(the knob can be used together with [<] or [>] to adjust the

resolution).

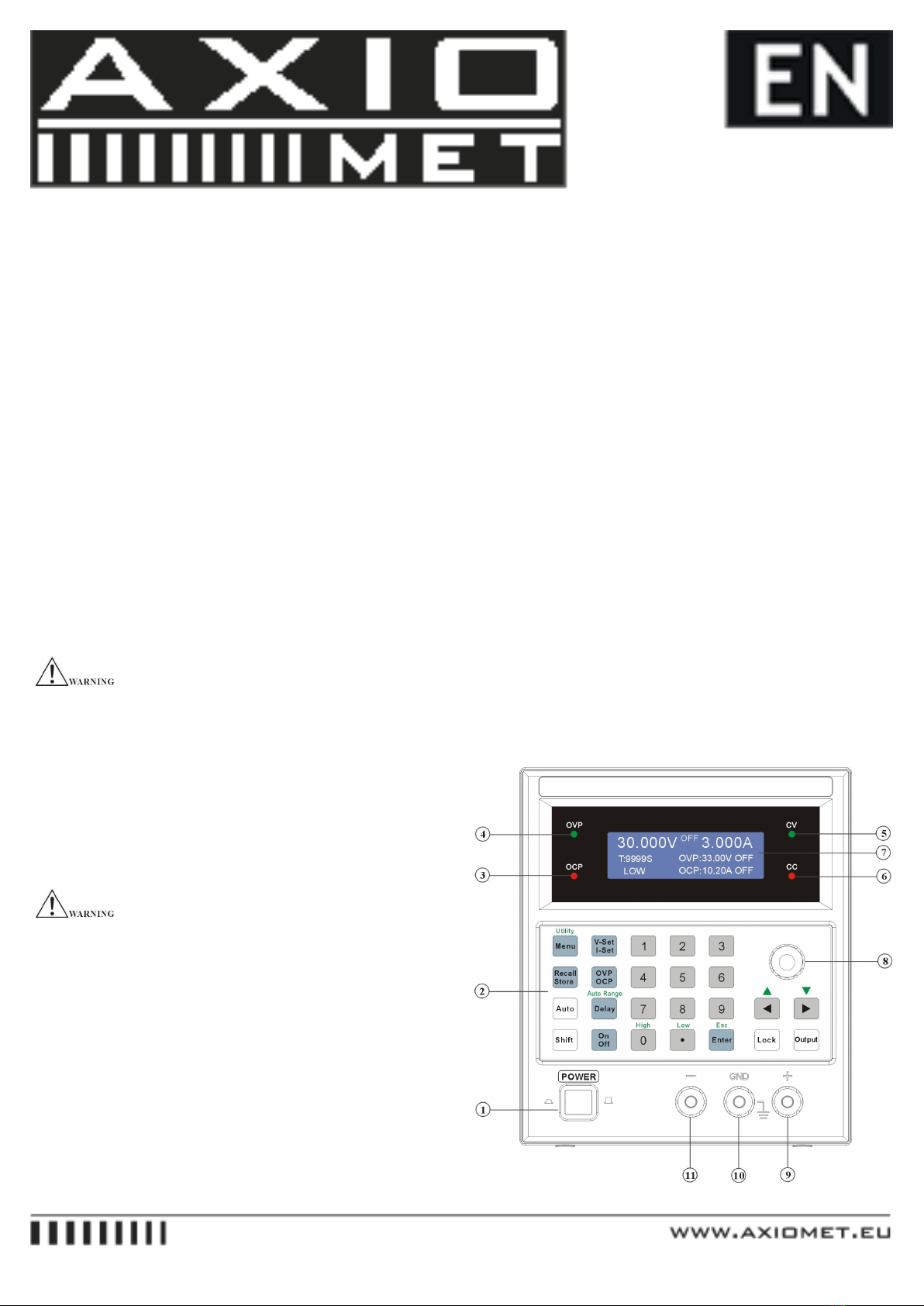

Set the desired output voltage value.

Press [V-Set/I-Set] until “Voltage” is shown on the LCD,

the panel operation is set to voltage value input mode, set the

desired change value by using the number key or the knob

(the knob can be used together with [<] or [>] to adjust the

resolution).

Start the output.

Press [Output] to enable output, now, the meter displays the

actual output measurement value.

Constant voltage mode confirmation.

Check whether the CV indicator is on or not to make sure the

output operation is under the constant voltage mode. If the

CC indicator is on, it needs to enlarge its current limit value

to assure that the output operation is under constant voltage

mode.

8.25.3. Constant Current Operation

Connect load to output terminal.

For the safety, when connect the load to output terminals of

(+) and (-), it must turn off the power.

Select output range.

Turn on the power after the load is well connected, select the

adequate operation range by pressing [High] or [Low].

Set the voltage limit value.

Press [V-Set/I-Set] until “Voltage” is shown on the LCD,

the panel operation is set to voltage value input mode, set the

desired change value by using the number key or the knob

(the knob can be used together with [<] or [>] to adjust the

resolution).

Set the desired output current value.

Press [V-Set/I-Set] until “Current” is shown on the LCD, the

panel operation is set to current value input mode, set the

desired change value by using the number key or the knob

(the knob can be used together with [<] or [>] to adjust the

resolution).

Start the output.

Press [Output] to enable output, now, the meter displays the

actual output measurement value.

Constant current mode confirmation.

Check whether the CC indicator is on or not to make sure the

output operation is under the constant current mode. If the

CV indicator is on, it needs to enlarge its voltage limit value

to assure that the output operation is under constant current

mode.

8.25.4. Store and Recall Operation

The storing setting function includes the store of the Output

range, Output voltage value, Output current value, Over

Voltage Protection level, Over Current Protection level,

Over Voltage Protection status, Over Current Protection sta-

tus and the Delay time.

Store the present setting status to the memory bank.

Press [Recall/Store] until “Utility Store” is shown on the

LCD, set the panel operation to storing setting selection,

input the desired memory address by using number key or

knob, then press [Enter] to complete the change of store.

Recall the setting status from the memory bank.

Press [Recall/Store] until “Utility Recall” is shown on the

LCD, set the panel operation to recall setting selection, use

the number key or knob to recall the desired memory address,

then press [Enter] to complete the change of recall.

8.25.5. Auto Running Operation

The function must be used together with the Delay setting

which is defined as the operation delay time of next running

operation. The Delay function is workable only under Auto

Running operation.

The setting and store of very group of data.

A group setting includes the Output range, Output volt-

age value, Output current value, Over Voltage Protection

level, Over Current Protection level, Over Voltage status

(ON/OFF), Over Current status (ON/OFF), and Delay time.

User can proceed the setting and store it to the memory bank

group by group up to 100 groups maximum.

Recall range setting (Auto running operation range).

Regarding the setting description, please refer to Auto Range

operation in section 3.5.

Enter Auto mode by pressing [Auto], now, the operation is

in the auto running function.