TABLE OF CONTENTS

1INTRODUCTION .................................................................................................................4

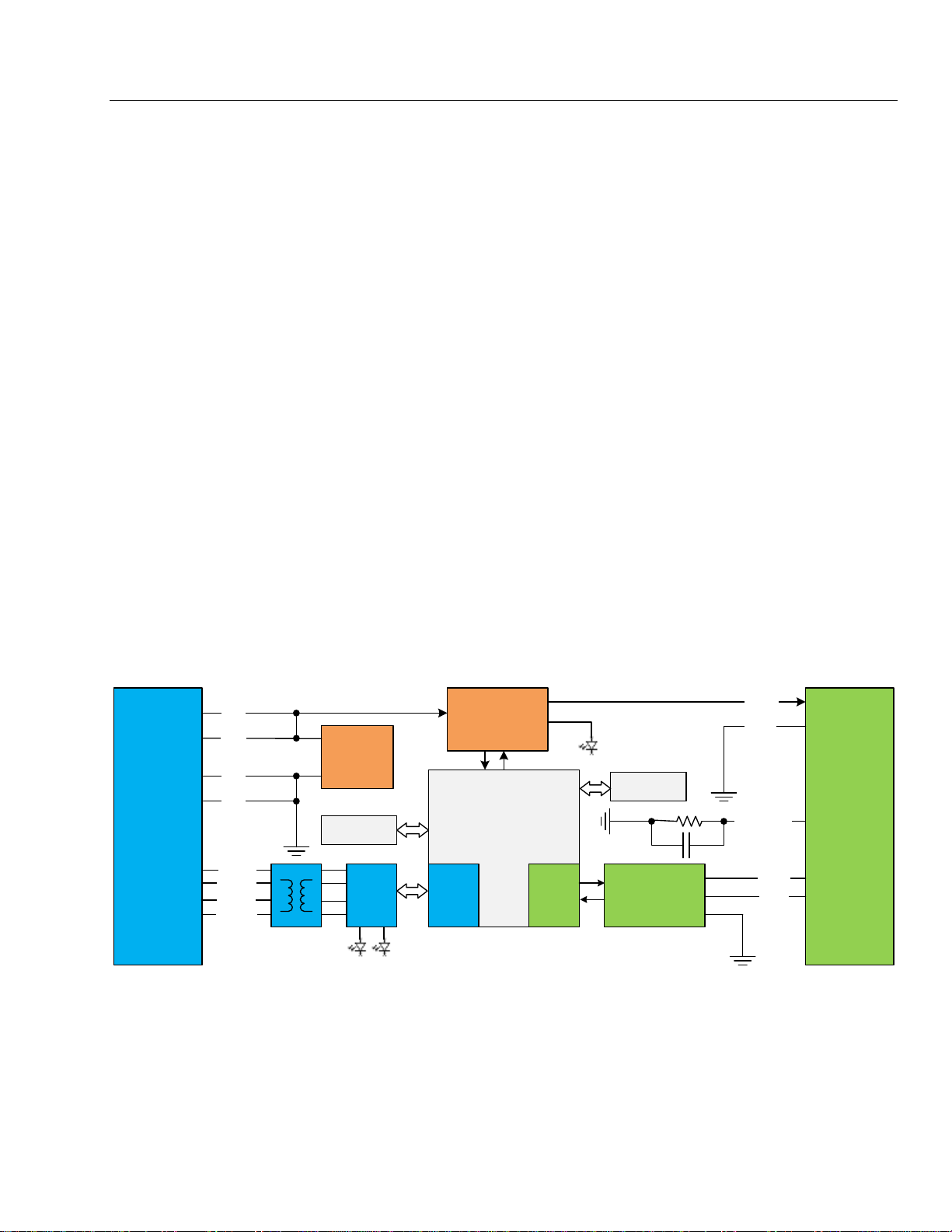

2CONVERTER DESCRIPTION.............................................................................................5

2.1 Hardware Block Diagram.................................................................................................5

2.2 LED Indicators.................................................................................................................6

2.3 Firmware Organization....................................................................................................6

2.3.1 Communication Device ...............................................................................................7

2.3.1.1 UDP Protocol ..............................................................................................................7

2.3.1.2 TCP Protocol...............................................................................................................8

2.3.2 Web Server.................................................................................................................9

2.3.3 Firmware Updates.......................................................................................................9

2.3.4 Network Discovery ......................................................................................................9

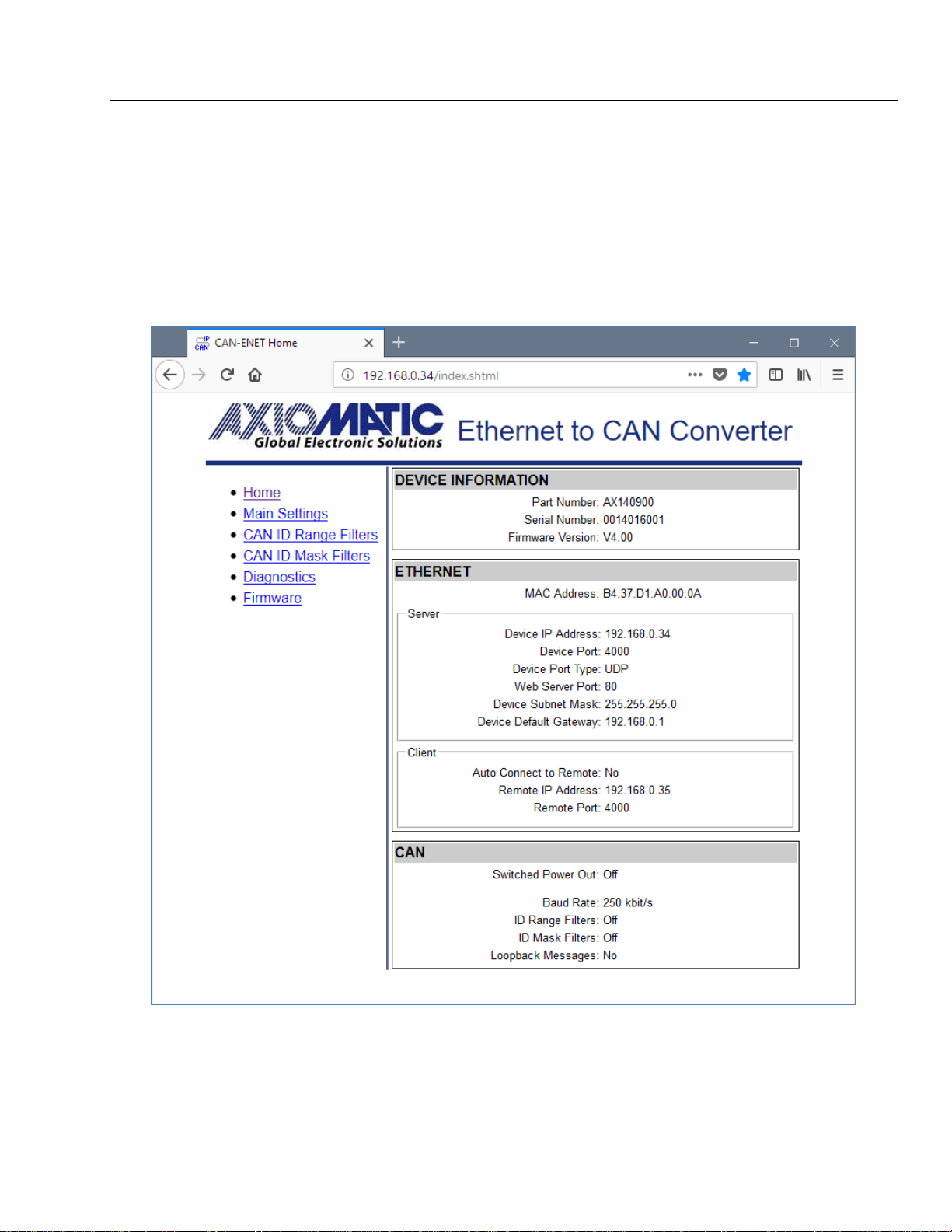

3CONVERTER CONFIGURATION .....................................................................................10

3.1 Changing Configuration Parameters .............................................................................11

3.2 Ethernet Configuration...................................................................................................14

3.3 CAN Configuration.........................................................................................................14

3.3.1 CAN ID Range Filters................................................................................................15

3.3.2 CAN ID Mask Filters..................................................................................................16

4CONVERTER DIAGNOSTICS...........................................................................................18

4.1 Health Status.................................................................................................................18

4.2 Converter Rebooting .....................................................................................................19

5FIRMWARE UPDATE........................................................................................................20

5.1 Uploading the New Firmware ........................................................................................20

5.2 Applying the New Firmware...........................................................................................21

6CONVERTER DEPLOYMENT...........................................................................................22

6.1 CAN Network Synchronization ......................................................................................22

6.1.1 Hardware Setup ........................................................................................................22

6.1.2 Converter Configuration............................................................................................23

6.1.2.1 Server Configuration .................................................................................................23

6.1.2.2 Client Configuration...................................................................................................24

7CONVERTER DISCOVERY..............................................................................................27

8TECHNICAL SPECIFICATIONS........................................................................................28

8.1 Power Supply ................................................................................................................28

8.1.1 Input..........................................................................................................................28

8.1.2 Output .......................................................................................................................28

8.2 Ethernet.........................................................................................................................28

8.2.1 Ethernet Connector...................................................................................................29

8.3 CAN...............................................................................................................................29

8.3.1 CAN Connector.........................................................................................................29

8.4 General Specifications...................................................................................................30

8.5 Accessories...................................................................................................................30

8.6 Housing .........................................................................................................................31

9THIRD PARTY SOFTWARE LICENSE NOTICES ............................................................32

10 VERSION HISTORY..........................................................................................................34