austriamicrosystems AS5046 User manual

Table of contents

Other austriamicrosystems Media Converter manuals

austriamicrosystems

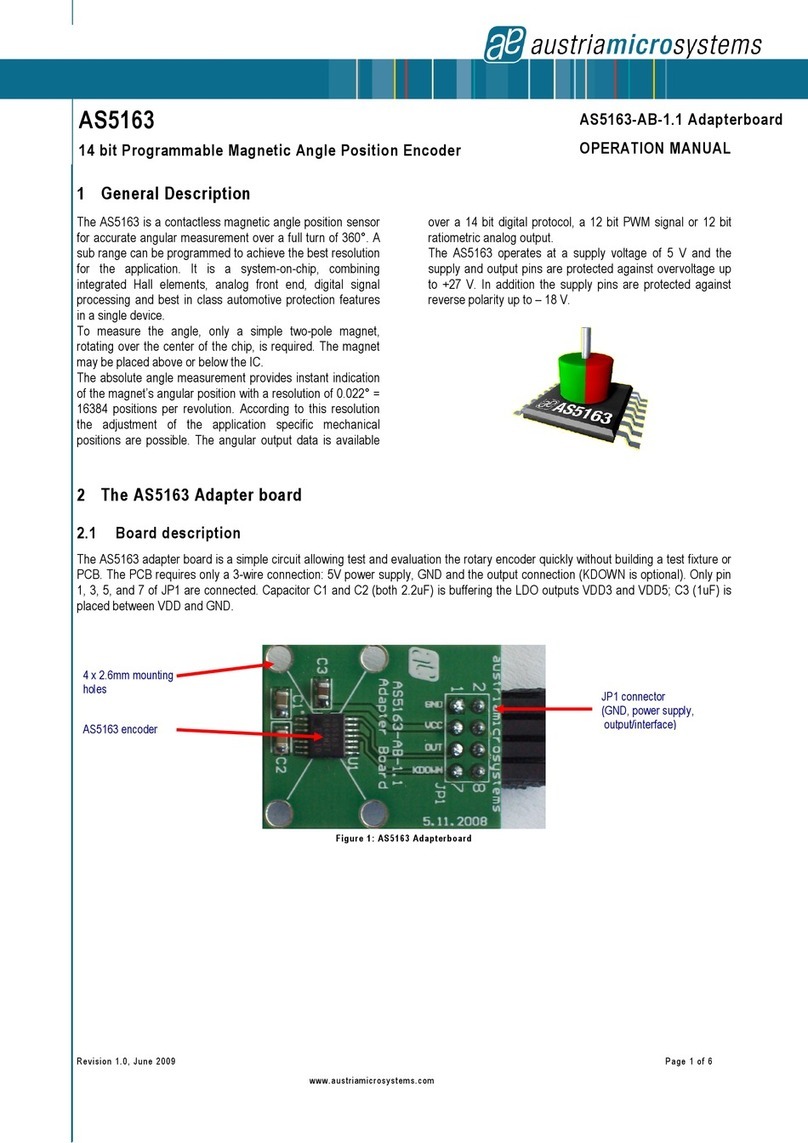

austriamicrosystems AS5163 User manual

austriamicrosystems

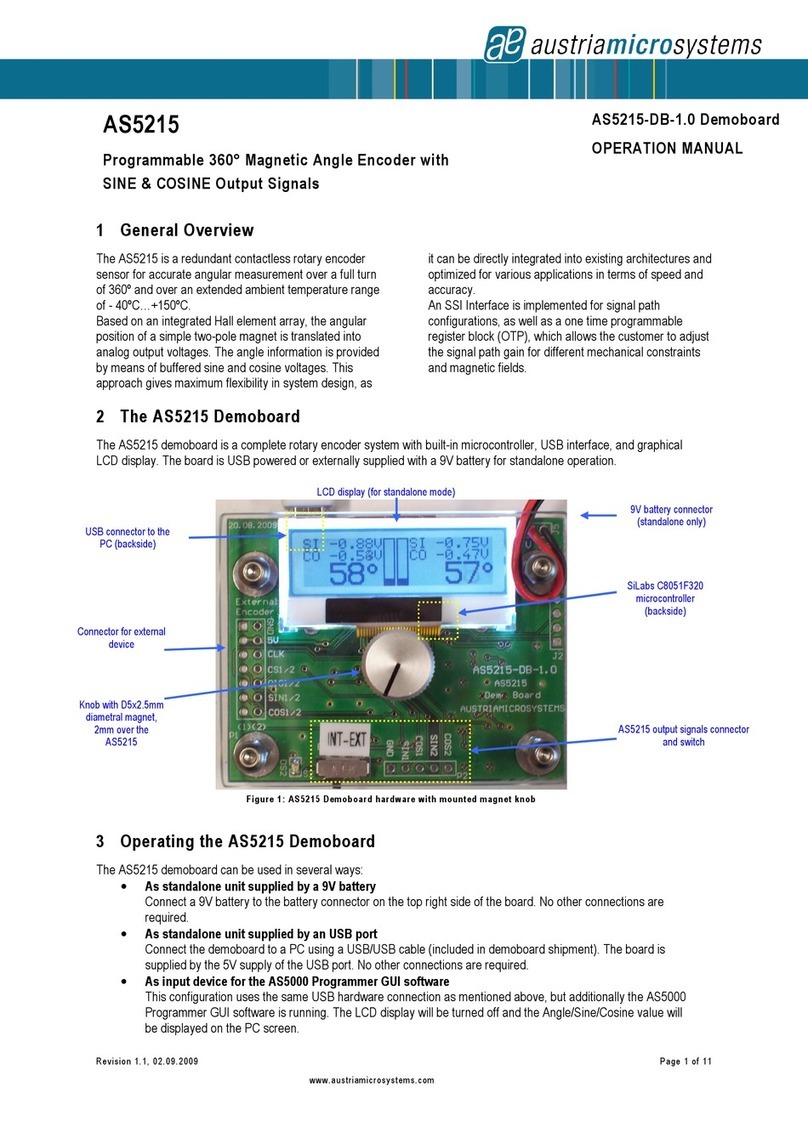

austriamicrosystems AS5215 User manual

austriamicrosystems

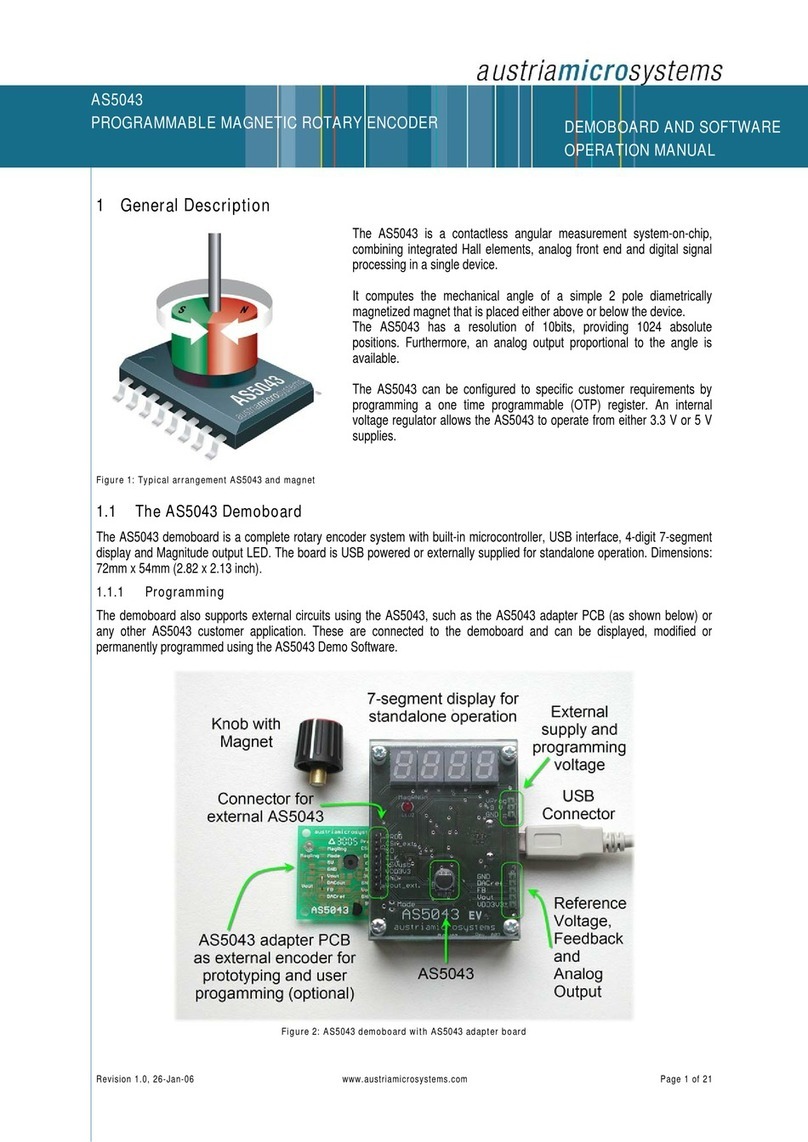

austriamicrosystems AS5043 User manual

austriamicrosystems

austriamicrosystems AS5163 User manual

austriamicrosystems

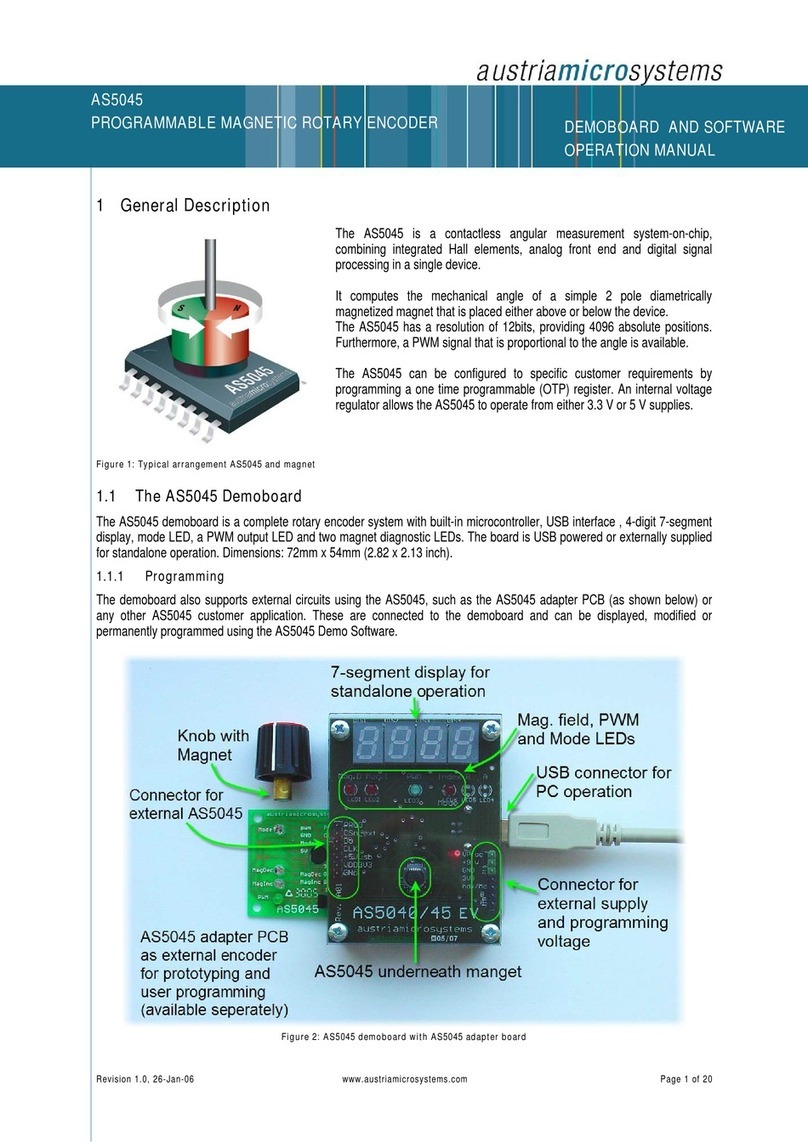

austriamicrosystems AS5045 User manual

austriamicrosystems

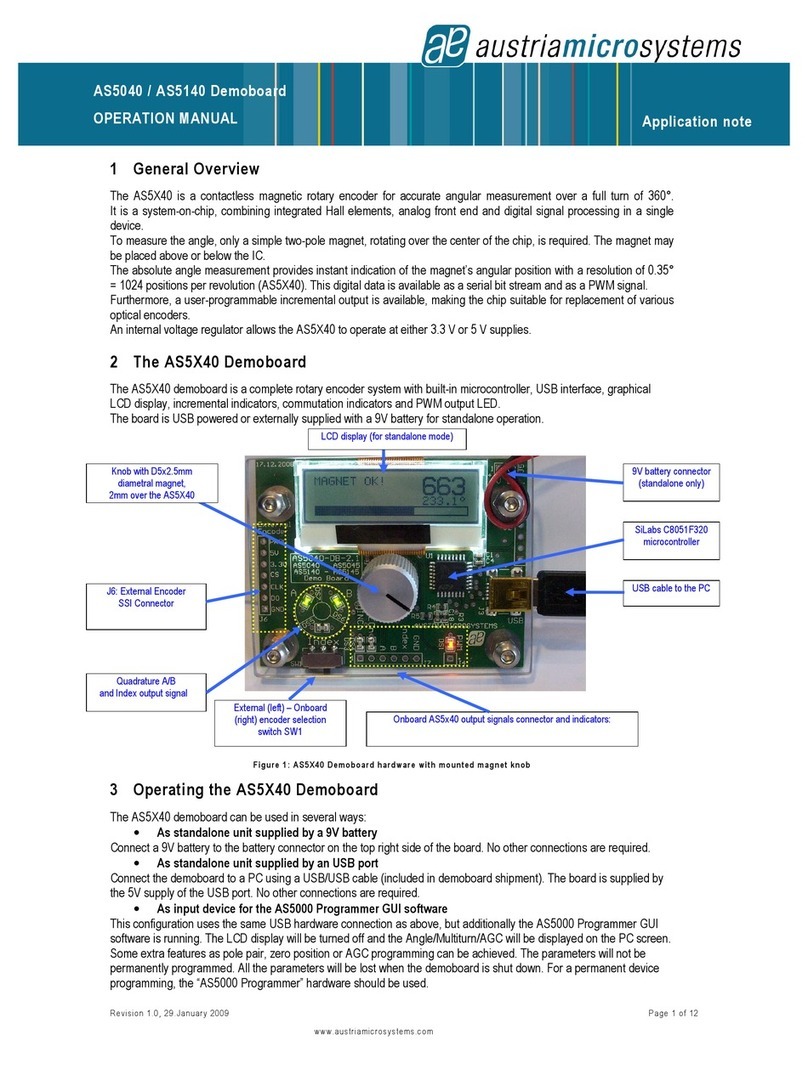

austriamicrosystems AS5040 User manual

austriamicrosystems

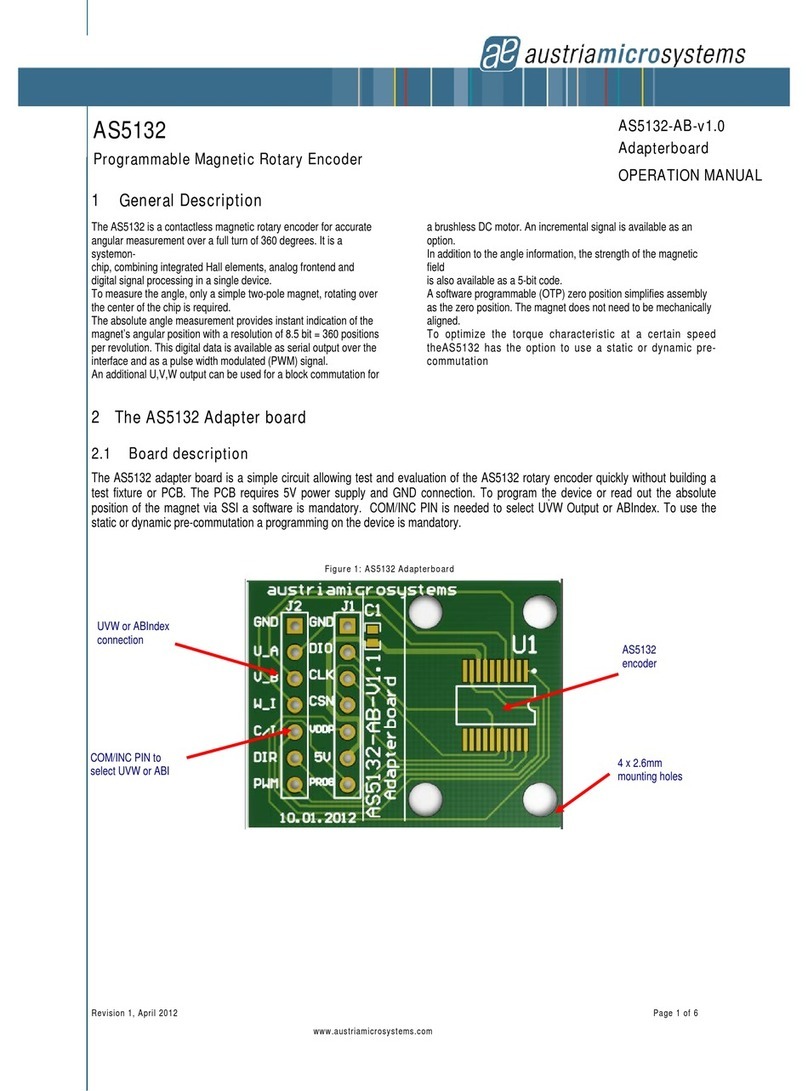

austriamicrosystems AS5132 User manual

austriamicrosystems

austriamicrosystems AS3990 User manual

austriamicrosystems

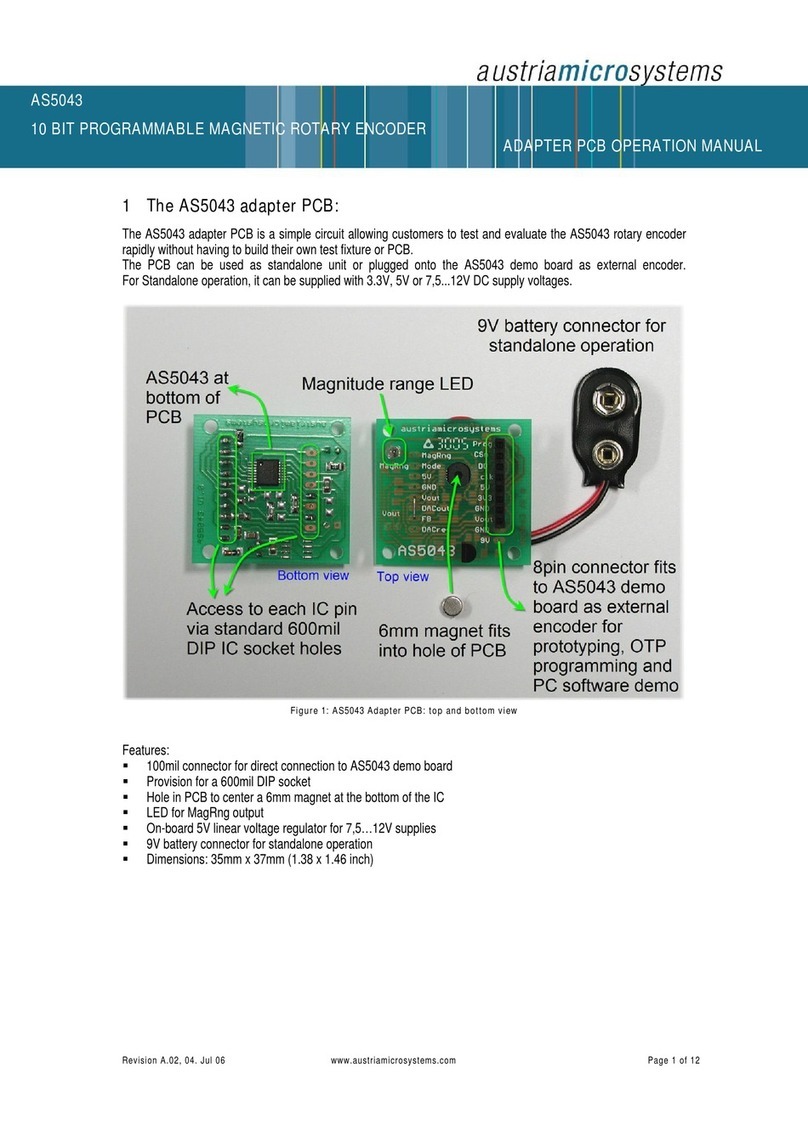

austriamicrosystems AS5043 User manual

austriamicrosystems

austriamicrosystems AS5130 User manual

Popular Media Converter manuals by other brands

Hall Research Technologies

Hall Research Technologies HHD264 user manual

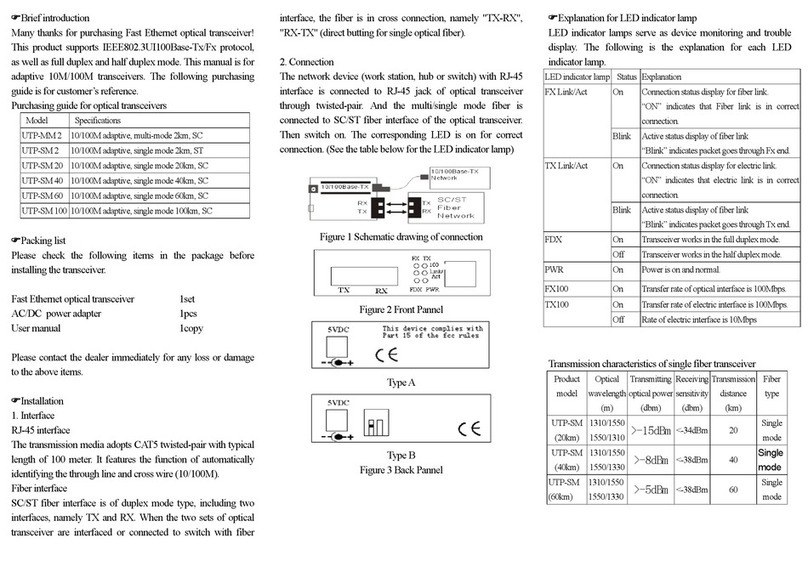

Repotec

Repotec UTP-MM 2 user manual

Transition Networks

Transition Networks S4110-4848 install guide

Questtel

Questtel B-HDMI-ASI-IP-4CH user manual

NetUP

NetUP Streamer HD v2 8-24x user manual

Extron electronics

Extron electronics AXI 016 Setup guide

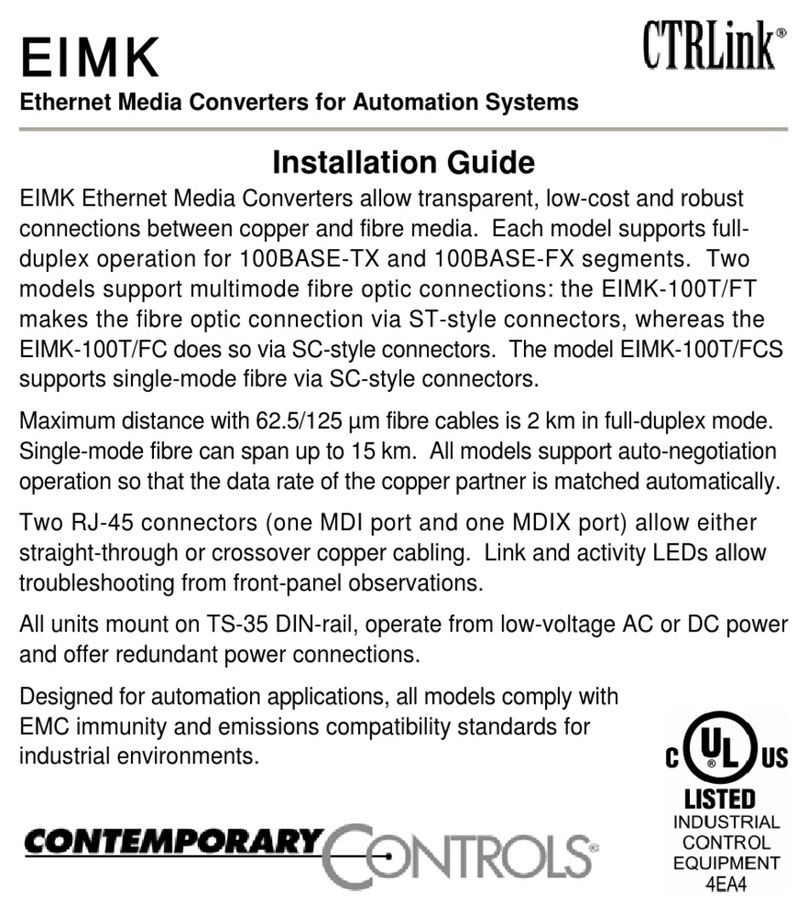

Contemporary Controls

Contemporary Controls CTRLink EIMK-100T/FT installation guide

Baudcom

Baudcom BD-3224V user manual

SMAR

SMAR FI303 Operation, maintenance & instruction manual

Extron electronics

Extron electronics NAV E 511 user guide

PR

PR 9116 Series product manual

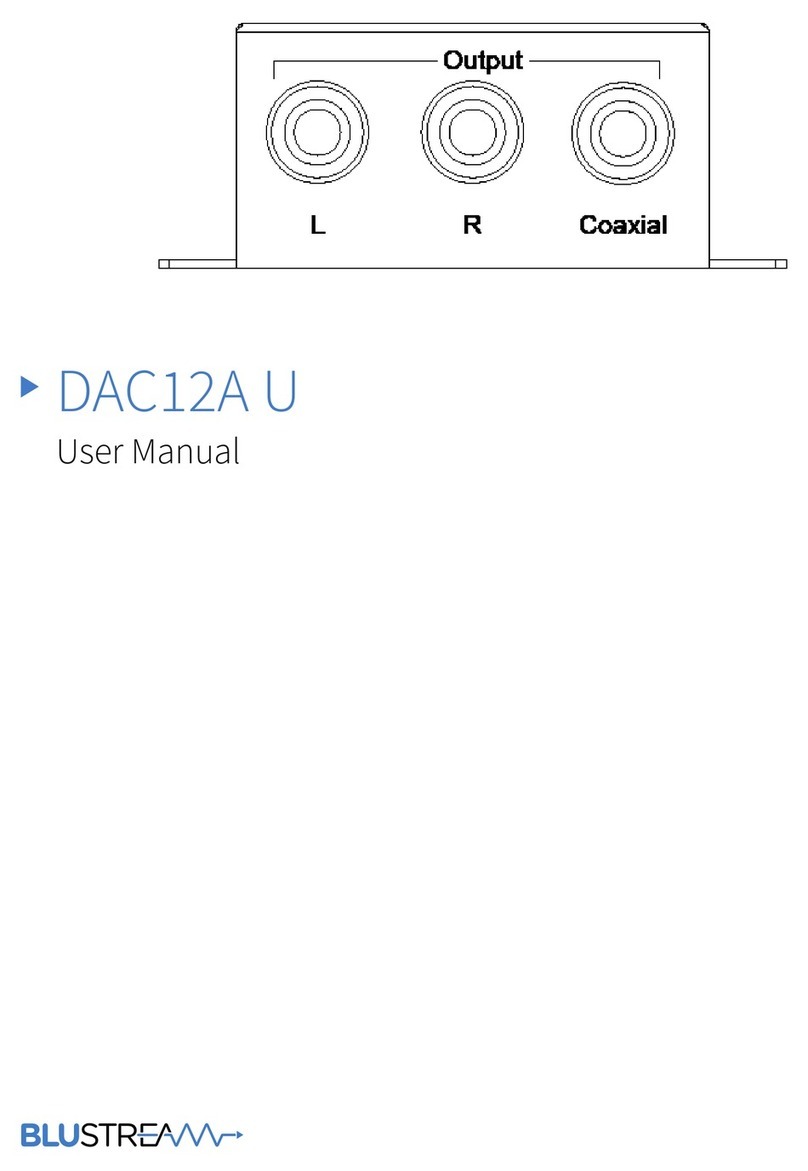

Bluestream

Bluestream DAC12A U user manual