AUMA AMExB 01.1 User manual

Certificate Registration No.

12 1

00/

1

0

442

69

Actuator controls

Short instructions bus connection

AUMA MATIC

AM 01.1/AM 02.1

AMExB 01.1/AMExC 01.1

Modbus

2

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

Scope of these instructions: These instructions are valid for multi-turn actuators of type ranges

SA(R) 07.1 – SA(R) 16.1 and SA(R)ExC 07.1 – SA(R)ExC 16.1 and for

part-turn actuators of type ranges SG(R) 05.1 – SG(R) 12.1 and SGExC

05.1 – SGExC 12.1 with the controls AUMA MATIC AM 01.1/AM 02.1

or AMExB 01.1 and AMExC 01.1 and Modbus interface.

Table of contents

1. Safety instructions 3

1.1 Range of application 3

1.2 Commissioning (electrical connection) 3

1.3 Maintenance 3

1.4 Warnings and notes 3

2. Short description 3

3. Electrical connection 4

3.1 Power supply (standard) 4

3.2 Bus connection (standard) 5

3.3 Fitting the cover 6

3.4 Remote position transmitter 7

3.5 AUMA MATIC on wall bracket 7

3.6 Test run 7

3.7 Mains and bus connection for Ex-version with plug/socket connector/terminal board (KP) 8

3.8 Mains and bus connection for Ex-version with plug-in terminal connection (KES) 10

3.9 Redundant bus connection 11

3.10 Bus cables 12

3.11 Setting the Modbus interface 13

3.12 Setting the communication parameters 14

3.13 Setting parameter seating mode in end position CLOSED, parity bits and number of stop bits 14

3.14 Setting the Modbus address 14

3.15 Setting the baud rate 15

4. Description Modbus interface 16

4.1 Indication during system start-up: 16

4.1.1 Indications of operation LEDs 7 to 0 16

4.1.2 System displays LEDs L1 to L4 17

4.2 Checking/setting the switches on the logic board 18

5. Appendix A Literature references 19

6. Appendix B Connecting the cable shield for AUMA MATIC AMExB/AMExC 01.1 19

Index 19

Addresses of AUMA offices and representatives 20

1. Safety instructions

1.1 Range of application AUMA actuators are designed for the operation of industrial valves,

e.g. globe valves, gate valves, butterfly valves and ball valves.

For other applications, please consult us. The manufacturer is not liable for

any possible damage resulting from use in other than the designated appli-

cations. Such risk lies entirely with the user.

Observance of these operation instructions is considered as part of the

controls’ designated use.

1.2 Commissioning

(electrical connection) During electrical operation, certain parts inevitably carry lethal voltages.

Work on the electrical system or equipment must only be carried out by a

skilled electrician himself or by specially instructed personnel under the

control and supervision of such an electrician and in accordance with the

applicable electrical engineering rules.

1.3 Maintenance The maintenance instructions must be strictly observed, otherwise a safe

operation of the multi-turn actuator/the controls is no longer guaranteed.

1.4 Warnings and notes Non-observance of the warnings and notes may lead to serious injuries or

damage. Qualified personnel must be thoroughly familiar with all warnings

and notes in these operation instructions.

Correct transport, proper storage, mounting and installation, as well as

careful commissioning are essential to ensure a trouble-free and safe

operation.

The following references draw special attention to safety-relevant proce-

dures in these operation instructions. Each is marked by the appropriate

pictograph.

This pictograph means: Note!

“Note” marks activities or procedures which have major influence on the

correct operation. Non-observance of these notes may lead to consequen-

tial damage.

This pictograph means: Electrostatically endangered parts!

The printed circuit boards are equipped with parts which may be damaged

or destroyed by electrostatic discharges. If the boards need to be touched

during setting, measurement, or for exchange, it must be assured that

immediately before a discharge through contact with an earthed metallic

surface (e.g. the housing) has taken place.

This pictograph means: Warning!

“Warning” marks activities or procedures which, if not carried out correctly,

can affect the safety of persons or material.

2. Short description AUMA actuators have a modular design. Motor and gearing are mounted in

a common housing.

The actuators are driven by an electric motor and controlled with the elec-

tronic controls AUMA MATIC Modbus. The electronic controls are included

in the scope of delivery.

3

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

3. Electrical connection .Work on the electrical system or equipment must only be

carried out by a skilled electrician himself or by specially

instructed personnel under the control and supervision of

such an electrician and in accordance with the applicable

electrical engineering rules.

.Installation regulations for Modbus must be observed for

the wiring.

(For literature references, please refer to appendix A)

Make sure to respect electromagnetic compatibility (EMC) when installing

cables:

Signal and bus cables are susceptible to interference.

Electric power cables are interference sources.

.Lay cables being susceptible to inferference or sources of interference at

the highest possible distance from each other.

.The interference immunity of signal and bus cables increases if the cables

are laid close to the ground potential.

.Avoid long cables, if possible, or make sure that they are laid in locations

with low susceptibility to interference.

.Avoid long parallel paths with cables being either interference sources or

susceptible to interference.

3.1 Power supply (standard) For explosion-proof version (type designation: AMExB/AMExC), please refer

to page 8 or page 10.

.Check whether type of current, supply voltage, and frequency comply with

motor data (refer to name plate at motor).

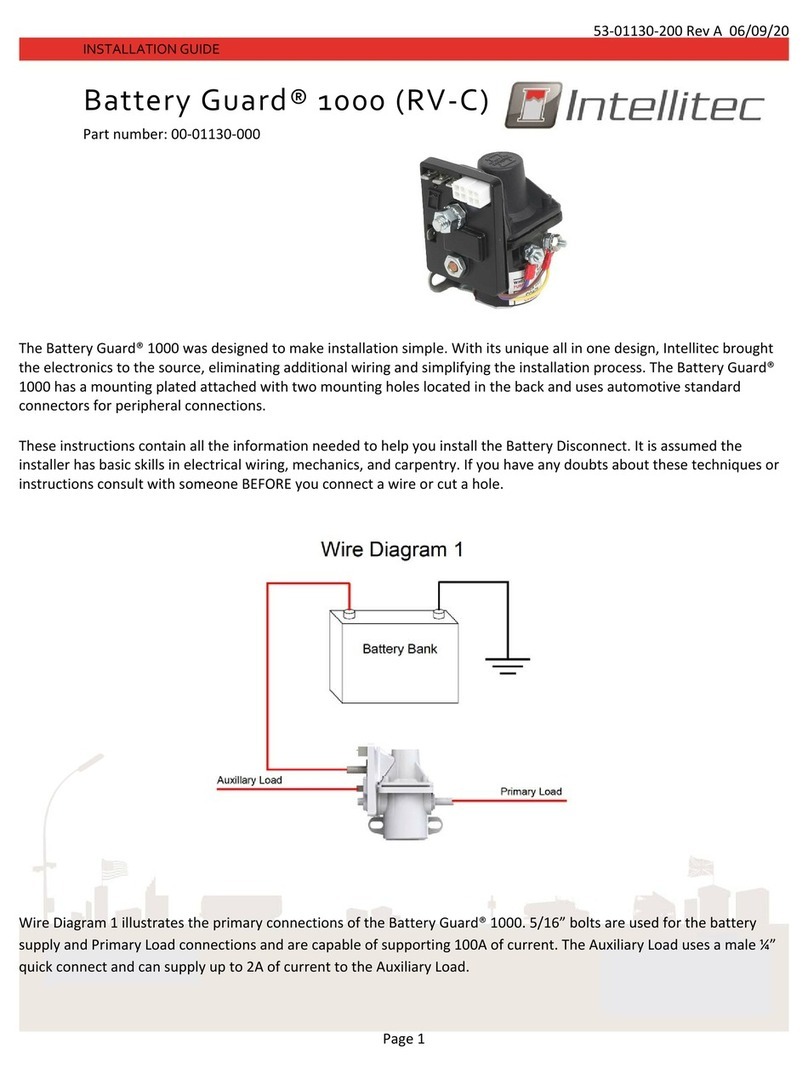

.Loosen bolts (50.01) (figure A-1) and remove connection housing.

.Loosen screws (51.01) and remove socket carrier (51.0) from plug cover

(50.0).

.Insert cable glands suitable for connecting cables.

(The enclosure protection stated on the name plate is only ensured if suit-

able cable glands are used).

.Seal cable entries which are not used with suitable plugs.

.Connect cables according to order-related wiring diagram.

The wiring diagram applicable to the actuator is attached to the handwheel

in a weather-proof bag, together with the operation instructions. In case

the wiring diagram is not available, it can be obtained from AUMA (state

commission no., refer to name plate) or downloaded directly from the

Internet (www.auma.com).

A special parking frame (figure B-2) for protection against touching the bare

contacts and against environmental influences, in case the electrical

connection has been removed, is available.

4

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

Figure A-1: Connection

50.0

50.01

51.0

51.01

Figure A-2: Parking frame (accessories)

Parking frame

Technical data Motor power connections1) Protective earth Control terminals

No. of contacts max. 6 (3 are used) 1 (leading contact) 50 pins/sockets

Marking U1, V1, W1, U2, V2, W2 1 to 50

Connecting voltage max. 750 V – 250 V

Nominal current max. 25 A – 16 A

Type of customer connection Screws Screw for ring lug Screws

Cross section max. 6 mm26 mm22.5 mm2

Material: Pin/socket carrier Polyamide Polyamide Polyamide

Contacts Brass (Ms) Brass (Ms) Brass, tin plated or gold plated (option)

1)Suitable for copper wires. For aluminium wires, please contact AUMA

Table 1: Technical data AUMA plug/socket connector for bus connection

3.2 Bus connection (standard) For explosion-proof version (type designation: AMExB/AMExC), please refer

to page 8 or page 10.

For version with FO (fibre optics), refer to separate operation instructions

“AUMA MATIC AM 01.1/AM 02.1 FO connection”.

.Connect bus cable. Refer to figures B-1 to B-4.

The termination resistors for channel 1 and channel 2 are switched in via

switches (S1) and (S2). Both switches are supplied in position ‘OFF’.

Only switch on the termination resistors (position ‘ON’) if the

actuator is the final device in the Modbus segment.

5

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

S1 ON Bus termination channel 1 ON

OFF Bus termination channel 1 OFF

S2 ON Bus termination channel 2 ON (option)

OFF Bus termination channel 2 OFF (option)

Table 2: Switch position of S1 and S2

Figure B-1: Connection board (standard)

S1

Bus termination

channel 1

Connection

channel 1

Screening

S2

Bus termination

channel 2

(option)

Connection

channel 2

(redundant)

Screening

X1

P/B N/A N/A

5V P/B GND

BA

A

B

Figure B-2: Connection (standard)

from previous / to next

Modbus device

channel 1

3.3 Fitting the cover After connection:

.Insert the socket carrier (51.0) into the plug cover (50.0) and fasten it with

screws (51.01).

.Clean sealing faces at the plug cover and the housing.

.Check whether O-ring is in good condition.

.Apply a thin film of non-acidic grease (e.g. Vaseline) to the sealing faces.

.Replace plug cover (50.0) and fasten bolts (50.01) evenly crosswise.

.Fasten cable glands with the specified torque to ensure the required

enclosure protection.

6

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

Figure B-3: Connection board (for overvoltage protection)

S1

Bus termination

channel 1

S2

Bus termination

channel 2

X1

1234

Figure B-4: Connection for overvoltage protection

from previous / to next

Modbus device

channel 1

Modbus

cable

AUMA

labelling at the

connection

AN/A

BP/B

Table 3: Assignment of Modbus cable

3.4 Remote position transmitter For the connection of remote position transmitters (potentiometer, RWG)

screened cables must be used.

3.5 AUMA MATIC on wall bracket The AUMA MATIC can also be mounted separately from the actuator on a

wall bracket.

.For the connection of actuator and AUMA MATIC on wall bracket, use suit-

able flexible and screened connecting cables.

(Preconfectioned cables can be obtained from AUMA on request)

.Permissible cable distance between actuator and AUMA MATIC amounts

to a max. of 100 m.

.Versions with potentiometer in the actuator are not suitable. Instead of the

potentiometer, an RWG has to be used in the actuator.

.Connect the wires in correct phase sequence.

Check direction of rotation before switching on.

The plug connection on the wall bracket is made as crimp version.

Use a suitable four indent crimp tool for crimping.

Cross sections for flexible wires:

Control cables: max. 0.75 to 1.5 mm²

Power supply: max. 2.5 to 4 mm²

The connector at the actuator is equipped with screw type connections.

Wire end sleeves have to be used.

3.6 Test run Perform test run. Please refer to the operation instructions pertaining to the

actuator (multi-turn actuator SA(R) .../part-turn actuator SG ...).

Check limit and torque switching:

Check limit and torque switching, electronic position transmitter RWG or

potentiometer (option) and re-set where appropriate.

The settings are described in the operation instructions pertaining to the

actuator (multi-turn actuator SA(R) ... part-turn actuator SG ... ).

For actuators with feedback signal (RWG, potentiometer), a reference

operation has to be performed after having changed the setting.

Perform reference operation:

.Operate actuator electrically (via the push buttons OPEN and CLOSE of

the local controls) once to the end position OPEN and once to the end

position CLOSED.

.If no reference operation is performed after changing the limit switching,

the feedback signal via the bus is not correct. The bus signals the missing

reference operation as warning.

7

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

Figure B-5: AM on wall bracket

Connection cable to actuator

3.7 Mains and bus connection for Ex-version with plug/socket connector/terminal board (KP)

When working in potentially explosive areas, observe the

European Standards EN 60079-14 “Electrical installations in

hazardous areas” and EN 60079-17 “Inspection and mainten-

ance of electrical installations in hazardous areas”.

For the Ex-plug/socket connector (figure C-1), the electrical mains connec-

tion is made after removing the plug cover (50.0) at the EEx e terminals of

the terminal board (51.0). The flameproof compartment (type of protection

EEx d) remains hereby closed.

.Check whether type of current, supply voltage, and frequency correspond

to motor data (refer to name plate at motor).

.Loosen bolts (50.01) (figure C-1) and remove plug cover.

.Insert cable glands with “EEx e” approval and of size suit-

able for connecting cables. For the recommended cable

glands refer to appendix B, page 19.

(The enclosure protection stated on the name plate is only

ensured if suitable cable glands are used).

.Seal cable entries which are not used with suitable plugs.

.No more than max. 2 wires with the same cross section

may be connected to one terminal.

.Remove cable sheathing in a length of 120 – 140 mm.

Strip wires: Controls max. 8 mm, motor max. 12 mm.

For stranded wires use end-sleeves according to DIN 46228.

.Connect bus cable. Refer to figure (C-3).

The termination resistor for channel 1 is connected through linking the

terminals 1 – 4 and 3 – 2 (standard).

.Only connect the termination resistor if the actuator is the final device in

the Modbus segment.

.Connect screen largely to the cable glands. For the recommended cable

glands refer to appendix B, page 19.

If the actuator must be taken from the valve, e.g. for service purposes, it can

be separated from the mains without having to remove the wiring

(figure C-2). For this purpose, the screws (51.02) are removed and the

plug/socket connector is pulled off. Plug cover (50.0) and terminal board

(51.0) remain together.

Flameproof enclosure! Before opening, ensure that no

explosive gas and no voltage is present.

A special parking frame (figure C-2) for protection against touching the bare

contacts and against environmental influences is available.

8

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

Figure C-1: Connection

50.0

50.01

51.0

Figure C-2: Disconnection from

the mains

50.0

51.0

51.02

9

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

Figure C-3: Bus connection for channel 1 (standard)

Another bus device follows the actuator

Actuator is final bus device

from previous

Modbus device

channel 1

to next

Modbus device

channel 1

Technical data Motor power connections1) Protective earth Control terminals

No. of contacts max. 3 1 (leading contact) 38 pins/sockets

Marking U1, V1, W1 1 to 24, 31 to 50

Connecting voltage max. 550 V –250 V

Nominal current max. 25 A –10 A

Type of customer connection Screws Screws Screws

Cross section max. 6 mm26 mm21.5 mm2

Material: Pin/socket carrier Araldite/Polyamide Araldite/Polyamide Araldite/Polyamide

Contacts Brass (Ms) Brass (Ms) Brass (Ms) tin-plated

1) Suitable for copper wires. For aluminium wires, please contact AUMA.

Tabee 4: Technical data Ex plug/socket connector with terminal board for explosion-proof actuators

3.8 Mains and bus connection for Ex-version with plug-in terminal connection (KES)

When working in potentially explosive areas, observe the

European Standards EN 60079-14 “Electrical installations in

hazardous areas” and EN 60079-17 “Inspection and mainten-

ance of electrical installations in hazardous areas”.

The bus connection is realised via terminals (figure D-1) The terminal

compartment is designed for explosion protection “EEx e” (increased

safety). The controls AUMA MATIC (type of protection EEx d) remain closed.

.Loosen bolts (1) (figure D-1) and remove terminal cover.

.Insert cable glands with “EEx e” approval and of size suit-

able for connecting cables. For the recommended cable

glands refer to appendix B, page 19.

(The enclosure protection stated on the name plate is only

ensured if suitable cable glands are used).

.Seal cable entries which are not used with suitable plugs.

Cross sections for connection:

Control cables: max. 2.5 mm2,

Motor connection: max. 10 mm2,

Suitable bus cables, see page 12.

.Connect bus cable to channel 1 according to configuration of the terminals

(figure D-2).

The termination resistor for channel 1 is connected through linking the

terminals 1 – 2 and 3 – 4.

.Only connect the termination resistors if the actuator is the final device in

the Modbus segment.

10

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

Figure D-1: Plug in terminal

connection

Terminal

cover

Terminals

Terminal

board

Figure D-2: Terminal configuration for Ex connection (KES)

Another bus device

follows the actuator

Previous Next

Modbus device Modbus device

Actuator is last

bus device

Previous

Modbus device

3.9 Redundant bus connection AUMA Modbus devices can be connected with a second (redundant)

Modbus cable. If the bus on channel 1 fails, e. g. through cable break, the

slave automatically switches to channel 2 after a waiting time.

Thus, the change-over is realised with a time delay (see parameter 5

“Time for channel changing in 0.1s).

Additionally, the communication cannot be carried out on both channels

simultaneously.

If the redundancy is activated (see parameter 4 “Redundancy”), the AUMA

MATIC transmits its data using both channels but receives the data only

using the active channel.

This cable redundancy may only be applied after previous

integration test using the desired process control system!

.For versions with AUMA plug/socket connector (subclause 3.2):

Connect redundant bus cable to channel 2 in the same way as channel 1

(figure B-2).

.For Ex-version with plug/socket connector/terminal board (KP)

(subclause 3.7):

Connect cable B to terminal 6, cable A to terminal 7.

The termination resistor for channel 2 is connected through linking the

terminals 5 – 6 and 7 – 8.

.For Ex-version with plug-in terminal connection (KES)

(subclause 3.8):

Connect cable B to terminal 6, cable A to terminal 7 (figure D-2).

The termination resistor for channel 2 is connected through linking the

terminals 5 – 6 and 7 – 8.

The setting of the redundant bus connection is realised via the parameters

4 and 5 (refer to operation instructions).

11

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

3.10 Bus cables Only cables according to the recommendations of EIA 485 standard may be

used for Modbus wiring.

A maximum of up to 32 Modbus devices may be connected in one segment.

If more stations are to be connected to one Modbus network, several

segments must be connected with repeaters.

The bus cable must be laid at a distance of at least 20 cm from other cables.

It should be laid in a separate, conductive, and earthed cable trunking.

It must be ensured that there are no potential differences between the indivi-

dual devices on the Modbus (perform a potential compensation).

The max. cable length without repeater amounts to 1,200 m (independent of

the baud rate).

Cable recommendation for Modbus

Characteristic impedance: 35 to 165 Ohm, at a measurement

frequency of 3 to 20 MHz.

Cable capacity: < 30 pF per metre

Core diameter > 0.64 mm

Core cross section: > 0.34 mm², corresponds to AWG 22

Loop resistance: < 110 Ohm per km

Screening: copper shielding braid or shielding braid and

shielding foil

12

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

Figure E: Example: Modbus with one segment

Bus termination

switched on

Bus termination

switched on

Modbus board

AUMA MATIC

Modbus

Connection

Board

2-wire cable

Controls (master)

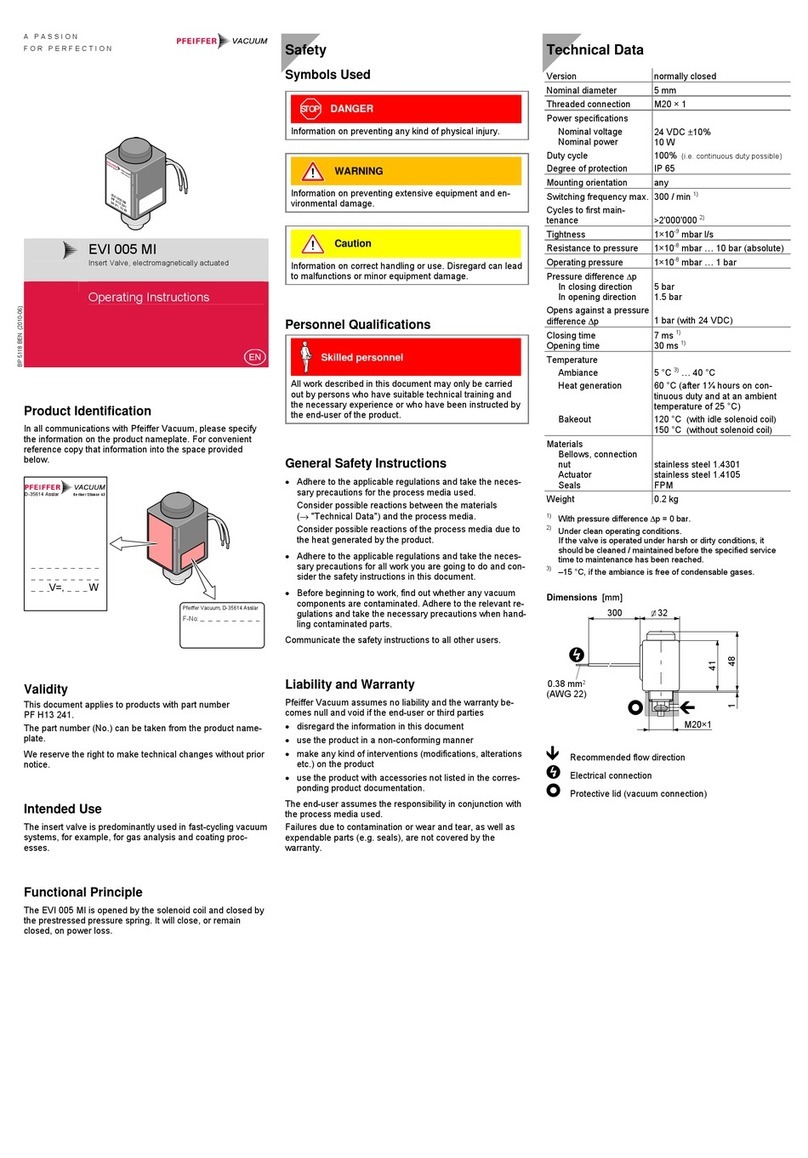

3.11 Setting the Modbus interface

A correct communication is only possible if the settings of

the baud rate, the parity, and the stop bits agree with the

master settings.

The settings are realised on the Modbus interface board.

.Loosen screws and remove cover (figure F-1)

13

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

Figure F-1

Screws

Modbus interface

board

Figure F-2: Modbus interface board

green LED illuminated:

ADDRESS MODE ON

Push buttons:

T1 RESET

T2 MODIFY

T3 CHANGE MODE

LEDs: 7 6 5 4 3 2 1 0 L1 L2 L3 L4

3.12 Setting the communication parameters

Push buttons:

T1 RESET

T2 MODIFY

T3 CHANGE MODE:

DEFAULT MODE: for status indication and basic programming,

ADDRESS MODE for address setting

BAUD RATE MODE for baud rate selection

Push button 3 (CHANGE MODE) is used to switch between the following

modes:

1) DEFAULT MODE is characterised by LED 7 (green) being switched off.

Display and modification of type of seating in end position CLOSED,

parity bits and stop bits as well as display of DataExchange, status,

BusActivity, and LocalError.

2) ADDRESS MODE is characterised by LED 7 (green) being illuminated.

The address is adjustable.

3) BAUD RATE MODE

is characterised by the blinking of LED 7 (green). The baud rate is adjustable. If no

push buttons are pressed for 30 seconds, the display will revert to DEFAULT MODE.

The push button MODIFY allows incrementation of the figure shown in

the LED row. The new value is immediately accepted in the DEFAULT

MODE.ForADDRESS MODE and BAUD RATE MODE, the value is

only accepted when leaving these modes.

3.13 Setting parameter type of seating in end position CLOSED, parity bits and number of stop bits

When not pressing push button CHANGE MODE, you are in the DEFAULT

MODE (LED 7 is not illuminated). LED 0, LED 1, and LED 2 show the value

of the three mentioned parameters:

Push button S3 “MODIFY” is used to set these parameters. If, for example,

type of seating in end position CLOSED = torque seating, parity setting =

even parity, and number of stop bits = 1 stop bit is to be selected, the combi-

nation 001 must be illuminated for the first 3 LEDs. The push button

“MODIFY”is operated until this combination appears. The parameter values

become immediately valid.

3.14 Setting the Modbus address The Modbus address is set using push buttons T2 and T3. This is done

according to the following sequence:

(a) Press push button T1 CHANGE MODE (hold down for 1 to 2 seconds):

The green LED 7 ADRESS MODE is illuminated (not blinking);

it indicates the programming mode for the Modbus address.

The actually set Modbus address is displayed as binary coding by LEDs

6 to 0 (1 to 127).

(b) Set desired bus address using push button T2 MODIFY:

(Factory setting: slave address 2)

(c) Each pressing of the push button increments the address value by one.

Address 1 will follow after address 127. If push button T2 MODIFY is

held down (approx. 1/3 s), the incrementation is done automatically.

14

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

LED Parameter LED On LED Off

0 Type of seating in end position CLOSED torque seating limit seating

1 Parity setting No Parity Even Parity

2 Number of stop bits 2 Stopbits 1 Stopbit

(d) After setting the required Modbus address, quit the programming mode

by pressing key T3 CHANGE MODE. The newly set address now

becomes valid.

Pressing the key T3 results in changing to BAUD RATE MODE;

renewed pressing of key 3 results in reverting to DEFAULT MODE.

(e) Alternatively to clause d), pressing the push button T3 may be ommitted.

After 30 s the status address mode is automatically quit and the

DEFAULT MODE is indicated. The set address is thus accepted.

3.15 Setting the baud rate

The baud rate is selected with the push buttons T2 and T3. This is done

according to the following sequence:

(a) Press push button T3 CHANGE MODE (hold down for 1 to 2 seconds):

The green LED 7 is illuminated (not blinking): the ADDRESS MODE is

active.

(b) Press push button T3 CHANGE MODE again (hold down for 1 to 2

seconds): The green LED 7 is blinking: now, the BAUD RATE MODE is

active.

(c) Select the desired Modbus baud rate pressing push button T2 MODIFY.

(d) The baud rate setting changes each time, push button T2 is pressed.

After the setting 56,400 bit/s (1001), the setting 110 Bit/s (0000) follows

again. If push button T2 MODIFY is held down (approx. 1/3 s), the

incrementation is done automatically. Only the first 4 LEDs count as only

10 baud rate settings are possible.

(e) After setting the required Modbus baud rate, close the programming

mode by pressing push button T3. The newly set baud rate becomes

valid and the interface is in DEFAULT MODE.

(f) Alternatively to clause e), pressing the push button T3 CHANGE MODE

may be omitted. After 30 s, the BAUD RATE MODE status is

automatically quit and the DEFAULT MODE is indicated. The set baud

rate is thus accepted.

15

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

Setting LED 3 LED 2 LED 1 LED 0 Baud rate

Bit/s Notes

0 0000 110

1 0001 300

2 0010 600

3 0011 1200

4 0100 2400

5 0101 4800

6 0110 9600 Defaul setting

7 0111 19200

8 1000 38400 Baud rate deviation

–2 % !

9 1001 56400 Baud rate deviation

+2.5 %

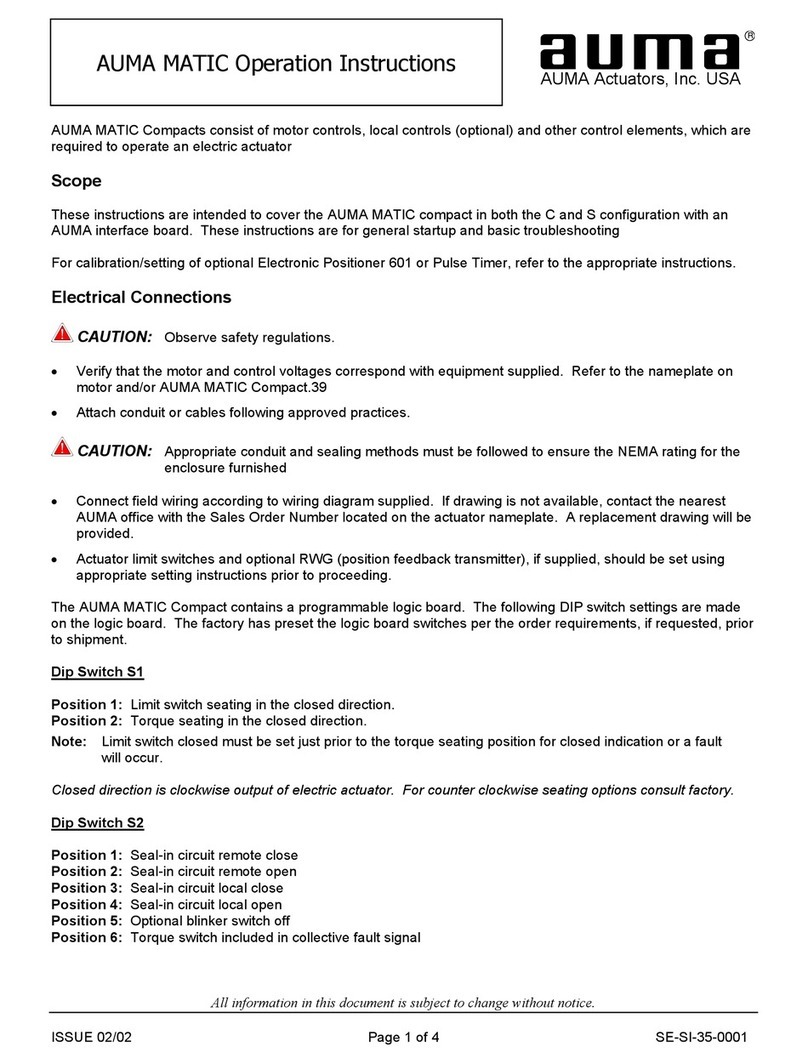

4. Description Modbus interface

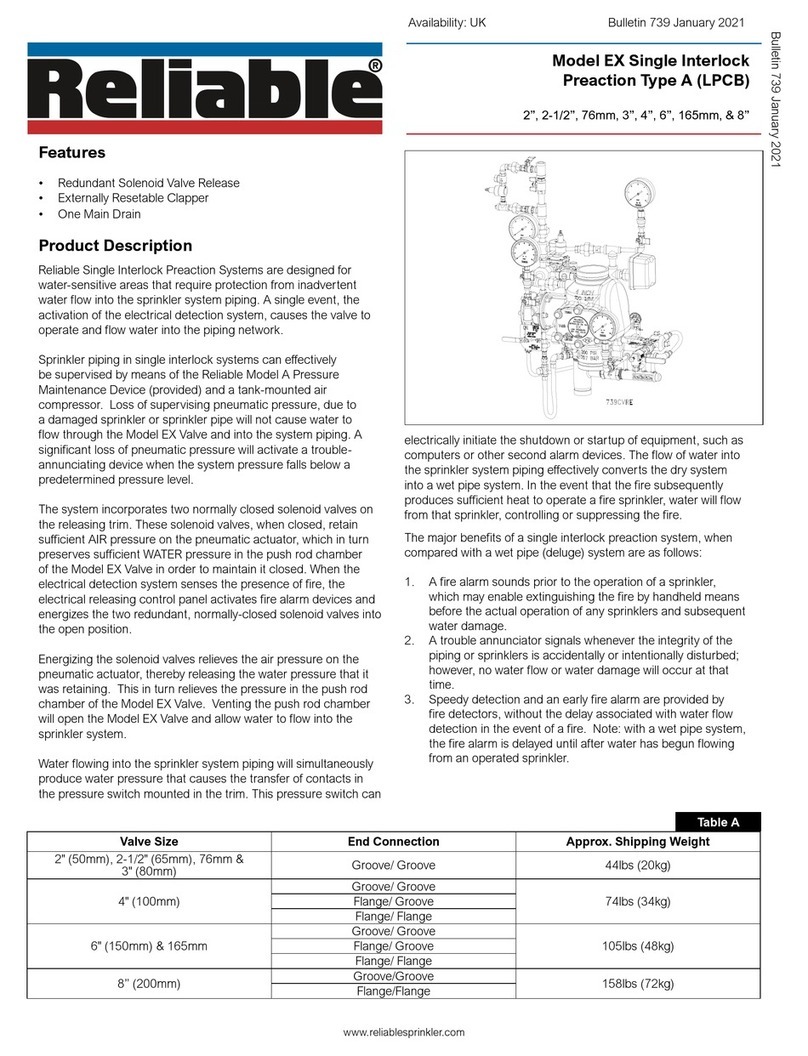

S1.1 When using the external analogue input X11 AI 3/4, the switch S1.1 must be

in position On.

S1.2 Switch for setting the position feedback via position transmitter potentiome-

ters/RWG (option).

S1.2 = OFF: The actuator is equipped with a potentiometer.

S1.2 = ON: Switch may only be in this position if an RWG (0/4 – 20 mA) is

installed in the actuator.

4.1 Indication during system start-up

When starting the system, the LEDs 0 to 7 will be illuminated. LEDs L1 to L4

are switched off. This signifies that the board is correctly started.

After a short time (approx. 1/4 s), the LED L1 (round red LED) will be illumi-

nated and the LEDs 0 to LED 7 will be switched off one after the other. This

means that the microcontroller is now operating. If LED L1 is switched off

and the LEDs 0 to 7 are still illuminated, then the system is in the reset

status (this situation can also be reproduced by constantly pressing push

button T1).

4.1.1 Indications of operation LEDs 7 to 0

LED 0 Indicates torque or limit switching in end position CLOSED

(illuminated for torque switching).

LED 1 Indicates the quantity of the parity bits from the Modbus protocol

(illuminated for No Parity). Only No Parity and Even Parity are

supported, Odd paritiy is not supported.

16

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

S1.2

ON

1

1

S1.1

111

6

6

64

Figure G: Modbus interface board

X7

X8 Modbus X11 X12 X10

Switch S1

(below cover plate)

Taster

T1

T2

T3

LEDs: 7 6 5 4 3 2 1 0 L1 L2 L3 L4

Indications of operation

LED Default Mode Significance

LED on LED is off Address

Mode

Baud rate

Mode

0 (red) torque seating limit seating 11

1 (red) no parity even parity 22

2 (red) 2 stop bits 1 stop bit 44

3 (red) data exchange no data exchange 88

4 (red) state (blinking) 16 –

5 (red) bus active no bus active 32 –

6 (red) local error no local error 64 –

7 (red) off on blinking

LED 2 Indicates the quantity of stop bits - 1 or 2 - (illuminated for 2 stop

bits)

LED 3 Is blinking for each incoming telegram which is assigned to the

actuator.

LED 4 Applications LED:

- is blinking in 1 s intervals for normal service

(0.5 s illumination, 0.5 s pause)

- is permanently illuminated in case of initialisation failure

- is blinking twice while Fail Safe status is active.

LED 5 Is blinking for each telegram which has been recognized at the bus.

LED 6 Local actuator signal:

- blinking once: Thermal fault

- blinking twice: Power failure

- blinking 3 times: TSO (DOEL) fault

- blinking 4 times: TSC (DSR) fault

- blinking 5 times: 24 V power supply > 28.3 V or <18 V

LED 7 indicates the setting mode:

Off: DEFAULT MODE

On: ADDRESS MODE

Blinking: BAUD RATE MODE

4.1.2 System displays LEDs L1 to L4

LED L1 indicates the actuator status. If L1 is illuminated, the actuator is

ready for operation.

LEDs L2 to L4 are illuminated if the actuator has received and processed a

feasible operation command via the bus. The following combinations are

valid:

17

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

System displays

L1 (red) System o.k. (CPU working)

L2 (red) Actuator runs OPEN

L3 (red) Actuator runs CLOSE

L4 (red) not assigned

Operation indications

LED 4 LED 3 LED 2 Signification

Off Off Off no operation

Off Off On operation direction OPEN

Off On Off operation direction CLOSE

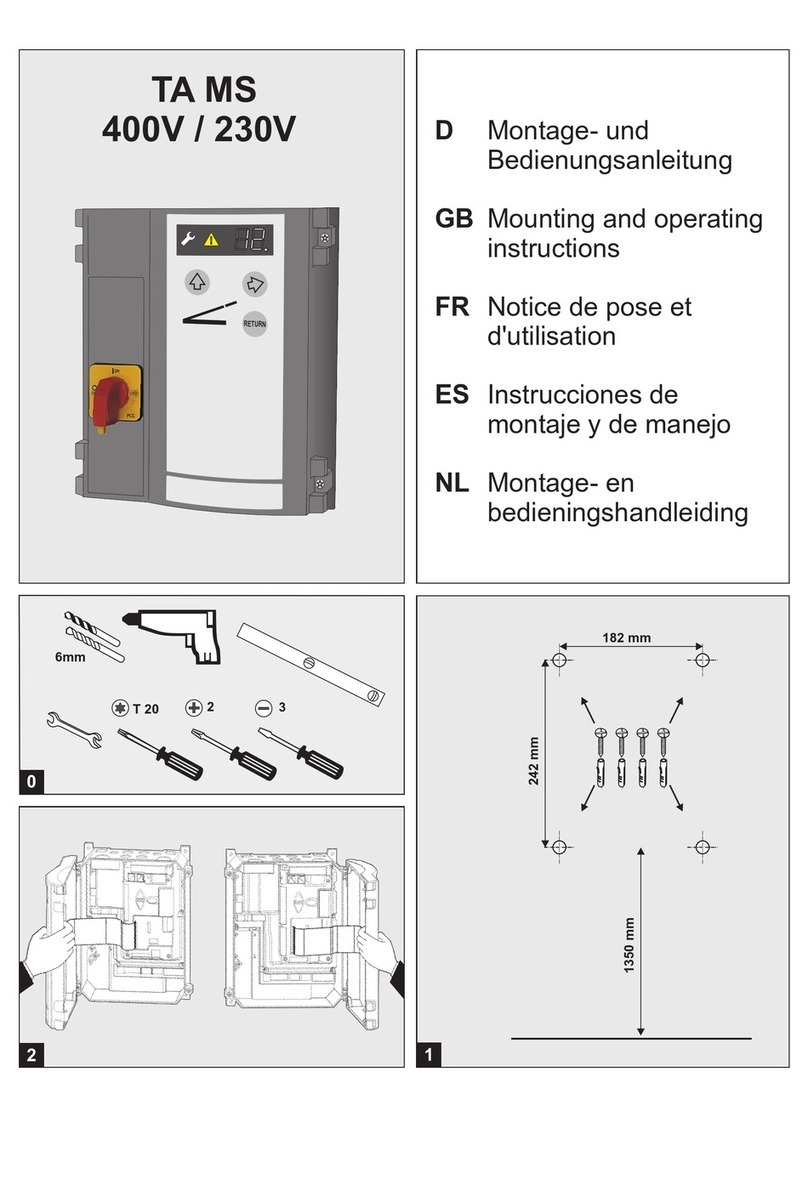

4.2 Checking/setting the switches on the logic board

The settings on the logic board are already made in the factory, according to

the order details.

The logic board is located below the Modbus board.

The setting of the end position seating in end position

CLOSED must be the same on the Modbus board (LED 0 in

default mode, figure G, page 16) and on the logic board

(switch S1-2).

18

Actuator controls AUMA MATIC AM/AMExB/AMExC

Modbus Short instructions

S3-2:

Switching-off in end position OPEN.

Switch position has no influence.

When controlling via Profibus DP,

switching-off is always realised by

limit seating in end position OPEN

Position 1:

Switching-off by limit seating in end

position CLOSED

Position 2:

Switching-off by torque seating in

end position CLOSED

S3-2

S1-2

S2-2

Figure H: Logic board

DIP switch S2-2 Programming

(ON = pressed)

Direction CLOSE Direction OPEN

Self-retaining REMOTE Self-retaining REMOTE

may not be used!

Push-to-run operation REMOTE

Self-retaining LOCAL

Push-to-run operation LOCAL

Blinker transmitter (option) Blinker transmitter must be

deactivated

Blinker transm. deact.

Torque error: torque switch tripping

(in mid-travel) contained in collecti-

ve fault signal (insignificant for

fieldbus interface)

Included Not included

Table 5

5. Appendix A Literature references

1. Modicon protocol:

Reference Guide PI-MBUS-300

2. http:/www.modbus.org

Modbus Application Protocol Specification

Modbus over serial line specification and implementation guide

6. Appendix B Connecting the cable shield for AUMA MATIC AMExB/AMExC 01.1

The shield of the fieldbus cable should be largely connected with the

respective threads.

Recommended threads e.g. WAZU-EMV/EX supplied by Hugro (refer to

www.hugro-gmbh.de).

19

Actuator controls AUMA MATIC AM/AMExB/AMExC

Short instructions Modbus

Index

B

Blinker transmitter 18

Bus cable 11,12

Bus connection 11

C

Cable capacity 12

Cable recommendation 12

Characteristic impedance 12

Collective fault signal 18

Connection board 5

Core cross section (bus cable 12

Core diameter (bus cable) 12

E

Electrical connection 3,4

L

Literature 19

Loop resistance 12

M

Maintenance 3

Motor connection 10

N

Name plate 8

O

Overvoltage protection 6

P

Parking frame 8

Plug/socket connector 8,9

Position transmitter RWG 7

Power supply 4

Push-to-run operation 18

S

Safety instructions 3

Screening (bus cable) 12

Self-retaining 18

Switching-off 18

T

Technical data 9

Termination resistors 5

Torque switching 7

W

Wall bracket 7

Warnings 3

Information also available on

the Internet: Wiring diagram, inspection records, and further actuator information

can be downloaded directly from the Internet by entering the order no. or

COMM. no (refer to name plate).

Our website: http://www.auma.com

Certificate Registration No.

12 100/1044269

www.auma.com

AUMA Riester GmbH & Co. KG

P.O. Box 1362

79373 Müllheim, Germany

Tel

Fax

www.auma.com

+49 7631 - 809-0

+49 7631 - 809 1250 +49 711 - 34803 0

+49 711 - 34803 34

AUMA Riester GmbH & Co. KG

P. O. Box 1151

D - 73747 Ostfildern

Tel

Fax

www.auma.com

For detailed information on AUMA products, please refer to the Internet:

Y004.018/003/en/1.08.01

.01Europa

AUMA Riester GmbH & Co. KG

Werk Müllheim

DE-79373 Müllheim

Tel +49 7631 809 - 0

Fax +49 7631 809 - 250

www.auma.com

Werk Ostfildern-Nellingen

DE-73747 Ostfildern

Tel +49 711 34803 - 3000

Fax +49 711 34803 - 3034

Service-Center Köln

DE-50858 Köln

Tel +49 2234 20379 - 00

Fax +49 2234 20379 - 99

Service-Center Magdeburg

DE-39167 Niederndodeleben

Tel +49 39204 759 - 0

Fax +49 39204 759 - 19

Service-Center Bayern

DE-85748 Garching-Hochbrück

Tel +49 89 329885 - 0

Fax +49 89 329885 - 18

Büro Nord, Bereich Schiffbau

DE-21079 Hamburg

Tel +49 40 791 40285

Fax +49 40 791 40286

Büro Nord, Bereich Industrie

DE-29664 Walsrode

Tel +49 5167 504

Fax +49 5167 565

Büro Ost

DE-39167 Niederndodeleben

Tel +49 39204 75980

Fax +49 39204 75989

Büro West

DE-45549 Sprockhövel

Tel +49 2339 9212 - 0

Fax +49 2339 9212 - 15

Büro Süd-West

DE-69488 Birkenau

Tel +49 6201 373149

Fax +49 6201 373150

Büro Württemberg

DE-73747 Ostfildern

Tel +49 711 34803 80

Fax +49 711 34803 81

Büro Baden

DE-76764 Rheinzabern

Tel +49 7272 76 07 - 23

Fax +49 7272 76 07 - 24

Büro Kraftwerke

DE-79373 Müllheim

Tel +49 7631 809 192

Fax +49 7631 809 294

Büro Bayern

DE-93356 Teugn/Niederbayern

Tel +49 9405 9410 24

Fax +49 9405 9410 25

AUMA Armaturenantriebe GmbH

AT-2512 Tribuswinkel

Tel +43 2252 82540

Fax +43 2252 8254050

AUMA (Schweiz) AG

CH-8965 Berikon

Tel +41 566 400945

Fax +41 566 400948

AUMA Servopohony spol. s.r.o.

CZ-10200 Praha 10

Tel +420 272 700056

Fax +420 272 704125

OY AUMATOR AB

FI-02270 Espoo

Tel +35 895 84022

Fax +35 895 8402300

AUMA France

FR-95157 Taverny Cédex

Tel +33 1 39327272

Fax +33 1 39321755

www.auma.fr

AUMA ACTUATORS Ltd.

GB- Clevedon North Somerset BS21 6QH

Tel +44 1275 871141

Fax +44 1275 875492

AUMA ITALIANA S.R.L.

IT-20023 Cerro Maggiore Milano

Tel +39 0331-51351

Fax +39 0331-517606

www.auma.it

AUMA BENELUX B.V.

NL-2314 XT Leiden

Tel +31 71 581 40 40

Fax +31 71 581 40 49

AUMA Polska

PL-41-310 Dabrowa Górnicza

Tel +48 32 26156 68

Fax +48 32 26148 23

www.auma.com.pl

AUMA Priwody OOO

RU-141400 Moscow region

Tel +7 095 221 64 28

Fax +7 095 221 64 38

www.auma.ru

ERICHS ARMATUR AB

SE-20039 Malmö

Tel +46 40 311550

Fax +46 40 945515

www.erichsarmatur.se

GRØNBECH & SØNNER A/S

DK-2450 København SV

Tel +45 33 26 63 00

Fax +45 33 26 63 21

www.g-s.dk

IBEROPLAN S.A.

ES-28027 Madrid

Tel +34 91 3717130

Fax +34 91 7427126

D. G. Bellos & Co. O.E.

GR-13671 Acharnai Athens

Tel +30 210 2409485

Fax +30 210 2409486

SIGURD SØRUM A. S.

NO-1301 Sandvika

Tel +47 67572600

Fax +47 67572610

INDUSTRA

PT-2710-297 Sintra

Tel +351 2 1910 95 00

Fax +351 2 1910 95 99

MEGA Endüstri Kontrol Sistemieri Tic. Ltd. Sti.

TR-06460 Övecler Ankara

Tel +90 312 472 62 70

Fax +90 312 472 62 74

CTS Control Limited Liability Company

UA-02099 Kiyiv

Tel +38 044 566-9971, -8427

Fax +38 044 566-9384

Afrika

AUMA South Africa (Pty) Ltd.

ZA-1560 Springs

Tel +27 11 3632880

Fax +27 11 8185248

A.T.E.C.

EG- Cairo

Tel +20 2 3599680 - 3590861

Fax +20 2 3586621

Amerika

AUMA ACTUATORS INC.

US-PA 15317 Canonsburg

Tel +1 724-743-AUMA (2862)

Fax +1 724-743-4711

www.auma-usa.com

AUMA Chile Respresentative Office

CL- La Reina Santiago de Chile

Tel +56 2 821 4108

Fax +56 2 281 9252

LOOP S. A.

AR-C1140ABP Buenos Aires

Tel +54 11 4307 2141

Fax +54 11 4307 8612

Asvotec Termoindustrial Ltda.

BR-13190-000 Monte Mor/ SP.

Tel +55 19 3879 8735

Fax +55 19 3879 8738

TROY-ONTOR Inc.

CA-L4N 5E9 Barrie Ontario

Tel +1 705 721-8246

Fax +1 705 721-5851

MAN Ferrostaal de Colombia Ltda.

CO- Bogotá D.C.

Tel +57 1 4 011 300

Fax +57 1 4 131 806

www.manferrostaal.com

PROCONTIC Procesos y Control Automático

EC- Quito

Tel +593 2 292 0431

Fax +593 2 292 2343

IESS DE MEXICO S. A. de C. V.

MX-C.P. 02900 Mexico D.F.

Tel +52 55 55 561 701

Fax +52 55 53 563 337

Multi-Valve Latin America S. A.

PE- San Isidro Lima 27

Tel +511 222 1313

Fax +511 222 1880

PASSCO Inc.

PR-00936-4153 San Juan

Tel +18 09 78 77 20 87 85

Fax +18 09 78 77 31 72 77

Suplibarca

VE- Maracaibo Estado, Zulia

Tel +58 261 7 555 667

Fax +58 261 7 532 259

Asien

AUMA (INDIA) PRIVATE LIMITED

IN-560 058 Bangalore

Tel +91 80 2839 4655

Fax +91 80 2839 2809

www.auma.co.in

AUMA JAPAN Co., Ltd.

JP-210-0848 Kawasaki-ku, Kawasa-

ki-shi Kanagawa

Tel +81 44 329 1061

Fax +81 44 366 2472

AUMA ACTUATORS (Singapore) Pte Ltd.

SG-569551 Singapore

Tel +65 6 4818750

Fax +65 6 4818269

www.auma.com.sg

AUMA Middle East Rep. Office

AE- Dubai

Tel +971 4 3682720

Fax +971 4 3682721

PERFECT CONTROLS Ltd.

HK- Tsuen Wan, Kowloon

Tel +852 2493 7726

Fax +852 2416 3763

DW Controls Co., Ltd.

KR-153-803 Seoul Korea

Tel +82 2 2113 1100

Fax +82 2 2113 1088/1089

www.actuatorbank.com

AL-ARFAJ Eng. Company W. L. L.

KW-22004 Salmiyah

Tel +965 4817448

Fax +965 4817442

BEHZAD Trading Enterprises

QA- Doha

Tel +974 4433 236

Fax +974 4433 237

Sunny Valves and Intertrade Corp. Ltd.

TH-10120 Yannawa Bangkok

Tel +66 2 2400656

Fax +66 2 2401095

Top Advance Enterprises Ltd.

TW- Jhonghe City Taipei Hsien (235)

Tel +886 2 2225 1718

Fax +886 2 8228 1975

www.auma-taiwan.com.tw

AUMA Beijing Representative Office

CN-100029 Beijing

Tel +86 10 8225 3933

Fax +86 10 8225 2496

www.auma-china.com

Australien

BARRON GJM Pty. Ltd.

AU-NSW 1570 Artarmon

Tel +61 294361088

Fax +61 294393413

www.barron.com.au

2005-09-06

This manual suits for next models

3

Table of contents

Other AUMA Control Unit manuals

AUMA

AUMA AC 01.2 User manual

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA Matic User manual

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA AM 01.1 User manual

AUMA

AUMA AUMATIC AC 01.2 User manual

AUMA

AUMA Aumatic AC 01.1 Manual

AUMA

AUMA AC 01.2 User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA SG 12.1 User manual

Popular Control Unit manuals by other brands

SSS Siedle

SSS Siedle BSG 650-02 manual

Novoferm

Novoferm TA MS 400V / 230V Mounting and operating instructions

ABB

ABB ACS880 Series Supplement

Helios

Helios AIR1-ULM Installation and operating instructions

Digital Systems

Digital Systems TYTAN DS459 installation manual

Pfeifer Vacuum

Pfeifer Vacuum wrn100 operating instructions