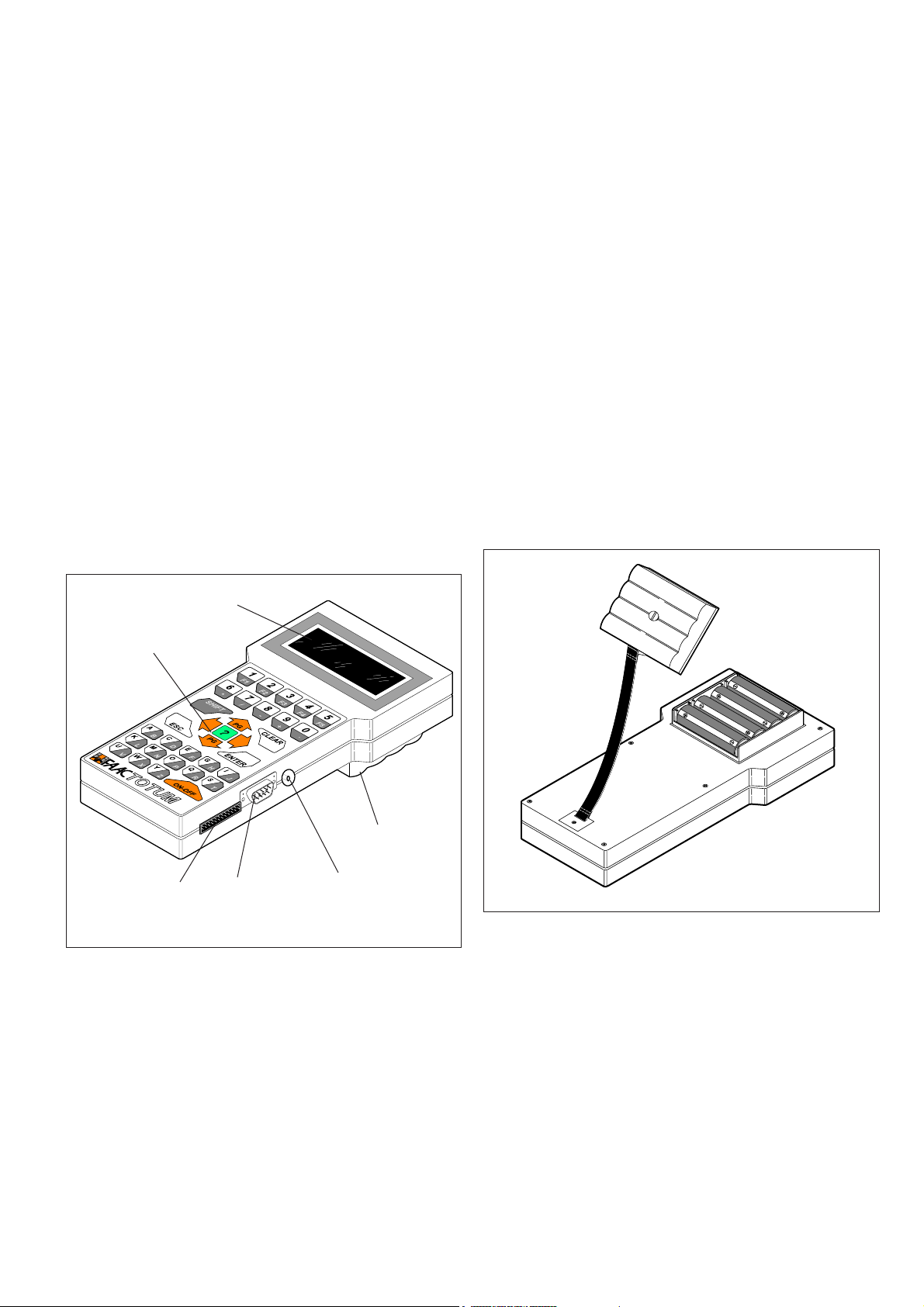

6. USING THE FAACTOTUM

The FAACTOTUM allows easy access to functions grouped

under three different main menus:

- Programming

- Diagnostics

- Special functions

The Programming mode is used to set the 460P card char-

acteristics and operating parameters.

It is important to distinguish between program and operat-

ing logic.

The logic consists of a series of indications (electronic regis-

ters) which instruct the 460P card (the microprocessor) on

how to behave according to the state of the gate and the

state of the terminal block inputs.

The conventional logics (LogicsA,S,E,EP, P,B,C and B/C) are

already available on the FAACTOTUM and it is also possible

to create new customised logics usingAdvanced Program-

ming.

A program includes the logic and other parameters which

specify the characteristics of the automation.

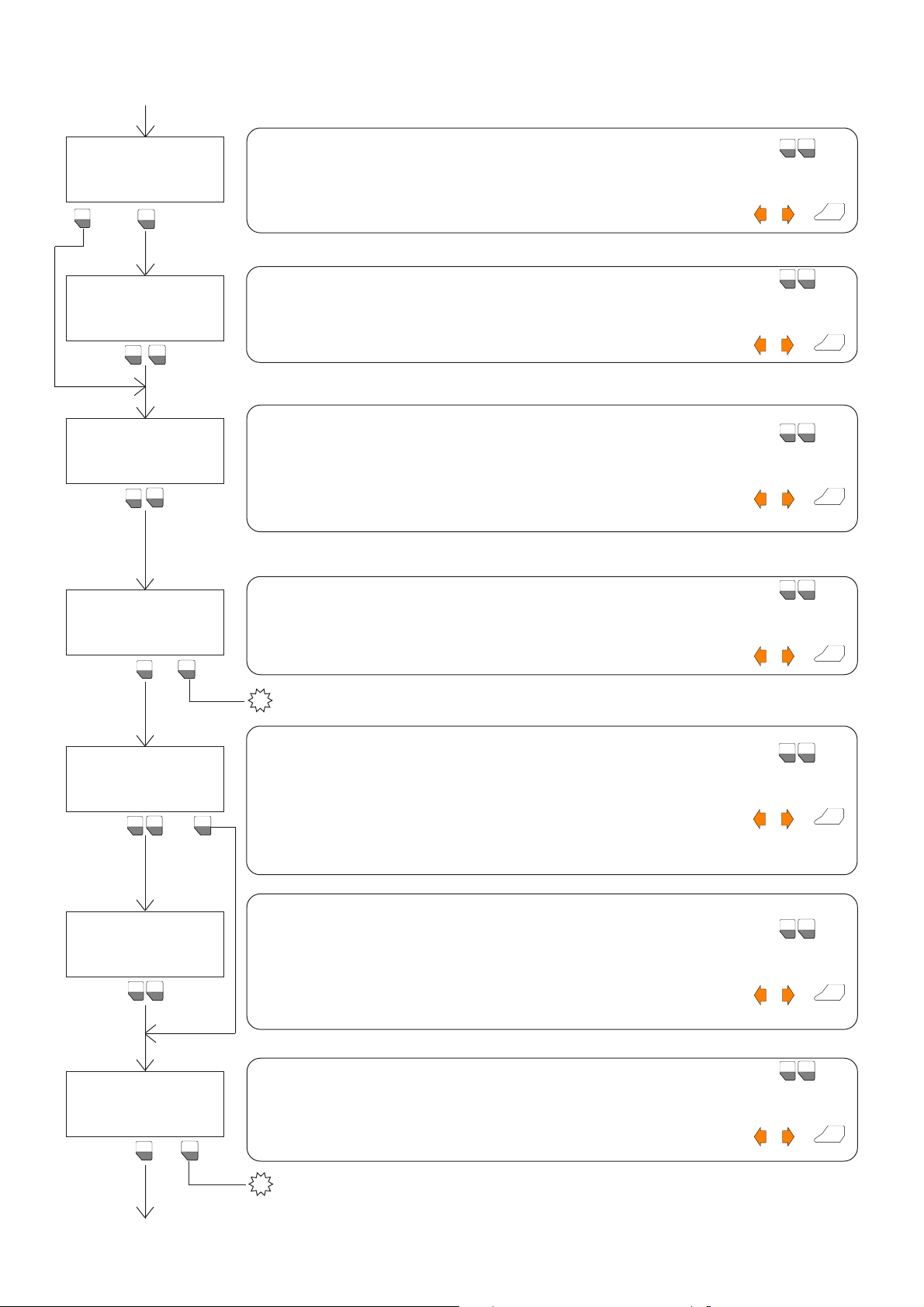

Card programming is performed according to a guided se-

quence of menus which appear in turn on the FAACTOTUM

display.

Generallyeachmenu requires aresponseor apieceof data

to be entered before proceeding to the subsequent menu.

In many of the menus the permitted choices are shown to

simplify programming.

Each selectable choice is associated with a number and

an arrow-shaped cursor indicates the currently active se-

lection.

see PROGRAMMING paragraph

see DIAGNOSTICS paragraph

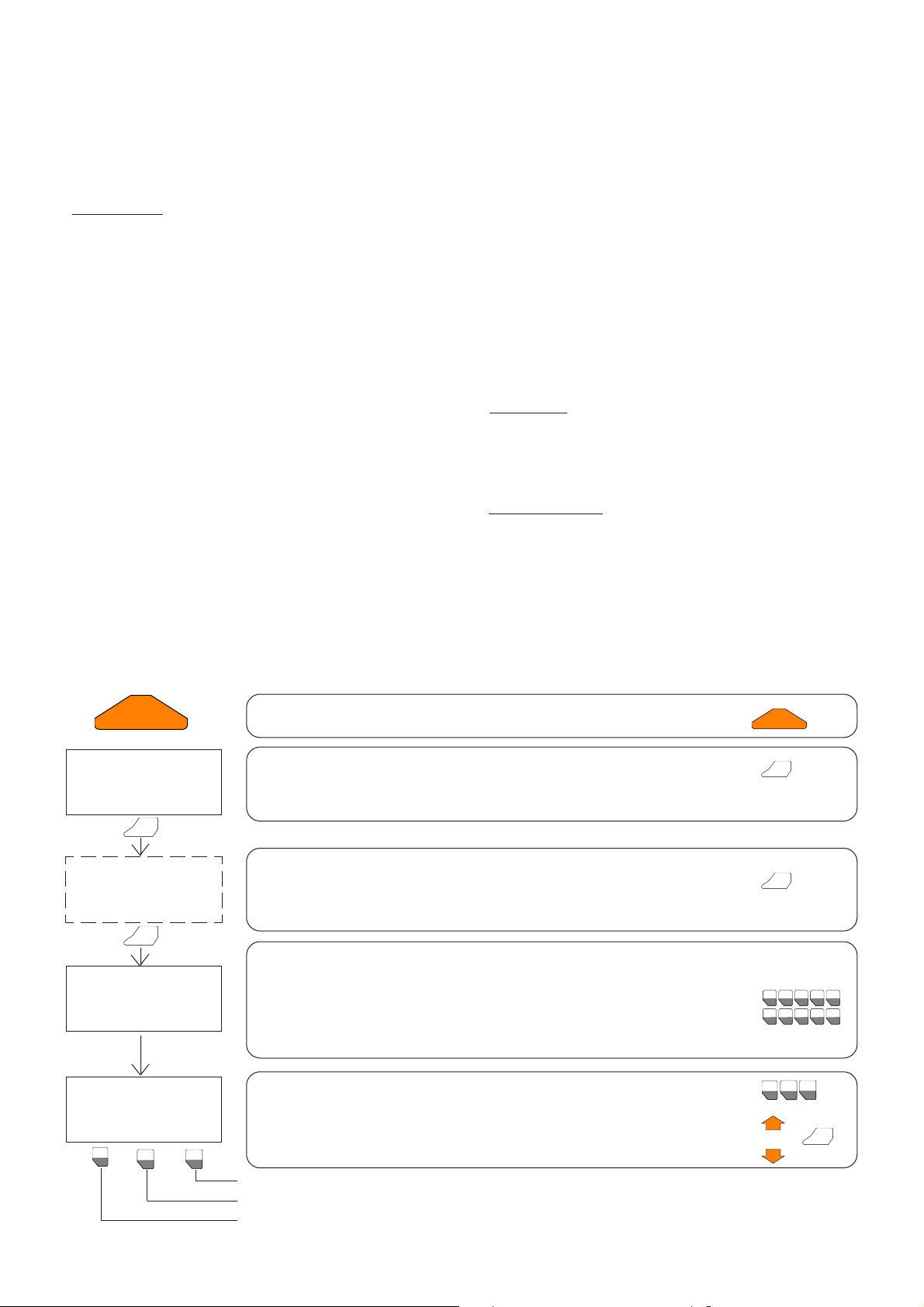

Pressthe ON button.

The initial screen shows the FAACTOTUM version number.

PressENTERtocontinue.Otherwiseafter5secondstheprogramautomatically

proceedstothenextmenu.

This message appears when the battery charge is running out: replace the

batteries.

Press the ENTER key to ignore this message and proceed.

If the password protection function has been enabled, enter the correct nu-

merical code. If you enter the incorrect password, an error message appears

asking you to press ENTER to return to this menu.

➲This function prevents the FAACTOTUM from being used by anyone who does

notknow the password,butit does not preventaccess totheconfigurationsaved

onthe 460P card.

Select the mode by moving the arrow-shaped cursor alongside the desired op-

tion using the vertical movement keys and pressing ENTER,or key in directly the

number for the desired function.

ENTER

ENTER

ON-OFF

PG

PG

ENTER

+

1

F1

3

F3

2

F2

or

1

6

2

7

3

8

4

9

5

0

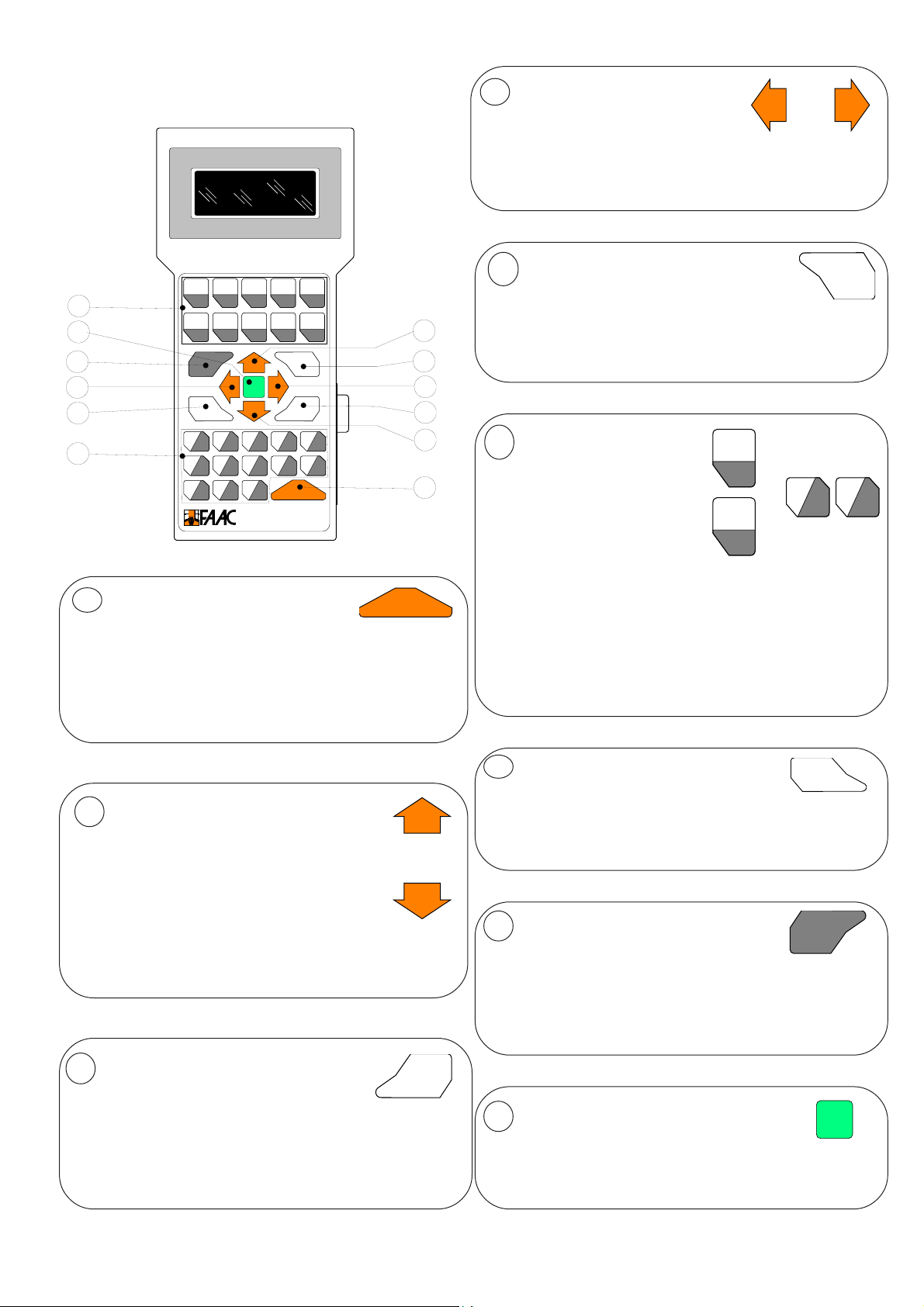

F1 F2 F3 F4 F5

*/-+

.

REPLACE BATTERIES

ON-OFF

FAACTOTUM V1.0

- - - - - - - - - - - - - - - - - - -

FAAC S.p.A.

BOLOGNA - ITALY

INSERT

PASSWORD

*****

ENTER

ENTER

see SPECIAL FUNCTIONS paragraph

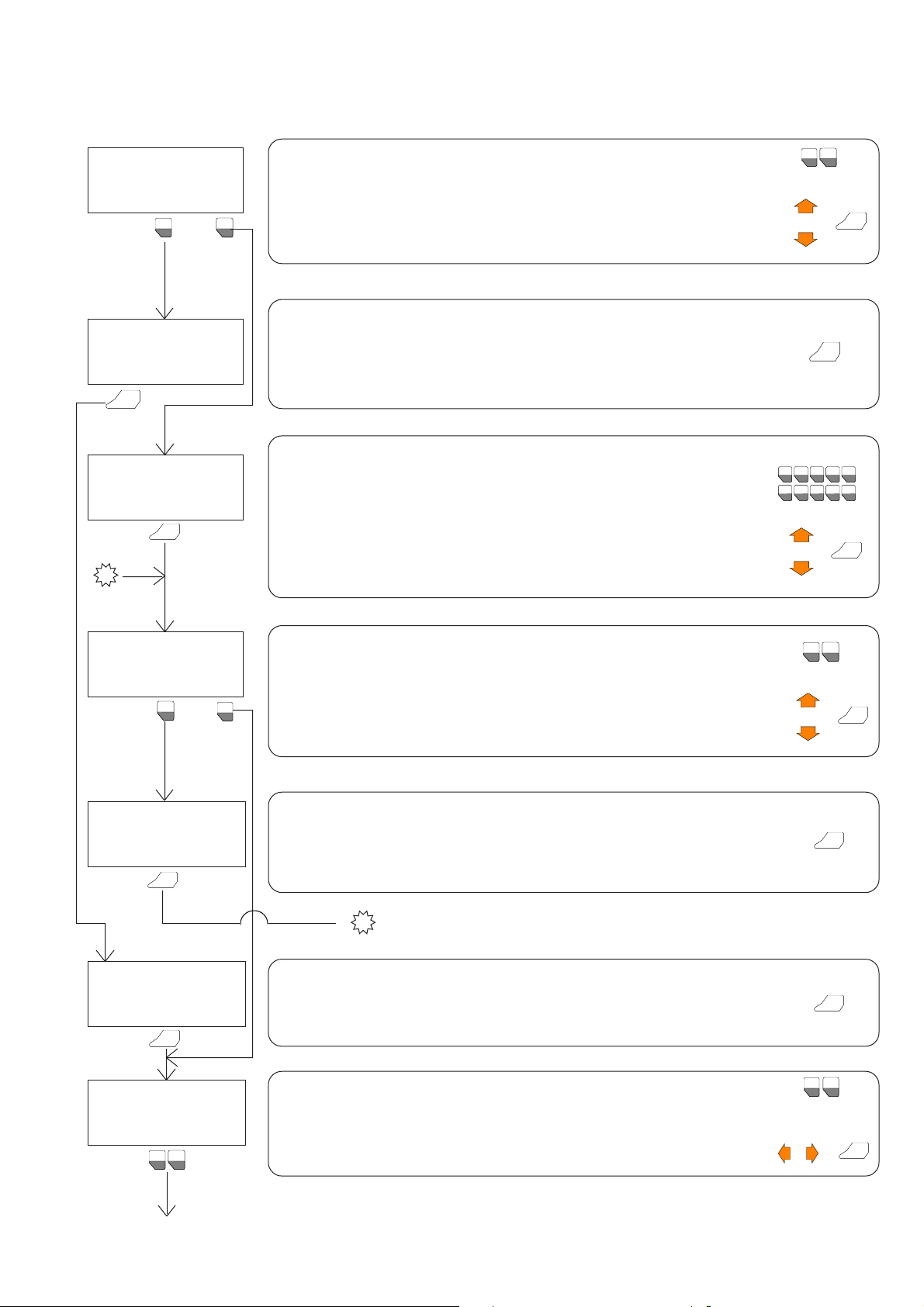

7. MODE SELECTION

There are two ways of changing the selection:

1) move the cursor to the desired choice using the vertical

or horizontal arrow keys (2-4,fig.6) and press ENTER (3,fig.6)

to confirm and go to the next menu.

2)enterthenumber corresponding to thedesired selection.

In the menus requiring a numerical or alphanumeric value

to be entered,after entering it press ENTER to confirm and

go to the subsequent menu.

During the programming phase the choices made with

menus can alter the sequence of the subsequent menus

becausetheones which areunnecessary will automatically

be skipped.

It is not advisable to turn off or disconnect the FAACTOTUM

during the programming sequence.

Until programming has been completed and the program

saved on the card and/or in the FAACTOTUM memory,turn-

ing the FAACTOTUM off will result in the loss of entered data

and it will therefore be necessary to restart programming

from scratch.

The Diagnostics mode can be used to check the voltages

on the card,the state of the terminal block inputs and the

state of the gate.

Also available is a motor test and completed cycle count

function (total and partial).

The Special functions mode comprises menus for language

selection,forpasswordsetting,forresettingthe standard con-

figuration of the card and for connecting the FAACTOTUM

to the PC.

SELECT MODE:

1->PROGRAMMING

2 DIAGNOSTICS

3 SPECIAL FUNCTIONS

4

MENU DESCRIPTION KEYS USED

1

F1

3

F3

2

F2

à

à

à