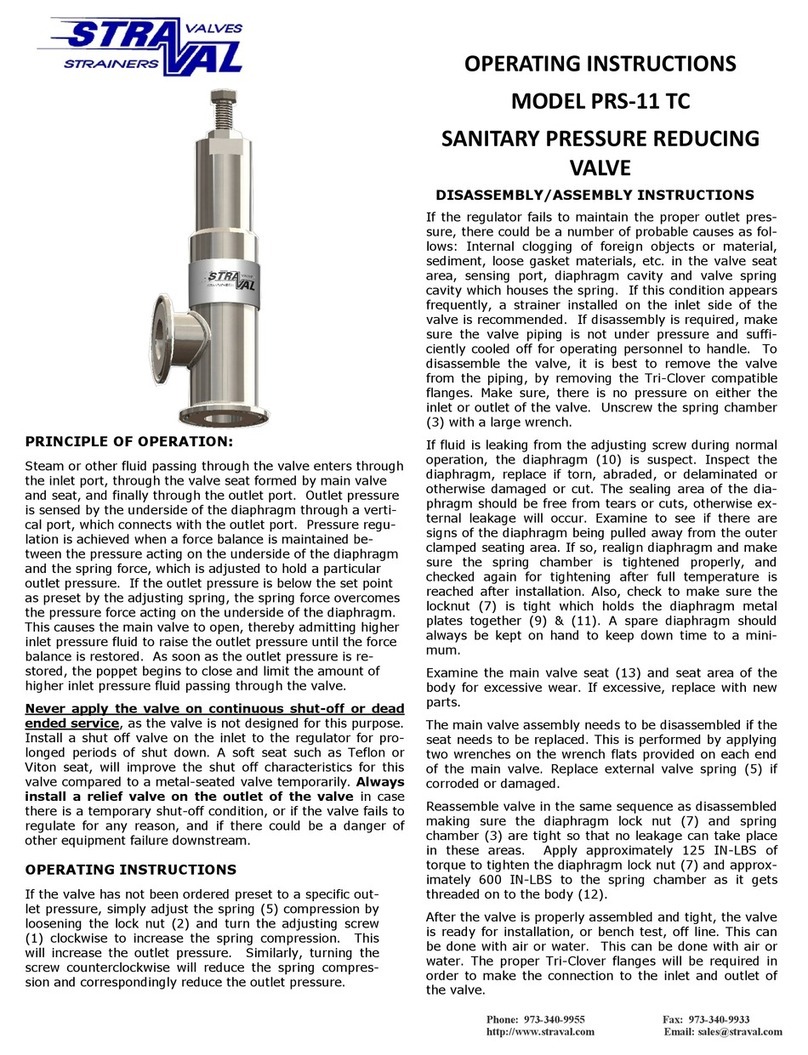

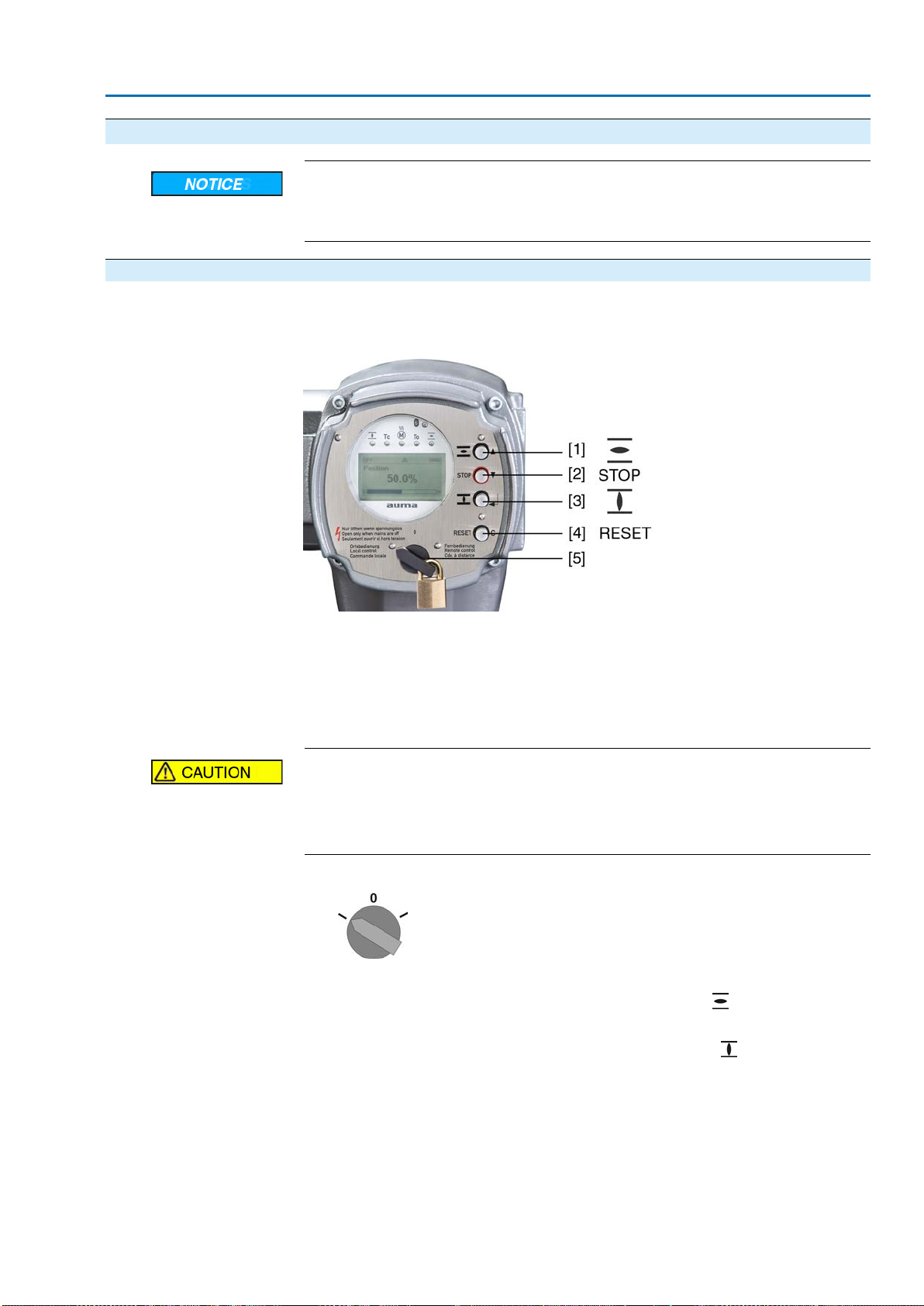

Figure 4: Local controls

[1] Push button for operation command in direction OPEN

[2] Push button STOP

[3] Push button for operation command in direction CLOSE

[4] Push button RESET

[5] Selector switch

Hot surfaces, e.g. possibly caused by high ambient temperatures or strong

direct sunlight!

Danger of burns

→Check surface temperature and wear protective gloves, if required.

→Set selector switch [5] to position Local control (LOCAL).

➥The actuator can now be operated using the push buttons [1 –3]:

-Run actuator in direction OPEN: Press push button [1] .

- Stop actuator: Press push button STOP [2].

-Run actuator in direction CLOSE: Press push button [3] .

Information The OPEN - CLOSE operation commands can be given either in push-to-run or in

self-retaining operation mode.For further information, please refer to <Push-to-run

operation or self-retaining local> chapter.

13

Actuator controls

AC 01.2/ACExC 01.2 Operation

3.2. Actuator operation from remote

→Set selector switch to position Remote control (REMOTE).

➥Now, it is possible to operate the actuator via remote control, via operation

commands (OPEN, STOP, CLOSE) or analogue setpoints (e.g. 0 –20 mA).

Information For actuators equipped with a positioner, it is possible to change over between OPEN

- CLOSE control (Remote OPEN-CLOSE) and setpoint control (Remote SET-

POINT). For further information, refer to chapter <Change-over between OPEN -

CLOSE control and setpoint control>.

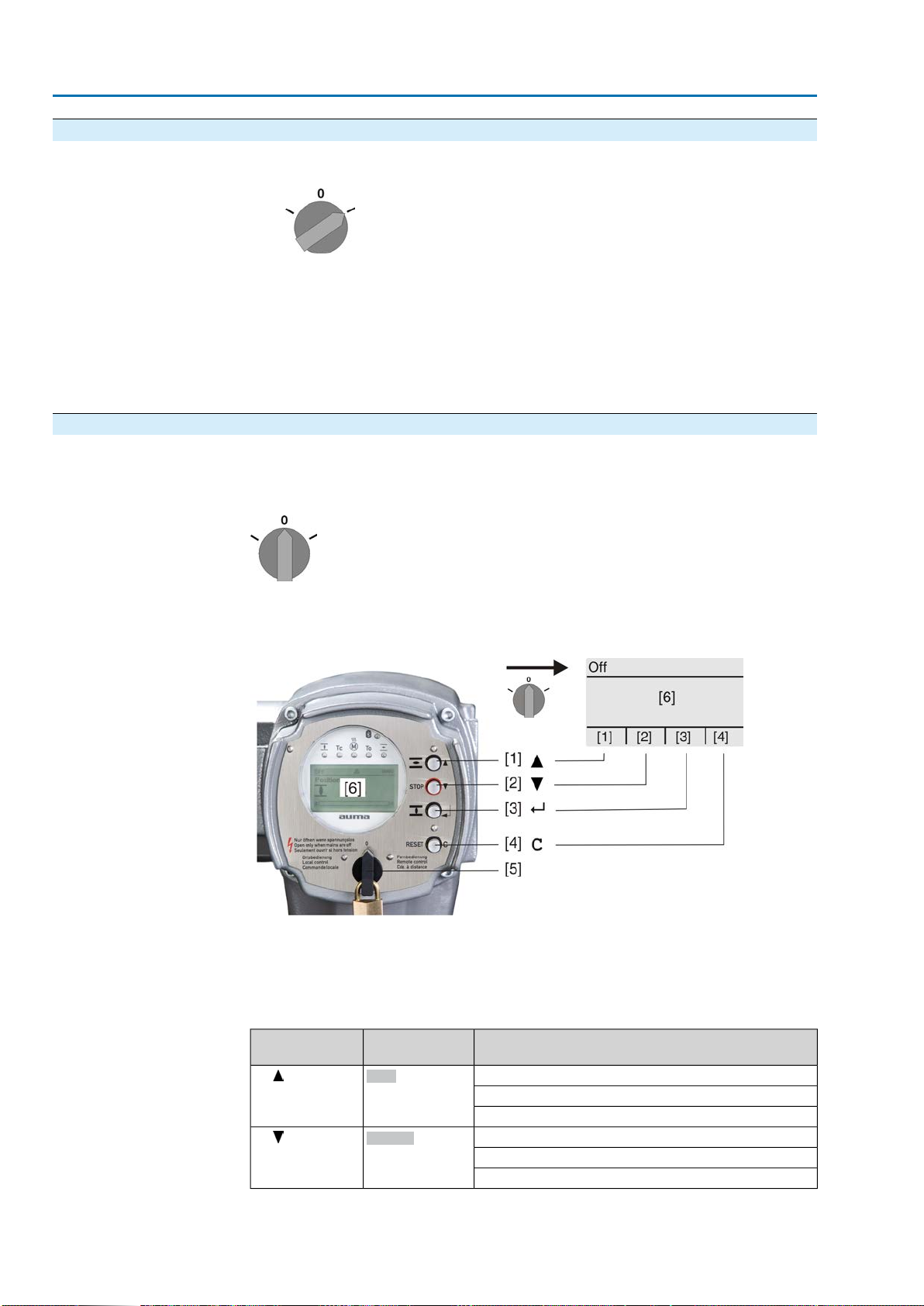

3.3. Menu navigation via push buttons (for settings and indications)

Menu navigation for display and setting is made via the push buttons [1 –4] of the

local controls.

Set the selector switch [5] to position 0(OFF) when navigating through the menu.

The bottom row of the display [6] serves as navigation support and explains which

push buttons [1 –4] are used for menu navigation.

Figure 5:

[1–4] Push buttons or navigation support

[5] Selector switch

[6] Display

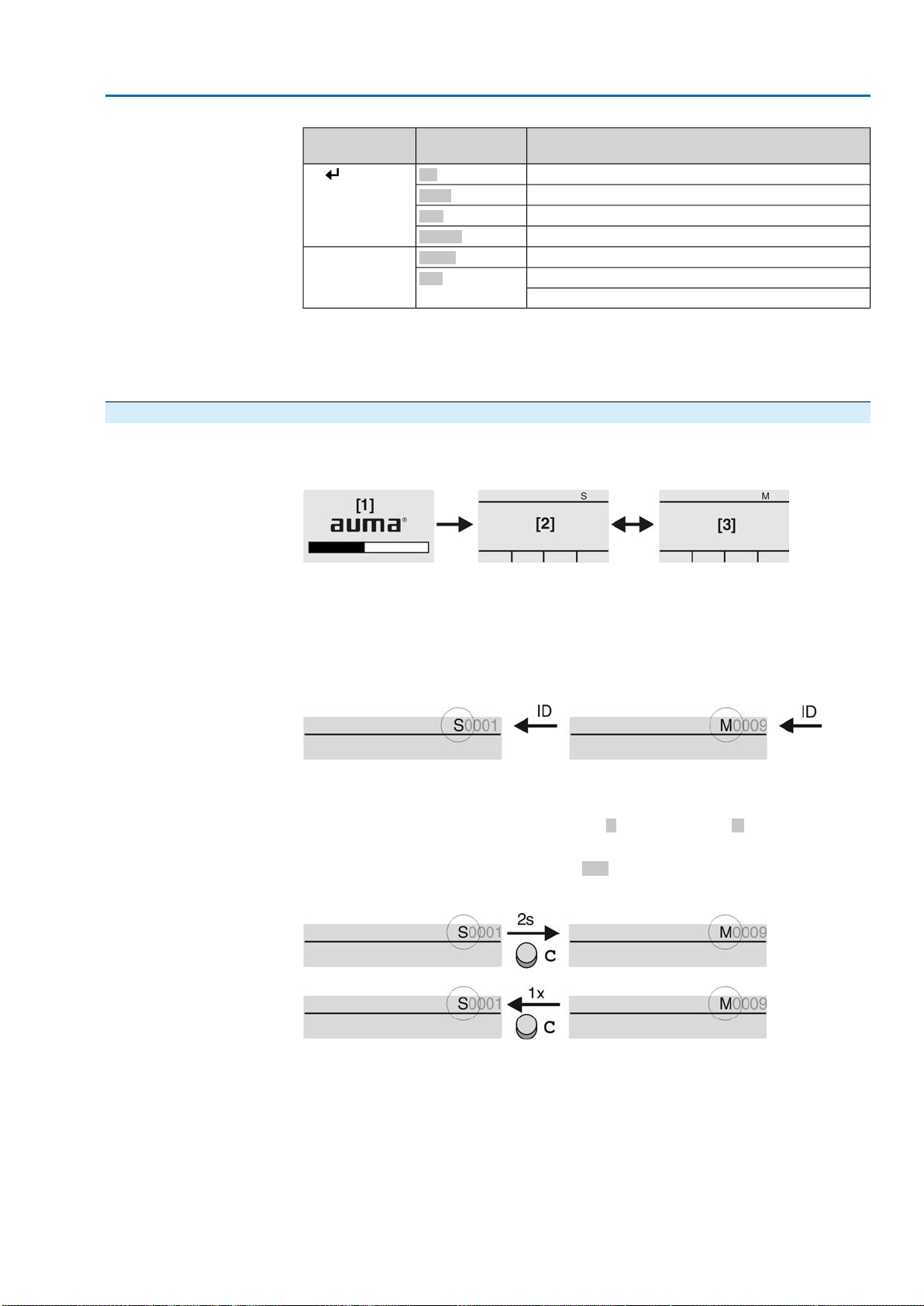

Table 3:Important push button functions for menu navigation

FunctionsNavigation sup-

port on display

Push buttons

Change screen/selection

Up ▲

[1] Change values

Enter figures from 0 to 9

Change screen/selection

Down ▼

[2] Change values

Enter figures from 0 to 9

14

Actuator controls

Operation AC 01.2/ACExC 01.2

FunctionsNavigation sup-

port on display

Push buttons

Confirm selection

Ok

[3] Save

Save

Enter <Edit> menu

Edit

Display more details

Details

Enter Main menu

Setup

[4] CCancel process

Esc

Return to previous display

Backlight ●The display is illuminated in white during normal operation.The backlight turns

to red under fault conditions.

●The screen illumination is brighter when operating a push button.If no push

button is operated for 60 seconds, the display will become dim again.

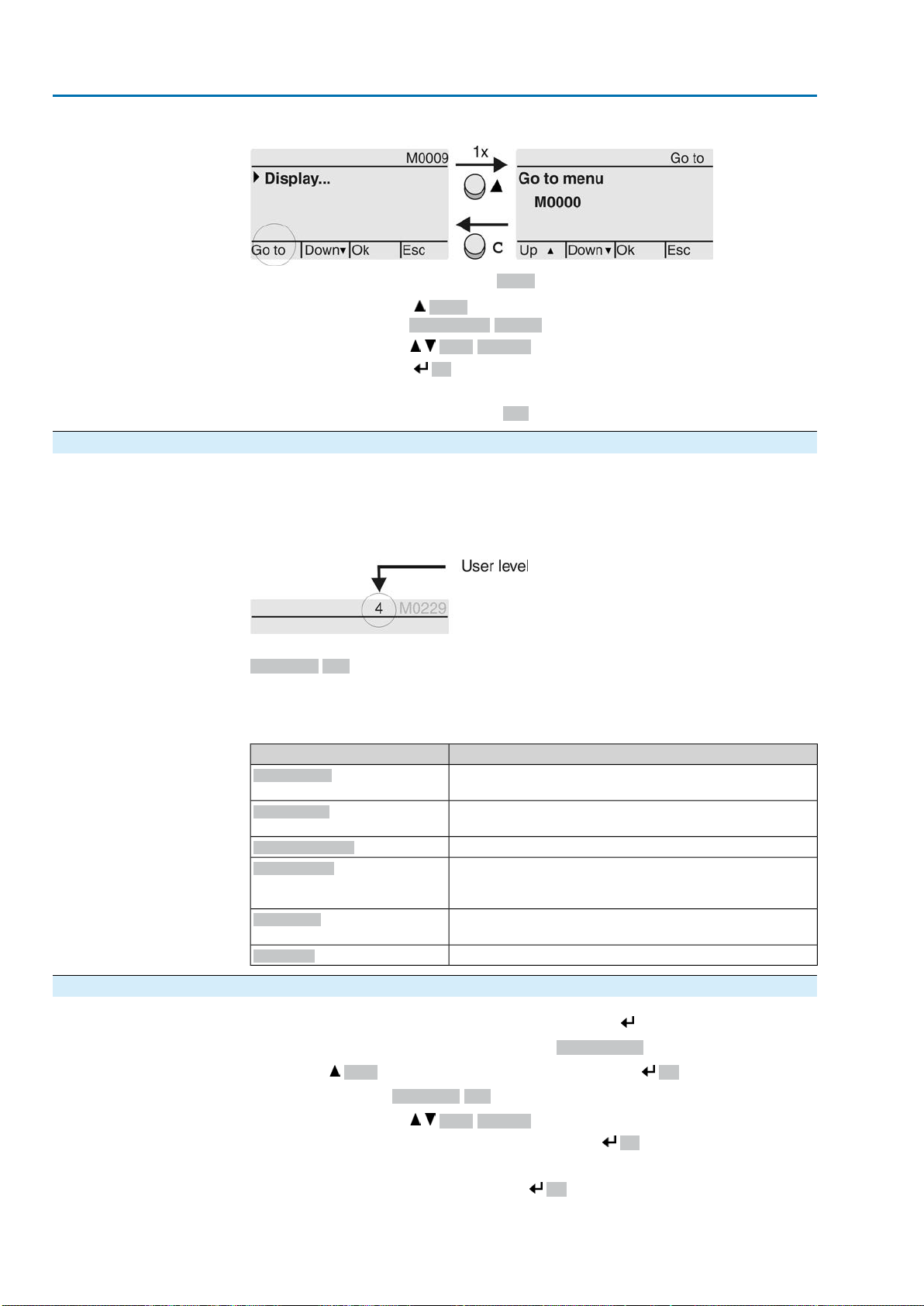

3.3.1. Menu layout and navigation

Groups The indications on the display are divided into 3 groups:

Figure 6: Groups

[1] Startup menu

[2] Status menu

[3] Main menu

ID Status menu and main menu are marked with an ID.

Figure 7: Marking with ID

SID starts with S= status menu

MID starts with M= main menu

Group selection It is possible to select between status menu Sand main menu M:

For this, set selector switch to 0(OFF), hold down push button Cfor approx. 2

seconds until a screen containing the ID M... appears.

Figure 8: Select menu groups

You return to the status menu if:

●the push buttons on the local controls have not been operated within 10 minutes

●or by briefly pressing C

Direct display via ID When entering the ID within the main menu, screens can be displayed directly (without

clicking through).

15

Actuator controls

AC 01.2/ACExC 01.2 Operation

Figure 9: Direct display (example)

Display indicates in the bottom row: Go to

1. Press push button Go to.

Display indicates: Go to menu M0000

2. Use push buttons Up ▲ Down ▼ to select figures 0 to 9.

3. Press push button Ok to confirm first digit.

4. Repeat steps 2 and 3 for all further digits.

5. To cancel the process: Press CEsc.

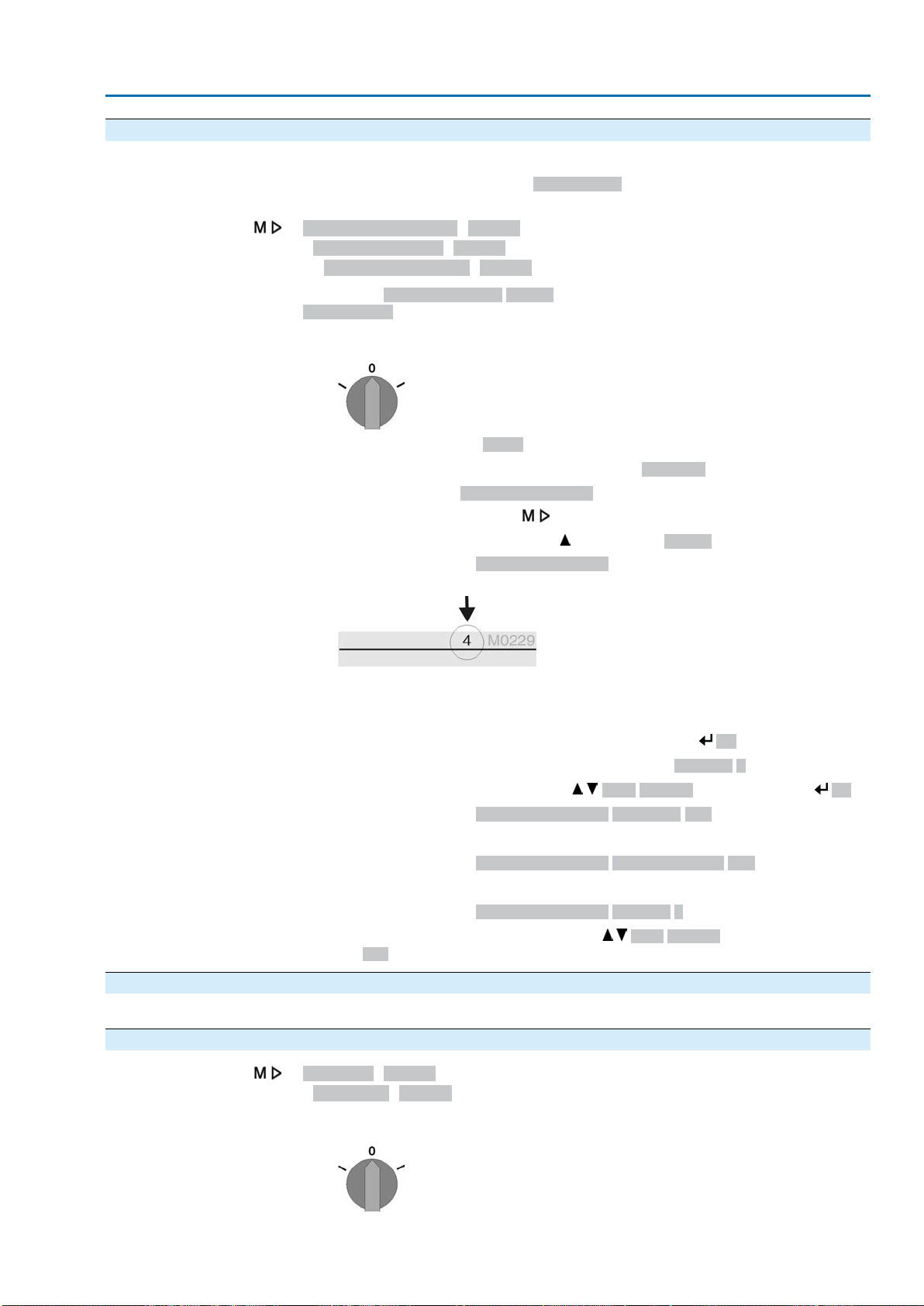

3.4. User level, password

User level Theuser leveldefineswhich menu items orparameterscan be displayedormodified

by the active user.

There are 6 different user levels.The user level is indicated in the top row:

Figure 10: User level display (example)

Password A password must be entered to allow parameter modification.The display indicates:

Password 0***

A specific password is assigned to each user level and permits different actions.

Table 4:User levels and authorisations

Authorisation/passwordDesignation (user level) Verify settings

No password required

Observer (1)

Change settings

Default factory password:0000

Operator (2)

Reserved for future extensions

Maintenance (3)

Change device configuration

e.g.type of seating, assignment of output contacts

Default factory password:0000

Specialist (4)

Service staff

Change configuration settings

Service (5)

AUMA administrator

AUMA (6)

3.4.1. Password entry

1. Select desired menu and hold down push button for approx. 3 seconds.

➥Display indicates the set user level, e.g Observer (1)

2. Press Up ▲to select a higher user level and press Ok to confirm.

➥Display shows: Password 0***

3. Use push buttons Up ▲ Down ▼ to select figures 0 to 9.

4. Confirm first digit of password via push button Ok.

5. Repeat steps 1 and 2 for all further digits.

➥Having confirmed the last digit with Ok, access to all parameters within one

user level is possible if the password entry is correct.

16

Actuator controls

Operation AC 01.2/ACExC 01.2

3.4.2. Password change

Only the passwords of same or lower user level may be changed.

Example:The user is signed in as Specialist (4).This authorises him or her to modify

the passwords between user levels (1) to (4).

Device configuration M0053

Service functions M0222

Change passwords M0229

Menu point Service functions M0222 is only visible if user level has been set to

Specialist (4) or higher.

Select main menu 1. Set selector switch to position 0(OFF).

2. Press push button CSetup and hold it down for approx.3 seconds.

➥Display goes to main menu and indicates: ▶ Display...

Change passwords 3. Select parameter Change passwords either:

→click via the menu to parameter, or

→via direct display: press and enter ID M0229

-Display indicates: ▶ Change passwords

- The user level is indicated in the top row (1 –6), e.g.:

- For user level 1 (view only), passwords cannot be changed.To change pass-

words, you must change to a higher user level. For this, enter a password via

a parameter.

4. For a user level between 2 and 6: Press push button Ok.

➥The display indicates the highest user level, e.g.:For user 4

5. Select user level via push buttons Up ▲ Down ▼ and confirm with Ok.

➥Display indicates: ▶ Change passwords Password 0***

6. Enter current password (→enter password).

➥Display indicates: ▶ Change passwords Password (new) 0***

7. Enter new password (→enter password).

➥Display indicates: ▶ Change passwords For user 4 (example)

8. Select next user level via push buttons Up ▲ Down ▼ or cancel the process

via Esc.

3.5. Language in the display

The AUMATIC display is multilingual.

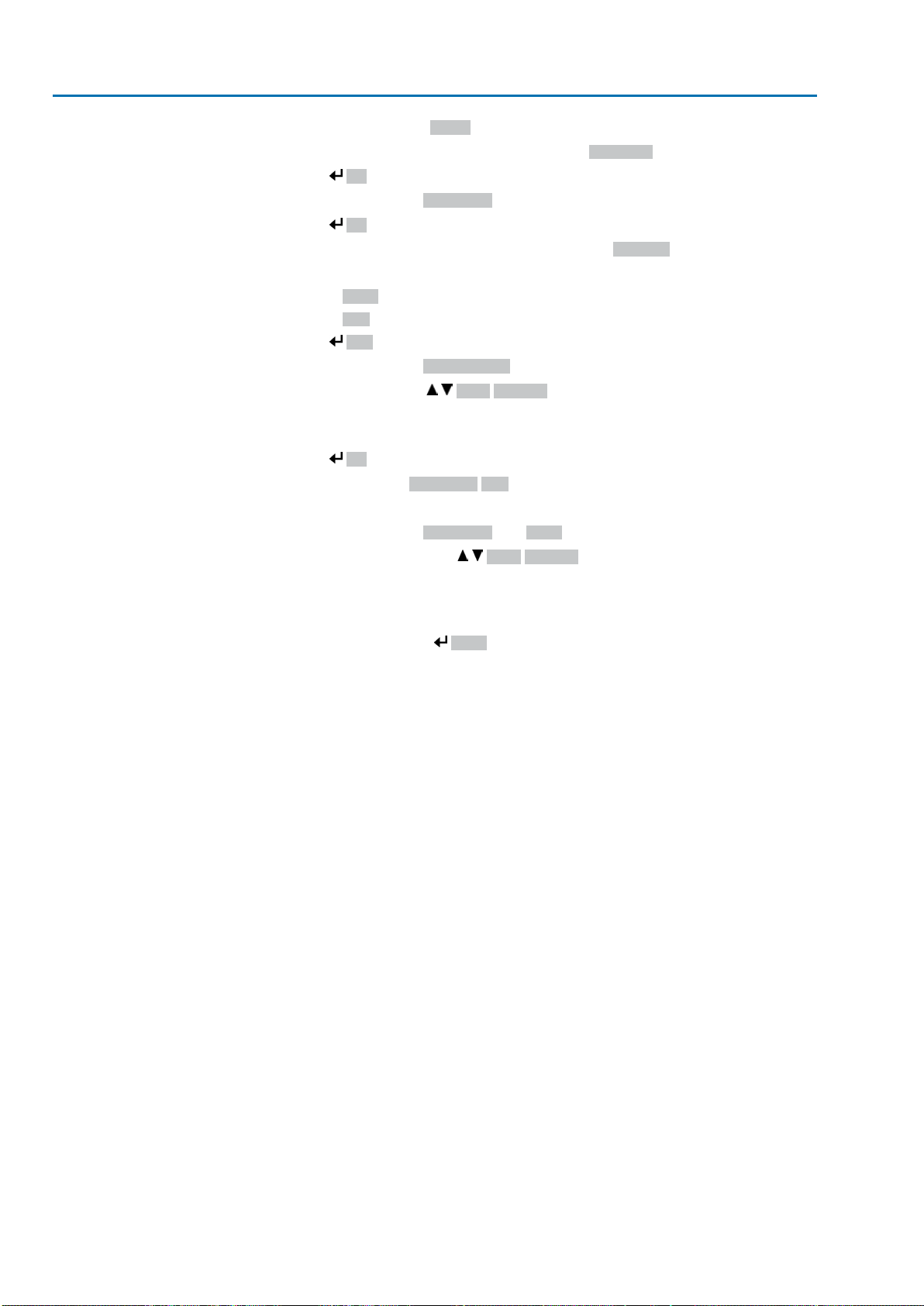

3.5.1. Language change

Display... M0009

Language M0049

Select main menu 1. Set selector switch to position 0(OFF).

17

Actuator controls

AC 01.2/ACExC 01.2 Operation

2. Press push button CSetup and hold it down for approx.3 seconds.

➥Display goes to main menu and indicates: ▶ Display...

Change language 3. Press Ok.

➥Display indicates: ▶ Language

4. Press Ok.

➥Display indicates the selected language, e.g.:▶ Deutsch

5. The bottom row of the display indicates:

→Save → continue with step 10

→Edit → continue with step 6

6. Press Edit.

➥Display indicates: ▶ Observer (1)

7. Select user level via Up ▲ Down ▼ resulting in the following significations:

→black triangle: ▶= current setting

→white triangle: ▷= selection (not saved yet)

8. Press Ok.

➥Display indicates: Password 0***

9. Enter password (→enter password).

➥Display indicates: ▶ Language and Save (bottom row)

Language selection 10. Select new language via Up ▲ Down ▼ resulting in the following significa-

tions:

→black triangle: ▶= current setting

→white triangle: ▷= selection (not saved yet)

11. Confirm selection via Save.

➥The display changes to the new language.The new language selection is saved.

18

Actuator controls

Operation AC 01.2/ACExC 01.2

4. Indications

4.1. Indications during commissioning

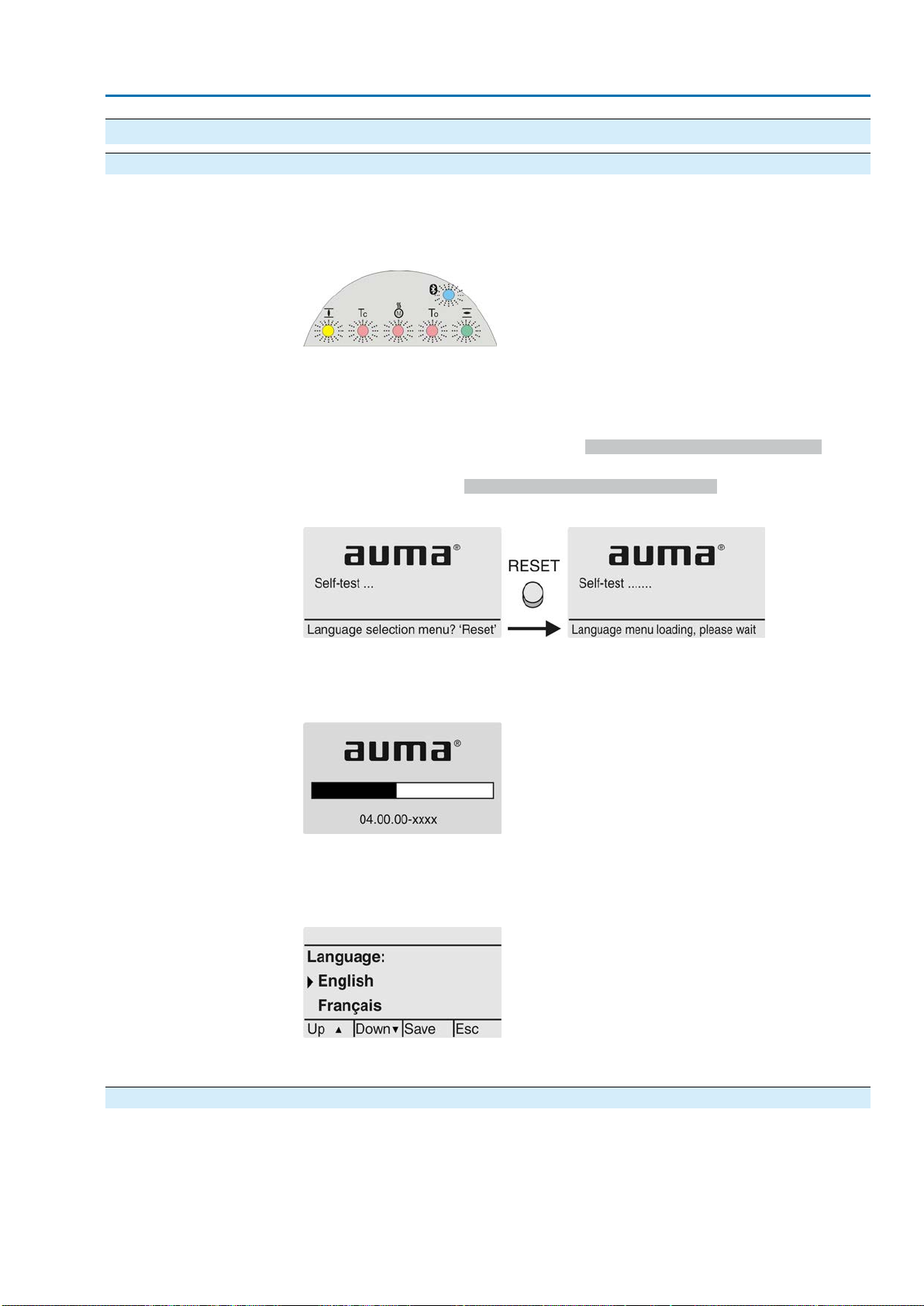

LED test When switching on the power supply, all LEDs on the local controls illuminate for

approx.1 second.This optical feedback indicates that the voltage supply is connected

to the controls and all LEDs are operable.

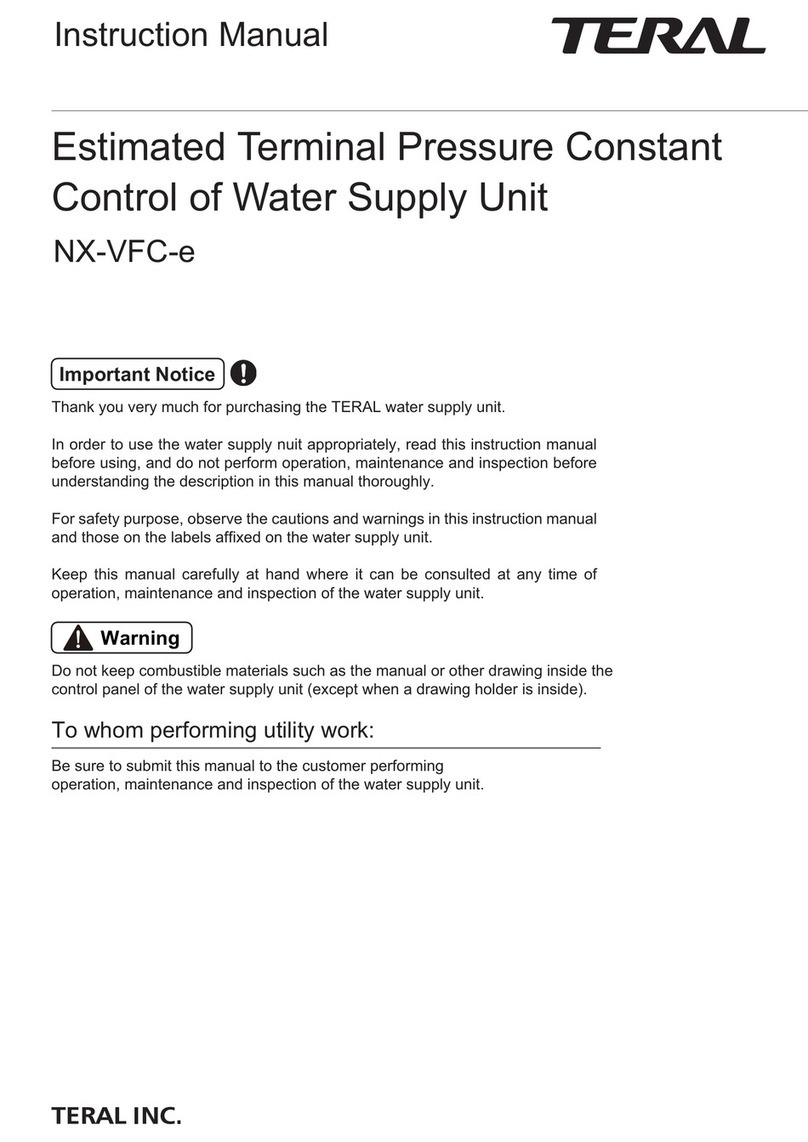

Figure 11: LED test

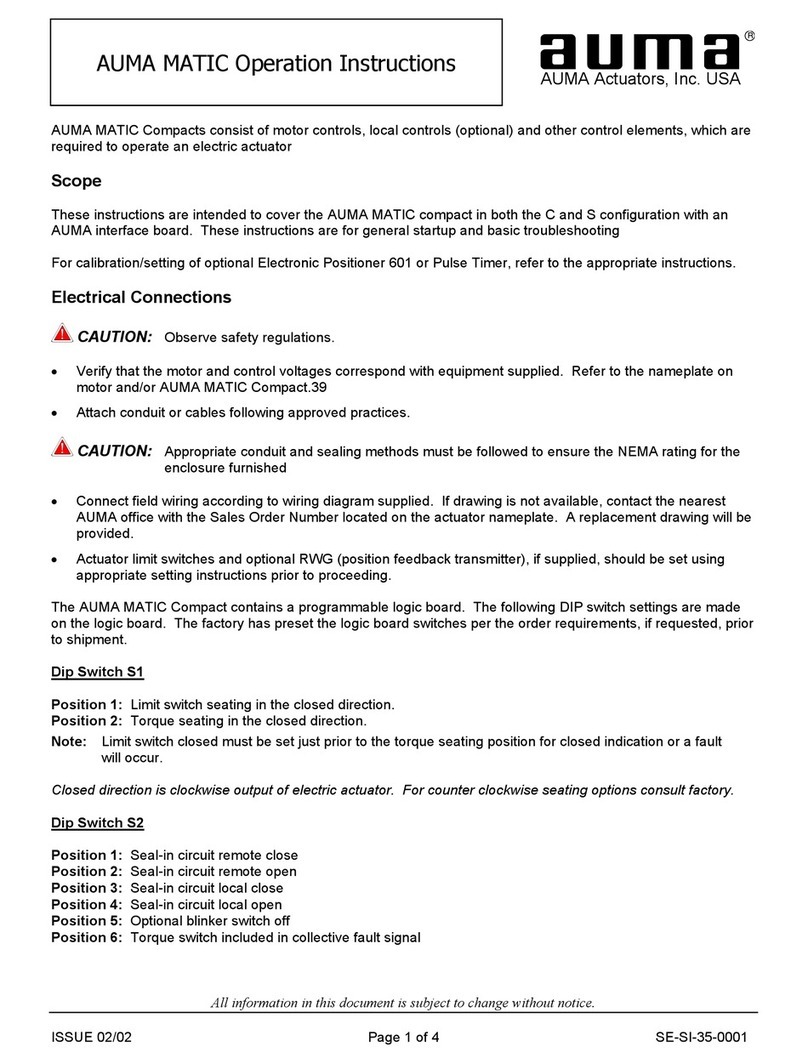

Language selection During the self-test, the language selection can be activated so that the selected

language is immediately indicated in the display. For this, set selector switch [5] to

position 0(OFF).

Activate language selection:

1. Display indicates in the bottom row: Language selection menu? 'Reset'

2. Press push button RESET and hold it down until the following text is displayed

in the bottom line: Language menu loading, please wait.

Figure 12: Self-test

The language selection menu follows the startup menu.

Startup menu The current firmware version is displayed during the startup procedure:

Figure 13: Startup menu with firmware version:04.00.00–xxxx

If the language selection feature has been activated during the self-test, the menu

for selecting the display language will now be indicated. For further information on

language setting, please refer to chapter <Language in the display>.

Figure 14: Language selection

If no entry is made over a longer period of time (approx.1 minute), the display

automatically returns to the first status indication.

4.2. Indications in the display

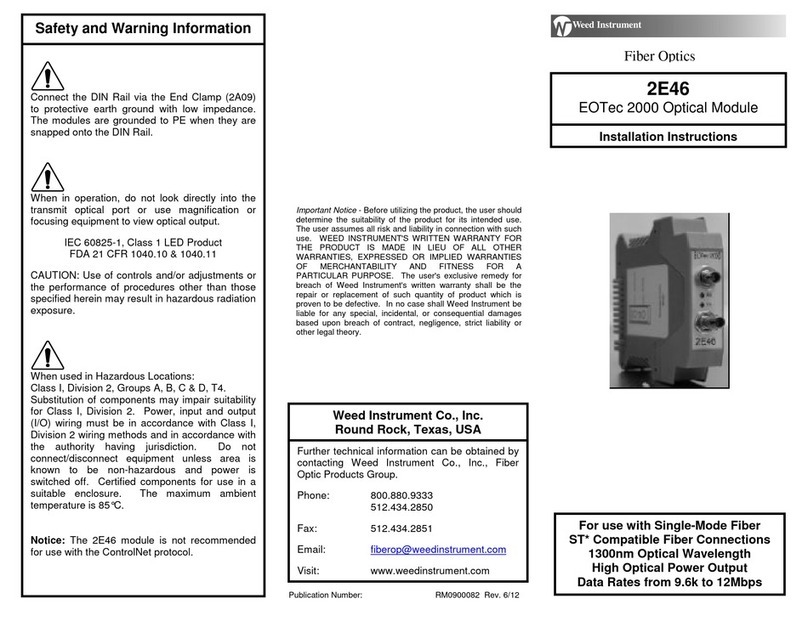

Status bar The status bar (first row in the display) indicates the operation mode [1], the presence

of an error [2] and the ID number [3] of the current display indication.

19

Actuator controls

AC 01.2/ACExC 01.2 Indications

Figure 15: Information in the status bar (top)

[1] Operation mode

[2] Error symbol (only for faults and warnings)

[3] ID number: S = Status page

Navigation support If further details or information are available with reference to the display, the following

indications Details or More appear in the navigation support (bottom display row).

Then, further information can be displayed via the push button.

Figure 16: Navigation support (bottom)

[1] shows list with detailed indications

[2] shows further available information

The navigation support (bottom row) is faded out after approx.3 seconds.Press any

push button (selector switch in position 0(OFF)) to fade in the navigation support.

4.2.1. Feedback indications from actuator and valve

Display indications depend on the actuator version.

Valve position (S0001)

This indication is only available if a position transmitter (potentiometer, EWG, RWG

or MWG) is installed in the actuator.

●S0001 on the display indicates the valve position in % of the travel.

●The bargraph display appears after approx.3 seconds.

●When issuing an operation command, an arrow indicates the direction

(OPEN/CLOSE).

Figure 17:Valve position and direction of operation

Reaching the preset end positions is additionally indicated via (CLOSED) and

(OPEN) symbols.

Figure 18: End position CLOSED/OPEN reached

0% Actuator is in end position CLOSED

100% Actuator is in end position OPEN

20

Actuator controls

Indications AC 01.2/ACExC 01.2

Other manuals for AC 01.2

1

This manual suits for next models

1

Table of contents

Other AUMA Control Unit manuals

AUMA

AUMA AMExB 01.1 User manual

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA AM 01.1 User manual

AUMA

AUMA Matic User manual

AUMA

AUMA Aumatic AC 01.1 Manual

AUMA

AUMA AUMATIC AC 01.2 User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA SG 12.1 User manual

AUMA

AUMA AC 01.2 User manual