Autoglide Magro-500 J User manual

Magro-J – Series

Swing Gate Opener

User Manual

www.autoglideglobal.com

2018

Dear users,

Thank you for choosing this product. Please read the manual carefully before assembling and using it.

Please do not leave out the manual if you send this product to a third party.

1. Safety Instruction

Please ensure that the using power voltage matches with the supply voltage of gate opener

(AC110V or AC220V); kids are forbidden to touch the control devices or the remote-control unit.

The remote-control unit is controlled by a single button mode or three button mode (please refer to

the instructions of the remote control in accordance with the actual gate opener type). The indicator

light on the remote-control unit will flicker when the button on it is pressed. Main engine and gate

can be unlocked by disengagement wrench and the gate can move with manual operation after

disengagement.

Please ensure that no one is around the main engine or gate when the switch is operated and it is

usually demanded to examine the stability of installation. Please temporarily stop using if the main

engine needs repairing or regulation.

The installation and maintenance of the products must be carried out by professionals.

2

2. Packing List (standard)

No. Picture Name Quantity

1

Main engine 2

2

Manual release bar 1

3

A

B

C

D

A

B

C

D

Remote control 2

4

Control box 1

5

Wall bracket 4

6

Front mounting bracket 2

7

Connecting bracket 2

8

Mounting screw (short) 2

9

Mounting screw (length) 2

10

Screw M8×25 4

11

Nut M8 8

12

Safety stopper (Optional) 1

3

2. Packing list (optional)

No. Picture Name Quantity

1

Infrared sensor 1

2

0

8

5 6

97

4

1 2 3

Wireless keypad 1

3

Alarm lamp 1

4

Electronic lock 1

5

Storage battery 2

3. Technical parameters

Model Magro - 500 J Magro - 650 J

Power supply 220V/50Hz;110V/60Hz 220V/50Hz;110V/60Hz

Motor power 80W 80W

Gate moving speed 18~22 second per 90 (approx) 18~22 second per 90 (approx)

Max.single-leaf weight 250 Kg 325 Kg

Max.single-leaf length 2.5M 3.0M

Max.piston stroke: 34cm 54cm

Max.force 1500N 1500N

Remote control distance ≥30m ≥30m

Remote control mode Single /Three button mode Single / three button mode

Storage battery (optional) DC24V (4.5AH or 9.0AH) DC24V (4.5AH or 9.0AH)

Noise ≤58dB ≤58dB

Working duty S2, 30min S2, 30min

Recording of up remote controls

25 25

Frequency 433.92 MHz 433.92 MHz

Working temperature -20°C - +70°C -20°C - +70°C

Package weight 17Kg 19Kg

4

4. Installation

Magro J Series swing gate opener is applicable to single leaf gate weight less than 225/300 kg, and

length of the single leaf swing gate should be less than 2.5m/3m. The drive mode adopts the worm

and worm gear to combine the screw rod transmission. This gate opener must be installed inside

the enclosure or yard for protection.

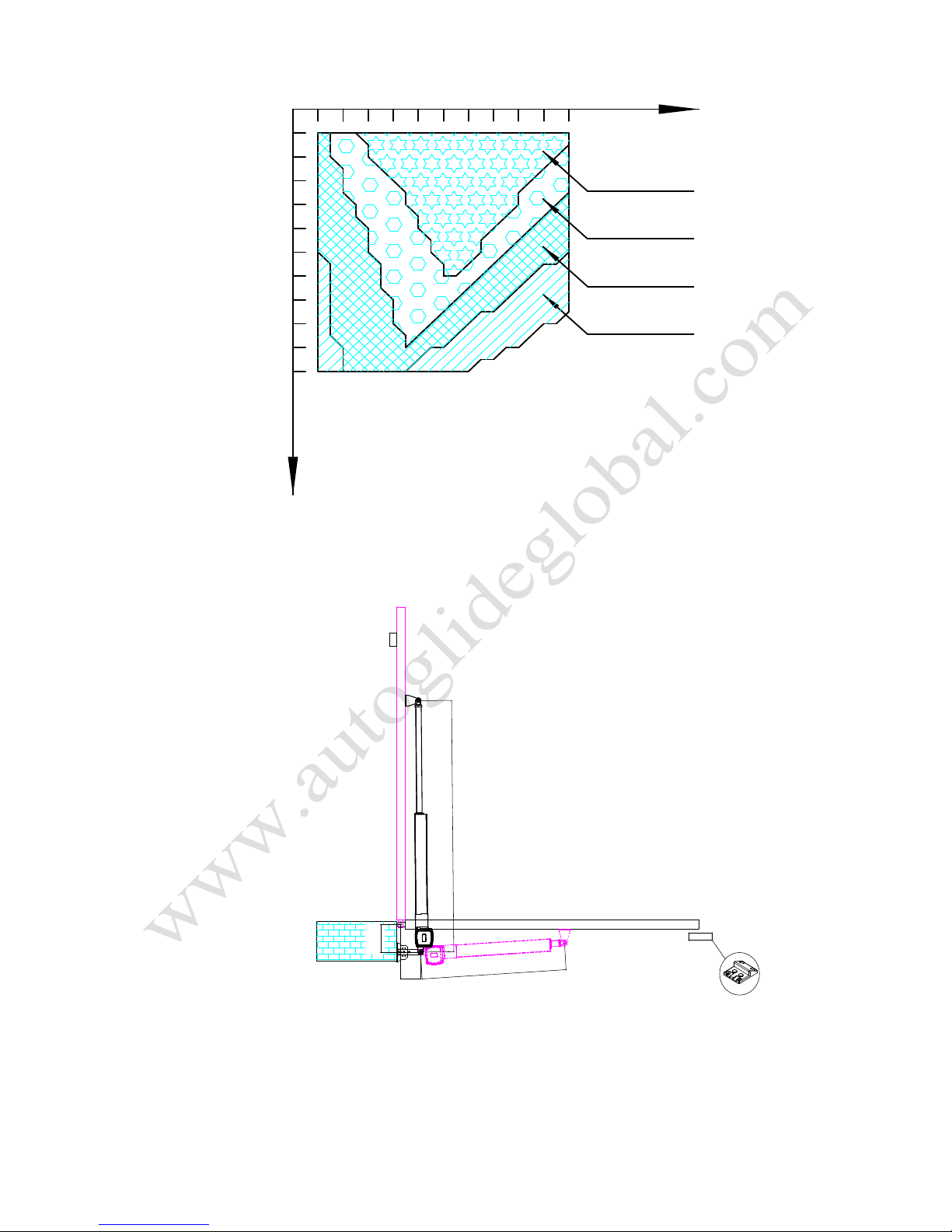

4.1 Installation drawing

0

8

5 6

97

4

1 2 3

⑦

①

③

④

⑤

②

⑧

⑥

Figure 1

① Control box; ② Gate opener; ③ Gate; ④ Alarm lamp (optional);

⑤ Infrared sensor (optional); ⑥ Stopper; ⑦ Remote control; ⑧ Wireless keypad (optional);

4.2 Size of main engine and accessories

4.2.1 Size of main engine

190

970Max

620Min

104

Magro - 500 J

5

190

1370Max

820Min

104

Magro – 650 J

Figure 2

4.2.2 Size of mounting plate

40

2× 8.5

70

8.5

17.5

43

Front mounting bracket Wall bracket

φ

Figure 3

4.3 Installation steps

4.3.1 Preparation before main engine installation

a) Before installing the door opener, please confirm the correct installation of the door to ensure that

the door can be easily manually operated, and the door safety stopper can effectively prevent the

door to continue moving.

b) Install the electric lock, the distance between the door bottom and ground should be 40-50mm. If

not install the electric lock, the distance between door bottom and ground should be ≥20mm;

c) The main engine recommended mounting height is about 300 ~ 800mm from the ground, and

make sure there are reliable fixed points for mounting brackets.

Cable

In order to ensure the normal operation of the door opener and protect the cable from damage,

please use PVC pipe laying motor, power cable, and control cables, and separate two PVC pipes to

lay (motor and power cable) and (control cable), respectively.

6

Mounting brackets

In order to install the Magro - 500 J / Magro - 650 J main engines firmly, recommend to use the

expansion screws to fix the mounting brackets.

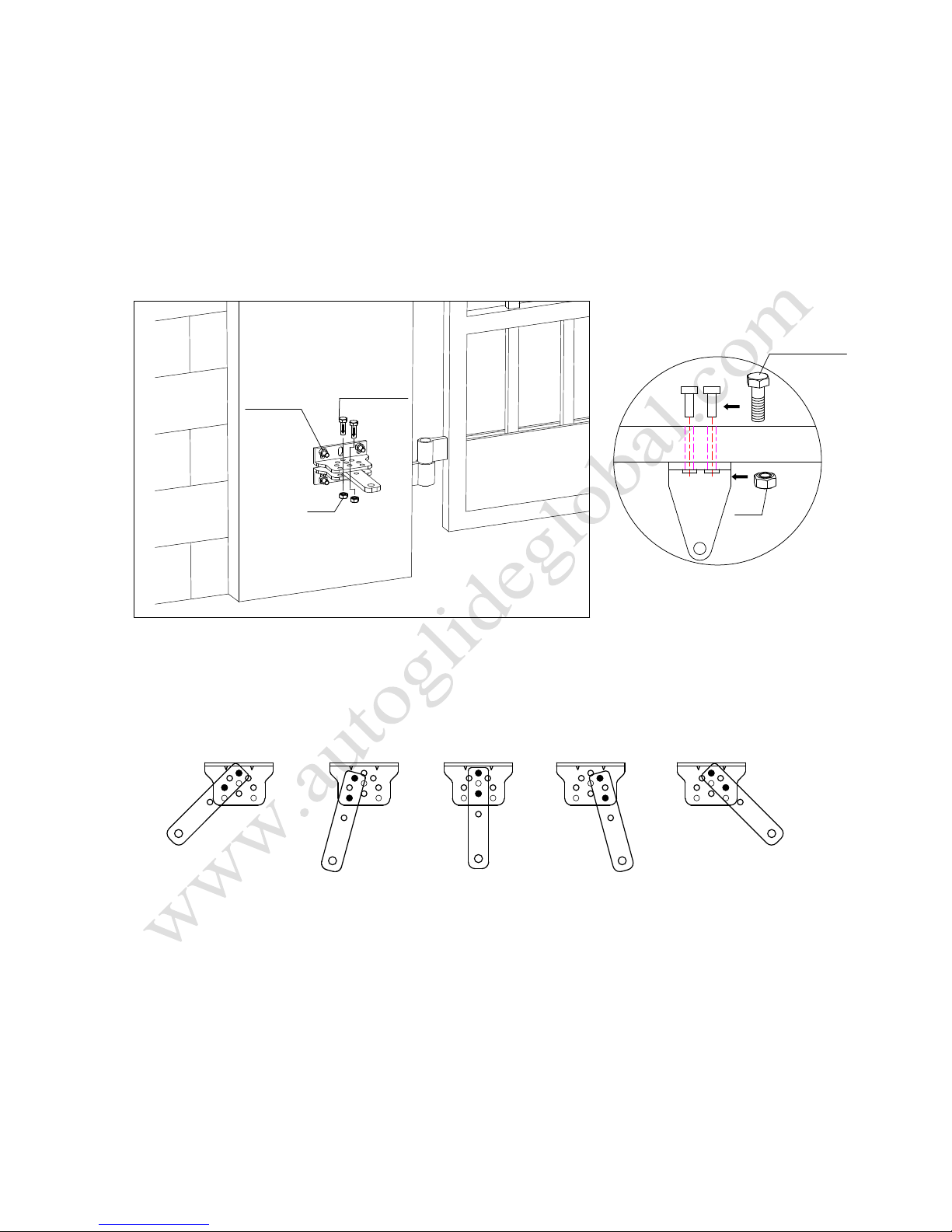

4.3.2 Accessory

a) Before installing the main engine, install the wall bracket on the wall, then fix the connecting

bracket, and install the front mounting bracket on the door.

Note: Please detect by gradienter before fixing, to ensure that the front mounting bracket

and the connecting bracket in the same level.

Expansion screw Hexagon screw

Nut Nut

Hexagon screw

Figure 4

b) The connecting bracket and the wall bracket can be connected according to different conditions,

as shown in figure 5.

Figure 5

c) Users shall prepare power cables for the control box and main engines, according to different

installation environment; the power cable of the control box is not less than 3 cores, and the motor

cable with 2 cores. If you need to install electric locks, infrared sensor, alarm lamp, external button

switch and other external equipment, please increase corresponding the embedded wire, and the

sectional area of electric lock cable core shall not be lower than 1.5mm², others shall not be lower

than 0.5mm². The length is determined by the user of according to the situation in the installation

site.

7

Note: The pipe outlet should be facing down to avoid rain water entering the pipe along the cable.

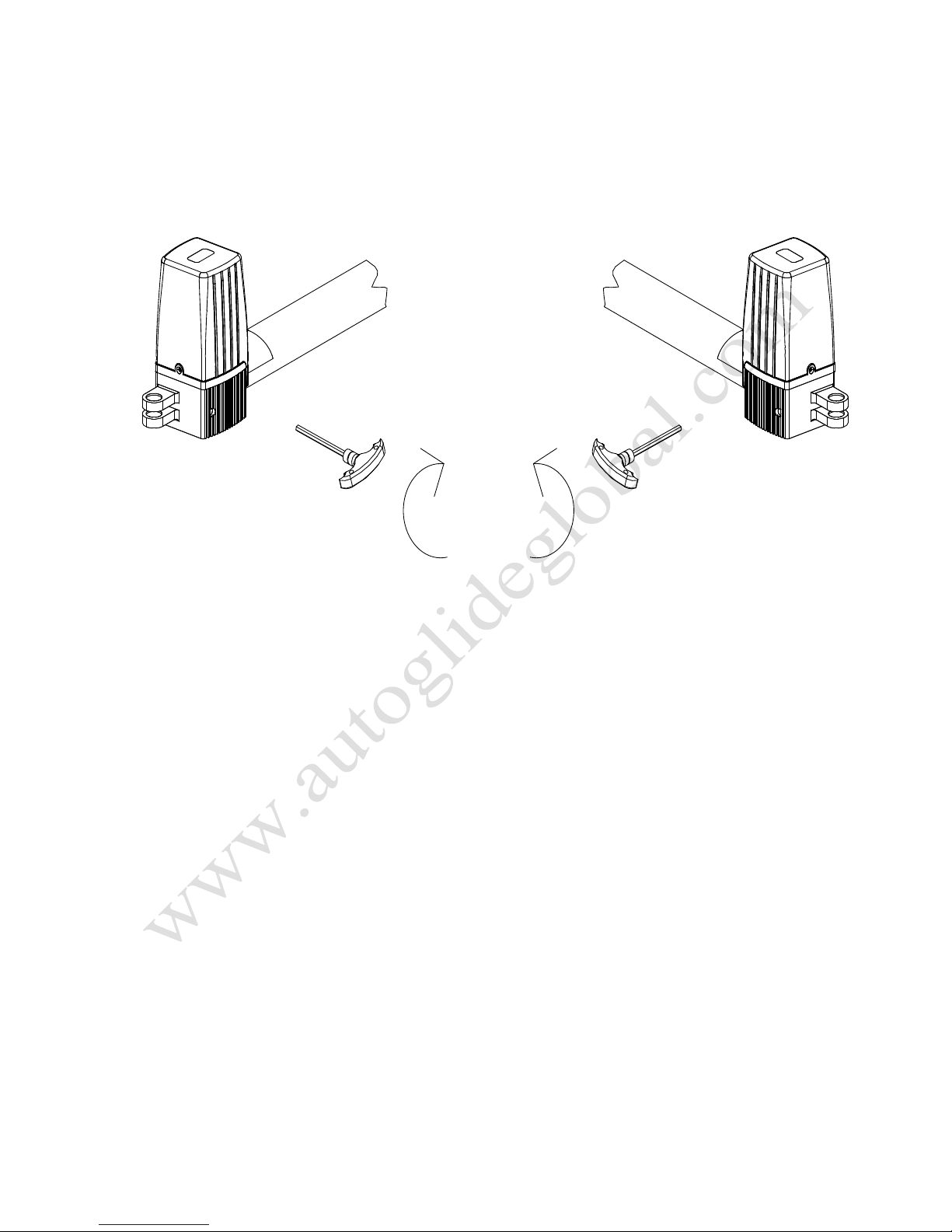

d) Before the installation, please unlock the main engine. Method: Remove the cover, insert the

manual release bar, rotate the bar until the release, as shown in Figure 6, then turn the telescopic

arm to make it easily stretch.

Left engine Right engine

Figure 6

4.3.3 Main engine installation

As shown in Figure 7, the tail of the main engine and the connecting bracket are fixed together

through the installation of screws, and then manually adjust the telescopic arm to the appropriate

length, and finally fix the telescopic arm connector and the front mounting bracket with the

installation screws. Pull the door after the completion of the installation to ensure the entire process

flexible without jamming.

8

Mounting screw (length)

Nut Mounting screw (short)

Nut

Figure 7

Installation direction: door open facing inward (Magro - 500 J)

Note:Note: SafetySafety stopperstopper mustmust bebe installedinstalled

L

K

L=620+5L=620+5

K

<

620+340620+340

A

B

Figure 8

9

100 110 120 130 140 150 160 170 180 190 200

100

110

120

130

140

150

160

170

180

190

200

Max 90°

Max 100°

Max 110°

Max 120°

mmmm

B

A

Figure 9

Note: Value B must be close to or equal to the value A to obtain the best mechanical

advantage.

Installation direction: door open facing outward (Magro - 650 J)

L

K

L=620+5L=620+5

K

<

620+340620+340

A

B

Note:Note: SatetySatety blockblock mustmust bebe

installed,installed, isis proviedprovied byby installerinstaller

Note:Note: SafetySafety stopperstopper mustmust bebe installedinstalled

Figure 10

10

100 110 120 130 140 150 160 170 180 190 200

100

110

120

130

140

150

160

170

180

190

200

Max 90°

Max 100°

Max 110°

Max 120°

mmmm

B

A

Figure 11

Note: Value B must be close to or equal to the value A to obtain the best mechanical

advantage.

Installation direction: door open facing inward (Magro - 500 J)

L

K

L=820+10L=820+10

K<820+540820+540

A

B

Note:Note: SafetySafety stopperstopper mustmust bebe installedinstalled

Figure 12

11

100 120 140 160 180 200 220 240 260 280 300

100

120

140

160

180

200

220

240

260

280

300

Max 90°

mmmm

A

B

Max 100°

Max 110°

Max 120°

Figure 13

Note: Value B must be close to or equal to the value A to obtain the best mechanical

advantage.

Installation direction: door open facing outward (Magro - 650 J)

L

K

L=820+10L=820+10

K<820+540820+540

A

B

Note:Note: SatetySatety blockblock mustmust bebe

installed,installed, isis proviedprovied byby installerinstaller

Note:Note: SafetySafety stopperstopper mustmust bebe installedinstalled

Figure 14

12

Max 120°

mmmm

B

A

Max 110°

Max 100°

Max 90°

100

120

140

160

180

200

220

240

260

280

300

100 120 140 160 180 200 220 240 260 280 300

Figure 15

Note: Value B must be close to or equal to the value A to obtain the best mechanical

advantage.

4.3.4 Size of control box

Figure 16

210

275

127.5

Warnings

·To ensure safety, when door open facing outward, the safety block must be installed at the OPEN

limit position to prevent the door opening angle from exceeding the machine range; the safety

stopper must be installed at the CLOSE limit position, to make two doors stopping at the CLOSE

limit position accurately (as shown in figure 10, 14). When door open facing inward, the safety

stopper must be installed at the CLOSE limit position (as shown in figure 8, 12).

·Before installing the main engine, make sure that the main engine and components are in good

mechanical performance and that the door can be operated manually.

·One control unit can control driving one main engine or two main engines.

·Earth leakage circuit breaker must be installed where the gate movement can be seen, and the

minimum mounting height of control box is 1.5m to protect it from being touched.

·After installation, please check whether the mechanical property is good or not, whether gate

movement after manual unlocking is flexible or not, and whether the infrared sensor (optional) is

installed correctly and effectively.

4.3.5 Control board wiring

M1M2

AlarmAlarm lamplamp

MainMain engineengine 1

ElectricElectric locklock

+24VDC+24VDC

CommonCommon terminalterminal

InfraredInfrared protectionprotection

15VDC15VDC

DoorDoor closeclose buttonbutton

Open/Stop/closeOpen/Stop/close controlcontrol buttonbutton

SingleSingle doordoor openopen buttonbutton

+

24VAC24VAC

BattaryBattary

TestTest buttonbutton

LearningLearning buttonbutton

-

IRIRCOMCOM+PWR+PWR

DCDC24V24V

LIGHTLIGHT MOTORMOTOR 1 MOTORMOTOR 2 LOCKLOCK 15V15V

P.SWP.SW P.SWP.SW

OPOP

CLCL 1

2

CN5CN5

C11C11

U4U4

78L0578L05

TESTTEST

REVREV

LEARNLEARN

+BATTERY-+BATTERY-

U3U3

PK300DCM-2PK300DCM-2

POWERPOWER

ACAC

MOTOR1MOTOR1 MOTOR2MOTOR2

VR1VR1 VR2VR2

ACAC FUSEFUSE

LED8LED8

LED6LED6

LED7LED7

OPOP

CLCL

VX1VX1

LED4LED4

OPOP

LED3LED3

CLCL

VX2VX2

LED2LED2

LOCKLOCK

RY8RY8

LED7LED7

D20D20

IN5408IN5408

C8C8

U2U2

6.2V6.2V

IC2IC2 F1F1

RX1RX1

15A15A

LM317LM317U6U6

8A8A

FUSEFUSE

6A106A10

D14D14

RY6RY6

RY4RY4

10UF10UF

C4C4

10UF10UF

C4C4

RY1RY1RY1RY1RY2RY2

470UF470UF 470UF470UF

C2C2 C1C1

C3C3

78157815

10A10A

U1U1

LED1LED1

6A106A10

D12D12

6A106A10

D13D13

6A106A10 6A106A10

D11D11 D10D10

RY5RY5

U5U5 78127812

Q2Q2 Q3Q3

SENSORSENSOR

CN4CN4CN3CN3CN2CN2

AN1AN1

MainMain engineengine 2

CommonCommon terminalterminal

CommonCommon terminalterminal

Figure 17

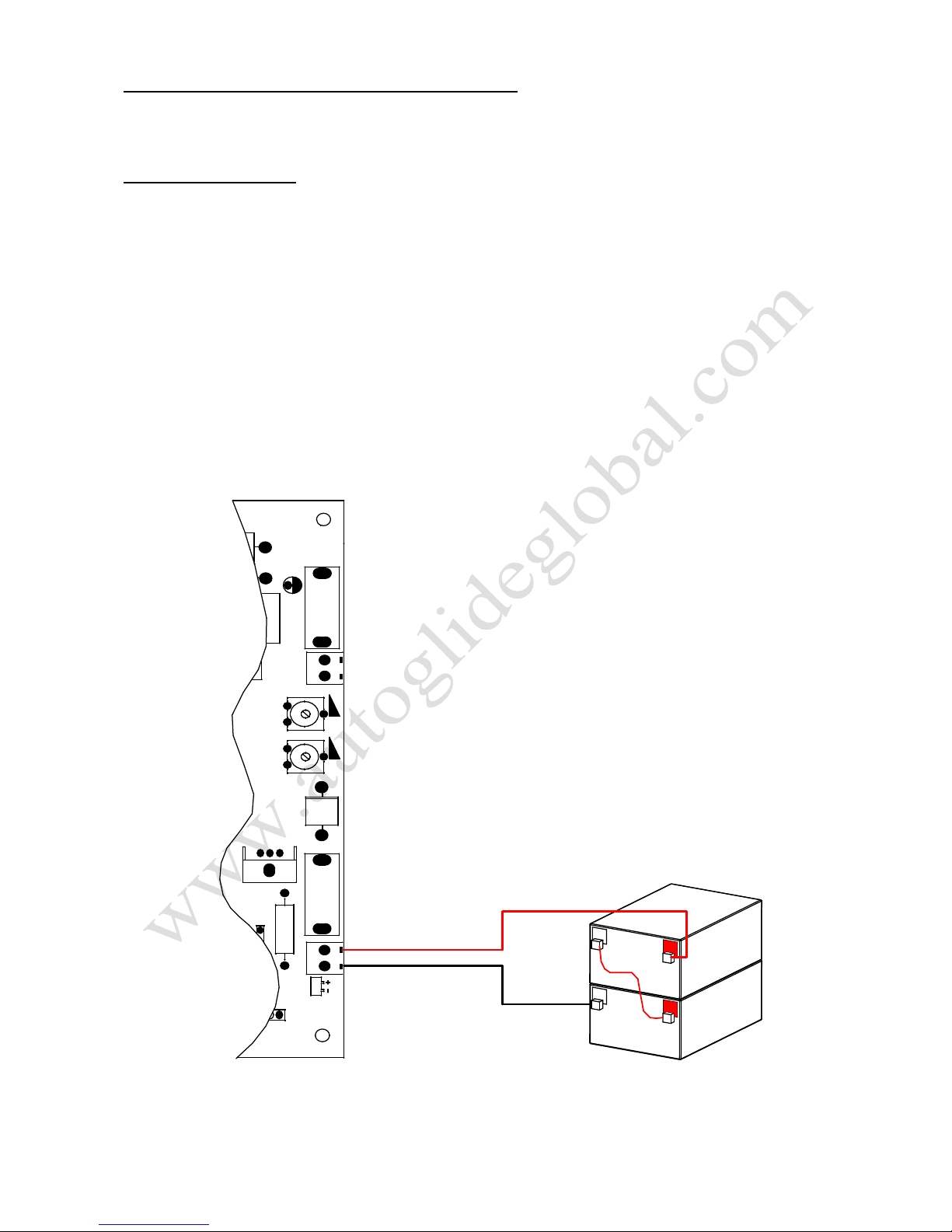

Wiring instruction:

POWER AC terminal 24VAC alternating current power.

+

BATTARY

-

terminal Storage battery.

8P terminal:

LIGHT Alarm lamp (24VDC);

MOTOR 1 Main engine 1;

MOTOR 2 Main engine 2;

LOCK Electronic lock (24VDC).

CN2 terminal

:

+

PWR Power supply for fittings +24VDC;

COM Common;

IR Input of infrared sensor (N.C.).

CN3 terminal: Power supply for fittings 15VDC.

CN4 terminal: Signal input of gate close control button;

Control button common terminal.

CN5 terminal: Open/Stop/Close/Stop loop control button;

Control button common terminal;

Single door opening button.

Transformer wiring

TransformerTransformer inputinput

220VAC/110VAC220VAC/110VAC

TransformerTransformer outputoutput 24VAC24VAC

REVREV

+BATTERY-+BATTERY-

POWERPOWER

ACAC

MOTOR1MOTOR1 MOTOR2MOTOR2

VR1VR1 VR2VR2

ACAC FUSEFUSE

F1F1

RX1RX1

15A15A

LM317LM317U6U6

8A8A

FUSEFUSE

6A106A10

D14D14

C3C3

78157815

10A10A

U1U1

LED1LED1

D12D12D13D13

U5U5 78127812

15

DIP switch

Dial Function

1 Door closing delay function:

ON: Enabled - Motor 2 is 5 seconds delay to close the door than Motor 1;

OFF: Disabled.

2 Door opening status:

ON: Enabled - Motor 1 and motor 2 conduct 0.5-second close action before open

the door;

OFF: Disabled.

3 Single / Double door mode:

ON: Single door mode;

OFF: Double door mode.

4 /

5 Automatic close function:

5 ON 6 ON——Automatic close time is 60s;

5 ON 6 OFF——Automatic close time is 10s;

5 OFF 6 ON——Automatic close time is 5s;

5 OFF 6 OFF——No automatic close function.

6

Adjusting knob

Adjust the sensitivity of meet obstacle: clockwise adjusting VR1 can reduce sensitivity of obstacle of

the motor 1; clockwise adjusting VR2 can reduce sensitivity of obstacle of the motor 2.

Infrared connection

Infrared photocell function: In the closing process, when infrared ray of the infrared sensor is

covered, the gate will open immediately, to protect user and property security.

The distance between photocell receiver and photocell emitter should be not less than 2 meters,

otherwise will affect the induction of the photocell.

If connect the infrared photocell, please remove the short connection between IR and COM on the

CN2 terminal.

16

ComCom OutOut

SETSET NCNC

InfraredInfrared receiverreceiver connectingconnecting

- +

- +

InfraredInfrared emitteremitter connectingconnecting

IRIRCOMCOM+PWR+PWR

LOCKLOCK

15V15V

P.SWP.SW P.SWP.SW

OPOP

CLCL 1

2

CN5CN5

TESTTEST

CN2CN2 CN3CN3

LED7LED7

D20D20

IN5408IN5408

SENSORSENSOR

Figure 19

Adjustment and operation

Remote control operation

Remote control is single button mode, one same button on the remote control to circularly control

the main engine OPEN/STOP/CLOSE/STOP.

OPENOPEN

CLOSECLOSE

STOPSTOP

A

B

C

D

Figure 20

17

Add extra remote control (remote control learning): Remove the upper cover of main engine;

press the learning button S1 on the control board, and indicator light LEARN will flash once and

then go out; press the same button on the remote control twice, the LEARN flashes repeatedly and

then goes out; remote control learning is succeed. At most 25 remote controls can be learned.

Delete remote control: Delete remote control that have been learned; press the learning button

S1 and LEARN will be on; loosen the button until LEARN is off. This indicates that all remote

controls that learned previously have been deleted.

Note: Unlock the door opener, move the door to the middle position, reversely rotate the manual

release bar to lock, electrify and then press TEST button after relay restoration, the door would

automatically operate once, LED4 LED6 on the control panel is the door-opening indicator light that

shows green; LED3 LED6 is the door-closing indicator light that shows red. If the opening-closing

direction is incorrect, the direct-current motor wire could be exchanged to alter the moving direction

of the electrical machine.

Battery connection:

REVREV

+BATTERY-+BATTERY-

POWERPOWER

ACAC

MOTOR1MOTOR1 MOTOR2MOTOR2

VR1VR1 VR2VR2

ACAC FUSEFUSE

F1F1

RX1RX1

15A15A

LM317LM317U6U6

8A8A

FUSEFUSE

6A106A10

D14D14

C3C3

78157815

10A10A

U1U1

LED1LED1

D12D12D13D13

U5U5 78127812

StorageStorage batterybattery

Figure 21

18

Solar panel connection:

CHARGECHARGE LOADLOAD BATTERYBATTERY

+ - + - + -

+

-

+

-

SolarSolar

panelpanel

SolarSolar chargercharger

StorageStorage batterybattery

REVREV

+BATTERY-+BATTERY-

POWERPOWER

ACAC

MOTOR1MOTOR1 MOTOR2MOTOR2

VR1VR1 VR2VR2

ACAC FUSEFUSE

F1F1

RX1RX1

15A15A

LM317LM317U6U6

8A8A

FUSEFUSE

6A106A10

D14D14

C3C3

78157815

10A10A

U1U1

LED1LED1

D12D12D13D13

U5U5 78127812

Figure 22

5. Others

5.1 Maintenance

Check whether the gate operates normally every month.

For the sake of safety, each gate is suggested to be equipped with infrared protector, and regular

inspection is required.

Before installation and operation of the gate opener, please read all instructions carefully.

Our company has the right to change the instruction without prior notice.

19

5.2 Troubleshooting

Problems Possible Reasons Solutions

The gate cannot open

or close normally, and

LED does not light.

1.The power is off.

2.Fuse is burned.

3.Control board power wiring

with problem.

1.Switch on the power

supply.

2.Check the fuse, change the

fuse if burnt.

3.Re wiring according to

instructions.

The gate can open but

cannot close.

1.Photocell wiring with problem.

2.Photocell mounting with

problem.

3.Photocell is blocked by

objects.

4.Sensitivity of obstacle is too

high.

1.If not connect photocell,

please make sure that the IR

and COM short circuit; if

connect infrared sensor,

please make sure the wiring

is correct and the photocell is

N.C.

2.Make sure that the

photocell mounting position

can be mutually aligned.

3.Remove the obstacle.

4.Reduce the sensitivity of

obstacle.

Remote control

doesn’t work.

1.Battery level of the remote

control is low.

2.Remote control learning is not

completed.

1.Change the remote control

battery.

2.Re-conduct remote control

learning.

Press OPEN, CLOSE

button, the gate is not

moving, motor has

noise.

Gate moving is not smoothly.

According to the actual

situation to adjust the motor

or the gate.

Leakage switch

tripped.

Power supply line short circuit or

motor line short circuit. Check wiring.

Remote control

working distance is too

short.

Signal is blocked.

Connect external receiver

antenna, 1.5 meters above

ground.

The gate moves to the

middle position to stop

or reverse.

1.Motor output force is not

enough.

2.Sensitivity of obstacle is too

high.

3.Gate meets obstacle.

1.Check whether the

transformer power is normal,

if not, change the

transformer.

2.Adjust the VR1, VR2.

3.Remove the obstacle.

This manual suits for next models

1

Table of contents

Other Autoglide Gate Opener manuals

Popular Gate Opener manuals by other brands

Mighty Mule

Mighty Mule UL325 SERIES installation manual

Genius

Genius MISTRAL Series GUIDE FOR THE INSTALLER

Gatekeeper

Gatekeeper SKC-500DC owner's manual

CAME

CAME Sipario Series Assembly and installation manual

Cardin Elettronica

Cardin Elettronica 200/BL203 instruction manual

King gates

King gates JET XL 230 Installation and use instructions and warnings

Nice

Nice Toona TO4006 Instructions for installation and use

BFT

BFT IGEA-BT Installation and user manual

King gates

King gates Couper 24 Installation and use instructions and warnings

BFT

BFT deimos ultra bt a 400 Installation and user manual

Mighty Mule

Mighty Mule MM272 installation manual

FAAC

FAAC FAACTOTUM manual