autocom BFK-U Guide

WARRANT

Y

If your supplier has not given advice or demonstration on how to set up or use our products,

please check with them before sending any goods back for warranty.

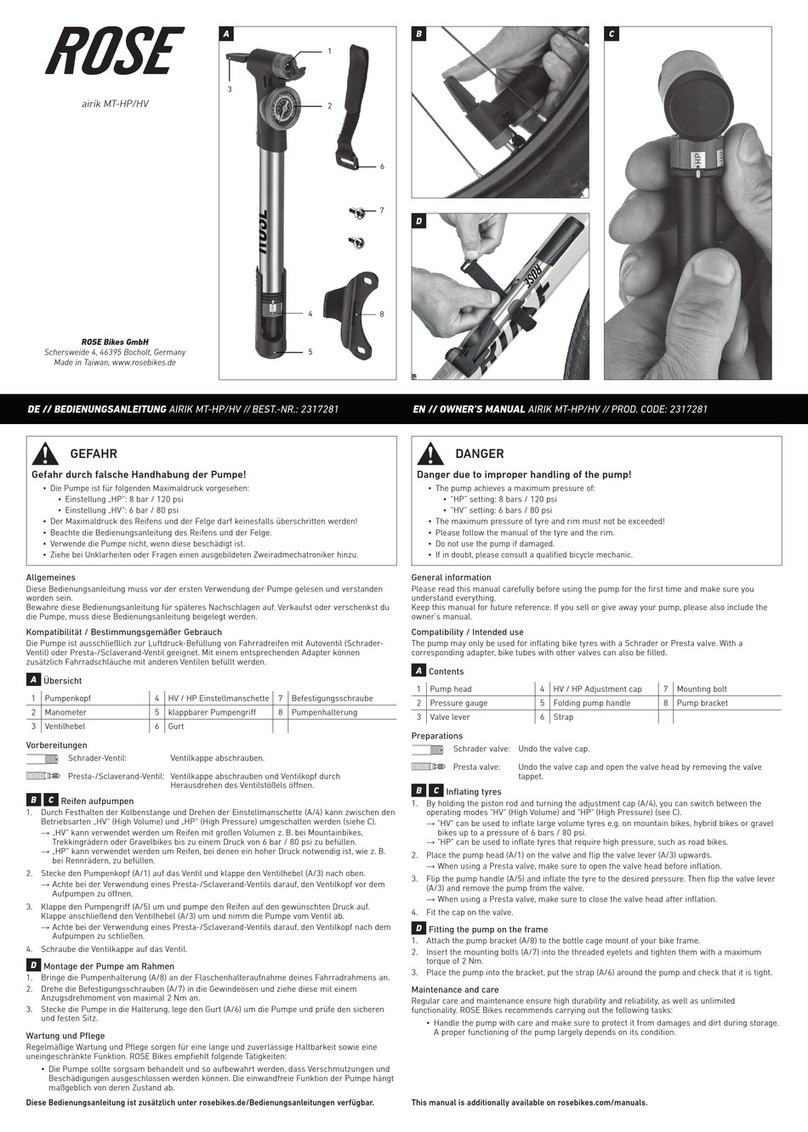

A

ll Autocom products are warranted for a period of 12 months from the date of original

purchase, to the original purchaser, from an authorised Autocom retailer, against faulty

materials or workmanship, subject to the goods being used only as stated, and only for the

purpose as described in the instruction manuals.

No manufacturer's warranty applies to the goods where they are used for any other purpose

or in any other way than is explained in the instructions. Nor where the goods have been

subjected to misuse, neglect or accidental damage, or used with any other vendor’s products,

including incorrect mechanical or electrical installation, or where the goods have been

repaired, modified or altered, without the manufacturers written authorisation.

The manufacturer's warranty is limited to the goods being returned pre paid to the

manufacture's factory, with the original packaging and the original proof of purchase date.

The goods must be intact for our examination.

Where goods are accepted by the manufacturer, under the terms of the warranty, they will be

repaired free of charge or replaced (at the option of the manufacturer). Where the goods are

returned as faulty and are found not to be, an inspection, testing and return postage and

packing charge will be payable.

This warranty does not cover any consumable items such as batteries, replaceable hygiene

foam coverings for speakers & microphones, or any other items that are described within the

instruction manuals as being a consumable.

The manufacturer's warranty does not effect your statutory rights.

PLEASE CONTACT YOUR SUPPLIER OR AUTOCOM FOR ANY FURTHER

HELP OR INFORMATION. We service what we sell

UK Manufacturer & Distributor. Autocom Products Ltd.

20 Hawkes Drive, Heathcote Industrial Estate, Warwick. CV34 6LX. England. Tel: +44 (0)1926 431249 Email

enquiries@autocom.co.uk WEBSITE www.autocom.co.uk

USA Distributor. Top Gear NY 12159 USA Tel: 518 449 8677 www.autocomamerica.com

German Distributor. Green Frog & JF Motor Sport Tel: +49 6002 911331 www.greenfrog.de

Netherlands & Belgium Distributor. Splash Design. Tel: +31 413 389089 www.splashdesign.nl

Norway Distributor. Spare Parts Service AS Norway Tel: 67 907800 www.sps.no

Finland Distributor. Tokimoto Oy Finland Tel: +358 9 838 6540. www.tokimoto.fi

Switzerland Distributor. Hostettler A.G. Tel: 0041 41926 6111 www.hostettler.com

New Zealand Distributor. Dold Industries Ltd 00647 849 4392 www.dold@ventura-bike.com

If you need support in any country not listed, please contact Autocom UK.

V3

It is VERY IMPORTANT that

you fully read & understand

ALL of these instructions

before installation & use

These parts are designed ONLY for

use with Autocom domestic

motorcycle communication systems

INSTRUCTION MANUAL & WARRANTY for

Part 150. (BFK-U) Universal Bike Fitting Kit

This basic fitting kit gives you the typical parts that are frequently required for installing an Autocom system

to most types of bike. Please note that you may require some parts that are not included in the kit. This will

depend on the bike you have and how you want the intercom fitted. Please check with your supplier for more

advice. PLEASE NOTE all parts of this fitting kit are consumables and so have a limited warranty .

The kit includes

5 of BLACK Tie wraps .

5 of WHITE TIE wraps.

1 of 150mm Hook Velcro (rough)

1 of 300mm Loop Velcro (soft)

2 of Black plastics clips.

1 of Blue eyelet crimp terminal

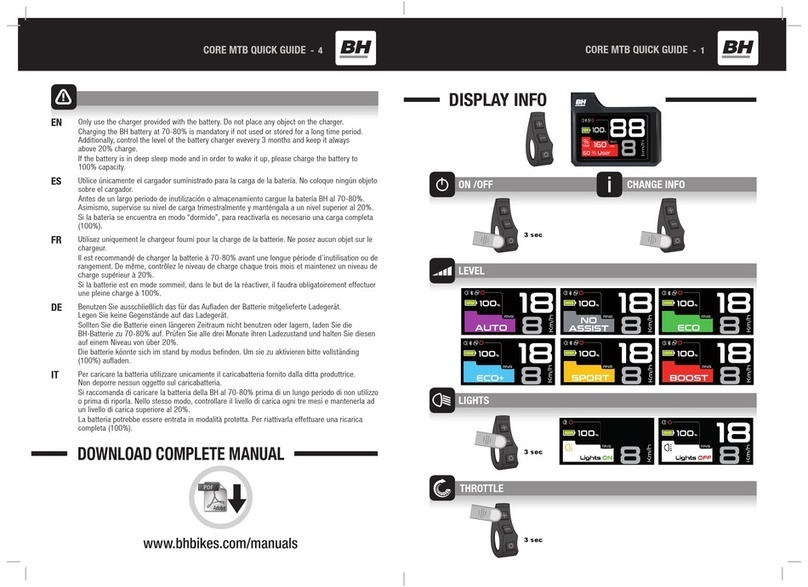

1 of Special electrical connector.(Fig 1 Part B)

1 of Black self-amalgamating tape

1 of 3.2mm Black heat shrink tubing

TIE wraps Use these where required to hold any cables in place. Make sure that you do not crush any

cables or tubing/breather/brake/clutch pipes on the bike by over tightening the tie wraps. Always cut the tie

wraps off squarely, as cutting them at an angle can leave a sharp pointed edge that can cause cuts.

Notes On Cables . Extreme care should be taken to ensure that the cables do not fall into the chain, wheel

or foul the steering etc, or be trapped or crushed by the seat or body panels. Pay particular attention to the

seat locking mechanism, which, if fouled, could cause problems with removing the seat. If required, use

some hard packing strips bonded in place either side of the cables, to prevent damaging the cables at any

pressure points, such as where the cables come from under the seat between the tank or body panels.

Avoid any sharp angles or edges that may damage or cut the cables.

Velcro. Cut one piece of hook and loop Velcro to about the same length as your intercom unit and use this

to fix the intercom to a clean, dry area, normally under the rear seat of the bike. (Ensure all surfaces are

clean and dry). If required use some of the remaining loop Velcro to cover any sharp edges, to protect the

cables.

Black clips. These can be used to hold the rider & passenger headset sockets neatly in place on the bike.

Make sure that the surface is flat, clean and dry before applying. Please note that the clips will tear off in the

event of an accident. They can sometimes be refitted using some suitable double-sided tape/glue.

Your Autocom system either comes with, or requires an optional power lead/adaptor to connect to your bikes 12-

volt supply. This power lead has two wires, one of which is RED (Positive +) and the other Black (Negative -)

CONNECTING THE NEGATIVE POWER LEAD TO YOUR BIKE.

Blue Eyelet Crimp Terminal Is for connecting your black negative power lead directly to your bikes battery

negative terminal. Position the main Autocom unit and lay all cables where you would like them to run and then try

the system with the engine running, listening for any electrical interference (A whining noise, engine speed related

is normally cause by the alternator, while a engine speed related ticking noise is normally related to HT spark plugs

or leads). If required, move the main unit and/or cables to locations that help eliminate any bike interference. Once

you are happy with your planned installation, fit the Blue Eyelet Crimp Terminal to the end of your black power

wire (If required, trim the wire to the required length before fitting the blue eyelet crimp). Connect the blue eyelet to

the bikes negative battery terminal. BE VERY CAREFUL WHEN WORKING WITH A BATTERY see your bikes

hand-book/manual about working with the battery.

CONNECTING THE POSITIVE LEAD TO YOUR BIKE

PLEASE NOTE if your bike has ABS braking and/or a brake light failure warning system you MUST consult

your bike supplier or manufacturer for approval before connecting to the brake light circuit. If connection to

the brake light circuit is not recommended, use some other ignition switched 12- volt supply, such as the rear tail

light live feed or any other recommended fused, switch ignition point.

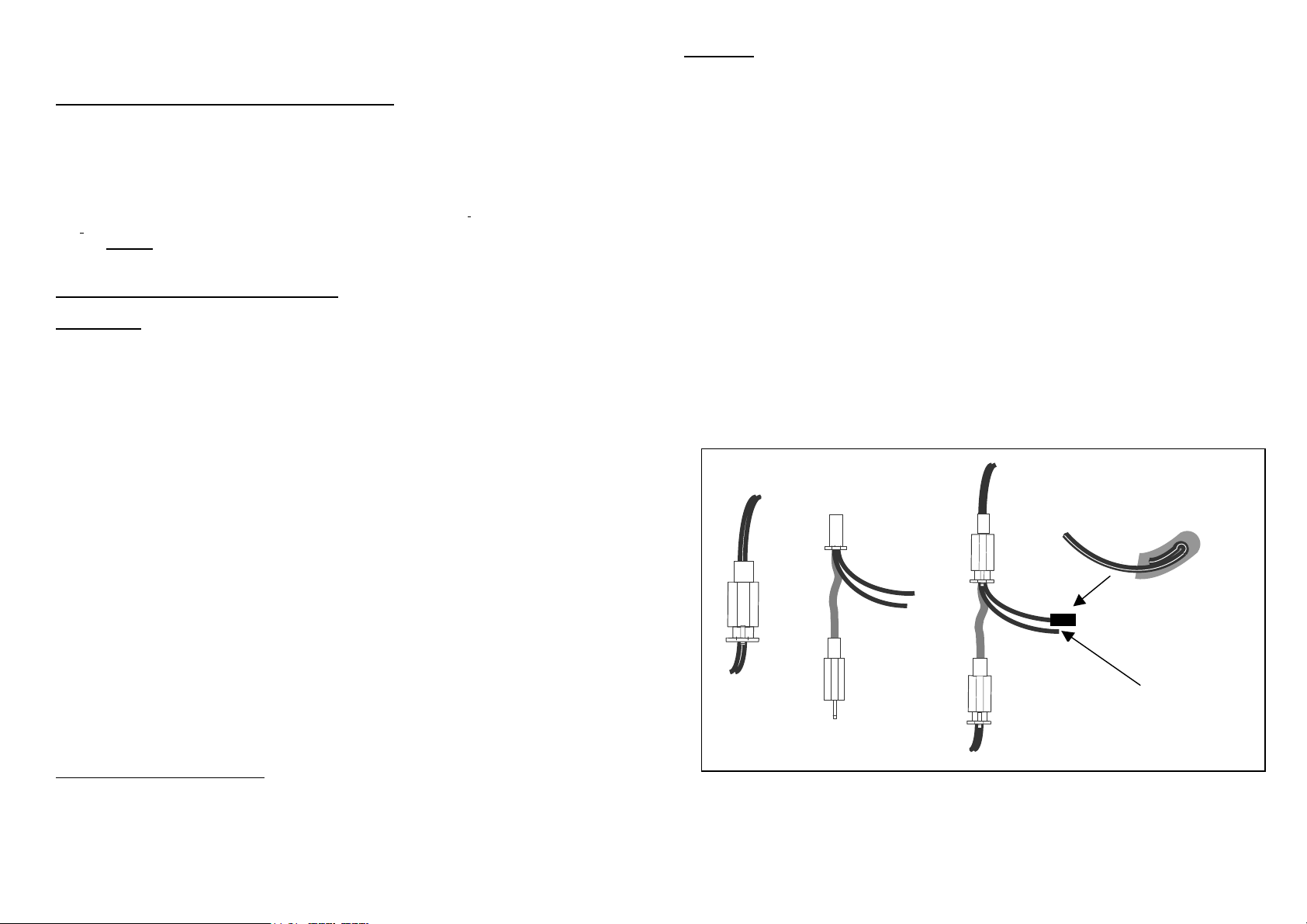

If you can connect to the rear brake light feed our special electrical connector (See FIG 1 Part B) can offer a very

easy and quick, quality electrical connection to most bikes, BUT BEFORE DOING SO please check that the rear

brake pedal only operates the brake light with the ignition on.

To use our special connector, follow the wire which runs from the rear brake light switch to where it connects into

the bikes main wiring loom, normally by a two way block connector (See fig 1 parts A & C).

With the ignition switched off, unplug the connector and then plug our special connector (Fig 1 Part B) in line with

parts A & C. When you have done this separate the two red wires, making sure that they do not touch any

earth/chassis points and then turn the ignition on. Test to make sure that the brake lights work properly. If not,

remove our connector and consult a motorcycle electrician or your dealer. If your rear brake light is working properly

with part B connected in between parts A & C, proceed by testing which of the two red wires becomes live with the

ignition switched on, being careful that neither wires touch the bike frame.

When you have established the correct wire, turn the ignition off and insulate the other wire using the heat shrink

sleeve provided, as show in Fig 1. Do this by folding the end over about 12mm (1/2 inch). Slide the heat shrink over

the end so that it completely covers the bare end, and then apply heat until it shrinks down. Then solder the

intercom’s positive (RED) wire to the live lead of part B and then insulate and seal the solder joint with part of the

Black Self Amalgamating tape.

Note, if you connect to the wrong wire, the intercom will only work when the rear brake pedal is operated, in this

case you must disconnect and connect to the other wire.

150mm Black self amalgamating tape. Use this tape to insulate and seal electrical joints. Cut to required length

(allowing for the fact that it will stretch about 50% when applying. Carefully wrap it around the joint, stretching it

around the joint. The benefit of this special tape is that unlike ordinary electrical sticky tape this tape has no sticky

glue, which often breaks down when it get hot. Instead this special tape will weld itself into one piece of rubber

within about 30 minutes. By stretching it around the joint it will provide a permanent water/air tight seal, which can

easily and cleanly be removed at any time.

General Tips

Before you install the system, study the bike and assess the best location for the control box and the routes for the

cables, (usually under near the tail lights). Before you finally install the system you should connect the power and

plug in a headset and test the intercom with the engine running to make sure that it is not picking up any

undesirable interference .As you position the intercom and each cable you should give the engine a few revs to

check for any interference. If any H.T. ignition or alternator electrical noise is present , move the intercom and /or

cables to a location where there is no interference. When you have done this you can start fixing the box and cables

properly in place.

Avoid areas of high heat such as engine & exhaust.

Avoid ignition coils and H.T. leads (causes engine speed related interference). Avoid other electrical cables,

especially the regulator and ignition box and alternator (causes whining/engine speed related interference)

Avoid areas where the control box may get extremely wet, in particular where water may be under pressure, such

as in the front of the fairing or by spray from the wheels and jet washing. Apply an additional water protection to

stop direct heavy water contamination. Also try to mount the box in such a way that any moisture will run off and not

into the sockets/connections.

Normally the rider’s lead will follow the bike frame and come out in between the seat and tank. If you like, use one

of the black clips provided to hold the socket in place on the tank. Do the same with the pillion lead so that it comes

out near the back of the seat, to one side (normally LHS) near the grab handle?

Part B MUST be connected ONLY to an ignition switched, fused power supply on you

bike. NEVER connect directly across the bike battery, which could cause severe

damage and a risk of fire/burns etc. If you have any doubts you should consult a

qualified auto electrician.

Part ‘A’

(To bike loom)

Part ‘C’

(To Brake

Light Switch)

Part ‘B’

Part ‘C’

(To Brake

Light Switch)

Part ‘A’

(To bike loom)

Part ‘B’

Heat shrink

Sleeve

p

rovided

To Intercom

Positive Lead

Fig 1

This manual suits for next models

1

Other autocom Bicycle Accessories manuals