Contents

1.1 SHARK 500/800 productsand accessories..................................................4

1.2 Dim ension...................................................................................................... 5

1.3 Gate variations...............................................................................................5

2.1 Generalnotes .................................................................................................6

2.2 Checks............................................................................................................6

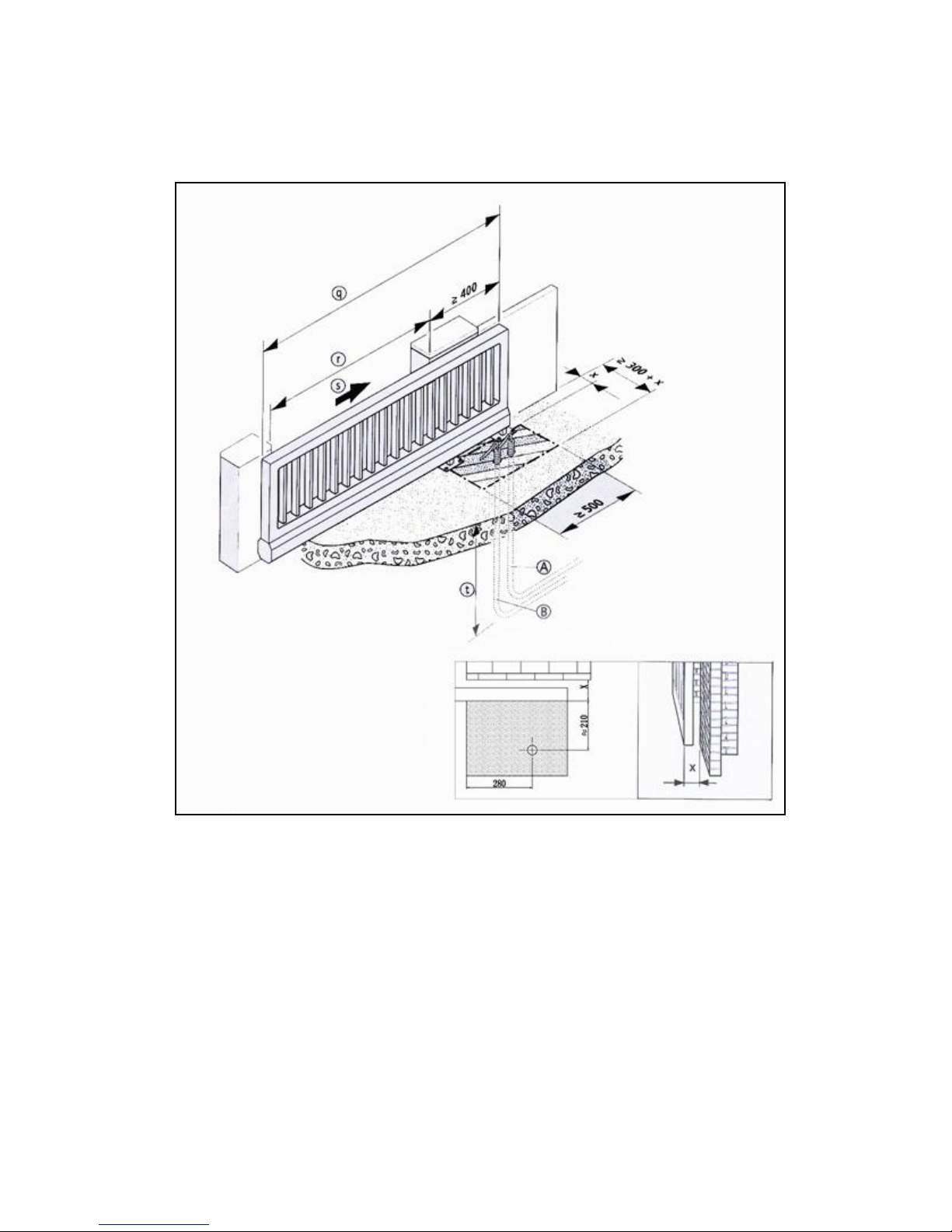

2.3 Gate andfoundation layout............................................................................8

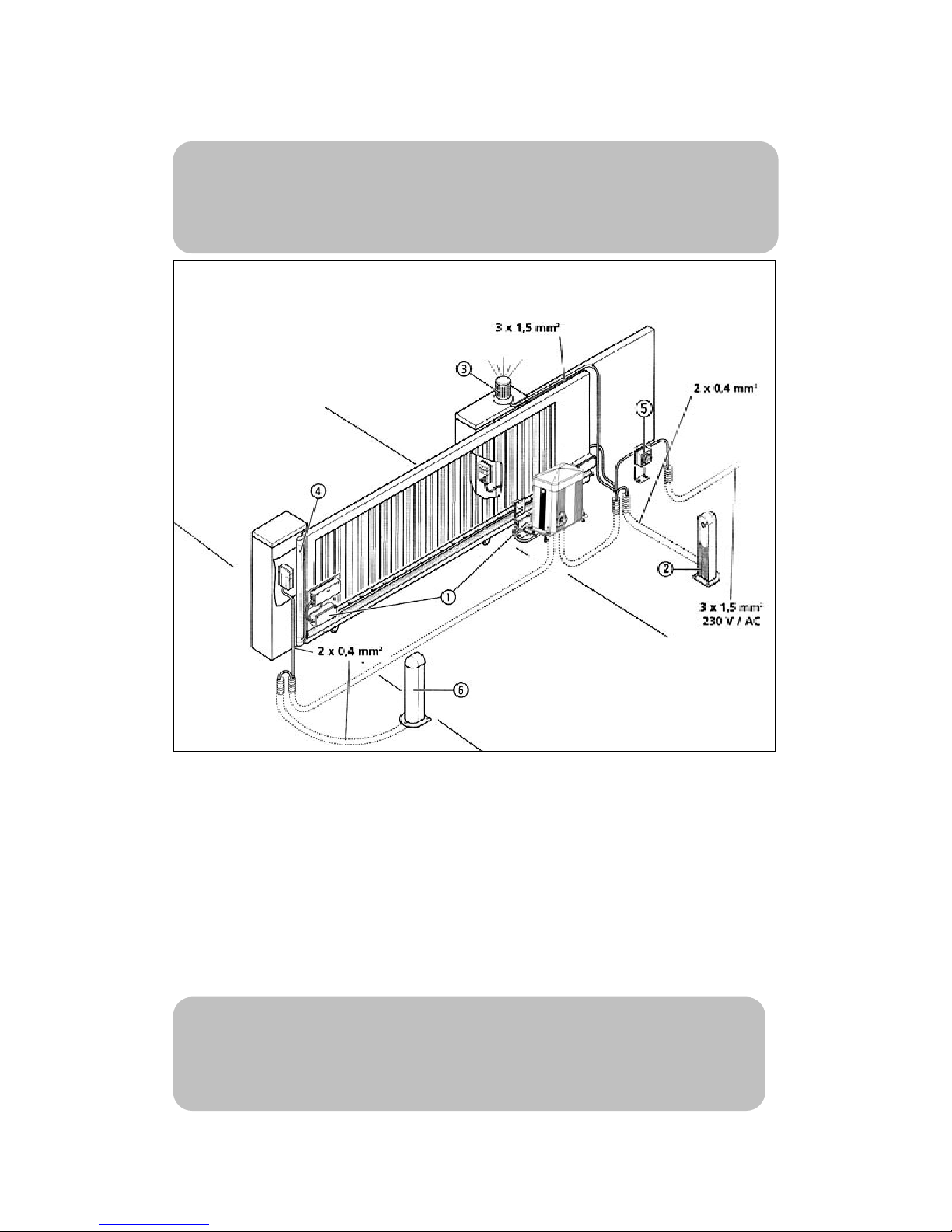

2.4Cabling layout................................................................................................9

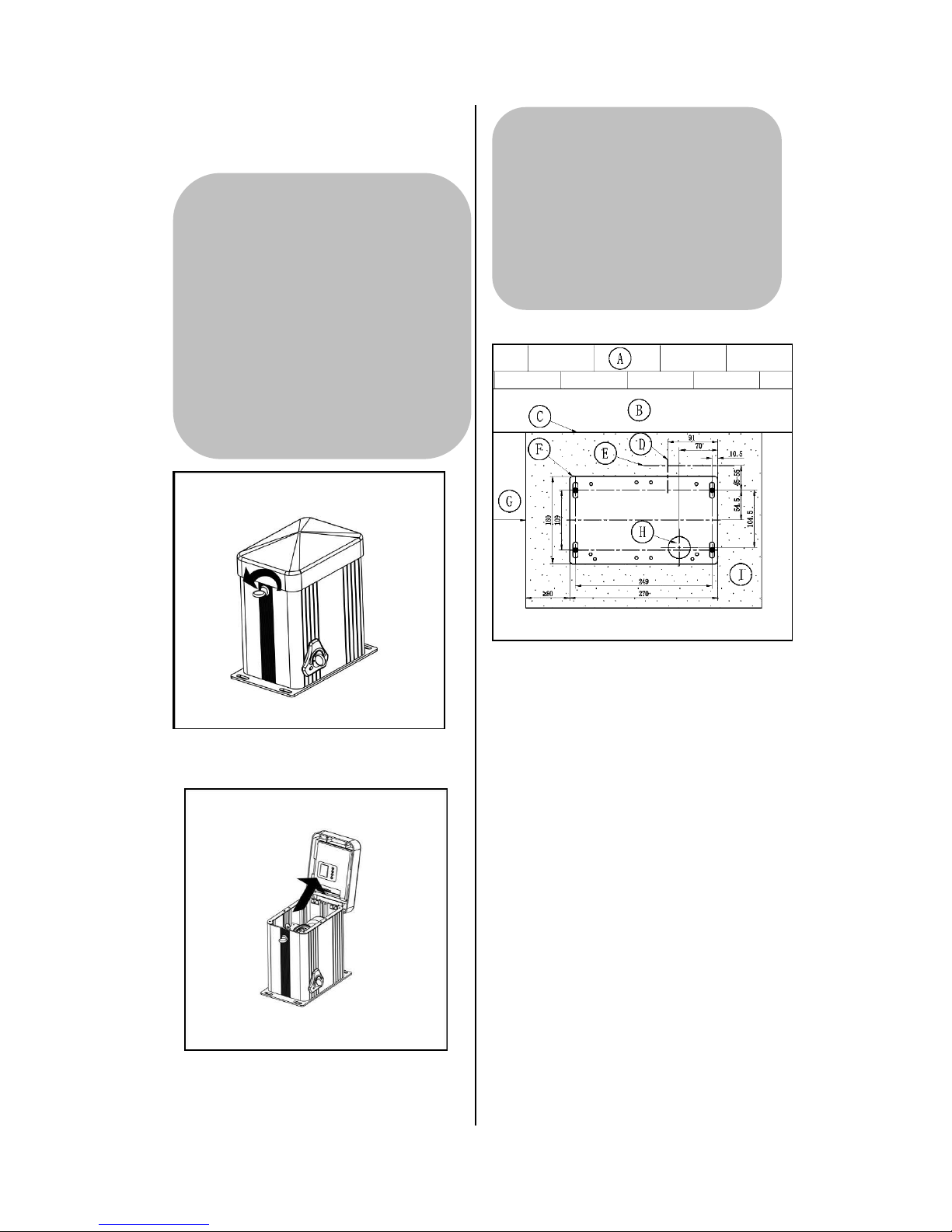

3.1 Installing the m otor unit............................................................................... 10

3.2 Mountingthe toothedrack........................................................................... 12

3.2.1General................................................................................................12

3.2.2Determ iningthe installationheight....................................................12

3.2.3 Determ ining the length and installation position of the toothed rack

...................................................................................................................... 13

3.2.4Adjustthe lengthof the toothedrack...............................................14

3.2.5Mountingthe toothedrack...............................................................15

3.2.6Adjustthe m otor unit.......................................................................16

3.3 Adjusting the heightof the m otor unit......................................................... 17

3.4 Mountingthe reference point m agnet..........................................................17

3.5 Release ......................................................................................................... 19

3.6 Locking .......………… ……… … ………… ……… … ………… ……… ….19

3.7Restore the lim it settingafter power restoration .......................................20