XR4F 3

VARIATION > ± 15%

PHASE A

PHASE B

MODIFICATION

The XR4F can be modified to easily adapt to new applications.

CAUTION

Do not attempt to modify the electrical connector

options of the XR4F while located in a hazardous

location or atmosphere. Doing so may create a severe

spark hazard which can result to damage to property,

injury, or even death.

TO CHANGE ELECTRICAL CONNECTOR STYLE:

1. Remove electrical power and disconnect the mating plug.

2. Unscrew the (4) M5 screws (4mm hex).

3. Pull the connector header away from the encoder gently.

4. Disconnect the ribbon connector to the encoder body.

5. Connect the ribbon connector to the new connector header

6. Attach the new connector header to the encoder using the (4) M5

screws. Tighten to 30 in-lbs [3.4n-m]. Be sure the ribbon

connector fits in the open pocket under the header and is not

crushed or pinched by the connector header.

WIRING

CAUTION

Be sure to remove power before wiring the encoder.

Be sure to ground the cable shield: Avtron recommends

grounding the shield at the isolator module for Zone 1

applications or in the drive cabinet for Zone 2

applications. Cable should not be grounded multiple

places. An intrinsic safety ground is required at the

XRB1 Isolator Module.

CAUTION

SMARTSafe encoders include a local ground lug for

customer convenience and encoder frame grounding if

required to meet local electric code requirements or

site operator protection standards. This is NOT the

required XRB1 intrinsic safety ground connection

required for hazard protection against ignition of

explosive atmospheres! Wiring diagrams are shown in

the following pages.

Wiring diagrams are shown in the following pages.

CAUTION

Zone 1 and Zone 21 applications utilize the XRB1

isolator which requires an intrinsic safety ground

to provide hazard protection. Failure to connect this

ground, or providing an inadequate safety ground path

could result in an spark/ignition hazard which can

result in property damage, injury, or even death.

Refer to the wiring diagrams and pinout and phasing tables for

specific information on each option.

The XR4F can be wired for single phase or two phase, either with

or without complements, with or without markers. For bidirectional

operation, Phase A channel typically leads phase B channel for

clockwise shaft rotation as viewed from the anti-drive or accessory

end of the motor (XR4F mounting end). See pinout and phasing tables

for exceptions

NOTE

Wiring option “G” provides a pinout compatible with

NorthstarTM encoders, with a cable shield connection

on pin 10. Note that this option does not ground the

shield.

CORRECTIVE ACTION FOR PHASE REVERSAL

1) Remove Power.

2) Exchange wires on cable, either at encoder cable end,

or at speed controller end (but not both).

a) Single Ended 2 Phase Wiring (see wiring diagram)

Exchange A with B

b) Differential 2 Phase Wiring (see wiring diagram)

Exchange either A with A– in the phase A pair OR

B with B– in the phase B pair but NOT both.

3) Apply Power.

4) Verify encoder feedback is correct, using hand rotation

of shaft, or jog mode of the speed controller.

Interconnecting cables specified in the wire selection chart are

based on typical applications. Cable must be selected and installed

in accordance with IEC/EN60079-14 and IEC/EN60079-25. Physical

properties of cable such as abrasion, temperature, tensile strength,

solvents, etc., are dictated by the specific application. General

electrical requirements are: stranded copper, 20 through 16 AWG

(Industrial EPIC connector type options can use 14 AWG), each wire

pair individually shielded with braid or foil with drain wire, .05 uf of

maximum total mutual or direct capacitance, outer sheath insulator.

See specifications for maximum cable length. Stranded 20 AWG wire

should not be used for cable runs greater then 61 meters. If 20 AWG is

used with EPIC type connector options the wire ends should be tinned.

FAULT-CHECK

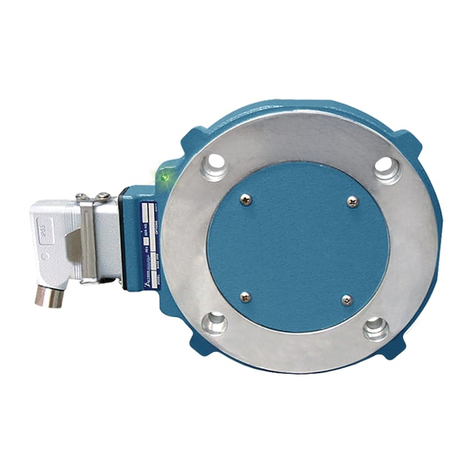

After power-up and the rotor position is checked by the sensor, the

Fault-Check LED will turn green.

If the adaptive electronics reach their adjustment limit for any reason,

the Fault-Check alarm and LED will notify the drive and operator of

an impending failure. The LED will turn red if the Adaptive Electronics

reach their adjustment limit. This output occurs before an actual

failure, allowing steps to be taken to replace the unit before it causes

unscheduled downtime. Fault-Check annunciation is available as an

“alarm” output through the connector (zone 2 configurations only) and

as an integral LED.

TROUBLESHOOTING

If the drive indicates a loss of encoder/tach fault and the XR4F

fault-check LED is not illuminated, check the encoder power supply.

If power is present, check polarity; one indicator of reversed power

supply is that all outputs will be high at the same time. If the drive

indicates encoder fault, but the LED shows GREEN, then check the

wiring between the drive and the encoder. If the wiring appears

correct and in good shape, test the wiring by replacing the XR4F. If the

new unit shows GREEN, and the drive still shows encoder loss/tach

fault, then the wiring is faulty and should be repaired or replaced.

If the alarm output and/or LED indicate a fault (RED) on a properly

mounted XR4F and the rotor is properly located, replace the XR4F.

An oscilloscope can also be used to verify proper output of the

XR4F encoder at the encoder connector itself and at the drive/

controller cabinet. If the outputs show large variations in the signals

at steady speed (jitter or “accordion effect”, see figure 5), replace any

magnetized material nearby with non-magnetic material (aluminum,

stainless) (shafts, etc). If variations persist, consider replacing with

super-shielded models, option -004.