OPERATING POWER (EACH OUTPUT)...................................

OUTPUT SIGNAL ......................................................................

PULSES PER REVOLUTION.....................................................

WAVE SHAPE ............................................................................

VOLTAGE OUTPUT....................................................................

OUTPUT PROTECTION ............................................................

FREQUENCY .............................................................................

MECHANICAL

SHAFT DIAMETER REQUIREMENTS....................................

SPEED RANGE .......................................................................

STARTING TORQUE................................................................

HUB INERTIA...........................................................................

ACCELERATION (MAX.)..........................................................

OPERATING TEMPERATURE ...................................................

WEIGHT .....................................................................................

15 V OPERATING VOLTAGE

12 TO 15 VDC AT APPROX. 70 mA (NO LOAD)

TWO CHANNELS IN QUADRATURE

(2-PHASE, BIDIRECTIONAL)

240, 360, 600, 1024, 1200, 2048 PPR STD.

— OTHERS AVAILABLE UPON REQUEST

SQUARE WAVE

HIGH: SUPPLY VOLTAGE MINUS 1 VOLT

(NO LOAD)

120 OHMS PULL-UP

LOW: 1.0 VOLT MAX.

50mA SINK

SHORT CIRCUIT PROTECTION TO COMMON

50 KHz MAX.

1.125 +.000/-.003 INCHES

0 TO 3600 RPM

3.9 OZ.-IN. (TYP.)

0.5 OZ.-IN.-SEC2

3000 RPM/SEC

0° TO 160°F AMBIENT

15 LBS.

24 V OPERATING VOLTAGE

24 VDC AT APPROX. 70 mA (NO LOAD)

TWO CHANNELS IN QUADRATURE

(2-PHASE, BIDIRECTIONAL)

240, 360, 600, 1024, 1200, 2048 PPR STD.

— OTHERS AVAILABLE UPON REQUEST

SQUARE WAVE

HIGH: SUPPLY VOLTAGE MINUS 1 VOLT

(NO LOAD)

330 OHMS PULL-UP

LOW: 1.0 VOLT MAX.

50mA SINK

SHORT CIRCUIT PROTECTION TO COMMON

50 KHz MAX.

1.125 +.000/-.003 INCHES

0 TO 3600 RPM

3.9 OZ.-IN. (TYP.)

0.5 OZ.-IN.-SEC2

3000 RPM/SEC

0° TO 160°F AMBIENT

15 LBS.

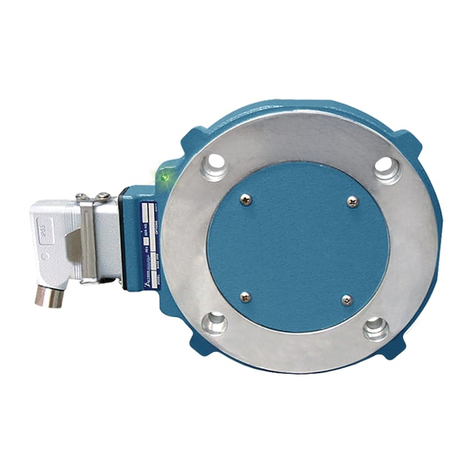

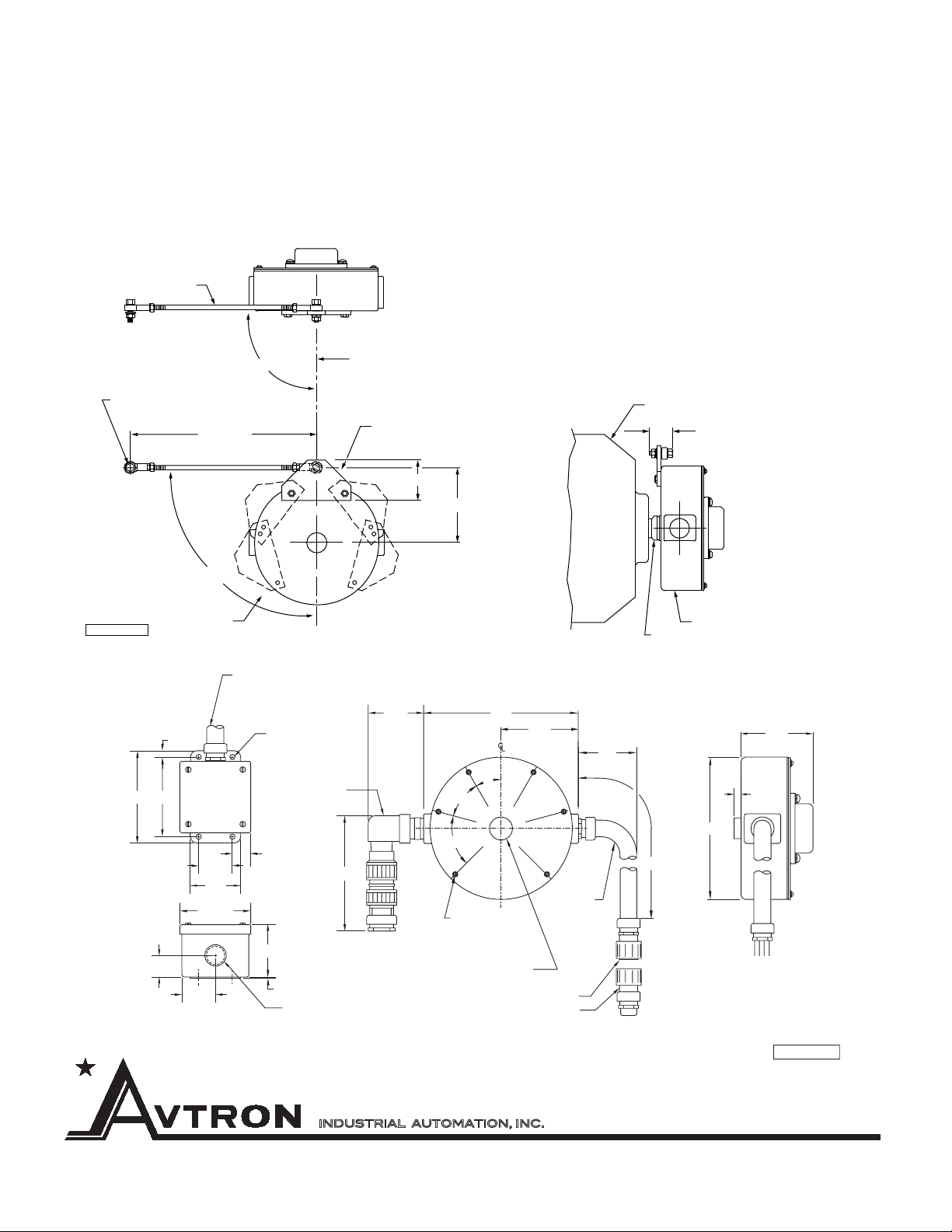

INSTALLATION

MACHINE SHAFT PREPARATION

Preparing the machine shaft prior to Pulse Generator instal-

lation is essential in providing an adequate barrier against

environmental contamination. In some cases, a separate stub

shaft (1.125" D x 4.5" long) will be installed on the motor. To

prepare the machine shaft that the M585 is to be installed on,

conduct the following procedures (see figures):

1. Remove from the M585 the four 1⁄4-20 UNC machine

screws which hold the end cap on the cover plate.

2. Remove the end cap, O-Ring, and wave spring, noting

the location of each to assist in reassembly.

CAUTION

SPANNER WRENCHES MUST BE USED DURING THE

FOLLOWING PROCEDURES. Using a substitute can distort

the 13⁄4" nut and damage the unit. Do not try to remove the

21⁄2" bearing locknut at any time.This locknut is factory adjusted

for optimum M585 performance.

NOTE

Two spanner wrenches, which are required for M585 installa-

tion, accommodate the 13⁄4" and 21⁄2" nuts found under the cap.

3. Holding the 21⁄2" bearing locknut, remove the 13⁄4" diame-

ter clamping nut and slide out the internal compression sleeve.

4. Verify that the compression sleeve can be installed by

hand on the shaft where the unit is to be installed. File any burrs

that obstruct sleeve installation and lightly oil the shaft.

5. If a keyway or flat exists on the shaft, provide a sealing

medium or true shaft back to round using metal putty or equal.

6. Return the compression sleeve to the M585 hub.

7. Thread the 13⁄4" clamping nut onto the M585 by hand until

resistance is felt. DO NOT TIGHTEN AT THIS TIME.

PULSE GENERATOR INSTALLATION

Installing the M585 and Anti-Rotation Arm:

1. The free end of the Anti-Rotation Arm must be secured

by the customer to a stationary member such as the floor or

machine frame. Refer to “Anti-Rotation Arm Mounting Guide-

lines” on the last page

for general require-

ments.

2. Based on the lo-

cation of the stationary

point and the guidelines

on page 4, attach the

1⁄4" thick mounting board

provided to one of five

places on the M585.

Use two 1⁄4-20 UNC by

3⁄4" long machine screws

provided.

3. Ensure that the

machine shaft is lightly

oiled. A packet of sili-

cone grease is provided

to lubricate the following

shaft seals: First, ALL

M585 types have an O-ring inside their hollow shafts at the mo-

tor end. In addition, in THRU SHAFT types, the clamping nut

has an O-ring on the inside, plus the outside of the clamping nut

requires lubrication for the radial lip seal per step 8b. Slide the

M585 onto the machine shaft, mounting board first. Ideally, the

M585 housing will be 1⁄2" to 1" from the motor or machine hous-

ing, but this may vary depending on the machine profile and the

anti-rotation arm clearance requirements. Consider shaft end

float when positioning the M585.

4a. FOR STUB SHAFT APPLICATIONS, place the M585

31⁄4" to 4" onto the shaft. The end of the machine shaft must ex-

tend completely through the M585 compression sleeve and be

approximately flush with the end of the 13⁄4" clamping nut.

4b. FOR THRU SHAFT APPLICATIONS, position the M585

as required.

5. Attach free end of the Anti-Rotation Arm to the

1⁄4" mounting board using the shoulder bolt provided.

6. Remove 13⁄4" clamping nut and apply liquid thread locker

to the threads. (Locktite grade 242, supplied, should be used in

most applications.)

NOTE

Where thread locker has been used, additional force is required

for M585 removal.

7. Replace 13⁄4" clamping nut and tighten so the gap is less

than or equal to 0.09", as shown in CLAMPING NUT sketch

(approx. 15-20 ft-lbs), holding the 21⁄2" bearing locknut in place.

Spanner wrenches are required for this operation.

8a. FOR STUB SHAFT INSTALLATIONS, replace the end

cap with the wave spring (loading spring) against the bearing

and the O-ring located in the cap groove. Secure the end cap

with the four 1⁄4-20 UNC machine screws previously removed.

Apply the supplied grade 242 Locktite to the screws when as-

sembling.

8b. FOR THRU SHAFT APPLICATIONS, prior to replac-

ing the end cap per step 8a, apply a small amount of silicone

grease (provided) to the seal surface on the 13⁄4" clamping nut.

The radial lip seal in the end cap will seal on this surface.

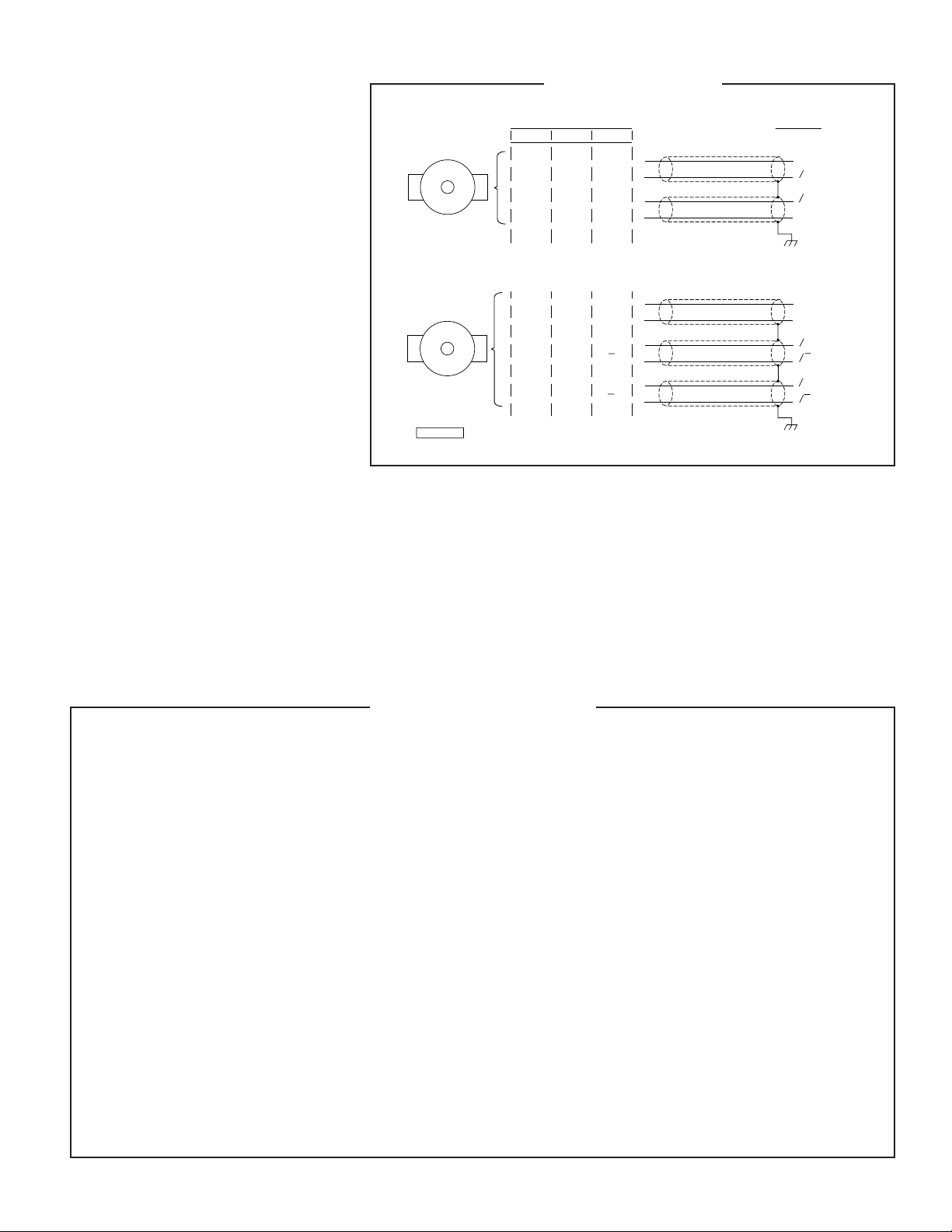

WIRING CONSIDERATIONS

For bidirectional operation of the SHAFTach™,

proper phasing of the two output channels is

important. Phase A channel leads phase B

channel for clockwise rotation as viewed from

the end-cap (anti-drive) end of the generator.

Interconnecting cables specified in the wiring

diagrams are based on typical applications.

Refer to the system drawing for specific cable

requirements where applicable.

Physical properties of cable such as abrasion,

temperature, tensile strength, solvents, etc.,

are dictated by the specific application. Gen-

eral electrical requirements are: stranded cop-

per, 22 thru 16 gauge, braid or foil with drain

wire, 0.05 MF maximum total mutual or direct

capacitance, outer sheath insulator, 1,000 ft.

max.

ENVIRONMENTAL

CONSIDERATIONS

Special attention is to be given to conduit runs, interconnection

wiring and NEMA type enclosure mounting. In those applications

where ambient temperatures are controlled within 40°F and high

humidity/washdown are not present, position the flexible conduit

with a slight sag to prevent any condensation from entering the

SHAFTach via conduit.

In harsh environments, which include temperature extremes, high

humidity, equipment washdown or atmosphere contamination,

extra care is required for interconnection. Follow these steps to

reduce potential problems:

1. Always mount connection points, conduit couplings, junc-

tion boxes, etc., lower than actual generator.

2. Venting of generator is beneficial. One method is to take

conduit run outside of hostile area where practical. (Applies to

conduit installations only.)

3. For washdown areas, shroud or otherwise cover the

SHAFTach to prevent direct water spray. Do not attach the shroud

directly to the generator.

4. Keep conduit outputs and axis of rotation horizontal.

5. Purging of SHAFTach should be reviewed with Avtron.

M585 SPECIFICATIONS

N

OUTPUT OPTIONS

CT

RED

BLUE

GREEN

BLACK

B

E

D

A

+V

B

A

COM

M585

FOR SINGLE ENDED

APPLICATIONS

CABLE BELDEN #8723

OR EQUIVALENT

OPERATING

VOLTAGE

0B

0A

COMMON

GROUND

FOR SINGLE ENDED APPLICATIONS

FUNCTION

GREEN

YELLOW

BLUE

GRAY

BLACK

RED

D

B

A

G

E

H

A

A

+V

COM

B

B

M585

FOR DIFFERENTIAL

APPLICATIONS

CABLE BELDEN #9773

OR EQUIVALENT

0A

OPERATING

VOLTAGE

COMMON

0A

0B

0B

GROUND

FOR DIFFERENTIAL APPLICATIONS

NOTE: 5’ FLEXIBLE CONDUIT STANDARD

FOR ALL OUTPUT OPTIONS

M585WD.MAC

WIRING DIAGRAM