Technical Information

no.

912-100-0108

page

3/11

status: 14.07.05

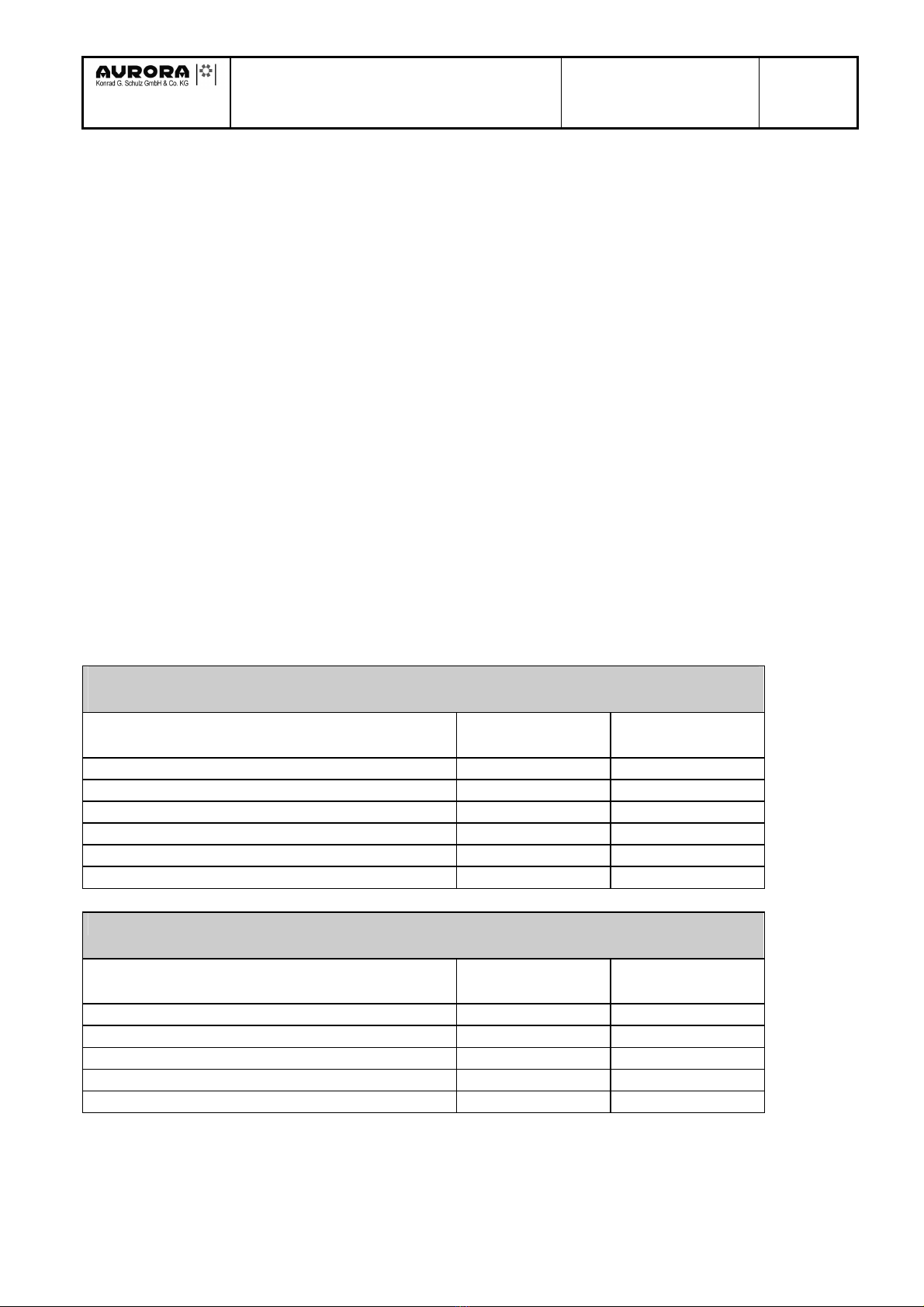

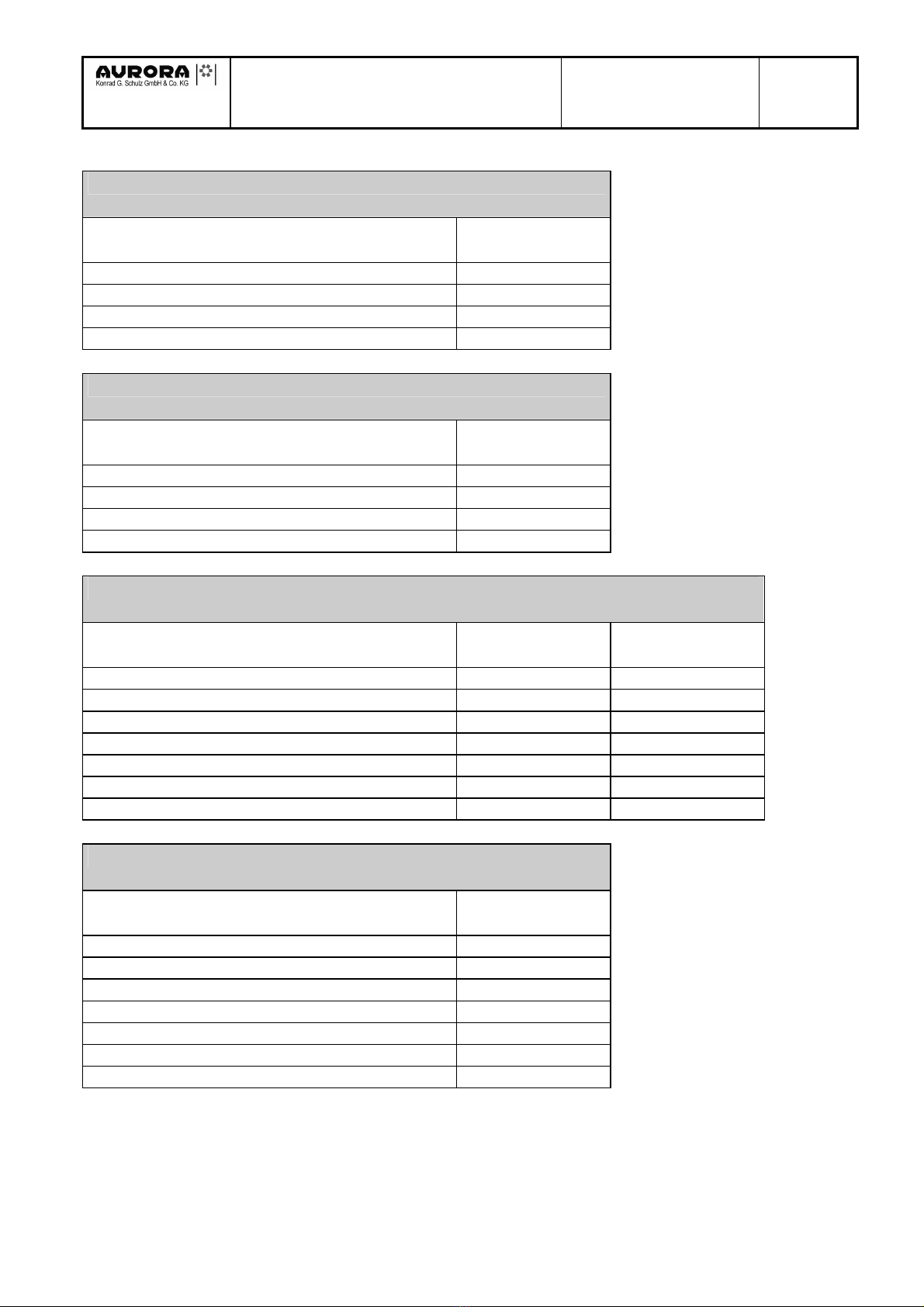

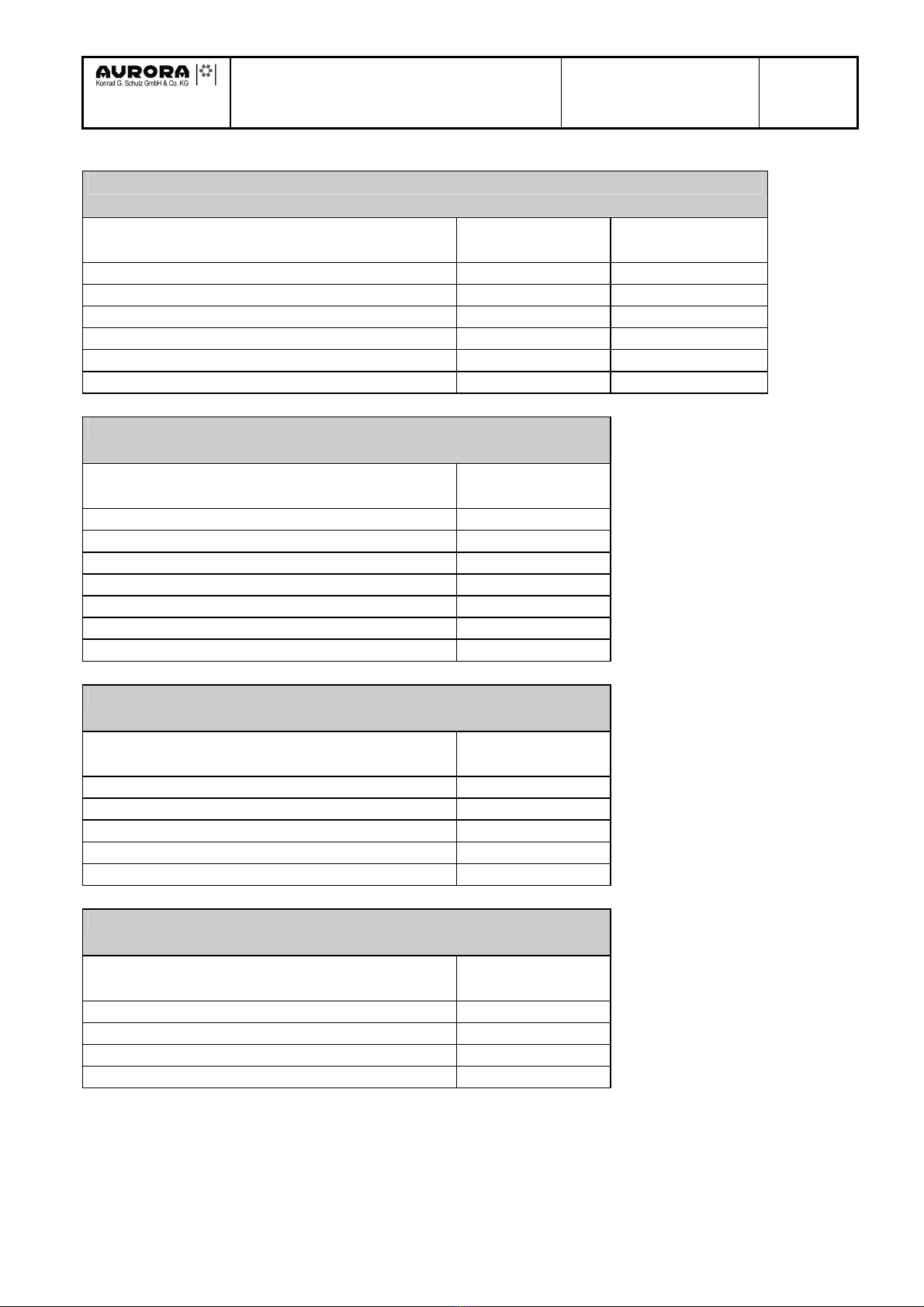

The heater versions differences are the nominal voltage, the sockets quantity

and diameter and the air outlets.

The version 151-701-0017 can be delivered without heat exchanger as an

ventilation unit with part no. 136-701-0017.

The version 151-701-0023 has an air suction case.

All versions have a housing made of steel sheet.

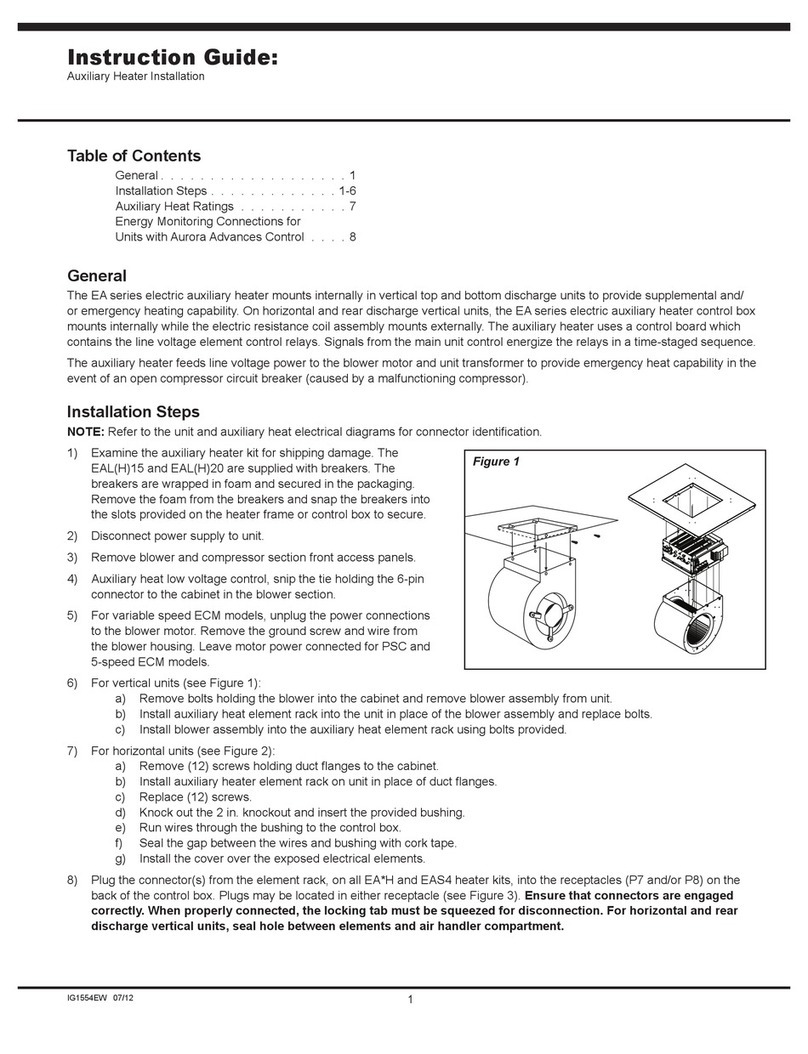

The heater is delivered by AURORA completely pre-mounted, the installation

into the vehicle is carried out by the customer.

The flat tube heat exchanger with connection diameter 15 mm and the twin

radial blower DRG 370 are integrated into the heater.

The different blower speeds are achieved using a dropping resistor.

The blower is protected against overload by a micro-temperature-fuse MTS

connected to the resistor.

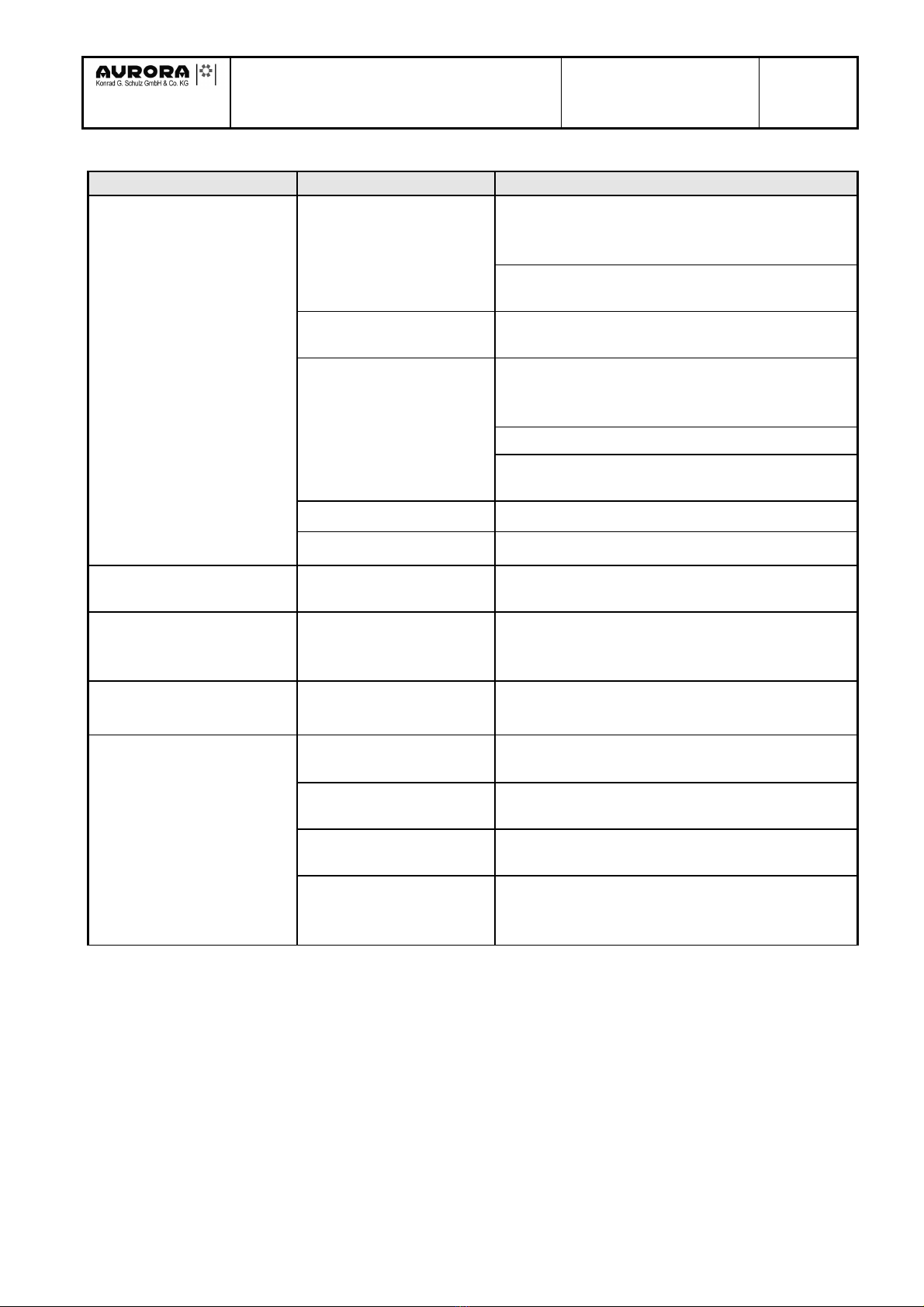

3 Function description

The blower sucks in the air via the opening. The air goes the heat exchanger,

heat up and will be lead into the interior.

You can choose between 1-,2-,and 3-speed level blower versions. The blower

will be operated with a switch, e.g. the AURORA Control-Panel, deliverable as

an option.

Example for a version with three speed level:

switch position 0 blower is out

switch position 1 slowest air outflow (slow speed level))

switch position 2 medium air outflow (middle speed level)

switch position 3 maximum air outflow (highest speed level)

The heat exchanger brought forward the heat to the air that flow through.

The heating power can be operated by opening or closing the water valve with

a control panel (accessoir)

4 Mounting informations

•Serving work may only be carried out by trained and authorised personnel.

The units should be handled and assembled expertly according to the

installation instructions.

•Modifications must be approved and released by AURORA. Otherwise the

guarantee will automatically become invalid.

•You should similarly agree the purpose of the application of the heating unit

with AUROA. This is particularly true where extreme environmental conditions

can arise at the installation location such as e.g. unusual temperatures,

vibrations etc.