Forematic AXEL F730 User manual

www.forematic.com

Underground gate opener

AXEL

AXEL

F730 installation

1Manual edition V1.1

AXEL installation

Page Contents

1Descripon & specicaons

2Responsibilies & consideraon

3Gate mounng

4Driveway layout

5Groundwork & cable ducts

6Pier design & ng

7Control panel wiring

7Commissioning

8 User instrucons

9 Safety record & tutorial

11 Warranty

Descripon

AXEL sets are suitable for presge estate gates. The

powerful PWM motors have internal encoders to

monitor gate posion. Stall sensors detect obstacles

and in order to reverse the gate’s direcon. Speed

and pressure are adjusted in compliance with safety

standards. AXEL sets are safe and green. They will

provide long and reliable service if ed and main-

tained according to the instrucons in this manual.

Remotes use a ‘Rolling Code’ format that changes

the code sent every me it is used. It can’t be cop-

ied, keeping your home secure.

A key operated manual release

mechanism allows access in

case of a power outage.

Though this equipment is com-

plex, user programming has

been kept simple. Foresee

have a planned program of

simple hi technology new prod-

uct releases to keep your home

secure and up to date.

Technical Specifications

Supply volt-

age 220-240Vac Motor power 100W @

24Vdc

Supply rating 2.5A @ 50-

60Hz Motor torque 250Nm max

Standby

power <10W Motor insula-

tion IP67

Ambient

temp -20° to +70° Open angle 100 degrees

Remotes 433MHz

50max Opening speed 4.5° /sec

Duty cycle 60% Max leaf size 2.5m wide, 5m²

area

Noise <70 dB Max leaf 500kgm (weight x

width)

Set contents

AK-424 The standard set is for double leaf

boarded gates, and heavy domesc gates. The

set includes two underground openers, control

panel, two remotes and a photo-beam. RIO-X

control panel requires a 230Vac supply.

AK-414 This single leaf version is approved for

gates leaves up to 2.8m when installed with an

electric lock (not included) or pedestrian gates.

AL-424 This is the AXEL low power set. The RIO-

XL control panel is powered by an ELV source

mounted remotely, oen in the house or garage.

RIO-XL includes 1.1Ahr baeries. Ideal for sites

where a long mains cable would be dicult or

expensive to run. The charging cable can also be

used for an intercom or other controls.

All sets include two remotes and a photobeam

set. Mains powered sets can be ed with the

baery backup set for up to 10 hours o grid.

Without baeries, gates will aempt to close

when power is restored.

Set contents are a starng point. Addional

devices may be added. Further safety devices

may be required. Mains isolator is not included

2

AXEL

Safety consideraons

European standards specify safety measures to

be used on applicaons with perceived risk. The

highest rang calls for photobeams and sensive

edges, in addion to control panel PSR.

Rangs for systems in public spaces used by un-

trained are higher than private gates operated

by trained. Autonomous devices such as mers

and vehicle detectors add a level of risk.

The safety tutorial at the end of this manual is

dedicated to dening ‘risk’. The design and

layout of a gate can eliminate many risks,

avoiding the need for more safety devices.

Control panel electronic measures do not make

the system compliant on their own.

Double leaf set

2x motor casings

2x motor gearboxes

Control panel with remote receiver

2x IR safety photo-beams

2x remote controls

Installer responsibility

An automated gate is a machine that must

comply with the EU Machines direcve. There

are many aspects of compliance that ensure the

gate is safe to users and public. ‘Automac gate’

signs are required on both sides of the gate

warning against risk of contact injury.

The installer must prepare a handover pack to

include details of the installaon, a user guide

and a risk statement. Much of that informaon is

included in this manual, along with guides to

indenfy site specic risks and gate aributes.

Good pracce is essenal to safety & reliability.

Note outdoor installaons electrical standards.

Homeowner responsibility

It is the responsibility of the owner to ensure

only trained people operate the gate, and they

are aware of potenal gate hazards. Owners are

responsible for injury resulng from failure to

meet the requirements in this manual.

The person operang the gate must take

responsibility for the safety of any person within

the hazard area. Never let children play near

gates in moon.

Gates must be robust, well maintained, and on

clean level ground. Keep the gate area clear of

objects. Have the gate properly maintained and

repaired by qualied personnel to maintain the

legal safety requirements.

3

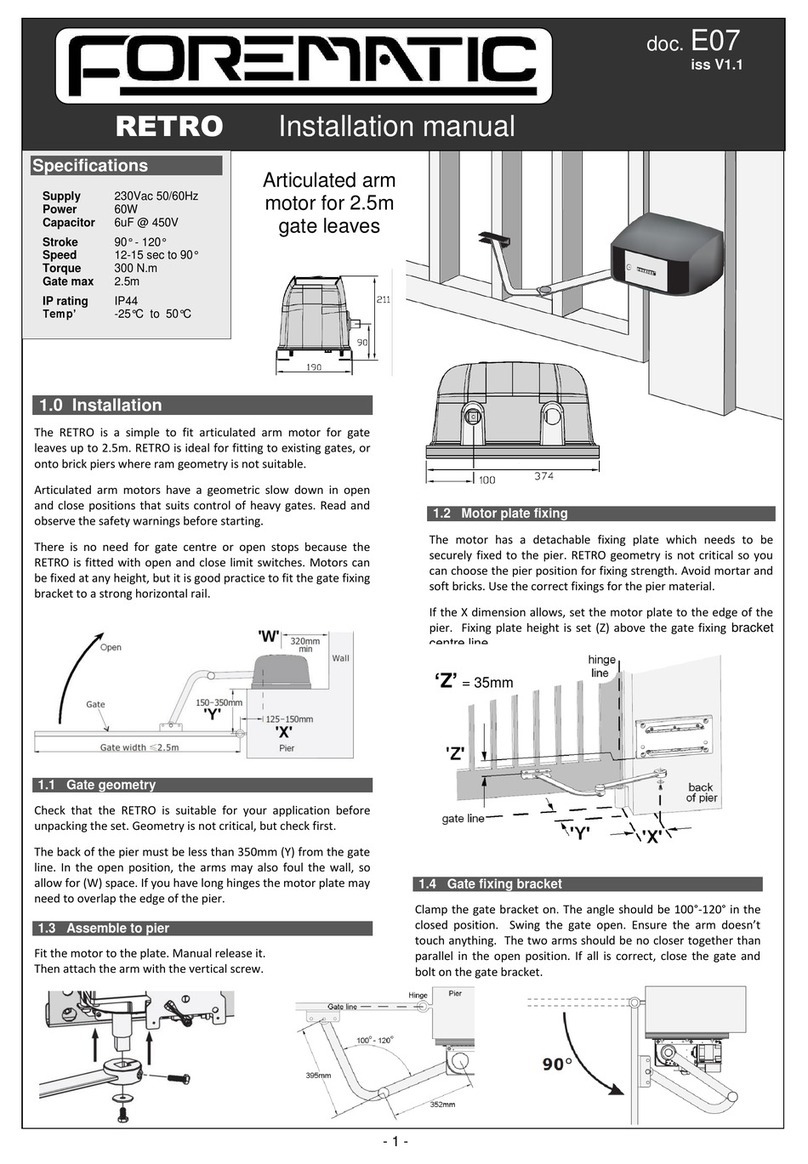

Stepped piers work beer for steel barred gates.

Boarded gates leave an unsightly gap. Filling the

gap is likely to cause a pinch hazard.

Rear hung gates, where the casement is on the

back of the pier (Fig 1c) eliminate the sight gap,

and can hide the necessary safety edge.

However on turning the casement the adjustable

closed stop no longer works. You will need a

centre stop or an alternave casement stop.

The top hinge on a boarded gate is crical to

quality installaon. Top hinges need to be plumb

above the casement pivot. Fig 3 gives some

alternaves.

The most common [D] requires the gate to be

o centre, and therefore will require a safety

edge to protect the pinch hazard.

[E] is on centre, but leaves a sight gap, or you

need to cope with a rear hung gate.

[F] is ideal, but needs a special hinge ng to

the top of the gate.

Be sure to discuss top hinge design with your

gate supplier. The design will aect safety, pier

design, the gate’s dimensions, opening angle and

entrance width.

Fig 1

Fig 3

Gate mounng

[A] is frequently requested, but requires extra safety edges

because of the crush risk between the gate and the pier.

[B] recommended for safety and has a good opening angle.

[C] casement must be turned through 90° and mounted on

the back face of pier. This results in a reduced opening angle.

Fig 4

Fig 2 A & B

C

4

AXEL

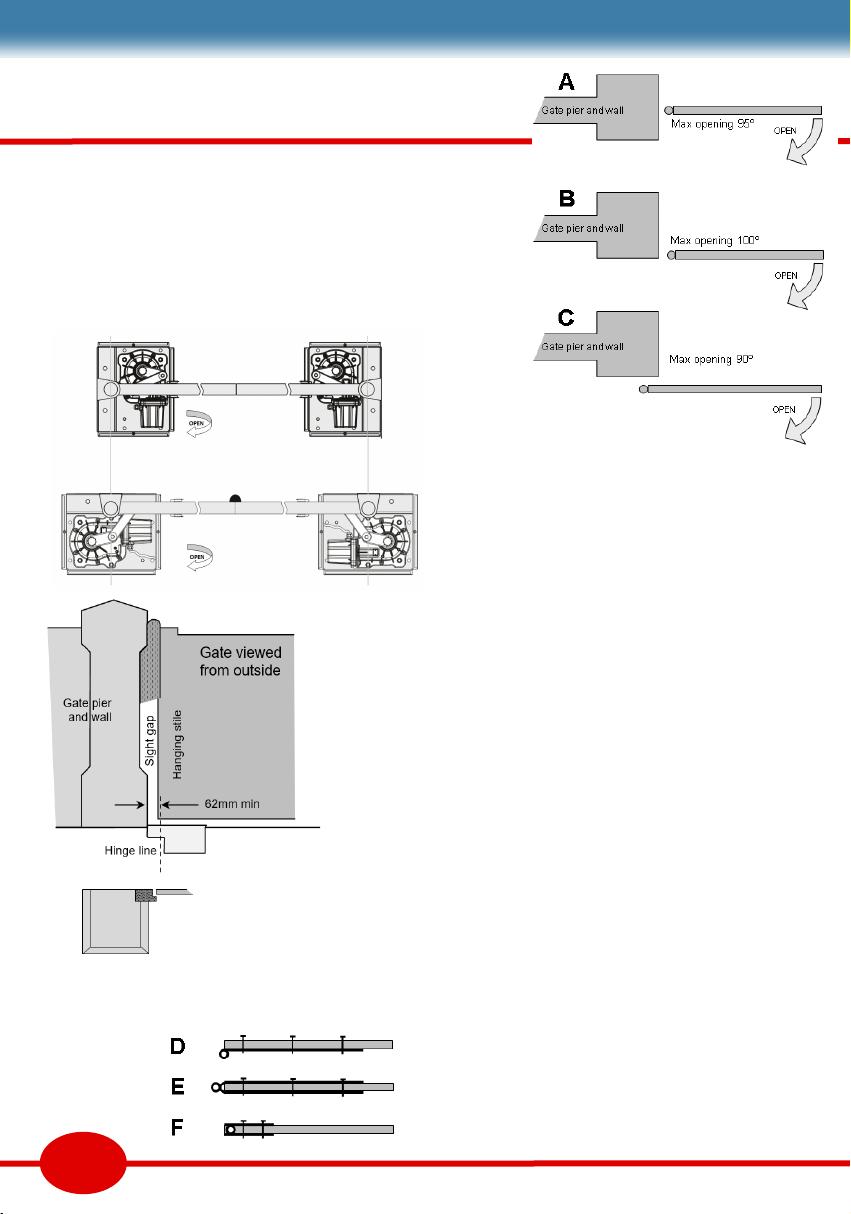

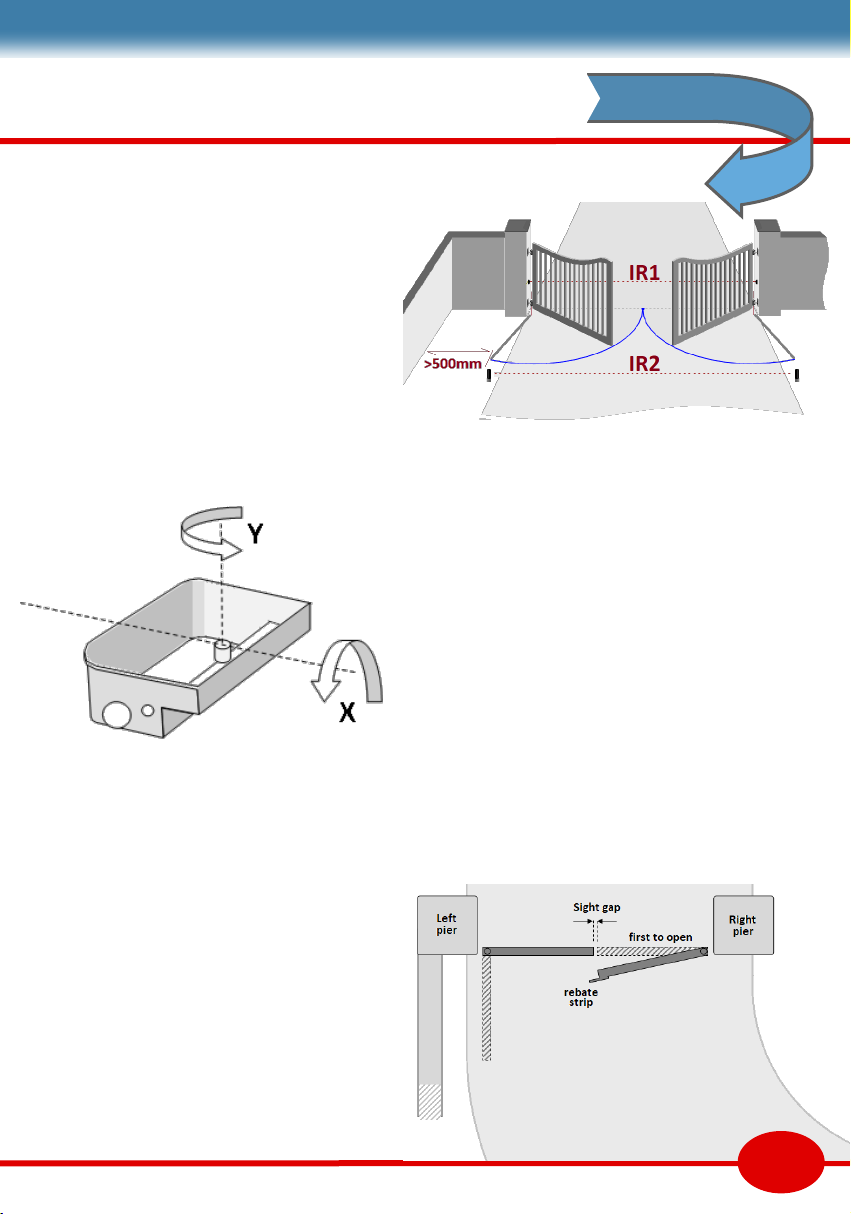

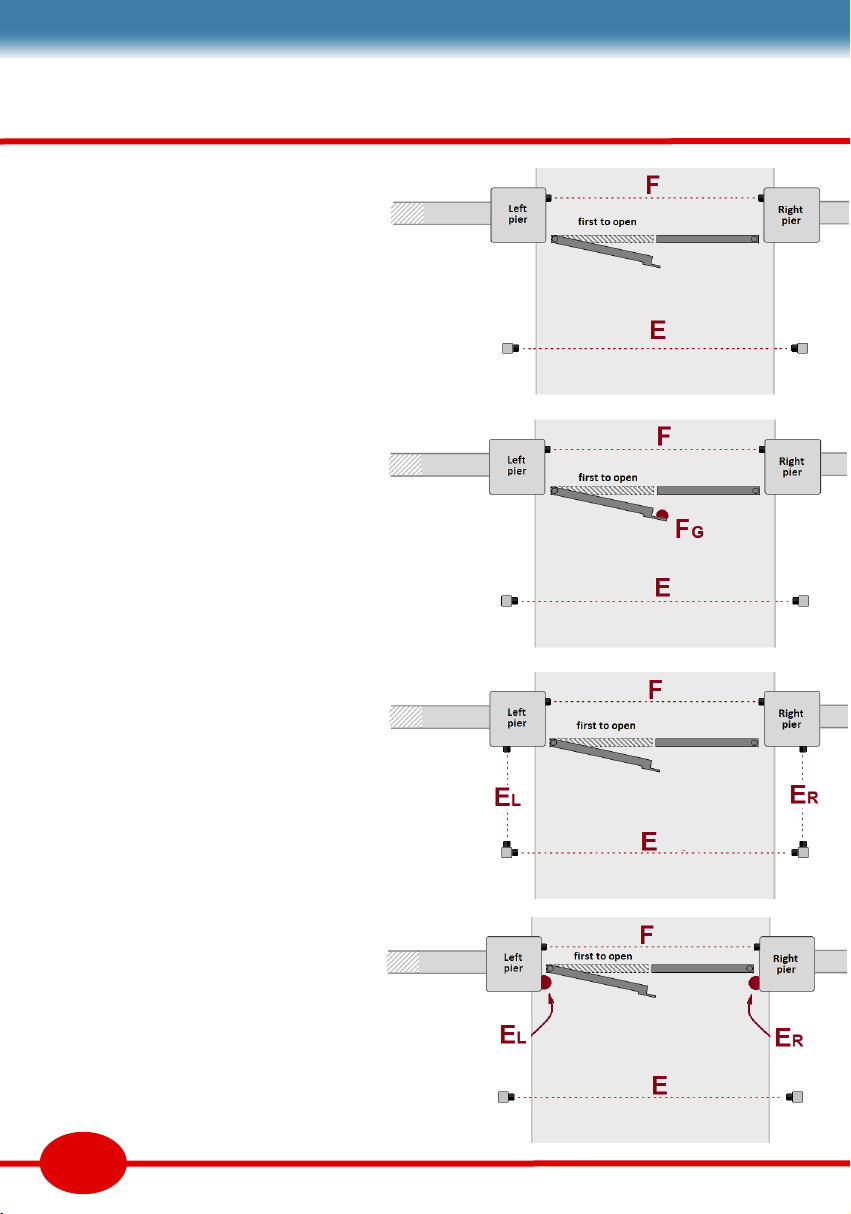

Driveway layout

Layout, like gate mounng, can minimise extra

safety devices without compromising safety.

Sets contain one photobeam, normally wired to

the re-open [F] input. The beam is xed to the

gate pier or post. A second pause photobeam on

[E] input is placed outside the swing of the gate.

The entrance should be on level ground from

pier to pier. The casements need to be at

nished ground level. It is possible to have

casements at dierent heights but one leaf will

need to be adjusted to suit.

Casements need funconing drainage. In most

cases, the drive will be higher than the water

table, so a soakaway may be sucient. Steep

private drives may have regular run os towards

the road that will frequently ll the casement,

then ll the soakaway. Consider a surface drain.

Wood swells when it absorbs moisture. A gap

between gate boards and between gate leaves is

essenal. Any sight gap between leaves can be

covered by a rebate on one leaf. This will dictate

the order that the leaves open and close. This

control panel funcon is also used for drives that

curve inside the property.

On a few occasions, the driveway may be so

steep that it is necessary for gates to open

outwards. This is to be discouraged as it puts the

public at more risk.

Similarly, the casement should be level on both

axes, pitch & roll. However, to adjust roll angle X

can compensate for a steep drive. This needs

careful calculaon that can be viewed on our

webpages.

The return wall on the le, or any other xed

solid feature, should be over 0.5m the area

swept by the gate. Any closer, and a protecon

device may be required.

Fig 6

Fig 5

Fig 7

5

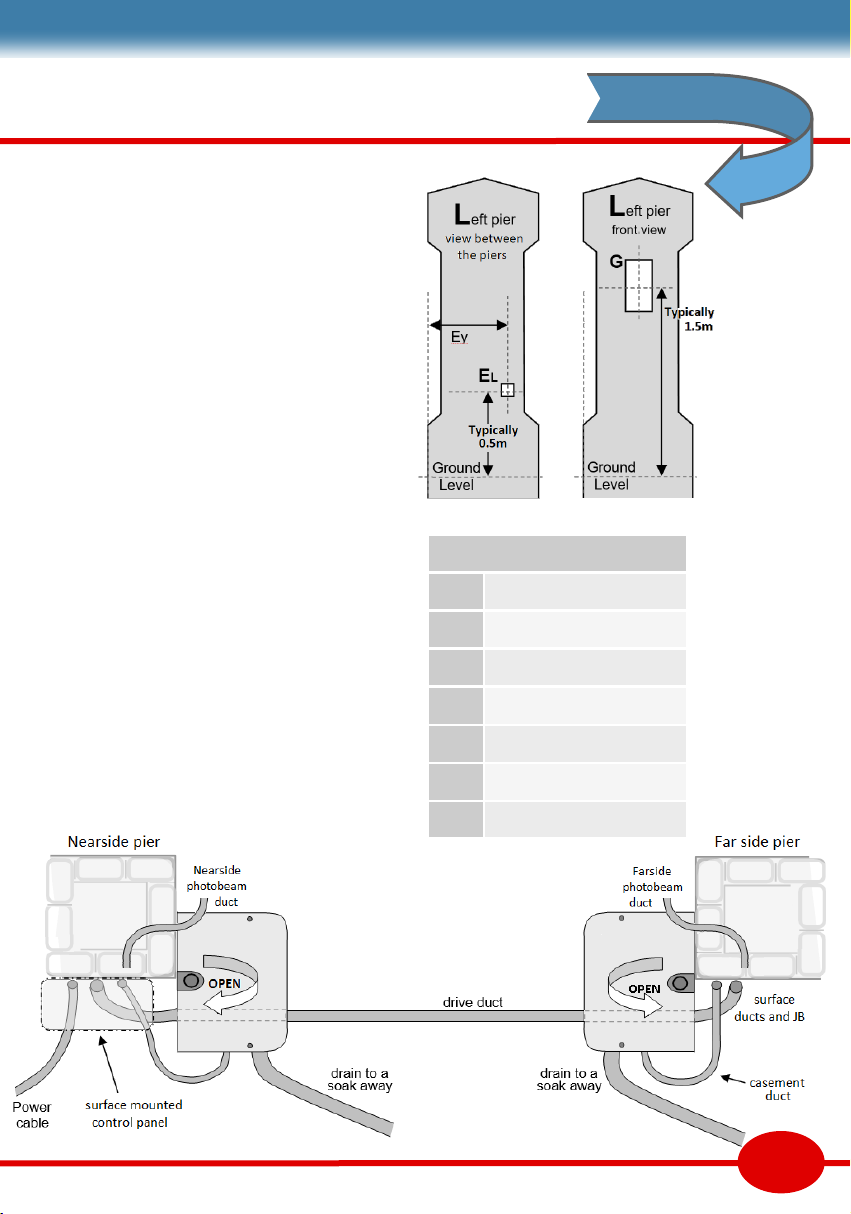

Foundaon depth depends on the ground and

pier weight. Gate width is crical, so it is safer to

lay the rst brick course before ordering the gate

to ensure it ts.

The casements can now be laid on a thin bed of

concrete over the concrete base. Fig7 shows an

alternave method where the casements are

suspended from a level bar resng on the rst

few brick courses. This ensures the casements

are level and packed underneath.

Push t ducts and drains in the casement.

Protect any exposed screw threads and tape up

any holes to prevent concrete ingress. Then

build concrete around the casement to at least

75mm, including under the pivot shelf.

Groundwork & cable ducts

Piers can be constructed hollow, inlled, or with

steel post reinforcement. That is a decision

beyond the scope of this manual.

Two concrete bases are required for the piers,

set at precisely the same level. Level o 170mm

below road level to give casements a solid base,

and space for ducts and drainage to be buried.

More ducts can be laid when the piers are half

height. We recommend 40mm ribbed duct for

cables and 50mm ribbed for drainage. Ducts in

the drawing below are shown terminated at the

base of the pier.

If the pier is to remain hollow, it is dier to run

cable ducts in the pier. If solid, run the ducts up

the side of the pier (Fig 9). It is a sensible prec-

auon to run a pull cord down any long ducts. If

you have the cable, run the cable as well.

Photobeams are set 500mm

above road level. Add a 20mm

duct in each pier run to an

access hole at on the back face.

The far pier has a JB. The near

pier will have the control panel.

Fig 8

Fig 9a Fig 9b

AXEL

Pier design

This is a good point to consider any other ducts

or cables that may be needed. See the accessory

page for more opons, such as an intercom, a

keypad, or a vehicle sensor.

The nearside pier normally has a power supply

cable and the control panel. In these examples it

is shown on the le, but could equally be on the

right. The farside pier has a juncon box (JB) to

make connecons to the motor and photobeam.

If there is an intercom or other access control, it

is normally ed to the le pier, because that is

the side visitors get out of their vehicles. Height

is typically 1.5m. Leave a suitable duct access

hole. Ducts will run either to the control panel,

or to an electrical juncon box on the rear.

Nearside piers are oen the closest to a garage

or the house, where there is a fuse box or

consumer unit. A garage makes a more secure,

safer, and less hosle control panel posion. It

must be within 10m of the gate and will require

more cabling.

Fig 11

6

Fig 10

Duct termination

A Far side JB

B Control panel

C Pier base nearside

D Pier base farside

E Nearside photobeam

F Farside photobeam

G Intercom

7

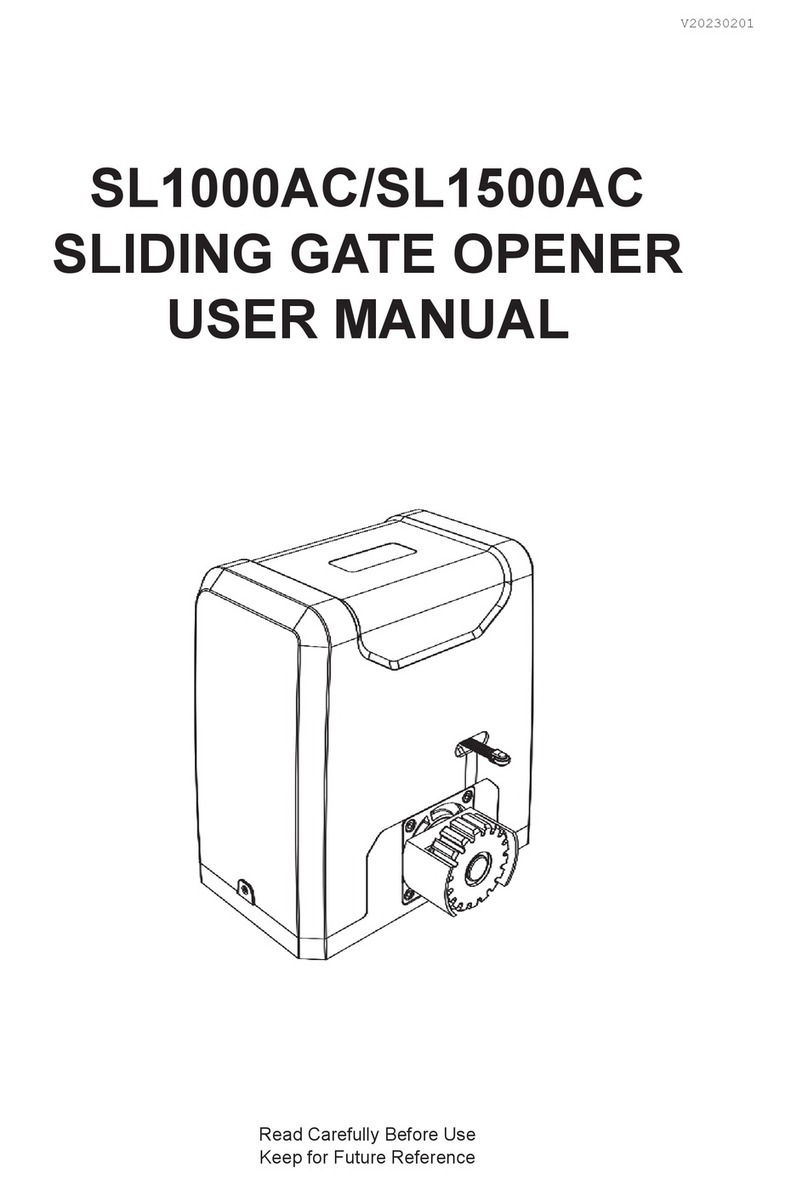

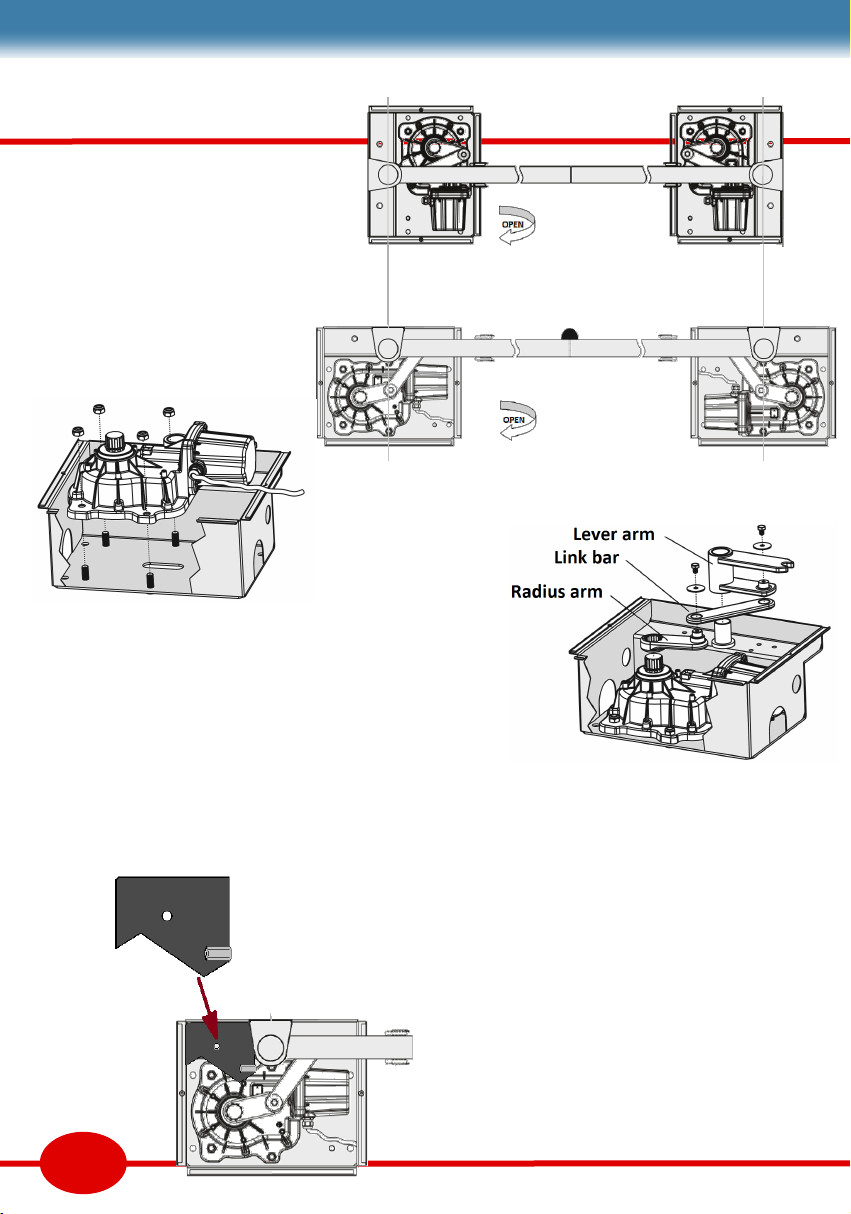

Fing the motors

The 2 casement orientaons are

shown in Fig.12 with the motor

posions. Place the motors over

the casement studs, then bolt

them down.

Gate xing levers will not be

ed unl later, though they are

shown on the diagram.

Stop plates

The stop plate has two limits. The close posion

is adjustable. The open posion is xed to the

limit of the casement. If you need the gate to

open less you can t an addion ground stop.

Fit the stub axle plate and stop plate over the

exposed studs in the upper shelf, then x with

the locking nuts.

Fig 12b

Motor arms

Motor arms can now be assembled on the stub

axle. Grease the motor splines. Place the radius

arm as Fig 14, then tap the arm on with using a

so mallet. Grease the stub axle well then add

the lever arm. Fit the link bar (thick end towards

the motor) and x with two screws..

It will not be possible to set the closed stop unl

the motors are under power.

Fig 13

Fig 14

Fig 15

Fig 12a

Running cables

We recommend star wiring. A ve core 0,6mm

cable (DC519) is run from the control panel to

most devices. Excepons are the motor cables

which are 3 core 1mm, and AK sets mains supply

cable (3 core 5A). Lock and lamp cables may also

dier, so check their cable specicaons.

Cables should enter the panel through glands.

Running the cables behind the PCB keeps the

limited space dy. It is beer to hide cables than

cut them too short. Mark all cables.

The wiring plan below shows individual cables

grouped in appropriate ducts. Only one juncon

box is shown. Others are likely to be required.

Capital leers refer to the terminal they service.

An intercom has been included as an example of

access control. Devices on terminals L, K, G, E

and D are oponal and not included in AXEL sets.

8

Fig 16

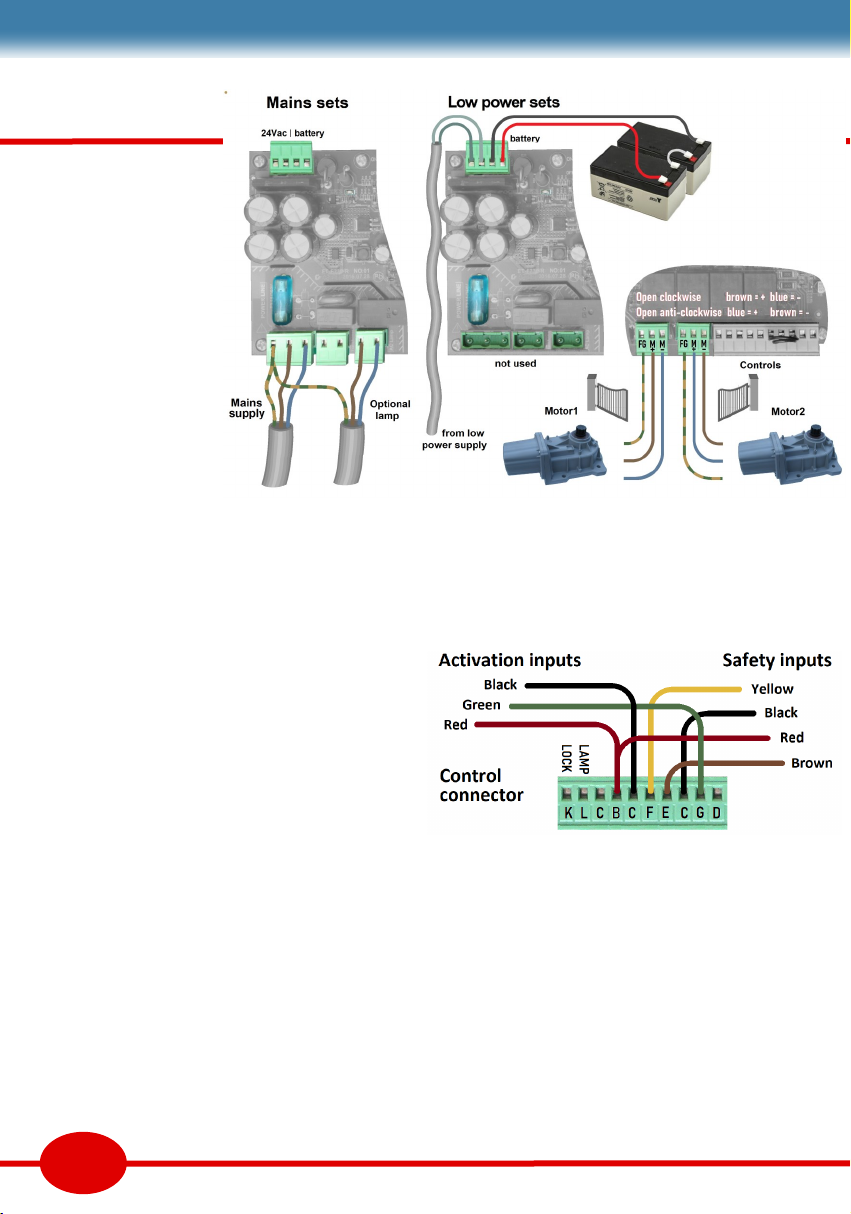

RIO-X panel

RIO-X is the mains

panel with a 24Vac

transformer. The only

other main wiring is

the warning lamp.

RIO-XL is a low power

version with baeries

charged is remotely.

Baeries a can also

be ed to RIO-X

giving about 10hrs o

grid service.

CONTROL WIRING

The 10 way control connector is for ‘acvaon’

and ‘safety’ devices. A standard colour scheme

simplies diagrams. Black [C] is common to all

devices. Use only compable devices.

WARNING LAMP [L & C] output gives 12Vdc

ON-OFF while the gate is in moon for lamps

without a asher circuit. The power board has

terminals for 230V lamps with internal ashers.

ELECTRIC LOCK [K & C] opon gives a DC pulse

on opening. Use wire over 1.5mm terminals.

ACTIVATION DEVICES [G & C] or [D & C]

Any number of extra acvaon devices can be

wired to [G & C]. Some examples are shown on

the next page. Move the green wire to [D] for

single leaf “door” opening. Remotes can be set

for these two funcons. See user instrucons.

SAFETY DEVICES [F & C] or [E & C]

There two inputs are for safety devices. Input [F]

prevents the gate closing (outside photobeams).

Devices on input [E] pause gate while opening or

closing (eg inside photobeam or safety edge).

See examples on the previous page.

Unlike acvaon devices, safety device contacts

are ’NC’. More than one device contact on the

same input need to be connected in series. If an

input has no device connected, it needs to be

linked to [C] common.

Examples on page 12 show single photobeams

on each input. Below that, there are examples of

a photobeams with one and two safety edges.

Safety device power (red) is 24Vdc. It is only

acve while the motor is running.

We recommend safety edges with an NC contact

for easy wiring. Not all edges need the power

supply. Resisve edges may need a processor.

Safety is a synergy of all measures and devices.

Refer to the safety tutorial for risks & soluons.

9

Fig 17

Fig 18

Control terminal functions

Lock output, 24Vdc K

Lamp output , 24Vdc L

Black Lamp & lock common C

Red Accessory power A

Black Common C

Yellow Safety, re-open F

Orange Pause either direction E

Black Common C

Green Full opening input G

Pedestrian opening D

Accessories below have NO contacts. FORESEE’s wireless buon

& keypad work on the remote channel so require no wiring.

Exit buon is normally in the property. A keyswitch can

on either side, or for use by authorised persons only (eg teachers)

Vehicle sensors are normally used for leaving the property,

oen described as ‘free exit’ sensor. A single point vehicle sensor

is placed in the driveway. Adding a me clock to work during the

day could be viable ‘free entry’ device for a commercial property.

Keypads are useful for friends, family or trusted delivery

drivers. This keypad can accept many codes, and some for single

use (less trusted delivery drivers).

Intercoms normally require a cable to the house. These two

types need only 2 wires (not shown here), which can be included

in a ’Low Power’ RIO-XL ’s power supply cable. Intercoms and

keypads are normally on the le pier to suit visitors by car.

Smartphone control oers a modern control method with

a device we all carry. A data cable to the house is not necessary

for simple control, but adds features if it is included at this early

stage. They can replace the intercom and addional remotes.

Acvaon device wiring

10

VY805

buon

FA61

Keyswitch

K15

Keypad

202

Audio intercom

502

Video intercom

VD909

vehicle

Sensor

Fig 19a-d

11

Further wiring plans

There are 2 safety inputs. [F] stops the gate

closing (Fig24). [E] pauses the gate in either

direcon (Fig25). More safety devices may

be added as required. Refer to the safety

page for guidance on the risks.

Mulple safety contacts must be wired in a

chain (series) on the same input. Photo-

beams have a receiver [Rx] and transmier

[Tx]. It helps if the beam direcon on [F] is

the reverse of the beam direcon on [E].

Fig20 The primary beam is [F]. An inside

beam [E] is recommended, ed to posts

or a wall. Note the hinge posion is on the

pier corner, so nger traps are less likely.

Fig21 An safety edge has been added to

the gate leaf that closes last. There are now

two devices on [F] wired as Fig26 or Fig27.

Fig22 This ring of photo-beams stops gate

movement if there is any incursion into the

area enclosed. There are 2 repeater posts

that need only power (Fig29). Fig25 Tx is

the start, and Fig25 Rx is the end of chain.

Fig23 The gate hinges have been moved

making a nger trap risk. Safety input [E]

needs 2 safety edges and a photo-beam.

Wire to Fig26 (le) and Fig27 (right).

SAFETY EDGES

DRI safety edges have a 4 core cable (Blue-

yellow-black-red) that needs power. Fig30

shows the alternave DCY or DTE edges.

Fig 20

Fig 21

Fig 22

Fig 23

12

AXEL

Optional

FA31 on

input E

standard

FA31 on

input F

Photobeam wiring

The first photobeam on F (yellow) is

compulsory. The E input (brown) is

optional. Inputs can take multiple

safety devices when

their volt free contacts

are wired in series.

Note jumper position !

Beam Fig 26

DRI edge

on the end

of the gate

E or F

power

Beam Fig 27

One DRI

edge on

on a pier

power

Beam Fig 28

Wiring 2 DRI’s

Yellow NC

Blue Com

Black Gnd

Red Supply

power

Open Timer

A wired switch or mer can hold a gate

open. The N/O contact opens the gate

[G]. The N/C contact stops it closing [F].

This circuit comes between RIO-X and

safety circuits on this page.

Fig 31

Fig 24 Fig 25

Beam Fig 30

DCY

or DTE

edges

power

Beam Fig 29

Power

Repeater circuit for ring of

beams. Each Rx enables the

next Tx. Only requires power.

13

Stac sengs

Open & close delays - DIP1 to 4

The rst leaf needs to start to open a few secs

before the second leaf. There is a similar delay

for closing. If your drive is straight the delays can

be set to minimum, so set all 4 DIPs o.

DIP5 OFF for double leaf gates. Set ON for

single leaf gates, connected to ‘Motor1’ output.

Auto-close delay - DIP11 to 13

Delays start when both gates are open. Delay is

set on DIPs 11-13. All DIPs o disables the auto-

close funcon. The table below gives delays.

Electric Lock

Can be set as an electro-lock or locking magnet.

The electro-lock can be set to 24Vdc or 12Vdc.

Maglock is 24V except while the gate is opening.

DIP15 OFF = electro lock ON = Maglock

DIP7 OFF = 24V lock ON = 12V lock

Opening order - DIP14

Sets which gate opens rst (and pedestrian gate)

DIP14 OFF; motor1 leaf opens rst, closes last.

DIP14 ON; motor2 leaf opens rst, closes last.

Motor1 is normally on the le pier. See page 13.

DIP11,12,13 Auto-close delay

100 010 110 001 101 011 111

5s 15s 20s 60s 65s 75s 80s

Delay 2s 3s 4s 5s

DIP 1&2 - opening 00 10 01 11

DIP 3&4 - closing 00 10 01 11

PCB buons

There are two buons on the PCB. The CODE

buon is used to set remotes. STEP is the same

as receiving an input on the [G] terminal.

Seng remotes

You can save up to 50 remotes. There are two

remote channels. Pedestrian channel opens one

gate only. Main opens both leaves.

Press and hold the ‘code’ buon for 2 secs.

LED1 will light. Press any buon on the remote

twice. LED1 now goes out.

Pedestrian opening - Press the ‘code’ buon

for 1 secs. LED1 will light. Press the ‘code’

buon again for 1 secs. Press the boom

remote buon twice. LED1 now goes out.

Remote funcon

In both states, assuming an auto-close delay is

set, a single remote buon press will open the

gate, pause for auto-close delay, then re-close.

4step auto sequence is ;

OPEN—STOP—CLOSE—STOP

Gate moon can be stopped at any point by

pressing remote buon. The next press

reverses direcon. If you want to hold the gate

open, wait unl the gates are almost open, or

just beginning to close, then press the remote

again to pause. Release with another press.

Remote funcon - DIP6

In both states, assuming an auto-close delay is

set, a single remote buon press will open the

gate, pause for auto-close delay, then re-close.

4step auto is default (DIP6 OFF) sequence is ;

OPEN—STOP—CLOSE—STOP

Gate moon can be stopped at any point in this

sequence by pressing remote. The next press

reverses direcon. If you want to hold the gate

open, wait unl the gates are almost open, then

press the remote again to freezes the gate.

Release with another press.

Remote funcon - DIP6

In both states, assuming an auto-close delay is

set, a single remote buon press will open the

gate, pause for auto-close delay, then re-close.

4step auto is default (DIP6 OFF) sequence is ;

OPEN—STOP—CLOSE—STOP

Gate moon can be stopped at any point in this

sequence by pressing remote. The next press

reverses direcon. If you want to hold the gate

open, wait unl the gates are almost open, then

press the remote again to freezes the gate.

Release with another press.

Remote funcon - DIP6

In both states, assuming an auto-close delay is

set, a single remote buon press will open the

gate, pause for auto-close delay, then re-close.

4step auto is default (DIP6 OFF) sequence is ;

OPEN—STOP—CLOSE—STOP

Gate moon can be stopped at any point in this

sequence by pressing remote. The next press

reverses direcon. If you want to hold the gate

open, wait unl the gates are almost open, then

press the remote again to freezes the gate.

Release with another press.

2 step auto (DIP6 ON) is OPEN - CLOSE only. If

the remote is pressed while the gate is opening,

it stops and re-closes (or vica versa). No pausing

the sequence; no gate hold open funcon.

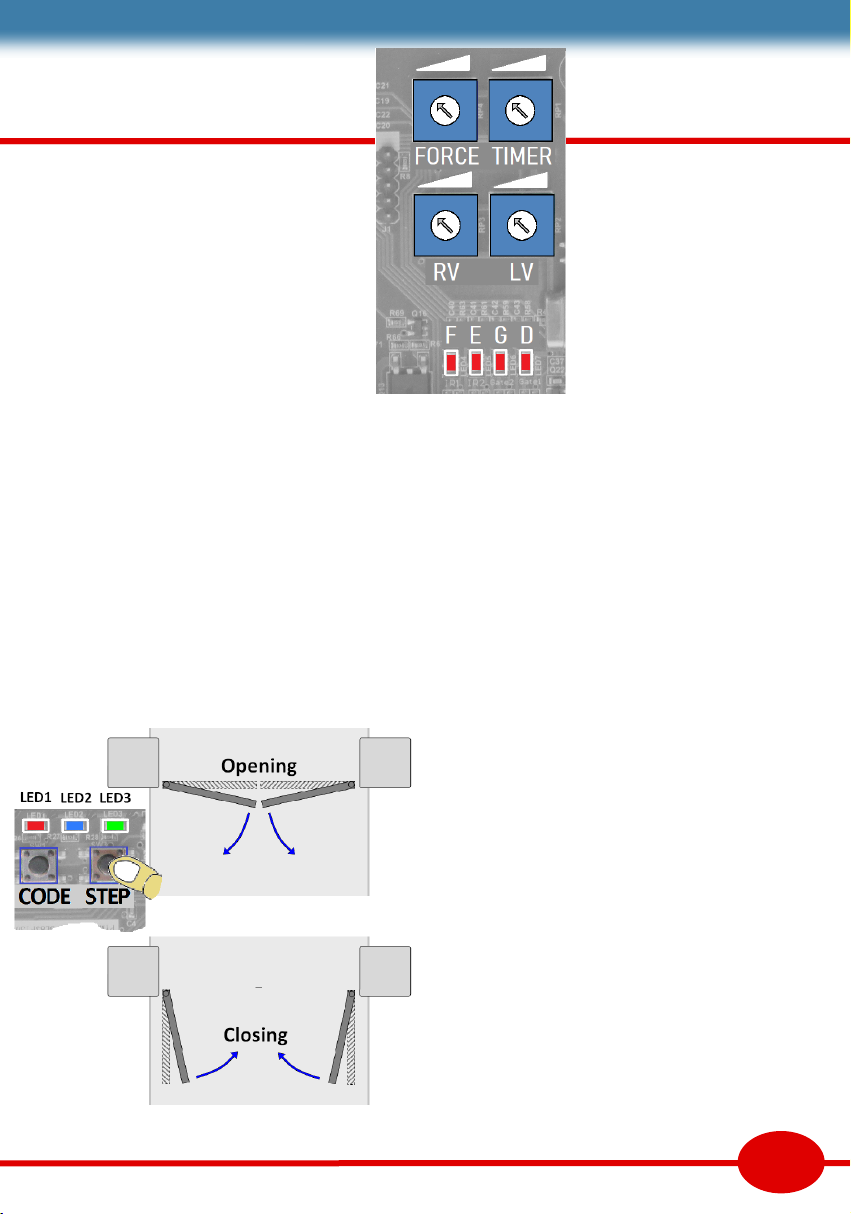

LED3 ashes while opening

LED3 stays on when open

LED2 ashes while closing

LED2 stays on when closed

Fine adjustment

Fine adjustments set the safe

running of the gate. Follow the

order below. Extra acvaon and

safety devices can be wired in

aer these adjustments without

the need to re-adjust.

RV. Mid travel speed. The gate should only run

fast when it is at least 500mm clear of know

objects. Set heavy gates to run slower.

__________________________________

LV. Speed at slow start & slow stop. Set to close

the gate rmly against the post. LV is a preset

percentage of the total run me.

__________________________________

Force. Regulates the maximum force applied by the

motor before obstacle detecon kicks in. Set

it high enough to move the gate reliably, yet

sll reverse on an obstacle.

__________________________________

Timer. Sets the default run me (30-63 secs). If the

motor fails to nd a physical stop. It mesout.

Refer to safety tutorial for force test limits. The safe

force limits need to be observed. Adjusng the rst

3 sengs will help comply. The adjustments above

should not aect the limit learning. Small changes in

physical limits may be necessary but big changes

will need the limit learning to be repeated.

Further support

Further wiring applicaons, support and fault

nding can be found on our website on the AXEL

support page.

14

Run me seng

LED1 Programming indicator

LED2 Flashes while closing. On when closed

LED3 Flashes while opening. On when open

LED4 Indicator for input [F]. On when safe.

LED5 Indicator for input [E]. On when safe.

LED6 Indicator for input [G]. On when acve

LED7 Indicator for input [D]. On when acve

Limit learning - DIP8

RIO-X uses encoder feedback from the motors to

monitor movement. On a test run, it can detect

the ends of travel set by physical stops allowing

it to nd its own limits and set slow down points.

The DIPs and remotes should have been set. The

four blue pots should be set to 10 o’clock (as

picture opposite). Pots will be ne set later.

Close the gates (this may need a 12V baery).

Set DIP8 to ON. Press STEP to start learning.

Fig 32

15

Deleng

remotes

You cannot delete remotes one at a

me. Delete all. Re-enter the ones

you want to keep. Press and hold

the ‘code’ buon for 8 secs. Delete

will not work while gate is moving

User Instrucons

Safe operaon

Installers must hand the gate over in a safe state.

Use a ‘competent person’ to keep the gate in

compliance with safety direcves. The home owner is

obliged to maintain the system in a safe state, and

keep maintenance records which will be passed to

new owners of the property.

Don’t let children operate or

play on the gate. Keep remotes

out of reach of children. Check

the safety device’s funcon of

once a month. Do not modify

the gates, as this will require a

new safety audit.

Fault nding

In the event of a failure, homeowners should seek

professional help to maintain safety. Our website

PICO support page has fault nding support.

You can save up to 50 remotes. There are two remote channels.

Pedestrian channel opens one gate only. Main opens both. You

will need to open the control panel to nd the ‘CODE’ buon. The

control panel will not accept coding while the gate is moving.

Add a remote

Press and hold the ‘code’ buon for 2 secs.

LED1 will light. Press

any buon on the

remote twice. LED1

now goes out.

Pedestrian opening - Press the ‘code’ buon

for 1 secs. LED1 will light. Press the ‘code’ buon again for 1 secs.

Press the boom remote buon twice. LED1 now goes out.

Manual release

Each leaf has a key release mechanism for

use in case of power failure. The key hole is

at the boom of the gate behind a round

plasc cover. Turn the key then pull the lever

towards you. When the lever has turned

through 90° the gate is be free to open. Be

sure to keep the keys in a place which is

accessible from both sided of the gate.

Fig 33

Fig 34

LED1 indicates a correct remote is being received,

or that you are in limit or remote learning mode.

LED2 Flashes while closing. On when closed.

LED3 Flashes while opening. On when open

LED4 Indicator for input [F]. On when safe.

LED5 Indicator for input [E]. On when safe.

LED6 Indicator for input [G]. On when acve

LED7 Indicator for input [D]. On when acve

LED8 Indicates the baeries are charging

Motor checks - 3 ohms between blue & brown.

Safety

DIPs

16

1 2 3 4 5 6 7 8 11 12 13 14 15

FORCE % TIMER % LV % RV %

1 User record

2

3

4

5

6

Input Position Device

F FA31

Installation record complete this table as part of your records

Activation

Input Position Device / code

G

Fault nding

There are 8 LED’s on RIO-X that show the states

of inputs and the gate posion.

Gate runs slowly This happens when there

has been a loss of power. The controller needs

to re-nd it’s limits. This is done automacally.

Gate will not close Check LED’s 4&5. They

should be ON unless a safety device is acve.

Randomly triggers There may be a missing

remote, or loose wiring in [G] or [D] .

Gate stops before fully open or closed.

Can be the stall detector has sensed an object.

Check for s or dry hinges. Increase FORCE pot.

LED3 ashes 4 mes - cannot nd the limit.

Gate will not operate - Are there any LED’s

on? Check power in, baery voltage and fuses.

Isolate wiring thus; link [E] to [C]. Link [F] to [C].

Empty terminals [G] and [D]. Does it now work

on remotes?

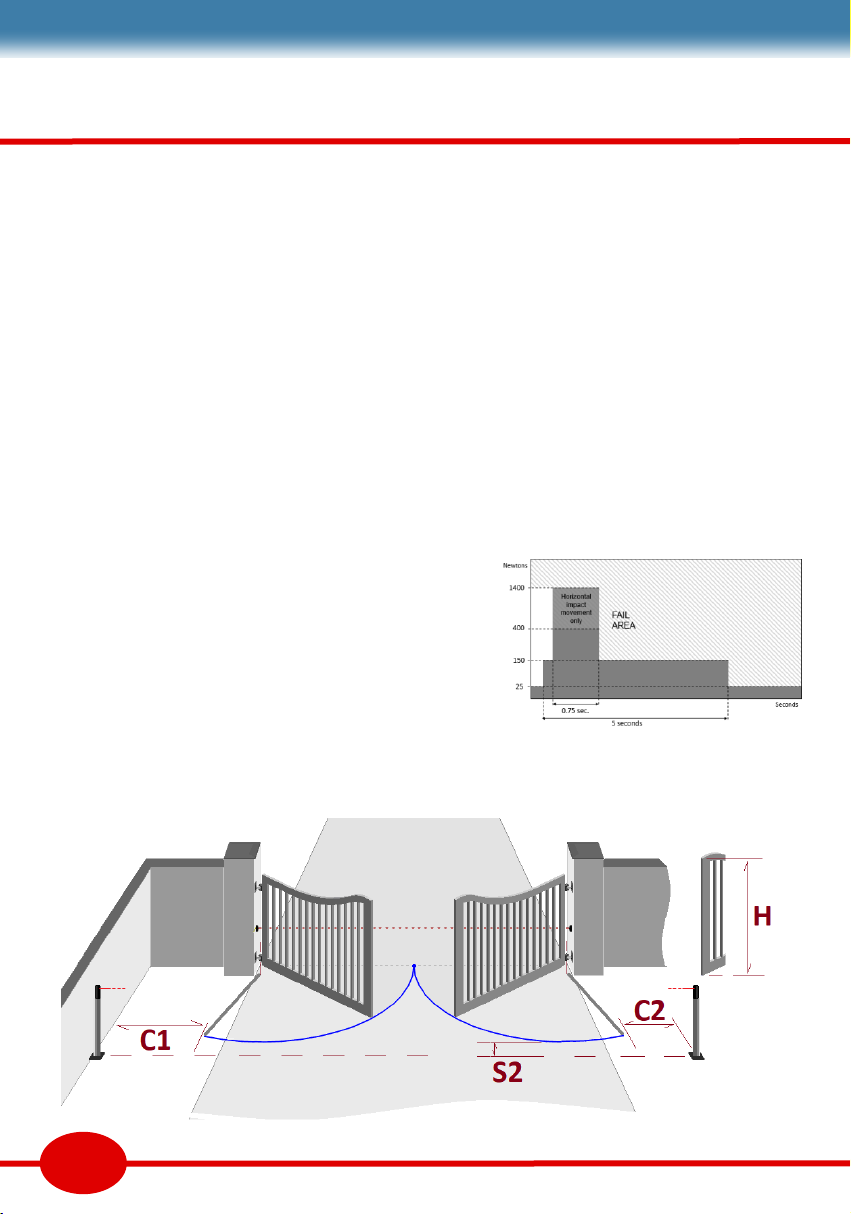

AXEL

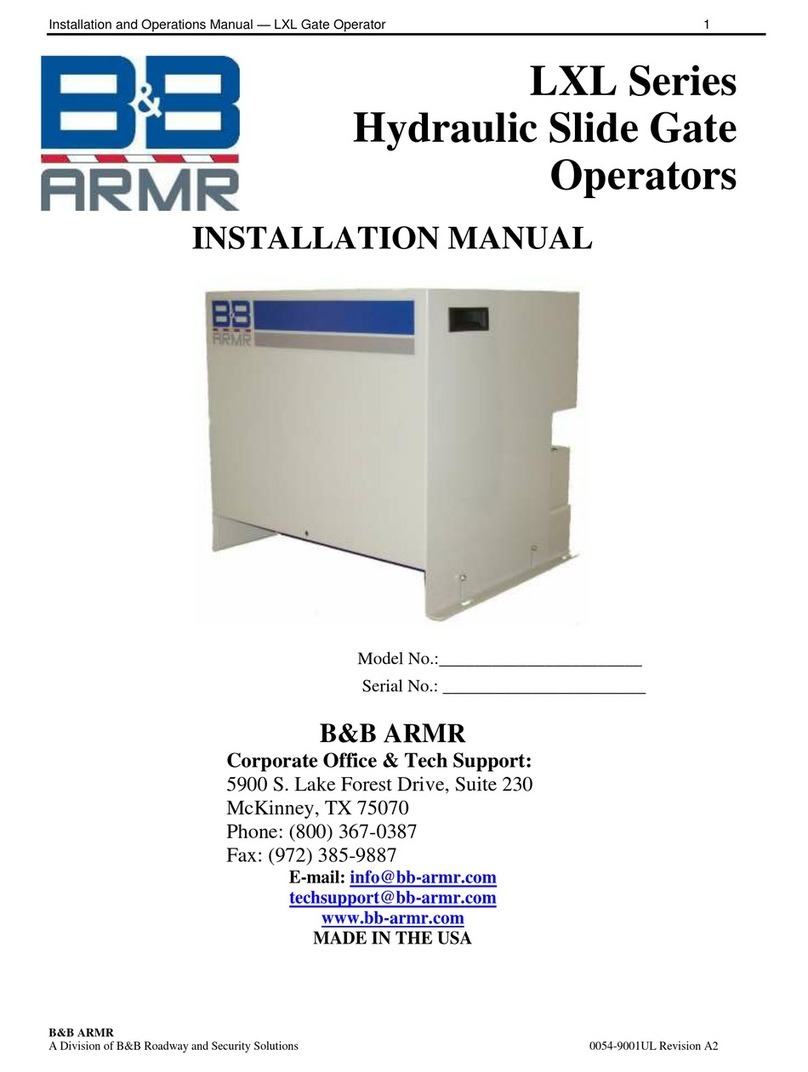

Overview

The gate installer builds a machine on site. The

machine must be declared safe by the builder and

comply with the EU Machinery Direcve. Parts for

the machine must be compliant and used as

directed by the manufacturer. Standards require

good design and good working pracces. Finished

machines must be declared safe. Handover to a

responsible person includes documentaon and

training to maintain the machine’s safety for users

& public. The latest DHF TS011 Code of Pracce

can be found at www.dhfonline.org.uk

Force tesng

EN12445 explains the method of tesng the

impact forces of a gate. The crux is a graph of

acceptable forces from the point of impact.

Safety device applicaons

Safety devices such as sensive edges and photo

beams are to stop, and if necessary, reverse the

gate movement in the “Risk Zone”. Applicaons

necessary for safety are primary devices. Other

applicaons that contribute to safety, but are

not necessary are supplementary devices. Some

devices are only rated for supplementary safety

use. Primary devices need to be Cat2 or Cat3 as

dened by EN954-1.

17

Gate Safety Code of Practice

Fig 35

Fig 36

Crush hazards marked C1 to C3

Crushing is between a moving part and a staonary

part. It is most signicant below 500mm when it

may be up to 400N for less than 750ms. Moving

part needs to reverse within 5 secs so that pressure

is released to 25N.

Impact zones marked R1 to R3

Impact refers to a moving object striking a person

outside the crush zone. This is 1400N for less than

750ms. There could be a temporary object (a car) in

the R zones, hence the use of photo-beams.

Safety distances marked S1 & S2,

At least one photo-beam 300—700mm high must

supplement force limitaon. Spacing between the

beams and the limit of the moving part must be less

than 200mm. Nominal spacing between vercal

gate bars is 100mm. Safety must be eecve to H,

the maximum height of the moving part, or 2.4m,

whichever is the least.

Edited from DHF TS 011 Code of Pracce

‘Draw in’ or Shear Gaps where a body

part could be drawn in are not allowed. Limbs have

dierent nominal sizes. Finger gaps need to be less

than 8mm (D2), arms less than 100mm etc. A solid

inll sliding gate needs to be less than 8mm from

the post. Vercal bars on sliding gates (D2) present

mulple shear risks against the supporng post.

Entrapment Ez is an area where a

person can be entrapped without being in contact

with the gate. Entrapment is not permied unless a

manual release is provided inside the zone.

Finger traps F1 is a nger trap as a result

of poor hinge design. Designs must ensure moving

gaps are under 100mm, and either under 4mm or

over 25mm, and the gap changes by less than 20%.

Motor PSR is not an acceptable nger trap soluon.

Hold to run speed of a closing gap in a crush zone

must be less than 0.5m/s. The gate must stop

within 50mm in the crush zone, or 100mm at mid

travel.

This guide is a helpful reference to idenfy risk.

It is not a direcve. It does not suggest soluons. AXEL

18

Fig 38Fig 37

RETRO

Complete your home security with

a Foresee gate automation set

PICO

sliding gate motors for confined spac-

es, sloping drives, and sharp corners

AVANTI

Warranty

Warranty covers defects to the Foresee product proven

attributable to a material or manufacturing fault during the

warranty period. We will repair, or refund, or replace faulty

product with a similar fault free product at our discretion. We

do not accept costs for dismantling, installation, or for

carriage. Parts replaced under warranty are the property of

the warrantor.

The warranty period for Radio Equipment is 24 months. The

period for replacement parts is 6 months or to the end of the

current warranty period, which ever is longer.

Warranty exceptions

The warranty does not cover damage caused through:

Wear & Tear or Improper Installation or Negligent Care or

lack of Maintenance or Misuse or Water ingress or Abnormal

Environmental Influences or Mechanical damage during

Transport or damage through improper Installation or

PRIMO

Garage door opener

Table of contents

Other Forematic Gate Opener manuals

Popular Gate Opener manuals by other brands

Chamberlain

Chamberlain SCS200 Installations

Chamberlain

Chamberlain LiftMaster LM3800A Additional Instructions for Installation and Operation

BFT

BFT ELI-250 manual

GiBiDi

GiBiDi SL 244 Instructions for installations

Keyautomation

Keyautomation 900FT-30 instruction manual

Entrematic

Entrematic Ditec PWR50H Technical manual