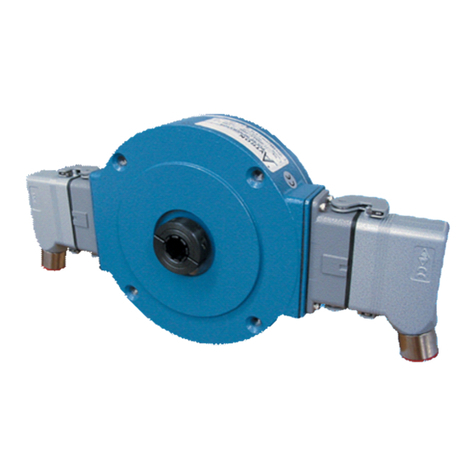

XR67 2

The XR67 construction materials contain less than 6% magnesium

by mass. These materials are not considered as able to trigger

an explosion in normal operating modes in accordance with the

requirements for category 2 or 3 equipment. These materials are

not known to react with any explosive atmospheres to which the

XR67 may be subject. It is however the responsibility of the end

user to ensure that the XR67 is selected correctly for the potentially

explosive atmosphere in which the equipment is to be put into

service.

The XR67 installation is similar to AV67. Installation and removal

videos for the AV56/67/85/115 are available on Avtron’s web site.

Refer to the back page of these instructions for outline and mounting

dimensions. The motor must comply with 1998 NEMA MG 1, section 4,

for tolerances on diameters and runout for shafts and accessory faces.

Axial float or endplay plus rotor location toleration must be less than

±0.050”.

In preparation for installing the Model XR67 encoder, it is first

necessary to clean both the accessory motor shaft and the mounting

face. These surfaces must be inspected and any paint, burrs, or other

surface imperfections removed.

Installation procedures should be performed only by qualified

personnel. Safety precautions must be taken to ensure machinery

cannot rotate and all sources of power are removed during

installation.

ROTOR INSTALLATION

The motor shaft must project at least 0.88” from the motor recessed

pilot. For set screw rotors only: Apply anti-seize compound to the

motor shaft. For all rotors: Slide the rotor onto the shaft with the

marking “Motor side” facing in, (toward the motor face). The rotor

centerline must match the sensor centerline. To accomplish this, use

the rotor locating gauge (A28504) and slide the rotor onto the shaft

until it is in the proper position as shown in Figure 1. If a guage is

not available, use the stator housing alignment grooves as shown in

Figure 3.

STANDARD CAM SCREW ROTOR INSTALLATION

Turn the cam screws of the rotor in the directions shown on the rotor

to engage the cams. Tighten to 50-60 in-lb [5.6 - 6.8 N-m] (See Figure

2) using the 3mm hex wrench. Total cam screw rotation will be less

than one turn.

CAUTION

Do not adjust the cam screws before motor shaft

mounting; bottoming out the screws, or backing them

out excessively, can lead to insufficient shaft holding

force. Thread locker is preapplied on the cam screws.

LARGE BORE SET SCREW ROTOR INSTALLATION

Apply thread locker to the rotor set screw holes, preferably from the

inside of the rotor bore before mounting. Tighten the rotor set screws

to 15 in-lb [2 N-m] using the 2mm T-handle hex wrench.

CAUTION

Use only a T-handle or torque hex wrench to tighten set

screws; using a right angle wrench will not provide

enough holding force, and the rotor may slip.

STATOR HOUSING INSTALLATION

The stator housing is attached to the motor using four socket head

cap screws (4) 3/8”-16 x 1”, locating on a 5.88” bolt circle. Longer

bolts (not included), are required for sandwich installation between a

motor and a brake. Install the four mounting bolts using thread locker

and torque to approximately 20-30 ft lbs [27 to 40 N-m] using the

5/16” T-handle hex wrench.

VERIFY ROTOR LOCATION

To ensure the rotor is properly located on the shaft: remove the back

cover if factory-preinstalled, and verify that the outer face of the rotor

is at the same depth as the alignment grooves, using a straight edge

tool. (Figure 3)

CAUTION

Do not use silicone sealants or caulk of any kind on

the motor or encoder face; these can cause

misalignment or sensor scraping damage. The XR67

electronics are fully sealed; water may enter and leave

the rotor area as needed. A drain hole option is available

if frequent moisture buildup is expected.

COVER INSTALLATION

Covers must not interfere with the motor shaft or rotor. The longest

shaft that can be used without interfering is 0.95” [25.1mm] with a

standard flat cover (Cover Style option “F”) and 2.80” [71.0mm] with

an extended “pie pan” cover (Cover Style option “E”). Through shaft

covers with seals are available for other applications (Cover Style

option “T”).

EXTENDED COVER MOUNT (Cover Style option “E”)

The extended cover mounts to the encoder housing using quantity 4

#6-32 x 0.31” screws, lock washers, and thread locker.

THRU SHAFT AND FLAT COVER INSTALLATION

(Cover Style option “T” and “F”)

The housing has a machined step in the outboard face to accept the

cover and a recessed groove for the retaining ring. Insert the cover,

line up ears on cover, smooth side facing out, fully into the machined

step until it seats against shoulder. Using a spiral assembly method,

install the retaining ring by first inserting the squared off end into the

machined groove. Flex the ring and insert it into the groove walking

it around the perimeter (A flat blade screwdriver can be used). Final

position should have the ring fully seated into groove. Remove the

cover by reversing above procedure, starting with the tang end.

V-RING INSTALLATION FOR THRU SHAFT COVERS

(Cover Style option “T”)

For thru shaft covers, verify that the shaft passes completely through

the hole in the cover. Apply a small amount of silicone lubricant to

the cover plate around the thru shaft hole. The V-Ring seal should

compress axially when it is pressed against the clean, smooth face

of the cover plate. See Figure 4 for proper installation and V-Ring

compression.

WIRING

CAUTION

Be sure to remove power before wiring the encoder.

Be sure to ground the cable shield: Avtron recommends

grounding the shield at the isolator module for Zone 1

applications or in the drive cabinet for Zone 2

applications. Cable should not be grounded multiple

places. An intrinsic safety ground is required at the

XRB1 Isolator Module.

CAUTION

SMARTSafe encoders include a local ground lug for

customer convenience and encoder frame grounding if

required to meet local electric code requirements or site

operator protection standards. This is NOT the required

XRB1 intrinsic safety ground connection required for

hazard protection against ignition of explosive

atmospheres!

Wiring diagrams are shown in the following pages.

CAUTION

Zone 1 and Zone 21 applications utilize the XRB1

isolator which requires an intrinsic safety ground to

provide hazard protection. Failure to connect this

ground, or providing an inadequate safety ground path

could result in an spark/ignition hazard which can

result in property damage, injury, or even death.