DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

Received setpoint cannot be performed as the positioner is

not available.

Bit: Setpoint disabled

(55) = "Bit:Wrong command"

Motor protection tripped.

Bit: Thermal fault

(56) = "Bit:Thermal fault"

●When connecting to a 3-ph AC system and with internal

24 V DC supply of the electronics: Phase 2 is missing.

●When connecting to a 3-ph or 1-ph AC system and with

external 24 V DC supply of the electronics: One of the

phases L1, L2 or L3 is missing.

Bit: Phase failure

(57) = "Bit: Phase fault"

The phase conductors L1, L2 and L3 are connected in the

wrong sequence.

Bit: Incorrect phase seq

(58) = "Bit:Wrong phase sequence"

Due to insufficient mains quality, the controls cannot detect

the phase sequence (sequence of phase conductors L1, L2

and L3) within the pre-set time frame provided for monitoring.

Bit: Mains quality

(59) = "Bit: Mains quality"

Torque fault in direction CLOSE

Bit: Torque fault CLOSE

(60) = "Bit:Torque fault CLOSE" Torque fault in direction OPEN

Bit: Torque fault OPEN

(61) = "Bit:Torque fault OPEN" Torque fault in directions CLOSE or OPEN

Bit: Torque fault

(62) = "Bit:Torque fault" Warning: Max. permissible operating time for an operation

(OPEN-CLOSE) exceeded

Bit: Op. time warning

(63) = "Bit: Operat. time warning"

Warning: Max. number of motor starts (starts) or max. run-

ning time/h exceeded

Bit: On time warning

(64) = "Bit: On time warning"

The internal 24 V AC voltage supply of the controls has ex-

ceeded the power supply limits.

The 24V AC voltage supply is used to control the reversing

contactors, to assess the thermoswitches, to supply the in-

ternal actuator heater and, as an option, to generate the 115

V AC supply for the customer.

Bit: 24 V AC internal

(65) = "Bit: 24 V AC, internal"

The 24 V DC auxiliary voltage (e.g. for supply of the control

outputs) is outside the supply voltage limits.

Bit: 24 V DC control volt.

(66) = "Bit: 24 V DC control volt."

The internal 24 V DC supply voltage of the controls for

supply of the electronic components is outside the supply

voltage limits.

Bit: 24 V DC internal

(67) = "Bit: 24 V DC, internal"

The external 24 V DC voltage supply of the controls has

exceeded the power supply limits.

Bit: 24 V DC, external

(68) = "Bit: 24 V DC, external"

Collective signal 14:Internal error

Bit: Internal error

(69) = "Bit: Internal error" Collective signal 15:Internal warning

Bit: Internal warning

(70) = "Bit: Internal warning" No actuator reaction to operation commands within the set

reaction time.

Bit: No reaction

(71) = "Bit: No reaction"

Incorrect configuration, i.e.the current setting is invalid.

Bit: Configuration error

(72) = "Bit: Configuration error" Parameter not available

Bit: Temp. fault controls

(73) = "Bit:Temp.fault controls" Parameter not available

Bit: Temp. fault motor

(74) = "Bit:Temp.fault motor" Parameter not available

Bit: Temp. fault gear

(75) = "Bit:Temp.fault gearbox" Heater failure at actuator (control unit)

Bit: Wrn heater

(76) = "Bit:Wrn heater" Real time clock has not yet been set.

Bit: RTC not set

(77) = "Bit: RTC not set" Parameter not available

Bit: Wrn humidity

(78) = "Bit:Wrn humidity" Warning:

Position feedback of actuator was not yet referenced for

limit end positions.

Bit: WrnRefActPos

(79) = "Bit:WrnRefActPos"

Warning:

Current position feedback signal range is outside the per-

missible range.

Bit: WrnSigRgeActPos

(80) = "Bit:WrnSigRgeActPos"

Warning:

A signal loss has occurred for actuator position feedback.

Bit: WrnSigLossActPos

(81) = "Bit:WrnSigLossActPos"

Warning: Actual position of actuator

Collective signal consisting of:

●(79) Bit: WrnRefActPos

●(80) Bit: WrnSigRgeActPos

●(81) Bit: WrnSigLossActPos

Bit: WrnActPosition

(82) = "Bit:WrnActPosition"

14

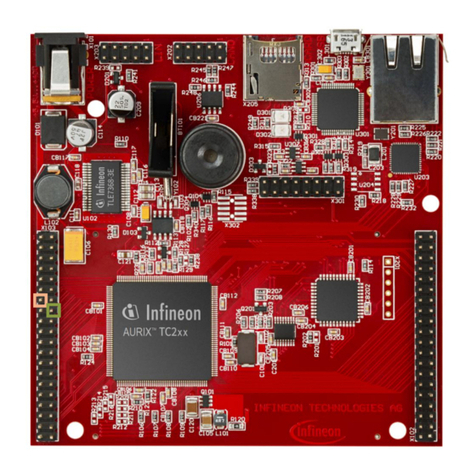

Actuator controls

Commissioning AC 01.2/ACExC 01.2 Profibus DP