Autoglide CASA-120-O User manual

AUTOGLIDE

Installation Manual and Owner’s Guide

CASA 120

PLEASE READ THE MANUAL CAREFULLY BEFORE

INSTALLATION AND OPERATION

AUTOGLIDE

Installation Manual and Owner’s Guide

CASA 120

-O

PLEASE READ THE MANUAL CAREFULLY BEFORE

INSTALLATION AND OPERATION

Installation Manual and Owner’s Guide

PLEASE READ THE MANUAL CAREFULLY BEFORE

2

Safeties & Cautions:

AUTOGLIDE series Remote Gate Opener need professional technician for the

installation:

(1)All the operations must be implemented according to the instructions this is

very important to personal safety. Improper installation or misuse of the product

might cause series damage to personal and property.

(2)Please read instructions carefully before installation.

(3)Installation and machine fittings must comply with standards related.

(4)Power supply should be consistent with the requirements of the machine and

well grounding. Electric leakage as well as circuit short protection device should be

equipped.

(5)Before system maintenance, cut off the power , and check if the grounding is

well connected

(6)Strongly recommended to install safety devices (such as infrared protection),

and take frequent check to ensure normal work.

(7)Our company is out of responsibility for any operation or use violating the

instructions.

(8)Our company is out of responsibility for the consequences caused by user’s

ignoring the process requirements of precision components during operation.

(9)Our product is in strict accordance with the instructions for the design and

manufacture. Any violation of the instructions may damage the product or cause

danger.

(10)Our company shall not be responsible for safety problems caused by using

fittings that isn’t produced by our company.

(11)Any attempts to change the structure of the components is forbidden.

(12)The installation personnel should give detailed operation methods to the users

as well as the regulations under emergency, also the “instructions ”should offered.

(13)During installation, keep the children and other unrelated person away from

the Installation site.

(14)Before electric control system operate, remove all the barriers within the door

covering area and any vehicles or person are forbidden to pass.

(15)Both the installation position and height of main control box should be proper,

do not be exposed to sunlight and rain, forbidden to let children to operate the

remote control as well as control panel switch.

(16)If it is neces

sary to install a outer shield, consider that if it may shield signal of

the remote control.

(17)

Place the remote control out of the reach of children in case of accident.

(18)

Any attempts to dismantle this machine privately is forbidden, please contact

professional technician.

(

19) Please save the instructions properly for future use.

Product introduction:

Function & Characteristic:

①

Install overheat protector in AC

when the temperature reach rated power after a long time working, in order to extend

the using life of motor.

②

The product has speedy clutch, inset the release key and turn it

re

lease the clutch when power off

②

Machine running smoothly, parking without inertia, accurate position.

remote control as well as control panel switch.

sary to install a outer shield, consider that if it may shield signal of

Place the remote control out of the reach of children in case of accident.

Any attempts to dismantle this machine privately is forbidden, please contact

19) Please save the instructions properly for future use.

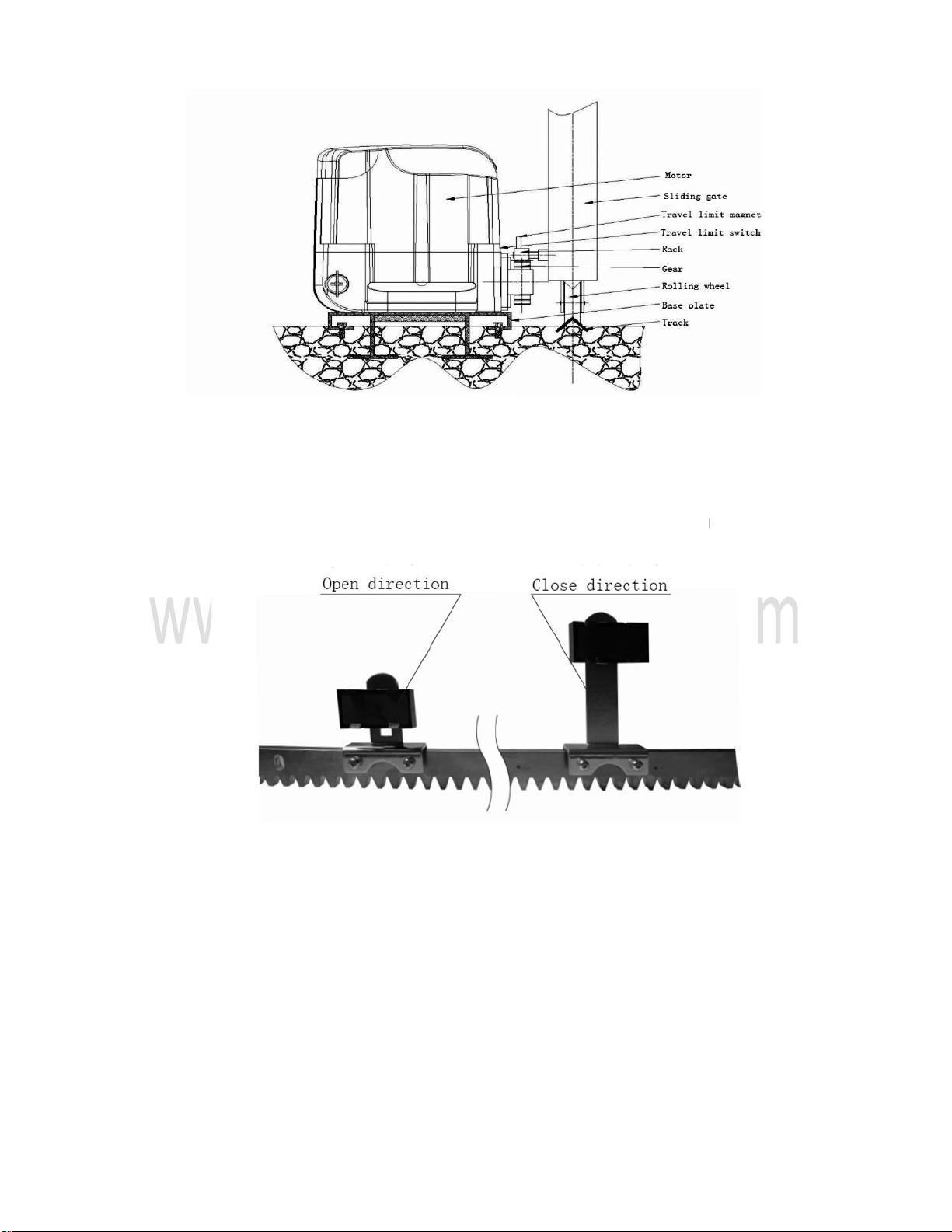

EXTERNAL SIZE (Fig.1)

Function & Characteristic:

Install overheat protector in AC

motor. The motor will cut off power automatically

when the temperature reach rated power after a long time working, in order to extend

The product has speedy clutch, inset the release key and turn it

100 degrees to

lease the clutch when power off

to realized manual operation. (Fig.2)

Machine running smoothly, parking without inertia, accurate position.

sary to install a outer shield, consider that if it may shield signal of

Place the remote control out of the reach of children in case of accident.

Any attempts to dismantle this machine privately is forbidden, please contact

motor. The motor will cut off power automatically

when the temperature reach rated power after a long time working, in order to extend

100 degrees to

Technical parameters:

Packing list

Picture

Screw (M8×30) ,washer, Nut

Model

Power supply

(Vac)

Max. gate weight (KG)

Max

.torque

Rated Power (W)

Tooth number of gear

Overheat protection (

Protection Class

Speed (m/min)

Temperature

Noise

Certification

Fig.2

Name

Quantity

Motor

Instruction Manual

Transmitter

Base plate

Screw (M8×30) ,washer, Nut

Limit switch magnet

CASA 120-

O

(Vac)

phase 110V/220V

~

240V

Max. gate weight (KG)

1200

.torque

35Nm

Rated Power (W)

550W

Tooth number of gear

15

Overheat protection (

℃) 120

Protection Class

IP44

Speed (m/min)

12

(℃) –45

~+

65

≤56dB

Certification

CCC/CE

Quantity

1

1

2

1

4

2

O

Picture

Expansion Bolt(M12×100)

Installation Diagram:

Note: Before installation please check if the motor meets your demand.

Name

Quantity

Bracket for limit switch

Release Key

Expansion Bolt(M12×100)

Note: Before installation please check if the motor meets your demand.

Fig.3

Quantity

2

1

4

Note: Before installation please check if the motor meets your demand.

Installation and Debugging:

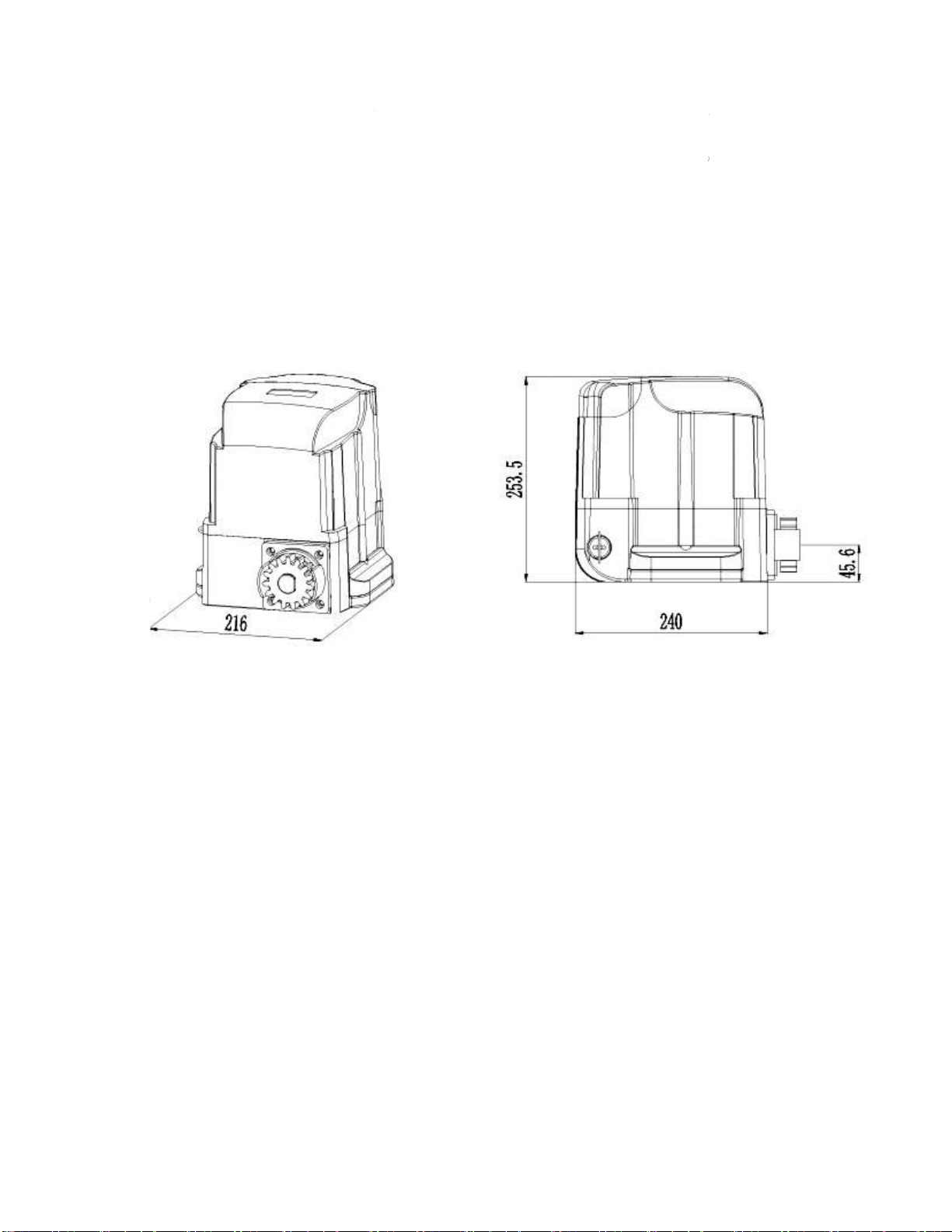

Gear installation

(Distance between gear and door body is

Base installation

:

Rack installation:

(Remark: Please check whether the sliding gate can be mov

before installation rele

ase the clutch with

Warning: There must be a clearance between the rack and gear as Fig. 7, in

case the motor function and manual operation may be

Installation and Debugging:

(Distance between gear and door body is

24mm)

Fig.5

Fig.6

(Remark: Please check whether the sliding gate can be mov

ed smoothly

ase the clutch with

the release key)

Fig.7

Warning: There must be a clearance between the rack and gear as Fig. 7, in

case the motor function and manual operation may be

affected.

ed smoothly

Warning: There must be a clearance between the rack and gear as Fig. 7, in

Limit switch bracket installation:

Move the gate manually to the open limit and

then fix t

he magnet bracket at the limit points on the rack. Pay attention to the

direction of limit switch bracket: if it i

Clutch lock:

When the

motor is out of electricity or ha

can use clutch key to release clutch lock then realize manual operation to open or

close the door.

Note: Engage the clutch when the motor resume normal work.

Limit switch bracket installation:

Move the gate manually to the open limit and

close limit,

mark the points on the rack,

he magnet bracket at the limit points on the rack. Pay attention to the

direction of limit switch bracket: if it i

s anti-installed, the motor can

not be positioned .

Fig.9

motor is out of electricity or ha

s faults, can

not work normally, customer

can use clutch key to release clutch lock then realize manual operation to open or

Note: Engage the clutch when the motor resume normal work.

Fig.8

mark the points on the rack,

he magnet bracket at the limit points on the rack. Pay attention to the

not be positioned .

not work normally, customer

can use clutch key to release clutch lock then realize manual operation to open or

Note: Engage the clutch when the motor resume normal work.

Fig.10

Install the electricity plug to an appropriate position according to safety standard.

Install the mounting plate as fig.11.

Note: ensure the base board is in horizontal.

Fig.11

Fix the base plate onto the frame with four expansion bolts (Fig.11) and put the

motor on the base plate, regulate the output gear to match the gear rack, then fasten

the nuts. (fig.12)

Fig.12

Weld the cylindrical nuts for gear rack fixed on proper position in the lower part of

door (Fig. 8), then fasten the gear rack onto the cylindrical nut by bolts or welding.

Regulate the washer behind the base plate base to make the gear match the rack.

(Note: the distance between gear and gear rack should keep1-2 mm)

The limit way of this model is through electrical magnetic limit switch. Please follow

fig. 7 and fig. 9 to install fixed-plate for limit magnetic steel.

Installation of fixed-plate for limit magnetic steel: use clutch key to release clutch like

fig.10.

Move the gate manually to the open limit and close limit, mark the points on the rack,

then fix the magnet bracket at the limit points on the rack, then close clutch for

automatic control. Regulate the position of fixed plate for limit magnetic steel till the

door can open and close properly, and fasten the fixed-plate for limit magnetic steel

finally.

Warning:

Maintenance operations and repairs can be only performed by qualified

technicians. Our company will not bear any legal liability for non-technicians operations.

USER GUIDE:

6-

1 User need to have a regular check whether the door is sliding smoothly,

add lubrication grease on the sliding rack regularly.

Common faults and removal methods:

(

Non professional is forbidden to touch the line and components on the control

board so as to avoid unnecessary damage)

1 User need to have a regular check whether the door is sliding smoothly,

add lubrication grease on the sliding rack regularly.

Common faults and removal methods:

Non professional is forbidden to touch the line and components on the control

board so as to avoid unnecessary damage)

1 User need to have a regular check whether the door is sliding smoothly,

Non professional is forbidden to touch the line and components on the control

11

AUTOGILE 1200KG SLIDING MOTOR

INSTRUCTION MANUAL

CASA 120-O

As newly developed product, this intelligent built-in controller for sliding door is

controlled by computer with reliable performance, with resistance rebound, when compared

with other liking products, it covers the following advantages:

1. Anti-collision design: when the door body travel is completed, only after press reverse

key, the motor can be activated so that the over-travel can be avoided.

2. Motor time protection: the default value is 90s in order to avoid motor continuously

working when travel is out of order for long time.

3. Auto close: the time can be adjust from 1-120 seconds.

4. Motor running force adjustment: running force of the motor is adjustable.

5. Motor resistance force adjustment: the resistance force of motor is adjustable.

6. Motor max starting torque: the starting torque is adjustable.

7. Soft start function: motor with soft star and soft stop, stable working and no inertia.

8. Adjust slow speed for push force:adjust the force for slow stop and start.

9. Single and four keys function: Interchange of single and four keys.

10. High security: AUTOGLIDE model with remote control function, control sensitively,

control long distance, strong anti-interference. Using the most advanced jump codec

technology, have 100 million password groups and cannot be deciphered , is more safe and

secretive than the traditional remote control (6561 password groups) in the market.

11. Anti-clamping function: when some barrier blocks the infrared rays, the door stops

travel and moves reversely in case clamp some people and object.

Technical parameters:

Voltage input: 220V+10%

Max output current: 5A Fuse: AC220V 5A

Remote control distance: open space >30-50 meters

Installation steps:

1. Motor installation

2. Power connecting and debugging

Usage of remote control:

The control box can only match 30PCS remote controls, when the 31th remote

controller is coded, the first one will invalid

A.

Remote control keypad operation: press the direction keys

remote control the motor

will work,

B. Lock manual keyboard: when press

locked( the indicator light flash

keys are locked, and can unlocked by p

When the control box is locked, only by press

keys of the remote control and manual operation key of the control box can be used.

2. Power connecting and debugging

Usage of remote control:

The control box can only match 30PCS remote controls, when the 31th remote

controller is coded, the first one will invalid

Remote control keypad operation: press the direction keys

( close

open)

will work,

press stop the motor will stop.

B. Lock manual keyboard: when press

lock of the remote control,

the control box is

locked( the indicator light flash

ing)

; i.e. Only the manual bottom and remote direction

keys are locked, and can unlocked by p

ressing stop

(the indicator light stop flashing).

When the control box is locked, only by press

stop of the remote control,

keys of the remote control and manual operation key of the control box can be used.

The control box can only match 30PCS remote controls, when the 31th remote

open)

of the

the control box is

; i.e. Only the manual bottom and remote direction

(the indicator light stop flashing).

the direction

keys of the remote control and manual operation key of the control box can be used.

C. Remote control lock function

other companies. For other companies,

off power,

the control box can be unlock.

key lock locked, only

remote control can unlock, power

to avoid thieves and other mishandles to cause some unnecessary loss. Since our key

is special (

only can unlocked by

program,

and the remote control is study style.

control). If use the lock

to study, the system will shut the lock function automatically and

will have no remote control lock function. All the remote control have no lock

leave the factory. Users can use any key among

and the lock function of remote control will start working. How to identify whether the

control board of remote control is locked or not: when the control board is locked, the

indicator light on control board flashing continuously, the buzzer will send ou

when you press any key on control box or remote control, and the motor do not work

D. Remote control increased: press the

the function indicator light off, press the

control lock function, finish setting after the function indicator light flashes three times; if

you don’

t need remote control lock function, press the

can use normally after the function indicato

the second, third remote control, etc.

E. Delete password:

press and hold

light, then release, all the coded passwords deleted.

Using method of

infrared interface

The control box can be connected with infrared (connect like following fig.). Make the

infrared to normal open during installation. During door closing, the motor will stop for 2

seconds if infrared protection device have actio

two-

wire electric eye, + connect to +,

C. Remote control lock function

: the key lock of our

remote control is different from

other companies. For other companies,

if the control box is locked by

lock

the control box can be unlock.

So the lock is meaningless.

However, once our

remote control can unlock, power

-off is useless. That’

s the real lock

to avoid thieves and other mishandles to cause some unnecessary loss. Since our key

only can unlocked by

stop of remote control),

so we do special deal to the

and the remote control is study style.

(Refer to the study instructions of remote

to study, the system will shut the lock function automatically and

will have no remote control lock function. All the remote control have no lock

function when

leave the factory. Users can use any key among

“ open, close,

stop

and the lock function of remote control will start working. How to identify whether the

control board of remote control is locked or not: when the control board is locked, the

indicator light on control board flashing continuously, the buzzer will send ou

t sound

when you press any key on control box or remote control, and the motor do not work

D. Remote control increased: press the

“Study”

key on the control board for one second and

the function indicator light off, press the

open two times continuously

if you need remote

control lock function, finish setting after the function indicator light flashes three times; if

t need remote control lock function, press the

lock

two times continuously

can use normally after the function indicato

r light flashes three times. Same

operations for

the second, third remote control, etc.

press and hold

“Study”

for 8 seconds and indicator light turn on normal

light, then release, all the coded passwords deleted.

infrared interface

The control box can be connected with infrared (connect like following fig.). Make the

infrared to normal open during installation. During door closing, the motor will stop for 2

seconds if infrared protection device have actio

n and t

hen perform open action.

wire electric eye, + connect to +,

-to FSW.

remote control is different from

lock

, only by cut

However, once our

s the real lock

to avoid thieves and other mishandles to cause some unnecessary loss. Since our key

lock

so we do special deal to the

(Refer to the study instructions of remote

to study, the system will shut the lock function automatically and

function when

stop

” to re-study,

and the lock function of remote control will start working. How to identify whether the

control board of remote control is locked or not: when the control board is locked, the

t sound

“DI DI”

when you press any key on control box or remote control, and the motor do not work

key on the control board for one second and

if you need remote

control lock function, finish setting after the function indicator light flashes three times; if

two times continuously

and

operations for

for 8 seconds and indicator light turn on normal

The control box can be connected with infrared (connect like following fig.). Make the

infrared to normal open during installation. During door closing, the motor will stop for 2

hen perform open action.

If it is

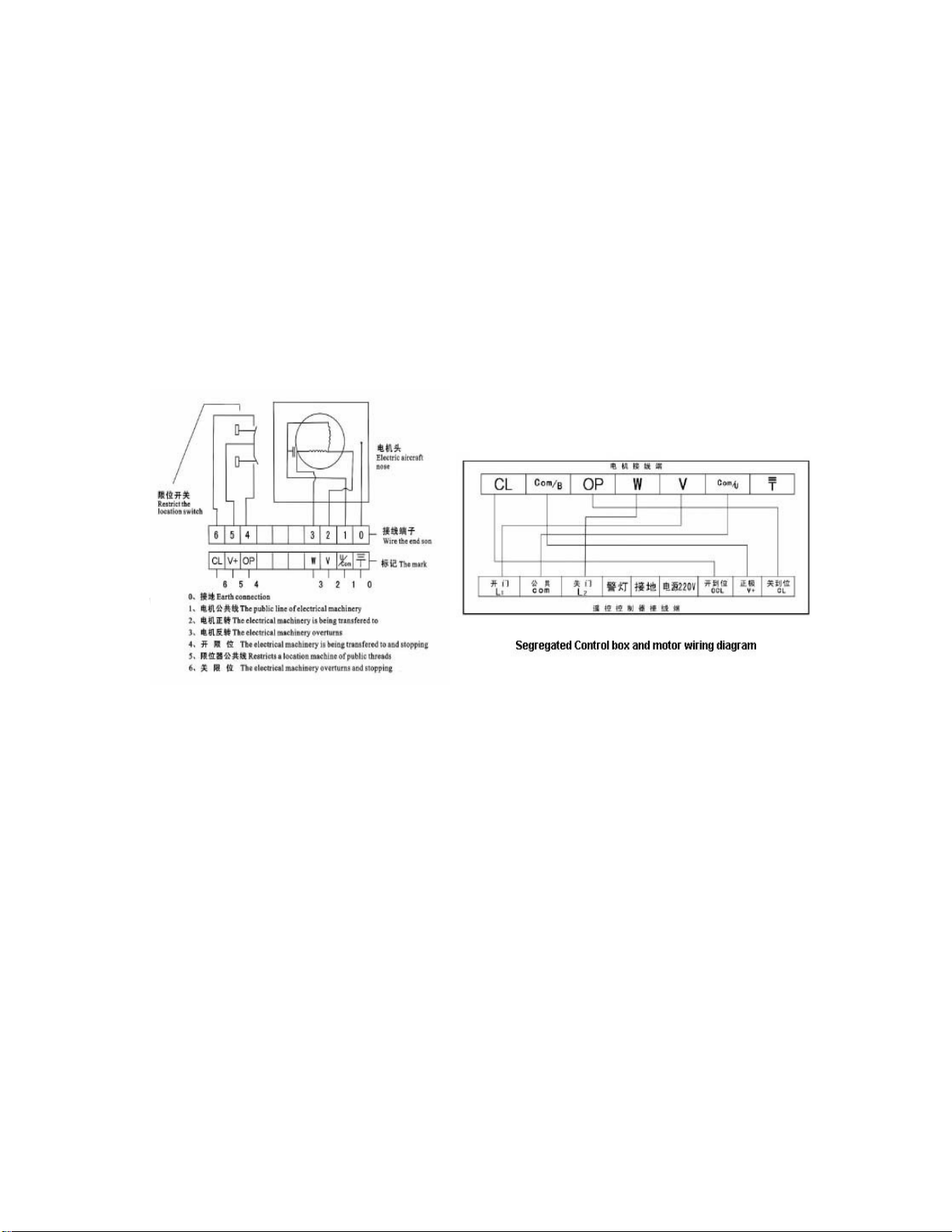

Travel connection:

Travel can choose machinery or dry reed board travel.

PUBLIC connect to -

, direction wires connect to

Motor connection:

Motor must installed according to the following diagram,

motor GND line connect to COM on the circuit board, or will cause the problem of

motor single direction operation.

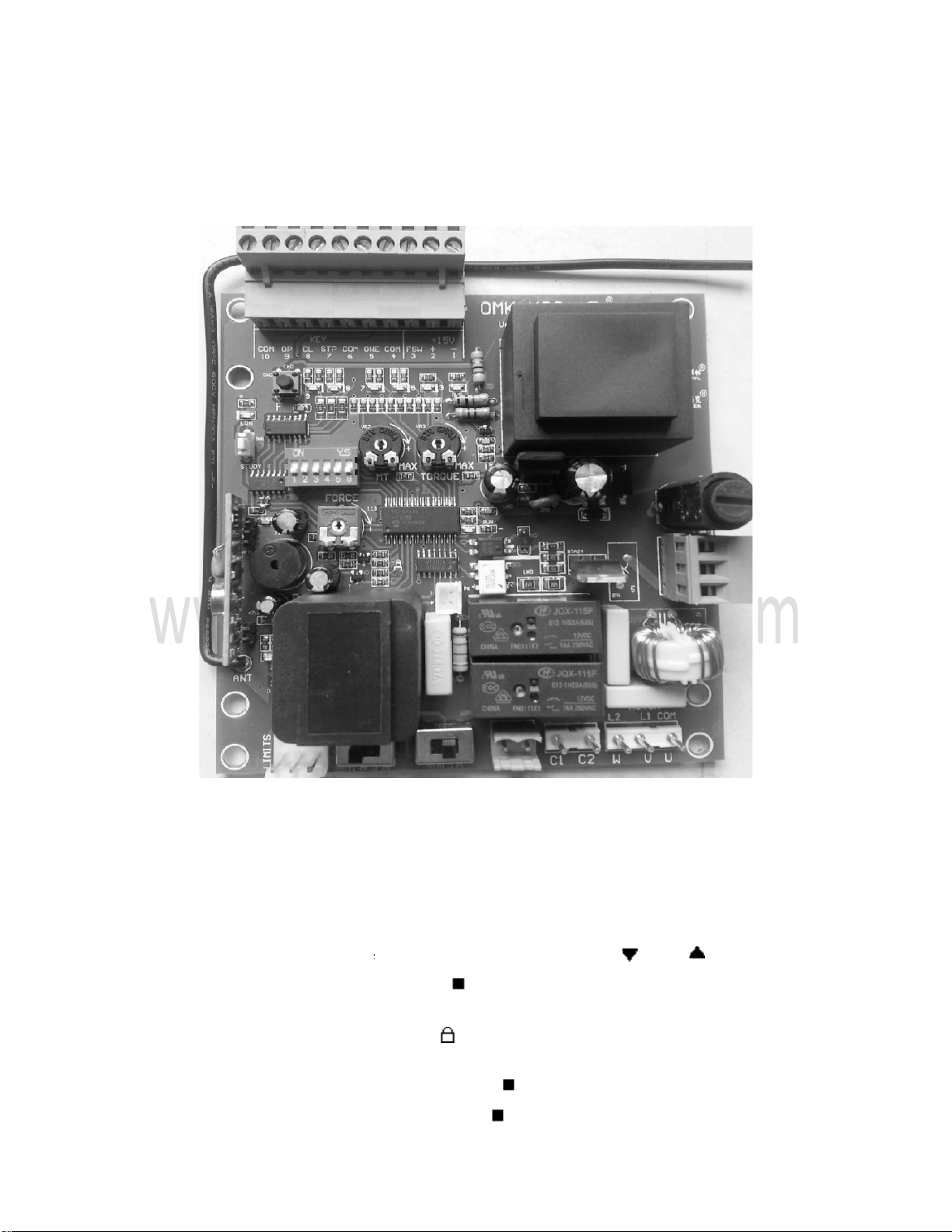

Setting of Red DIP switch on control boa

DIP 1 switch : Single key circulation function

Turn on DIP1 switch to OFF,

Turn on DIP1 to ON=single key circulation,

perform circulation action

.For example:

press open

again=door stop,

again=door open, circulat

e in this way.

DIP 2 switch : OFF

For push switch ( com & one)

DIP 3 switch :

Auto close function

Travel can choose machinery or dry reed board travel.

, direction wires connect to

C.L and O.L.

Motor must installed according to the following diagram,

motor GND line connect to COM on the circuit board, or will cause the problem of

motor single direction operation.

Setting of Red DIP switch on control boa

rd:

DIP 1 switch : Single key circulation function

open close stop

keys control individually.

Turn on DIP1 to ON=single key circulation,

that is with which key to study,

this key will

.For example:

use open to study ,press open

= door open,

again=door stop,

press open once more=door close,

press

e in this way.

Use single key control function.

For push switch ( com & one)

Auto close function

motor GND line connect to COM on the circuit board, or will cause the problem of

keys control individually.

this key will

= door open,

press

open

15

Turn on DIP 3 switch to OFF, without auto close function.

Turn on DIP 3 switch to ON with auto close function.

Auto close time setting: Turn on DIP3 switch and DIP6 switch to ON,

Each press of F key the auto close time delay one second, when reach the demand time,

return DIP6 back to OFF. Auto time setting is completely. When setting auto close

function, the door open to the limit, and perform auto close delay, at the same time function

light flash in 1HZ.

When reach the setting time, the door will auto close.

DIP 4 switch: Soft start and stop function

Turn on DIP 4 to OFF, without soft star and stop function.

Turn on DIP 4 to on, with soft star and stop function.

DIP 5 switch : Maximum starting torque function

Turn on DIP 5 to OFF, the motor starting by MT force

Turn on DIP 5 to ON, the motor starting by full output torque

DIP 6 switch : Set

Turn on DIP6 switch to ON to set the function of circuit board, and return it back to OFF

when the setting is completely.

Auto close function setting:

Users can set the auto close function as their need: stir DIP[3] to ON, auto close function

Working, shut down when connect to OFF. When the auto close function working, the

door travel to limit and execute auto close timing with indicator light flash at 1 Hz. When

reach the Setting time, the controller execute auto close operation.

Soft start and soft stop function setting:

Noted that the soft start and soft stop function can only be set after installation of open and

close limits→power off→ Turn on DIP 4 switch and DIP 6 switch to ON→ power on→

press F key two seconds→ motor start and the door open completely→auto close→ close

completely→ Return DIP 6 switch back to OFF→setting completely.

Note: DIP 6 switch must be return back to OFF after setting.

Otherwise F key as single open function will be invalid.

Function adjustments: increase by clockwise, decrease by anticlockwise

FORCE:

adjust

the strength of resistance when meet obstructions during closing or

opening.

MT:

adjust the starting strength during soft star

TORQUE:

adjust the travel torque of motor:

can be adjust to avoid clamping when the door run into resistance. (Note: at

this time motor is still working, just its force is not strong enough to push the

door, so you must stop the motor working manually

power-

off ),to avo

Attentions:

1. The working voltage of the control box is

2. The wire buried underground should use thick, double conductor. The three

shielding layer of trave

l switch should be well grounded and not a adapter between. The

conducting wire should be set into PVC tube or pipe and do waterproof processing.

3.The default value is 90 seconds. Use battery of DC12V, 27A for remote controller,

working life is one year.

Remote controller can not be moisture, crashed. If want to reset

password, please refer to password setting.

4. If can only control a short distance, please check if the mainframe is installed in the

position

that is shielded by metal objects or nearby.

5. Non-

professional personal is forbidden to install the control box and circuit. We are

out of responsibility

for any personal safeties caused.

6. If the control box has any qu

the strength of resistance when meet obstructions during closing or

adjust the starting strength during soft star

.

adjust the travel torque of motor:

During operating of motor,

the travel

can be adjust to avoid clamping when the door run into resistance. (Note: at

this time motor is still working, just its force is not strong enough to push the

door, so you must stop the motor working manually

(by remote control or

off ),to avo

id long-

time running of the motor and causes problems.

1. The working voltage of the control box is

~220V+ 10%, don’

t connect to 380V.

2. The wire buried underground should use thick, double conductor. The three

l switch should be well grounded and not a adapter between. The

conducting wire should be set into PVC tube or pipe and do waterproof processing.

3.The default value is 90 seconds. Use battery of DC12V, 27A for remote controller,

Remote controller can not be moisture, crashed. If want to reset

password, please refer to password setting.

4. If can only control a short distance, please check if the mainframe is installed in the

that is shielded by metal objects or nearby.

professional personal is forbidden to install the control box and circuit. We are

for any personal safeties caused.

6. If the control box has any qu

ality problem, please send to ag

ent for dealing with. If

the strength of resistance when meet obstructions during closing or

the travel

torque

can be adjust to avoid clamping when the door run into resistance. (Note: at

this time motor is still working, just its force is not strong enough to push the

(by remote control or

time running of the motor and causes problems.

t connect to 380V.

2. The wire buried underground should use thick, double conductor. The three

-core

l switch should be well grounded and not a adapter between. The

conducting wire should be set into PVC tube or pipe and do waterproof processing.

3.The default value is 90 seconds. Use battery of DC12V, 27A for remote controller,

Remote controller can not be moisture, crashed. If want to reset

4. If can only control a short distance, please check if the mainframe is installed in the

professional personal is forbidden to install the control box and circuit. We are

ent for dealing with. If

17

repaired by self, we are out of responsibility for any loss caused by self-repair.

Simply faults and debug:

Ⅰ. When control box has no effective to motor, distinguish is the control box or wire fault.

Judging method: through the indicator lights in the control box to judge the position of

fault. The common faults:

1. Wire broken or unwell connection can check by multimeter.

2. Moisture and electricity leakage, can change wire.

Ⅱ. The fuse of control box burned after connecting to power, check if the voltage is high or

Connect to 380V mistakenly.

Ⅲ. When remote controller is out of order, try to redeploy a new one or check if the remote

Controller has electricity.

Ⅳ. Remote control distance is short:

1. Control in open space >30 meters: since radio wave is affected by weather, the control

Distance will be shorter under bad weather like rainy, foggy, windy. This is normal.

2. Old battery will also make the control distance shorter. Try after replace a new battery.

www.autoglideglobal.com

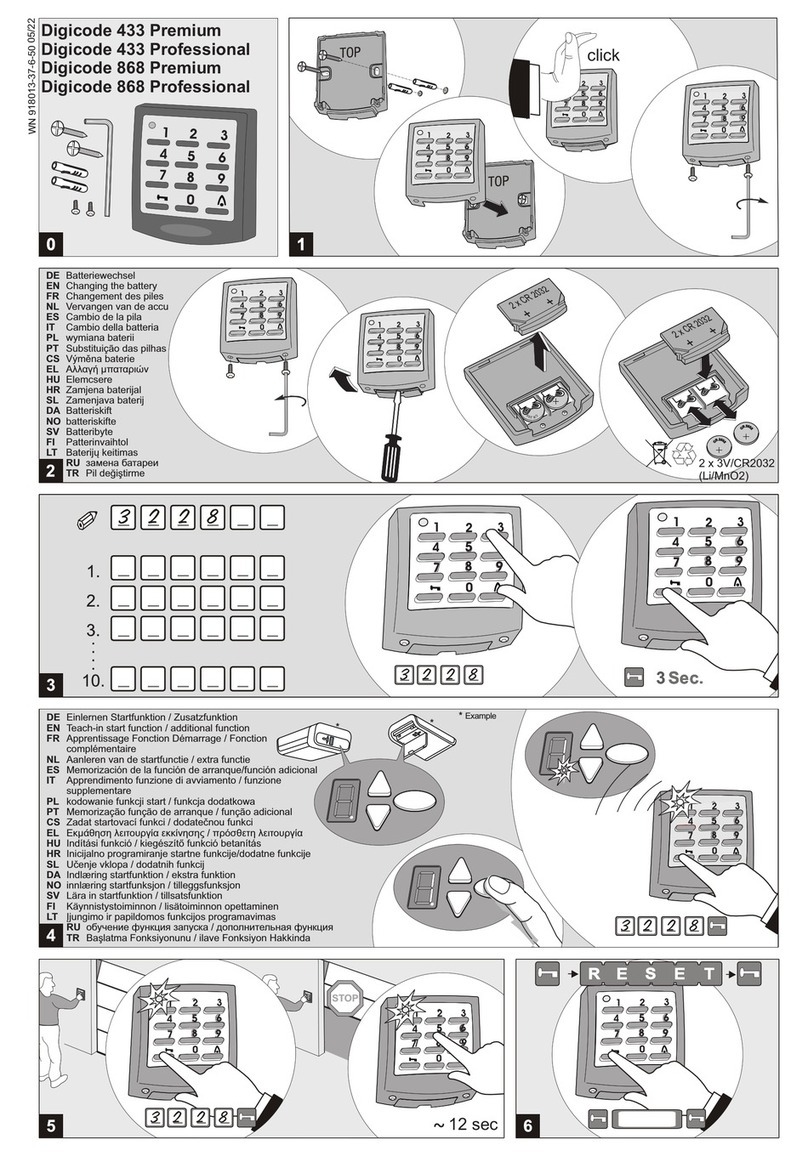

Table of contents

Other Autoglide Gate Opener manuals

Popular Gate Opener manuals by other brands

Tormatic

Tormatic Digicode 433 Premium Fitting and operating instructions

Chamberlain

Chamberlain ELITE Series Wiring diagram

DITEC

DITEC SECTOR RESET Installation, use and maintenance manual

fadini

fadini HINDI 880 SPRINT instruction manual

DKS

DKS 9200 owner's manual

Viking Access Systems

Viking Access Systems Q-7 installation instructions