CET ART User manual

Operation Manual

www.critical-environment.com

ARTInfrared Refrigerant Transmitter

Rev. 5 | 2018.03

ART - Operation Manual Rev. 5 | 2018.03

2 © 2018 All rights reserved. Data subject to change without notice.

TABLE OF CONTENTS

1 POLICIES..........................................................................................................5

1.1 Important Note................................................................................................5

1.2Warranty Policy................................................................................................6

1.3 Service Policy...................................................................................................6

1.4 Copyrights........................................................................................................7

1.5 Disclaimer........................................................................................................7

1.6 Revisions..........................................................................................................8

2 INTRODUCTION .............................................................................................9

2.1 General Description..........................................................................................9

2.2 Key Features.....................................................................................................9

3 INSTRUMENT SPECIFICATIONS .................................................................10

3.1Technical Specications..................................................................................10

3.2 Enclosure Dimensions ....................................................................................13

4 SENSOR SPECIFICATIONS...........................................................................14

4.1 List of Available Internal Refrigerant Gases....................................................14

4.2 Special Considerations for Infrared Sensors....................................................15

4.3 Changing GasTypes and Accuracy..................................................................16

5 FEATURES......................................................................................................18

5.1 Front Exterior Enclosure .................................................................................18

5.2 Interior System Layout...................................................................................20

5.2.1 Front of the Enclosure ..................................................................................... 20

5.2.2 Back of the Enclosure ......................................................................................21

6 MOUNTING / INSTALLING ..........................................................................22

6.1Warnings and Prerequisites............................................................................22

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 3

6.2 Mounting Locations .......................................................................................23

6.2.1 General Placement Guidelines ........................................................................23

6.2.2 Machinery Rooms ...........................................................................................23

6.2.3 Refrigerated Spaces......................................................................................... 24

6.2.4 Chillers............................................................................................................25

6.3 Mounting Procedure ......................................................................................25

7 WIRING AND CONFIGURATION .................................................................28

7.1 Overview........................................................................................................28

7.2Wiring Supply Power (24 VAC or 24 VDC)........................................................29

7.2.1 Maintaining Neutral Polarity........................................................................... 30

7.3Wiring Alarm Output (Analog Signal).............................................................31

7.4Wiring Digital Alarm Output Relay.................................................................32

7.5 Connecting to a Controller..............................................................................33

7.6 Modbus Network Conguration.....................................................................33

7.7 Conclusion .....................................................................................................35

8 OPERATION AND STABILIZATION .............................................................36

8.1 Power Up andWarm-up.................................................................................36

8.2 Stabilization...................................................................................................36

8.3 Perform a Manual Zero...................................................................................36

8.4 Behavior During Alarm Conditions.................................................................37

8.5 Gas Detector Faults ........................................................................................37

8.5.1 Overview.........................................................................................................37

8.5.2 Non-Critical Faults...........................................................................................37

8.5.3 Critical Faults................................................................................................... 38

9 CONFIGURING / SETTING THE PARAMETERS..........................................39

9.1 User Interface Overview.................................................................................39

9.2 Setting Parameters ........................................................................................40

ART - Operation Manual Rev. 5 | 2018.03

4 © 2018 All rights reserved. Data subject to change without notice.

9.2.1 Overview.........................................................................................................40

9.2.2 Conguring Parameters ..................................................................................40

9.3 Completing Setup..........................................................................................49

10 FUNCTIONAL TESTS AND GAS ADJUSTMENTS....................................50

10.1Warnings and Cautions ................................................................................50

10.2 BumpTest vs Adjusting Detector Response..................................................51

10.3 BumpTesting...............................................................................................52

10.4 Adjustment Using Calibration Gas................................................................54

11 MODBUS COMMUNICATIONS.................................................................56

11.1 Introduction.................................................................................................56

11.2 Communication Settings..............................................................................56

11.3 Analog Input Registers.................................................................................57

11.4 Analog Output Registers..............................................................................58

11.5 Input Status Flags ........................................................................................59

11.6 Output Status Flags......................................................................................60

12 REPLACEMENT PARTS AND ACCESSORIES ...........................................60

12.1 Calibration Kit..............................................................................................60

12.2 Metal Protective Guard ................................................................................61

12.3 Splash Cover.................................................................................................62

12.3.1 Splash Cover Mounting .................................................................................62

13 TROUBLE SHOOTING ................................................................................64

13.1 Fault Codes...................................................................................................64

13.2 Diagnostic Attributes (P.-18)........................................................................66

13.3 Resetting to DefaultValues..........................................................................68

13.4 Other Symptoms..........................................................................................69

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 5

1 POLICIES

1.1 Important Note

Read and understand this manual prior to using this instrument. Carefully read the warranty policy,

service policy, notices, disclaimers and revisions on the following pages.

This product must be installed by a qualied electrician or factory trained technician and according

to instructions indicated in this manual. This instrument should be inspected and calibrated

regularly by a qualied and trained technician. For more information, refer to Section 10 Functional

Tests and Gas Adjustments of this manual.

This instrument has not been designed to be intrinsically safe. For your safety, do not use it in

classied hazardous areas (explosion-rated environments).

INSTRUMENT SERIAL NUMBER:

______________________________________________________

PURCHASE DATE:

______________________________________________________

PURCHASED FROM:

______________________________________________________

ART - Operation Manual Rev. 5 | 2018.03

6 © 2018 All rights reserved. Data subject to change without notice.

1.2 Warranty Policy

Critical EnvironmentTechnologies Canada Inc. (CETCI), also referred to as the manufacturer,

warrants this instrument, (excluding sensors, battery packs, batteries, pumps and lters) to be free

from defects in materials and workmanship for a period of two years from the date of purchase

from our facility. The sensors have a warranty period of one year on a pro-rated basis from

the date of purchase from our facility. If the product should become defective within this

warranty period, we will repair or replace it at our discretion.

The warranty status may be aected if the instrument has not been used and maintained per the

instructions in this manual or has been abused, damaged, or modied in any way.This instrument

is only to be used for purposes stated herein.The manufacturer is not liable for auxiliary interfaced

equipment or consequential damage.

Due to ongoing research, development, and product testing, the manufacturer reserves the right to

change specications without notice. The information contained herein is based on data considered

accurate. However, no warranty is expressed or implied regarding the accuracy of this data.

All goods must be shipped to the manufacturer by prepaid freight. All returned goods must be

pre-authorized by obtaining a Returned Merchandise Authorization (RMA) number. Contact the

manufacturer for a number and procedures required for product transport.

1.3 Service Policy

CETCI maintains an instrument service facility at the factory. Some CETCI distributors / agents may

also have repair facilities; however, CETCI assumes no liability for service performed by anyone

other than CETCI personnel.

Repairs are warranted for 90 days after date of shipment (sensors have individual warranties).

Should your instrument require non-warranty repair, you may contact the distributor from whom it

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 7

was purchased or you may contact CETCI directly.

Prior to shipping equipment to CETCI, contact our oce for an RMA #. All returned goods must be

accompanied with an RMA number.

If CETCI is to do the repair work, you may send the instrument, prepaid, to:

Attention: Service Department

Critical Environment Technologies Canada Inc.

Unit 145, 7391 Vantage Way

Delta, BC, V4G 1M3

Always include your Returned Merchandise Authorization (RMA) number, address, telephone

number, contact name, shipping / billing information, and a description of the defect as you

perceive it.You will be contacted with a cost estimate for expected repairs, prior to the performance

of any service work.

For liability reasons, CETCI has a policy of performing all needed repairs to restore the instrument to

full operating condition.

Pack the equipment well (in its original packing if possible), as we cannot be held responsible for

any damage incurred during shipping to our facility.

1.4 Copyrights

This manual is subject to copyright protection; all rights are reserved. Under international and

domestic copyright laws, this manual may not be copied or translated, in whole or in part, in any

manner or format, without the written permission of CETCI.

1.5 Disclaimer

Under no circumstances will CETCI be liable for any claims, losses or damages resulting from or

ART - Operation Manual Rev. 5 | 2018.03

8 © 2018 All rights reserved. Data subject to change without notice.

arising out of the repair or modication of this equipment by a party other than CETCI service

technicians, or by operation or use of the equipment other than in accordance with the printed

instructions contained within this manual or if the equipment has been improperly maintained or

subjected to neglect or accident. Any of the foregoing will void the warranty.

Under most local electrical codes, low voltage wires cannot be run within the same conduit as line

voltage wires. It is CETCI policy that all wiring of our products meet this requirement.

It is CETCI policy that all wiring be within properly grounded (earth or safety) conduit.

1.6 Revisions

This manual was written and published by CETCI.The manufacturer makes no warranty or

representation, expressed or implied including any warranty of merchantability or tness for

purpose, with respect to this manual.

All information contained in this manual is believed to be true and accurate at the time of printing.

However, as part of its continuing eorts to improve its products and their documentation, the

manufacturer reserves the right to make changes at any time without notice. Revised copies of this

manual can be obtained by contacting CETCI or visiting

www.critical-environment.com.

Should you detect any error or omission in this manual, please contact CETCI at the following

address:

Critical Environment Technologies Canada Inc.

Unit 145, 7391VantageWay, Delta, BC, V4G 1M3, Canada

Toll Free: +1.877.940.8741

Telephone: +1.604.940.8741

Fax: +1.604.940.8745

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 9

Email: mark[email protected]

Website: www.critical-environment.com

In no event will CETCI, its ocers or employees be liable for any direct, special, incidental or

consequential damages resulting from any defect in any manual, even if advised of the possibility

of such damages.

2 INTRODUCTION

2.1 General Description

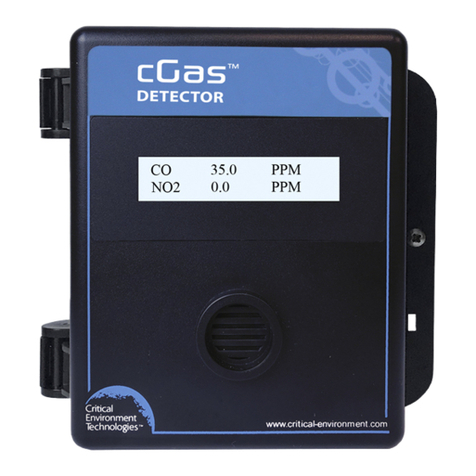

Thank you for purchasing our ART Infrared Refrigerant Transmitter. The ART is a single channel,

non-dispersive infrared, xed gas detector which can detect a wide range of refrigerant gases.

The fast-responding sensor accurately detects refrigerant gas leaks without cross-interference

from combustible or toxic gases. It can be used on a stand-alone basis, connected to a controller or

integrated into a Building Management System (BMS).

If after reading through the manual, you have any questions, please do not hesitate to contact our

service department for technical support.

2.2 Key Features

• Long-life, non-dispersive infrared refrigerant sensor allows for accurate low-level leak

detection with no cross-interference from other non-refrigerant gases

• Detects all refrigerants (CFC, HCFs, HCFC, HFOs) including HF01234YF, HFO1234Ze,

HFO1233ZD, R410a, R22, R32, and more

• Use as a standalone system or integrate into a larger system

• Modbus® RTU interface to connect to a BAS/BMS/DDC

• User selectable, Modbus® or analog output 4-20 mA, 0-5V, 1-5V, 0-10V, 2-10V

ART - Operation Manual Rev. 5 | 2018.03

10 © 2018 All rights reserved. Data subject to change without notice.

• On-board alarm relay

• LED real-time display with on-board audible and visual alarms

3 INSTRUMENT SPECIFICATIONS

3.1 Technical Specications

GAS TYPE

Refrigerants

R22, R32, R123, R134a, R404a, R407a, R407c, R407f. R410a, R422a, R422d, R427a, R448a,

R449a, R452a, R507, R513a, R514a, HFO1233ZD, HFO1234YF, HFO1234Ze,

MECHANICAL

Enclosure ABS plastic with a UL ammability rating of 94V-0

Weight 180 g / 0.40 lb / 6.3 oz

Size 4.0”x 5.5”x 1.5” / 102 mm x 140 mm x 37 mm

ELECTRICAL

Power Requirement 24VDC @ 0.5 A min

24VAC, 5 VA min @ 50 - 60 Hz, 2.5W max

Wiring 24VAC or 24VDC two-conductor shielded 14 to 22 AWG stranded

within conduit

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 11

INPUT / OUTPUT

Analog Outputs 4-20 mA, 0-5V, 0-10 V, 1-5V, 2-10V

Modbus RTU over

RS-485

Baud rate:

Start bits:

Data bits:

Parity:

Stop bits:

Re-entry time:

End of msg:

9,600 or 19,200 (selectable)

1

8

none, odd, even (programmable)

1 or 2 (programmable)

500 ms (min time between retries)

silent 3.5 characters

Relays One relay rated 1 A @ 24VAC/VDC (0.5A, 125V AC UL rating)

SENSOR

Type Infrared

Range 0 - 3,500 ppm

Squelch

Readings below 75 ppm are squelched by default. Meaning, when

ltering is disabled (see Parameter P.-19 on page 48), the unit will

respond to concentrations sub -10 ppm.

ResponseTime, T90 < 5 minutes

USER INTERFACE

Display Green LED Power ON indicator and bright, alpha-numeric LED real-

time display

ART - Operation Manual Rev. 5 | 2018.03

12 © 2018 All rights reserved. Data subject to change without notice.

Audible Alarm Buzzer; enable/disable

Visual Alarm Red 4-digit LED display

Alarm Delay Selectable; 0 to 15 minutes

Fault Monitoring Fault codes presented to user

ENVIRONMENTAL

Operating

Temperature -30°C to 40°C (-22°F to 104°F)

Operating Humidity 5 - 90% RH non-condensing

CERTIFICATIONS

Conforms to CE / UL / CSA / IEC / EN 61010-1

IP Rating Not IP rated. An accessory splash guard is available for areas requiring

additional protection from wash down.

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 13

3.2 Enclosure Dimensions

ART - Operation Manual Rev. 5 | 2018.03

14 © 2018 All rights reserved. Data subject to change without notice.

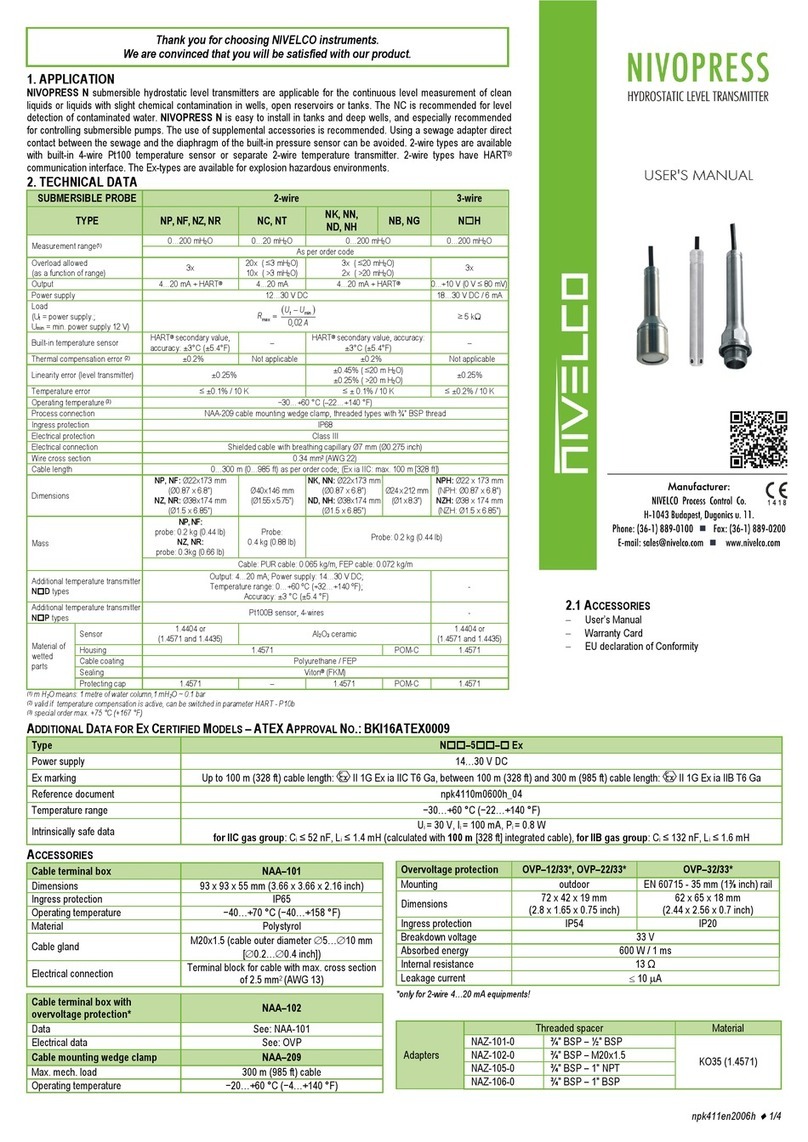

4 SENSOR SPECIFICATIONS

4.1 List of Available Internal Refrigerant Gases

The ART is shipped factory certied and calibrated to the target refrigerant. For more information

on Parameter 11 and refrigerant conguration instructions, see Section 9 Setting and Conguring

the Parameters.

Part Number Refrigerant Range Accuracy Lifespan

ART-B-R22 R22 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R32 R32 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-123 R123 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R134A R134a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R404A R404a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R407A R407a 0 - 3,500 ppm ±3% 7-10 yrs

ART-B-R407C R407c 0 - 3,500 ppm ±3% 7-10 yrs

ART-B-R407F R407f 0 - 3,500 ppm ±3% 7-10 yrs

ART-B-R410A R410a 0 - 3,500 ppm ±3% 7-10 yrs

ART-B-R422A R422a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R422D R422d 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R427A R427a 0 - 3,500 ppm ±3% 7-10 yrs

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 15

ART-B-R448A R448a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R449A R449a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R452A R452a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R507 R507 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R513A R513a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-R514A R514a 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-HFO1234YF HFO1234YF 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-HFO1234ZE HFO1234ZE 0 - 3,500 ppm ±5% 7-10 yrs

ART-B-HFO1233ZD HFO1233ZD 0 - 3,500 ppm ±5% 7-10 yrs

4.2 Special Considerations for Infrared Sensors

Using infrared sensor technology will ensure the highest degree of sensor accuracy if monitoring an

area where there are other contamination gases or multiple refrigerants in the same area.

Infrared refrigerant sensors should not be used in locations that have corrosive chemicals such as

chlorine, ammonia and other oxidizers that are present, especially if there is a higher humidity

level. High humidity environments can eect response and promote corrosion.

Typically requires 10 to 20 minutes to equalize after a sudden variation in temperature. May take up

to 30 minutes to stabilize from a sudden change in humidity.

Water or vapour condensation in wet environments may impair the optics ability to function.

ART - Operation Manual Rev. 5 | 2018.03

16 © 2018 All rights reserved. Data subject to change without notice.

Installing the splash cover is recommended in wet environments where spray downs occur.

Dusty/dirty environments can coat the optics and impair the sensor response. A regular maintnance

schedule that includes cleaning the optics may be necessary.

No minimum level of oxygen is required; operates in the absence of, or enriched presence of

oxygen.

The ART can be re-calibrated in the eld to new target gases. Use optional calibration instructions

in Section 10 Functional Tests and Gas Adjustments for increased accuracy when detecting a new

target gas that is dierent from the“as shipped”target gas.

4.3 Changing Gas Types and Accuracy

As Shipped

The ART-R22 is factory calibrated to R22 and has an AS-SHIPPED R22 response

accuracy of ±5% of reading.

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 17

Changed Gas Type

(Reduced Accuracy)

The gas detector may be changed to respond to any of the other listed refrigerants

(see Parameter P.-11 in Section 9.2 Setting Parameters). If changed, the gas detector

will have a lower accuracy for the target refrigerant (without calibration). In this

example, that accuracy is ±16% of reading.

Optional Calibration

(For Improved Accuracy)

By applying calibration gas containing the NEW target refrigerant, and via the

routine described in Section 10.4 Adjustment Using Calibration Gas, the gas detector

may then be adjusted to respond with the calibrated accuracy of ±5% of reading as

shown in the chart in Section 4.1.

ART - Operation Manual Rev. 5 | 2018.03

18 © 2018 All rights reserved. Data subject to change without notice.

5 FEATURES

5.1 Front Exterior Enclosure

Œ

Ž

•

•

terior Enclosu

re

•

‘

“

’

Rev. 5 | 2018.03 ART - Operation Manual

© 2018 All rights reserved. Data subject to change without notice. 19

NUMBER FEATURE FUNCTION

ŒPower LED Green LED, indicates unit power is ON.

•4-digit LED Display Alpha-numeric display (to show concentration in

real-time)

ŽInformation Button

Used to access the parameter list. Used to back up

one level without writing to memory when the

parameter list is active. Used to mute the audible

alarm for the time period congured in parameter

P.-12.

•Up Button Used to increment the value or parameter displayed.

•Down Button

Used to decrement the value or parameter

displayed. (When the Up Button and Down Button

are pressed and held together for 5 seconds, this key

combination manually zeroes the gas detector.)

‘Enter/Select Button Saves the currently displayed parameter to memory.

’Cable Glands

(2 places)

Pre-installed cable gland is on the left.The optional

cable gland is on the right (if installed). See Section

7 Wiring and Conguration.

“Test Gas Port Used to connect the regulator during testing.

ART - Operation Manual Rev. 5 | 2018.03

20 © 2018 All rights reserved. Data subject to change without notice.

5.2 Interior System Layout

5.2.1 Front of the Enclosure

NUMBER FEATURE FUNCTION

ŒIR Bench Location of the Infrared sensor.

•Relay Pluggable terminal for relay connection.

Œ

Ž

•

•

Table of contents

Other CET Transmitter manuals

Popular Transmitter manuals by other brands

Honeywell

Honeywell XNX quick start guide

Endress+Hauser

Endress+Hauser Deltabar M PMD55 Brief operating instructions

ADEMCO

ADEMCO 5819 Installation instructions and operators manual

Webasto

Webasto Telestart T70 installation instructions

Suntor

Suntor ST15NMT-MiNi user manual

Thermokon

Thermokon DPA+ Dual quick start guide