Avery Weigh-Tronix 1080 User manual

Model 1080

Indicator

User Instructions

AWT 35-500445 Issue AD April 2011

© Avery Weigh-Tronix, LLC 2010. All rights reserved.

No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written consent of

the copyright owner, or as permitted by law or under license. Full acknowledgment of the source must be given.

Avery Weigh-Tronix is a registered trade mark of the Avery Weigh-Tronix, LLC. This publication was correct at the

time of going to print however, Avery Weigh-Tronix, LLC reserves the right to alter without notice the specification,

design, price or conditions of supply of any product or service at any time.

All third party brands and product names used within this document are trademarks or registered trademarks of

their respective holders.

1080_u_en_500445.book

1080 Indicator User Instructions 3

Table of Contents

page

Chapter 1 General information and warnings ......................................................................................... 5

About this manual ..............................................................................................................5

Text conventions ......................................................................................................... 5

Special messages ....................................................................................................... 5

Installation .......................................................................................................................... 6

Safe handling of equipment with batteries .................................................................. 6

Wet conditions ............................................................................................................. 6

Routine maintenance ......................................................................................................... 6

Cleaning the machine ........................................................................................................ 7

Training .............................................................................................................................. 7

Sharp objects ..................................................................................................................... 7

FCC and EMC declarations of compliance ........................................................................ 7

Declaration of Conformity .................................................................................................. 8

Chapter 2 Introduction ............................................................................................................................ 10

Specifications ................................................................................................................... 10

Chapter 3 Front Panel ............................................................................................................................. 11

Annunciators .................................................................................................................... 12

Numeric Entry Procedure ................................................................................................. 13

Chapter 4 Indicator Operations .............................................................................................................. 14

General Gross Weighing .................................................................................................. 14

General Tare/Net Weighing ............................................................................................. 14

Using Outputs in the General Weighing Application ................................................. 15

Accumulator Weighing ..................................................................................................... 16

Using Outputs in the Accumulator Application .......................................................... 17

Batch Weighing ................................................................................................................ 18

Auto Batching by Weight ........................................................................................... 21

Manual Batching by Percentage ............................................................................... 22

Checkweighing ................................................................................................................. 23

Limits Mode: Entering Upper and Lower Limits ......................................................... 24

Performing a Checkweighment in Limits Mode ......................................................... 24

Sample Mode: Using Product to Set Target Weight .................................................. 25

Performing a Checkweighment in Sample Mode ...................................................... 25

Using the Statistics Feature ...................................................................................... 25

Using Outputs in Checkweigher Application ............................................................. 28

Target Outputs .......................................................................................................... 29

Counting ........................................................................................................................... 30

Bulk Sampling ........................................................................................................... 30

Dribble Sampling ....................................................................................................... 31

Displaying Count Information .................................................................................... 32

Using Outputs in the Counting Application ................................................................ 32

Peak Weighing ................................................................................................................. 33

Using Outputs ............................................................................................................ 33

Split (Axle) Weighing ........................................................................................................ 35

Chapter 5 Communications .................................................................................................................... 36

Thermal Labels Print Formats .......................................................................................... 37

Chapter 6 Error Messages ...................................................................................................................... 39

Chapter 7 Menu Mode ............................................................................................................................. 40

4 1080 Indicator User Instructions

User Menu ....................................................................................................................... 40

Supervisor Menu .............................................................................................................. 41

DATE (Set date) ........................................................................................................ 43

HOUR (Set time) ....................................................................................................... 44

SETUP (Setup menu) ................................................................................................ 44

TEST (Test menu) ..................................................................................................... 61

AUDIT (Audit counters) menu ................................................................................... 65

Chapter 8 Indicator Diagnostics ............................................................................................................. 67

Testing Indicator Functions .............................................................................................. 67

Chapter 9 Ethernet Industrial Protocols ................................................................................................ 70

Ethernet IP Explicit Messaging ........................................................................................ 70

AWTX Input Point Object (Data Out) ......................................................................... 70

AWTX Output Point Object (Data In) ......................................................................... 70

Ethernet IP Implicit Messaging ........................................................................................ 71

AWTX Assembly Instance for PLC Configuration ..................................................... 71

ModBus/TCP .................................................................................................................... 71

Starting Register Locations for PLC Configuration .................................................... 71

1080 Indicator User Instructions 5

1.1 About this manual

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appear at the top of alternating

pages of the manual to remind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. If a key

has dual functions, the function is shown first followed by the key name in parentheses

and in bold, such as in these examples: F1, SELECT, PRINT, etc.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

signal words have specific meanings to alert you to additional information or the relative

level of hazard.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may

have major consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

6 1080 Indicator User Instructions

General information and warnings

1.2 Installation

1.2.1 Safe handling of equipment with batteries

1.2.2 Wet conditions

Under wet conditions, the plug must be connected to the final branch circuit via an

appropriate socket / receptacle designed for washdown use.

Installations within the USA should use a cover that meets NEMA 3R specifications

as required by the National Electrical Code under section 410-57. This allows the unit

to be plugged in with a rain tight cover fitted over the plug.

Installations within Europe must use a socket which provides a minimum of IP56

protection to the plug / cable assembly. Care must be taken to make sure that the

degree of protection provided by the socket is suitable for the environment.

1.3 Routine maintenance

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

NO USER SERVICEABLE PARTS. REFER TO QUALIFIED SERVICE

PERSONNEL FOR SERVICE.

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufacturer. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

1080 Indicator User Instructions 7

1.4 Cleaning the machine

1.4 Cleaning the machine

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

To avoid the risk of RSI (Repetitive Strain Injury), place the machine on a surface which

is ergonomically satisfactory to the user. Take frequent breaks during prolonged usage.

1.6 Sharp objects

Do not use sharp objects such as screwdrivers or long fingernails to operate the keys.

1.7 FCC and EMC declarations of compliance

United States

Canada

European Countries

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray the cloth when using a proprietary

cleaning fluid

Spray any liquid directly on to the display windows

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

8 1080 Indicator User Instructions

General information and warnings

1.8 Declaration of Conformity

1080 Indicator User Instructions 9

1.8 Declaration of Conformity

10 1080 Indicator User Instructions

Introduction

2 Introduction

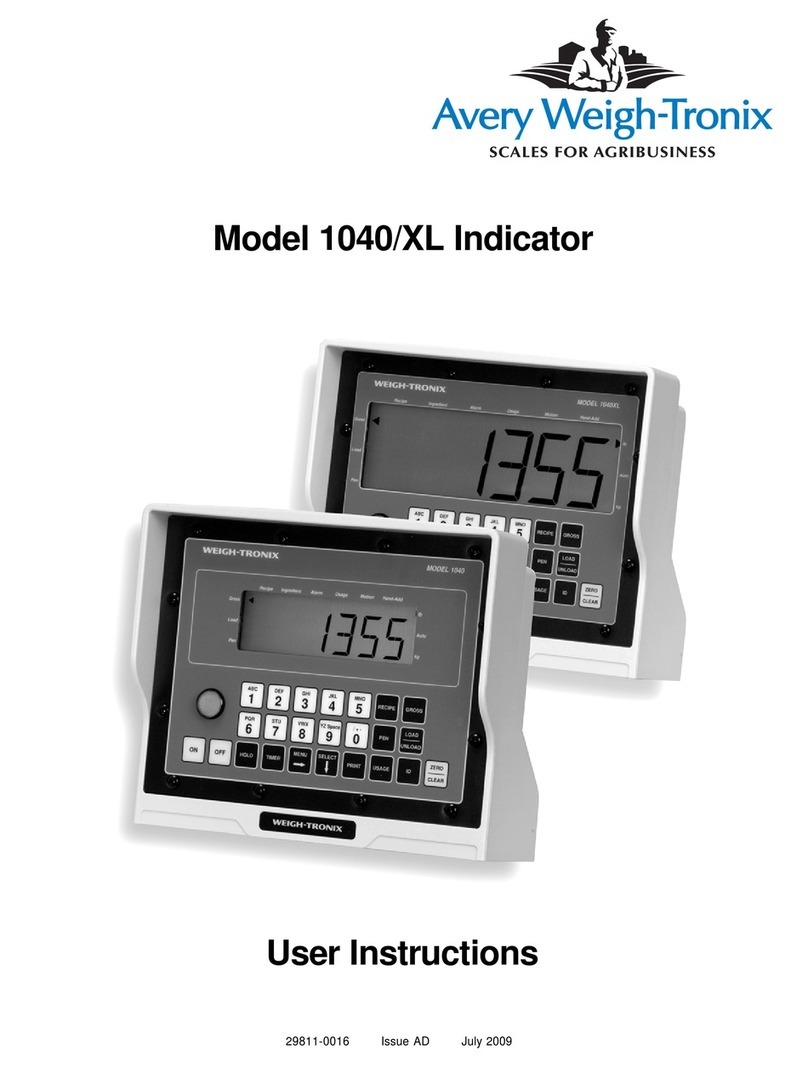

The Model 1080, shown in Figure 2.1,is an easy to use, uncomplicated, panel mount

indicator for weighing with the built-in capability to provide network controls and share

data via Ethernet, PROFIBUS and DeviceNet. It is ideal for tank weighing applications

providing process control interface and data management. These same features are

also available when used with applications using bench scales and floor scales. The

display includes annunciators for fast visual awareness for checkweighing. Also the

indicator can perform counting functions, peak weight functions, be an axle weigher

and act as a remote display for all Avery Weigh-Tronix E-series indicators.

Figure 2.1 Front panel of the 1080 indicator

In addition to connecting to network interfaces, the 1080 can connect to printers,

remote displays, computers and one SensorComm.

There are three setpoint control outputs and the indicator can accommodate three

remote switch inputs for Zero, Print, Tare, Units, F1, Start and Stop.

2.1 Specifications

Power Requirements: 9-36 VDC 5Amps

Climatic Environment: -10 to + 40C, closed, non-condensing

EM Classification: E2

Weight: 2.75 lb, 1.25kg

Dimensions: 6.06 inch W x 3.23 inch H x 5.82 inch D

(154mm W x 82mm H x 148mm D)

SensorComm available in North America only.

1080 Indicator User Instructions 11

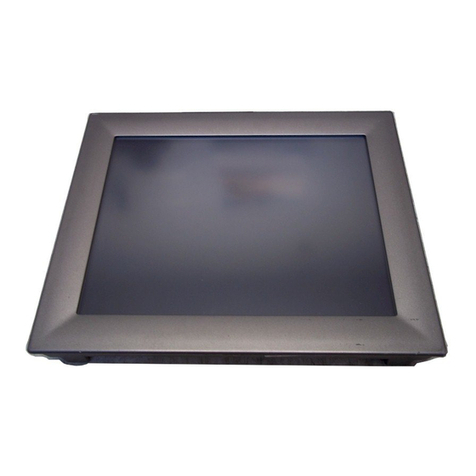

3 Front Panel

The front panel, shown in Figure 3.1, consists of the keys and display.

Figure 3.1 Model 1080 front panel

There are seven keys on the front panel. Their functions are listed below.

Never press a key with anything but your finger. Damage to the overlay may result if

sharp or rough objects are used.

Press the TARE key to perform a tare function. Also acts as a left arrow key when

in the menu structure.

Press the SELECT key to toggle between Gross, Net, Tare, Count, Gross

Accumulator, Net Accumulator, Transaction Counter, Piece Weight, and Peak.

Dependent on the current application. Also acts as an up arrow key when in the

menu structure. Press and hold to access the outputs menu.

Press the ZERO key to zero the display. Also acts as an Escape key when in the

menu structure.

Press the PRINT to send information to a peripheral device through the Comm

port. Also acts as a down arrow key when in the menu structure.

Press the UNITS key to scroll through the available units of measure while in

normal operating mode. Also acts as a right arrow key when in the menu structure.

Press the F1 key to select application specific choices. Also acts as an ENTER key

in the menu structure

Press and release the ON/OFF key to turn the unit on. Press and hold the key until

the unit turns off.

12 1080 Indicator User Instructions

Front Panel

3.1 Annunciators

There are several annunciators around the edge of the display. Figure 3.2 explains

each one.

Figure 3.2 Annunciators.

Motion Lights during scale motion. Goes out when scale is stable

Gross Lights when gross weight is displayed

Net Lights when net weight is displayed

Tare Lights when tare weight is displayed

Print Lights when print format sent through serial port

OP 1 (Under) Lights when output one is activated or for Under condition during

checkweighing

OP 2 (Accept) Lights when output two is activated or for Accept condition

during checkweighing

OP 3 (Over) Lights when output three is activated or for Over condition during

checkweighing

Preset Tare Lights when preset tare is active

Custom Unit Lights when a custom unit of measure is active

Accumulator, Count

or Peak

Lights when an accumulation occurs and while in the count and

peak applications

Network &

SensorComm

Status

This is configurable to light to show status of the Network 1,

Network 2 or SensorComm. See the note following this table.

(SensorComm available in North America market only.)

LB Lights when pounds is the active unit of measure

Center of Zero Lights when weight on the scale is within the zero range

KG Lights when kilograms is the active unit of measure

1080 Indicator User Instructions 13

3.2 Numeric Entry Procedure

3.2 Numeric Entry Procedure

Some keys have alternate functions when you need to enter numbers. See Figure 3.3.

Figure 3.3 Alternate key functions

In screens where numeric entry is possible, choose the first digit using the SELECT or

PRINT keys. Use the TARE and UNITS keys to advance or backspace through the

entry. Press the F1 key to accept an entry. Below is an example:

Example: To key in the number 507:

Repeatedly press the SELECT or PRINT key until 5 appears on the display.

Press the UNITS key once to move cursor one space to the right.

Repeatedly press the SELECT or PRINT key until 0 appears on the display.

Press the UNITS key once to move cursor one space to the right.

Repeatedly press the SELECT or PRINT key until 7 appears on the display.

Press the F1 key to enter the value.

Far Right LED color

(Chosen as SCOM or Network in configuration. Can’t be both.) SCOM:

Red – a cell has been ghosted. Check the ghost log.

Green – a sensorcomm error has occurred. Check the error log.

Off – Scale is functioning normally.

Network 1 or 2:

Red – A network error has occurred. Check the network settings on the indicator and

PLC, and reboot the indicator.

Green – The network connection has been established.

Amber – The network is ready for a connection, but no connection has been

established

Press the ZERO key to terminate a value entry and leave the previous value, if any,

active

14 1080 Indicator User Instructions

Indicator Operations

4 Indicator Operations

The Model 1080 comes equipped with several weighing applications;

lGeneral weighing (default setting)

lAccumulator weighing

lBatch weighing

lCheckweighing

lCounting

lPeak weighing

lSplit or Axle weighing

The 1080 can also perform as a remote display if so enabled. Ask your supplier for

information about setting up this indicator as a remote display.

These different applications are activated using a password protected menu. Contact

your local supplier for assistance with the password protected menu and enabling

applications.

The general weighing application comes as the default application. You can do gross

weighments, tare/net weighments and print a print format. Below are instructions for

each.

4.1 General Gross Weighing

To perform gross weighing, power up the unit and follow these steps:

1. Empty the scale and press ZERO key to zero the display…

0is displayed.

2. Place item to be weighed on the scale…

Weight is displayed.

4.2 General Tare/Net Weighing

To perform a net weighment, power up the unit and follow these steps:

1. Empty the scale and press ZERO key to zero the display…

0is displayed.

2. Place item to be tared on the scale…

Weight is displayed.

To change unit of measure, press the UNITS key.

1080 Indicator User Instructions 15

4.2 General Tare/Net Weighing

3. Press the TARE key…

0is displayed and the NET annunciator lights.

4. Place material to be weighed on the scale…

Net weight of material is displayed.

5. Repeatedly press the SELECT key to scroll through gross, tare, and net

modes. Remove the weight from the scale and press TARE to return to gross

mode.

4.2.1 Using Outputs in the General Weighing Application

The output will trigger when weight goes above the target set for that output and will

remain on until the weight falls below the target. Follow these steps to configure three

outputs:

1. With the indicator powered up, press and hold the SELECT key until…

OP1 is displayed.

2. Press the PRINT key to set the value for the output…

Use the numeric entry procedure to key in a value, see note below, and

press the F1 key to accept the value. OP1 will be displayed

OR

Press the ZERO key to select the next output.

3. Repeat step 2for each output. Press ZERO key to select the next output and

then return to normal operation with the ingredients active.

To clear a tare weight, remove all weight from the scale and press the TARE key.

Choose the first digit using the UP or DOWN keys. Use the LEFT and RIGHT keys to

advance or backspace through the entry.

Output operation in the general weighing application:

Below Configured Value:

Outputs are ON

Annunciators are OFF

TIU3 Relays are ON

Above Configured Value:

Outputs are OFF

Annunciators are ON

TIU3 Relays are OFF

16 1080 Indicator User Instructions

Indicator Operations

4.3 Accumulator Weighing

The accumulator is memory that collects individual weighments (gross and net) and

stores the totals. These totals can be recalled at any time. The number of weighments

included in the totals can be displayed and all information can be reviewed and deleted.

To use the accumulator, power up the unit and follow these steps:

1. Empty the scale and press ZERO key to zero the display…

0is displayed.

2. Place item on the scale…

Weight is displayed.

3. Press the F1 key or PRINT key to add weight to the accumulator. Pressing the

PRINT key also prints the default print format …

A circle annunciator lights briefly on the right side of the display to show

the weight was accumulated.

4. Remove weight from the scale. Weight must return to zero before another

accumulation can be recorded.

5. Repeat steps 2through 4for each weighment you want to accumulate.

6. To review the accumulator total and the number of weighments, remove all

weight from the scale and press the SELECT key repeatedly…

1st press = Net weight displayed

2nd press = Tare weight displayed

3rd press = Display toggles between showing ACCUM. and gross total of all

weighments

4th press = Display toggles between showing ACCUM. and net total of all

weighments

5th press = Display toggles between showing TOTAL and number of

weighments

6th press = Display returns to gross weigh mode

You need the supervisor’s password to clear the accumulator. See Supervisor Menu on

page 41

You can use tare/net weighing with the accumulator application. The accumulator

stores both gross and net totals for later recall.

You must remove all weight from the scale to scroll through the items listed above.

With weight on the scale, repeatedly pressing the SELECT key will only show the

gross, net and tare values.

1080 Indicator User Instructions 17

4.3 Accumulator Weighing

4.3.1 Using Outputs in the Accumulator Application

If enabled, you can use the outputs function while in the accumulator application.

Outputs are enabled in a password protected menu. Contact your local supplier for

assistance with the password protected menu. Follow these steps to set up to three

outputs:

1. With the indicator powered up, press and hold the SELECT key until…

OP1 is displayed.

2. Press the PRINT key…

The current value for OP1 is displayed.

3a. Press the F1 key to accept the displayed value

OR

3b. Key in a value using the numeric entry procedure, see note at left, and press

the F1 key.

OP1 is displayed.

4. Scroll through all three outputs by using the TARE or UNITS key.

Repeat steps 2and 3a or 3b for each output.

5. Press ZERO key…

SAvE is displayed.

6. Press the F1 key to save the changes or the ZERO key to abort the changes…

The unit returns to normal operation mode with the saved outputs active.

Choose the first digit using the UP or DOWN keys. Use the LEFT and RIGHT keys to

advance or backspace through the entry.

Output operation in the Accumulator application:

Below Configured Value:

Outputs are ON

Annunciators are OFF

TIU3 Relays are ON

Above Configured Value:

Outputs are OFF

Annunciators are ON

TIU3 Relays are OFF

18 1080 Indicator User Instructions

Indicator Operations

7. As you apply weight to the scale, output one will activate below its setpoint and

deactivate above its setpoint. The same is true for the other two setpoints.

Each output’s annunciator will light on the display when the output value is

reached.

4.4 Batch Weighing

This section applies if your indicator has the batching application active.

The batching application has a recipe with up to eight ingredients. In the recipe, the

following items are set.

Batch type can be by weight, percentage or gross. Each explained below.

Constant Weight Batches are all the same size and the weight of each ingredient is

predetermined by the recipe.

Percentage Batch size is chosen by the operator and each ingredient is

determined by the percentage set in the recipe.

Gross Each ingredient runs until the gross weight on the scale reaches

the value that was set, regardless of the weight on the scale when

the batch was started.

After a batch has been started, it can be aborted by pressing the F1 key.

Batching mode can be Manual, Automatic, Filling, Reverse Filling or Continuous.

Manual If the recipe is set up for manual mode, you press the F1 key to

start the batch and you need to press the F1 key each time a

setpoint is reached to activate the next ingredient output. See

important note below.

Automatic If the recipe is set up for automatic mode, you press the F1 key to

start the batch and each output is activated and deactivated

automatically by the indicator.

When in Manual Mode, you must press the F1 key during ingredient filling to abort the

operation. If you press F1 during a configured delay time, the key press is ignored. An

F1 press after the delay time will start the next ingredient.

1080 Indicator User Instructions 19

4.4 Batch Weighing

Filling In Fill mode, any recipe that has been setup is ignored. The filling

process is run based on the values set for the outputs. In order to

complete the filling process, at least one output must be enabled.

See the following note.

Reverse Fill In reverse filling mode, any recipe that has been setup is ignored.

The reverse filling process is run based on the values set for the

outputs. In order to complete the filling process, at least one output

must be enabled. See the previous note and the following

instructions:

1. Press the F1 key to begin the reverse filling process.

2a. If output one is enabled, and the net weight on the scale is

above the value of the output, output 1 will come on.

2b. If output two is enabled, and the net weight on the scale is

above the value of the output, output 2 will come on.

2c. If output three is enabled, and the net weight on the scale

is above the value of the output, output 3 will come on.

3. Each output will remain on until its output value is met.

4. The reverse filling process can be restarted by pressing

the F1 key.

Continuous Continuous batching mode. This mode is very close to the Auto

mode but, in continuous mode another batch is started

immediately after the previous batch has finished. In auto mode

the user must press the F1 key to start each batch.

The Basis of each ingredient can be weight or time.

Weight If an ingredient basis is weight, the output activates at the

appropriate time and deactivates when the weight set in the recipe

is reached.

Time If an ingredient basis is time, the output activates for the time set

in the recipe and then deactivates.

The batching modes, Filling and Reverse Filling, can be configured to operate in two

ways.

Absolute mode Setpoints activate when the F1 key is pressed. When the net

weight on the scale reaches the configured output value, the setpoint will deactivate.

Relative mode When the F1 key is pressed, the starting weight is captured and

the outputs activate. The output will not deactivate until the net weight on the scale

reaches the starting weight plus the configured output value.

See Batch Weighing on page 18 for information about setting these modes.

20 1080 Indicator User Instructions

Indicator Operations

In filling mode the process can be changed by changing the value(s) of the outputs.

Follow these steps to set up the three outputs:

1. With the indicator powered up, press and hold the SELECT key until…

OP1 is displayed.

2. Press the PRINT key…

The current value for OP1 is displayed.

3. Press the F1 key to accept the displayed value (or ZERO to abort) or key in a

value and press the F1 key.

OP1 is displayed.

4. Scroll through all three outputs by using the left and right arrow keys.

5. Repeat steps 2and 3for each output.

6. Press the ZERO key to exit the outputs setup.

7. Press F1 to save the changes or the ZERO key to abort the changes

In automatic or manual mode, a recipe must be setup. The recipe values are set in a

password protected menu. However, a shortcut can be used to change the amount of

each ingredient.

To access this shortcut menu:

1. Press and hold the SELECT key until

ingr 1 is displayed

2. Press the PRINT key to change the amount of ingredient 1 to batch.

A numerical value is displayed.

Output operation in the Batching application:

Before activation by recipe:

Outputs are OFF

Annunciators are OFF

TIU3 Relays are OFF

After activation by recipe:

Outputs are ON

Annunciators are ON

TIU3 Relays are ON

Key legend reminder.

Other manuals for 1080

1

Table of contents

Other Avery Weigh-Tronix Touch Panel manuals

Avery Weigh-Tronix

Avery Weigh-Tronix E1070 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix 1040/XL User manual

Avery Weigh-Tronix

Avery Weigh-Tronix ZM303 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix ZM305 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix E1010 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix 640XL User manual

Avery Weigh-Tronix

Avery Weigh-Tronix WI-130 User manual