Mounting kit for stone installation clamp 2020 1

CONTENTS

1. FOREWORD ............................................................................................................................................4

2. DESIGNED PURPOSE OF USE.............................................................................................................5

3. SAFETY INSTRUCTIONS .....................................................................................................................6

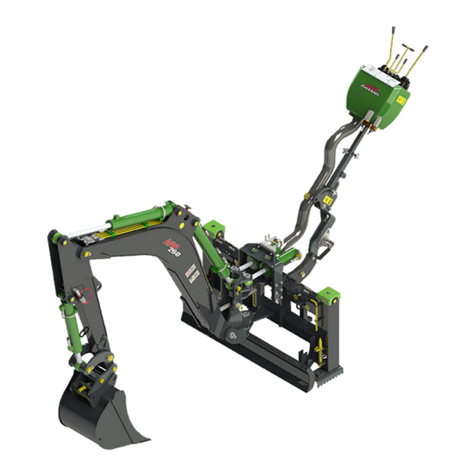

4. TECHNICAL SPECIFICATIONS ..........................................................................................................9

4.1 Outreach ................................................................................................................................................................. 9

4.2 Safety labels and main components of the attachment.................................................................................. 10

5. ASSEMBLING THE ATTACHMENT....................................................................................................12

5.1 Connecting and disconnecting hydraulic hoses............................................................................................... 13

5.2 Coupling an attachment to the mounting kit................................................................................................... 15

5.3 Connecting Mounting kit hydraulics.................................................................................................................. 15

5.3.1 Safety instructions for hydraulic assemblies ............................................................................................ 17

5.3.2 Tightening hydraulic fittings......................................................................................................................... 18

5.4 Electric connection................................................................................................................................................ 19

5.4.1 To connect the electric harness of the attachment to the loader ..................................................... 20

6. USING THE MOUNTING KIT ..............................................................................................................21

6.1 Checks before use................................................................................................................................................. 22

6.2 Operator qualification .......................................................................................................................................... 22

6.3 Controlling the stone installation clamp - different functions of the attachment.................................... 23

6.3.1 Using the hydraulic functions of the Mounting kit ................................................................................. 24

6.4 Material handling.................................................................................................................................................... 25

6.5 Transport position ................................................................................................................................................ 25

6.6 Storing the attachment......................................................................................................................................... 26

6.6.1 Storage............................................................................................................................................................. 26

6.6.2 Storage with attachment.............................................................................................................................. 26

7. MAINTENANCE AND SERVICE ..........................................................................................................27

7.1 Inspection of hydraulic components.................................................................................................................. 27

7.2 Cleaning the attachment ...................................................................................................................................... 28

7.3 Lubrication .............................................................................................................................................................. 28

7.4 Inspection of metal structures............................................................................................................................ 28

8. WARRANTY TERMS..............................................................................................................................29