UMAX141520 Version 1B 2-19

TABLE OF CONTENT

1. GENERAL INFORMATION.................................................................................................................................. 3

1.1 Introduction....................................................................................................................................................... 3

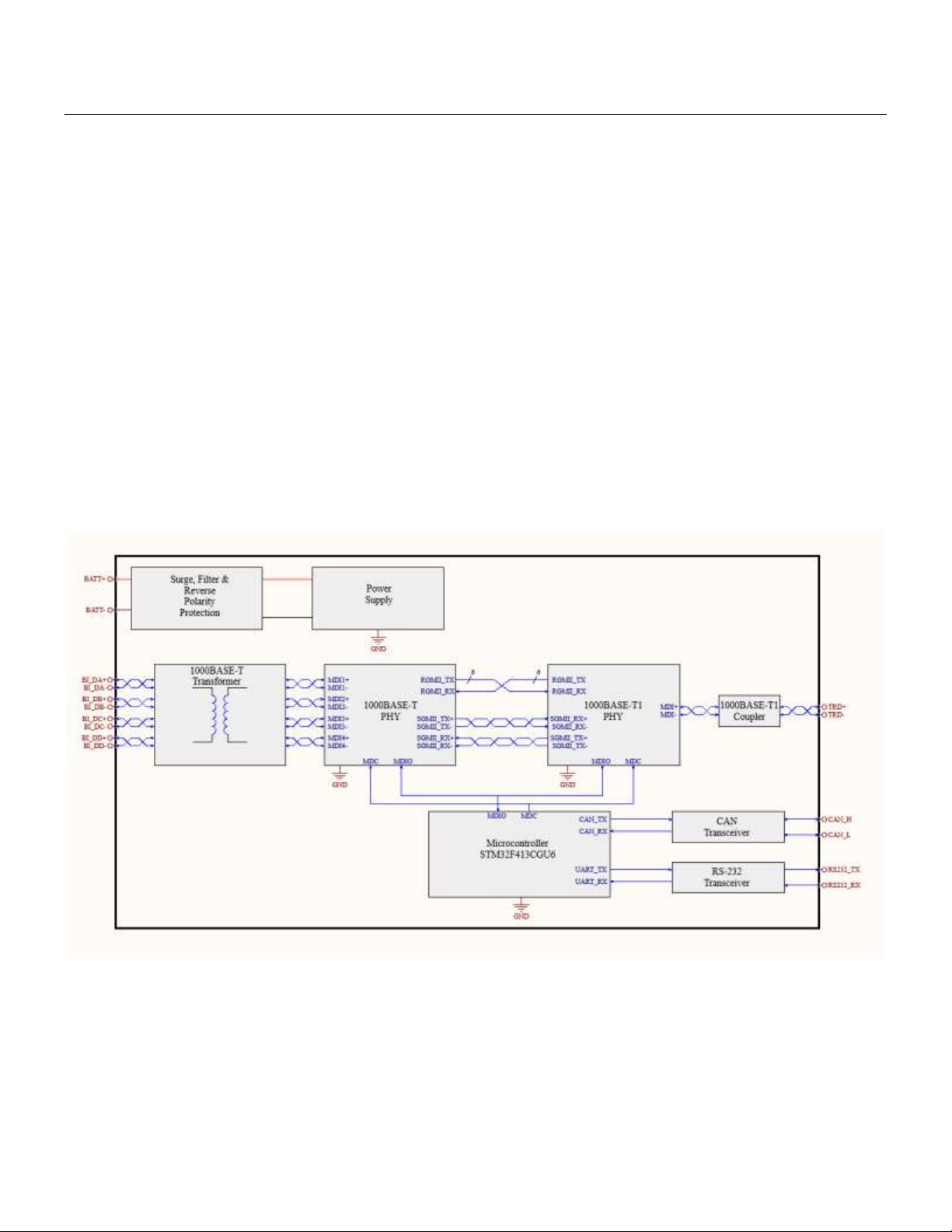

1.2 Functional Block Diagram of the Converter ...................................................................................................... 3

2. CONNECTORS....................................................................................................................................................... 4

2.1 M12 8-pin .......................................................................................................................................................... 4

2.2 M12 12-pin ........................................................................................................................................................ 4

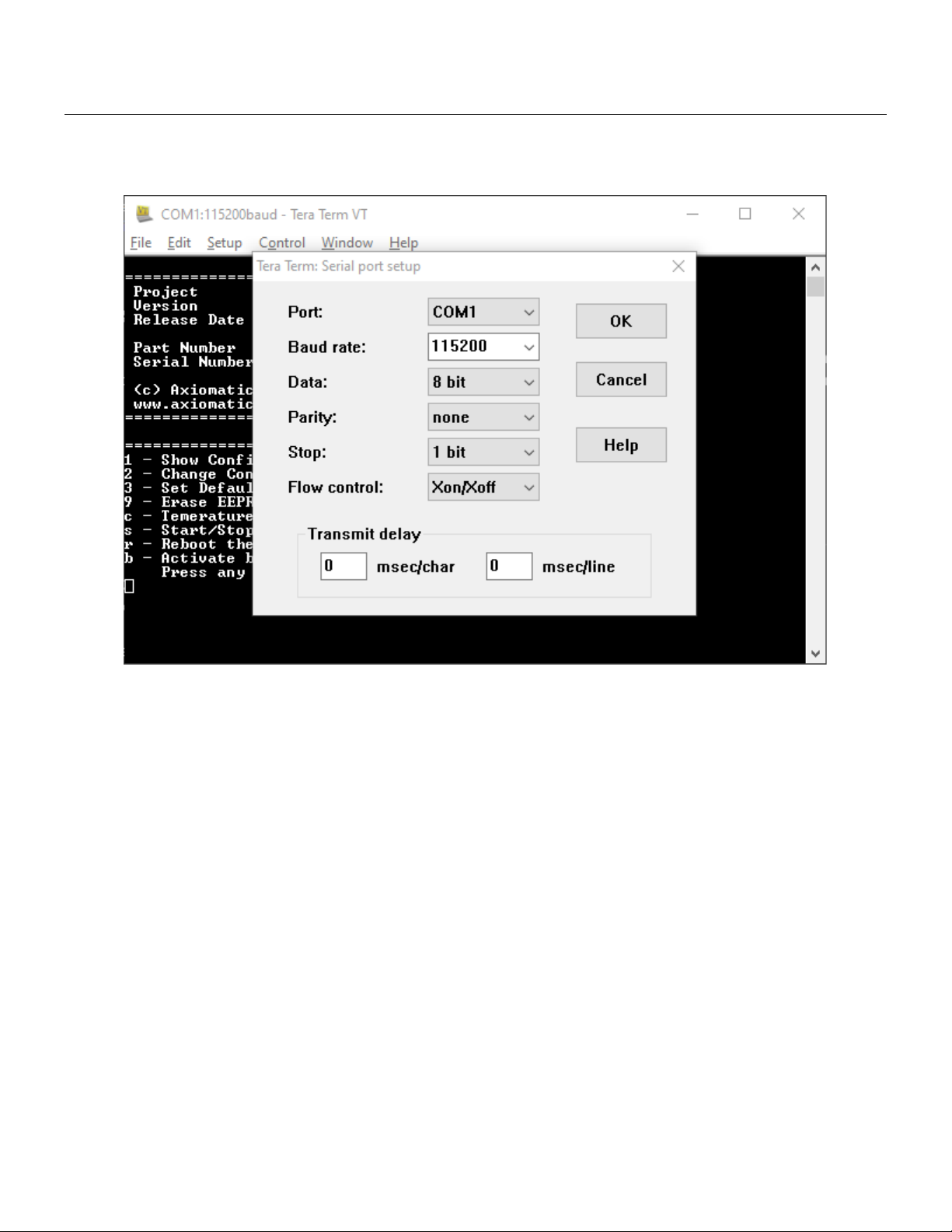

3. CONFIGURATION USING RS-232..................................................................................................................... 5

3.1 Show Configuration Parameter......................................................................................................................... 8

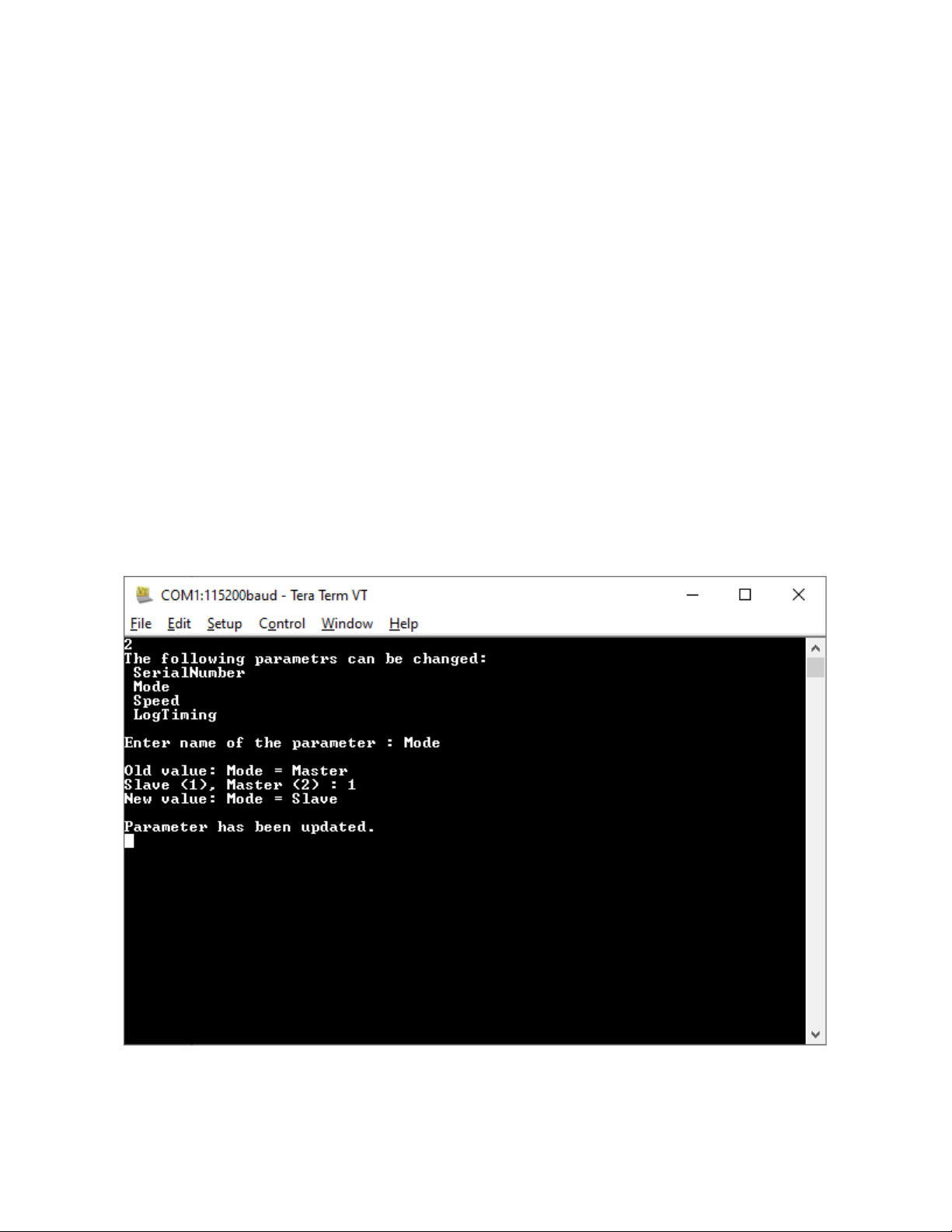

3.2 Change Configuration Parameters .................................................................................................................... 9

3.3 Set Default Configuration Parameters ............................................................................................................ 10

3.4 Erase EEPROM ................................................................................................................................................. 10

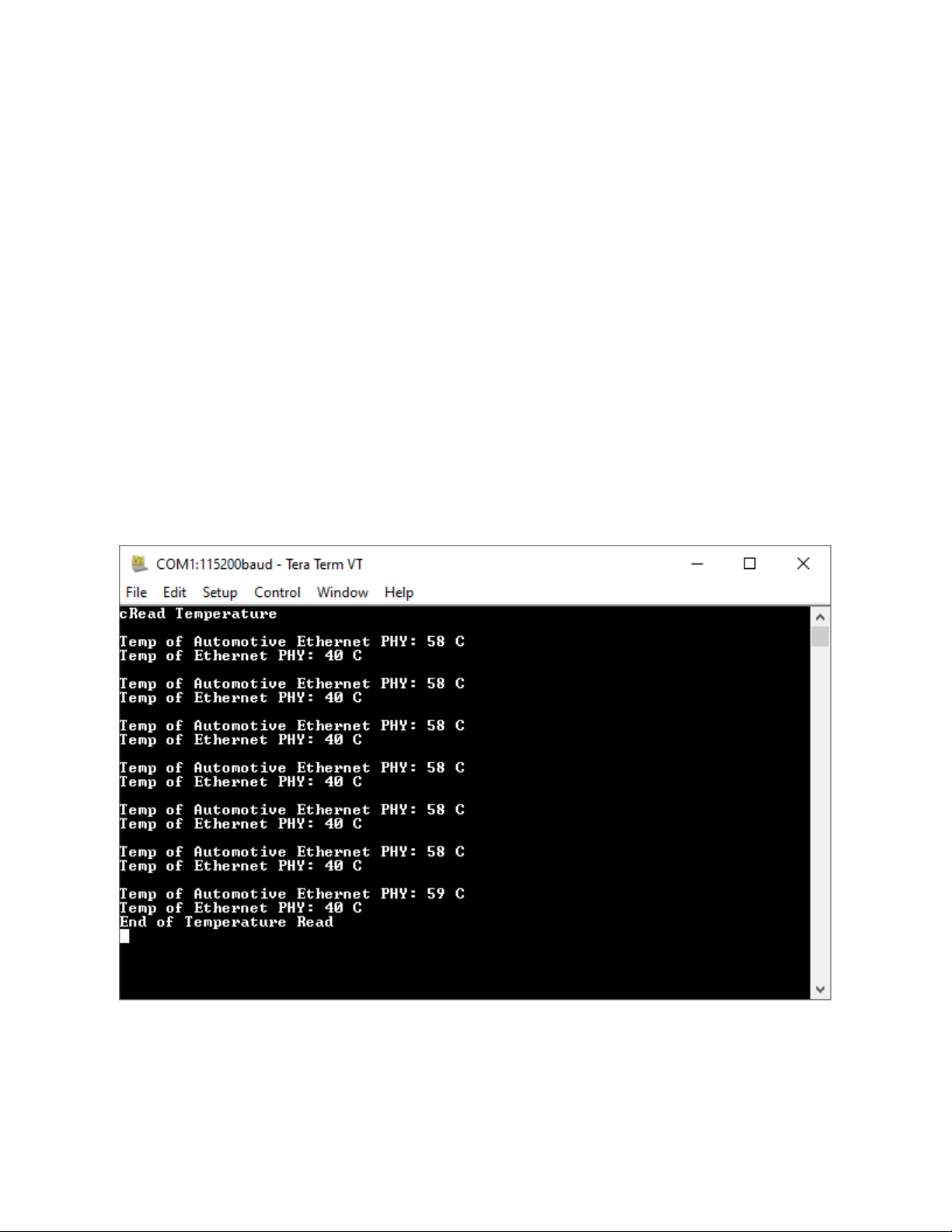

3.5 Temperature of Ethernet PHYs ....................................................................................................................... 10

3.6 Start/Stop Logs ................................................................................................................................................ 11

3.7 Reboot the Controller...................................................................................................................................... 11

3.8 Activate bootloader......................................................................................................................................... 11

3.8.1 Load New Application Firmware ............................................................................................................. 12

4. TECHNICAL SPECIFICATIONS ....................................................................................................................... 14

4.1 Power Supply Input ......................................................................................................................................... 14

4.2 Automotive Ethernet....................................................................................................................................... 14

4.3 Ethernet........................................................................................................................................................... 14

4.4 Interfaces......................................................................................................................................................... 15

4.5 General Specifications..................................................................................................................................... 15

4.6 Housing............................................................................................................................................................ 16

4.7 Electrical Connectors....................................................................................................................................... 17

5. VERSION HISTORY............................................................................................................................................ 19