HS6M 2

Equipment needed for installation

Supplied:

HS6M Encoder

Anti-Rotation Tether

Optional:

Shaft Sizing Insert

Not Supplied:

Wrenches

Dial Indicator Gauge

Caliper Gauge

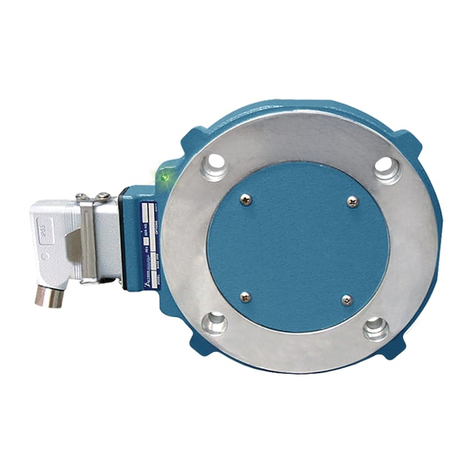

The hollow shaft HS6M design eliminates the potential for coupling

failures from misalignment, however, excessive housing movement

(wobble) may cause undesirable vibrations and bearing damage.

The higher the RPM, the more severe the vibration will be from

housing movement. In a typical installation a housing movement of

0.004” [0.1mm] TIR or less (as measured at the outside diameter of

the main encoder body) will not have an adverse effect.

1) Disconnect power from equipment and encoder cable.

2) Use caliper gauge to verify motor shaft is proper diameter and

within allowable tolerances: +0.000”, -0.0005”

[+0.00, -0.013mm].

3) Clean machine shaft of any dirt and remove any burrs.

4) Use dial indicator gauge to verify the motor shaft: Total

Indicated Runout (TIR) <0.002” [0.05mm].

5) Install the anti-rotation bracket tether to the face of the encoder

included with the tether.

6) Loosen clamping collar screws.

7) Test Fitting: carefully slide the encoder onto the shaft to verify

fit. Ensure a minimum of 1/16” [1mm] between encoder and

mounting surface. DO NOT FORCE. Encoder should slide on

easily. If the encoder does not fit easily, remove it, verify shaft

size, and check for burrs and shaft damage.

8) Slide the HS6M onto the shaft. Ensure minimum insertion

requirements shown on drawing page are met.

9) Tighten screws on clamping collar evenly until snug, then

tighten each screw as follows:

For bore sizes up to 1” [25mm] 38 in-lb [4.3 Nm]

For bore sizes >1” [25mm] 66 in-lb [7.5 Nm]

DO NOT USE A STANDARD RIGHT ANGLE WRENCH. Use only a

T-handle hex wrench or torque wrench with hex bit.

10) Secure free end(s) of the anti-rotation bracket to frame using

bolt or T-bolt provided. The bracket should be parallel to the

encoder face, 90 degrees to the shaft to avoid encoder bearing

damage. Use additional washers as needed to ensure the

tether is parallel to the encoder face.

12) Turn shaft by hand and verify the shaft turns freely and does

not produce excessive runout/wobble of the encoder (<0.005”

TIR [0.13mm], Total Indicated Runout.) Ensure the tether arm is

secure and the encoder body cannot rotate.

13) Connect cable as shown in wiring diagram.

14) Apply power to the encoder.

15) Rotate the shaft by hand, or using jog mode of the speed

controller and verify proper direction and position output.

ENVIRONMENTAL CONSIDERATIONS

Follow these steps to reduce potential problems:

1) Always mount connection points, conduit couplings, junction

boxes, etc., lower than actual encoder.

2) For washdown areas, shroud or otherwise cover the encoder to

prevent direct water spray. Do not attach the shroud directly to

the encoder.

REPAIRS

REMOVAL INSTRUCTIONS:

1. Unbolt tether arm from mounting point(s) on motor.

2. Loosen clamping collar screw(s).

3. Slide the encoder off the motor.

REPLACING PARTS

The HS6M has two items that are user-replacable in the field in

case of damage, or to change the encoder electrical or mechanical

interface:

1. Shaft sizing insert: Simply slide the insert out of the HS6M and

replace it with the new bore size insert. Insert should remove

and install with modest force-do not pound the insert into the

HS6M.

2. Tether system: To replace the tether system, remove the

retaining screw(s), then replace with the new tether.

CAUTION

Do not attempt to remove, service, or adjust any of the

internal components of the HS6M.

INSTALLATION

Refer to the back page of these instructions for outline and mounting

dimensions.

Equipment needed for installation

Supplied:

Encoder

Optional:

(none)

Not Supplied:

Open Wrenches, Hex Wrenches, Dial Indicator Gauge

Caliper Gauge, Mounting Screws

WIRING INSTRUCTIONS

CAUTION

Remove power before wiring.

Interconnecting cables specified in the wire selection chart are

based on typical applications. Refer to the system drawing for

specific cable requirements where applicable.

Physical properties of cable such as abrasion, temperature, tensile

strength, solvents, etc., are dictated by the specific application and

communications bus. Do not use unshielded cable. Ground one end

(only) of the shield to earth ground.

Do not run encoder wiring parallel to power cable wiring for

extended distances, and do not wrap encoder cable around power

cables.

TROUBLESHOOTING:

If the controller indicates a loss of encoder fault, check the encoder

power supply at the encoder. If power is present at the encoder,

check polarity. If the wiring appears correct and in good shape,

test the wiring by replacing the HS6M. If the controller still shows

encoder loss/fault, then the wiring is faulty and should be repaired or

replaced.

An oscilloscope can also be used to verify output of the HS6M

encoder at the encoder connector itself and at the drive/ controller

cabinet. Depending on the communication method, signals will vary

but the oscilliscope should show the output signals varying. Keep in

mind that SSI and Profibus DP are master-slave systems and require

the controller to signal the encoder to transmit position.

SSI TROUBLESHOOTING

For SSI, monitor the clock input line to ensure the controller is

triggering the encoder to send position. The clock should obey the

signal requirements shown in the SSI signal section, and should

appear as a rapid set of transitions on the clock line. The encoder

data transmit lines should change state as data is clocked out. Note

that the varying binary patterns representating position can produce

pulses of varying width--this is normal.

PROFIBUS-DP TROUBLESHOOTING