04

General Instructions for 230V Machines

cutters and blades or when making any adjustments.

• Before using any machine or power tool, ensure that

all locking-nuts, chucks etc, are tightened and secure.

Check that all loose keys, spanners and other tools have

been removed.

• Always check that the correct machining or cutting

speed has been selected.

• Do not operate machinery or power tools when tired

or under the influence of alcohol, drugs or certain

medicines.

• Always ensure that long hair is tied back or retained

by a band, hat or safety helmet. Remove all loose

jewellery to prevent it from catching in rotating parts

of the machine.

WHEN USING MACHINES ALWAYS WEAR SUITABLE EYE PROTECTION,

EAR DEFENDERS AND DUST OR FUME INHALATION PROTECTION.

WARNING!! KEEP TOOLS AND EQUIPMENT OUT OF THE REACH OF

CHILDREN, UNLESS THEY ARE UNDER SUPERVISION.

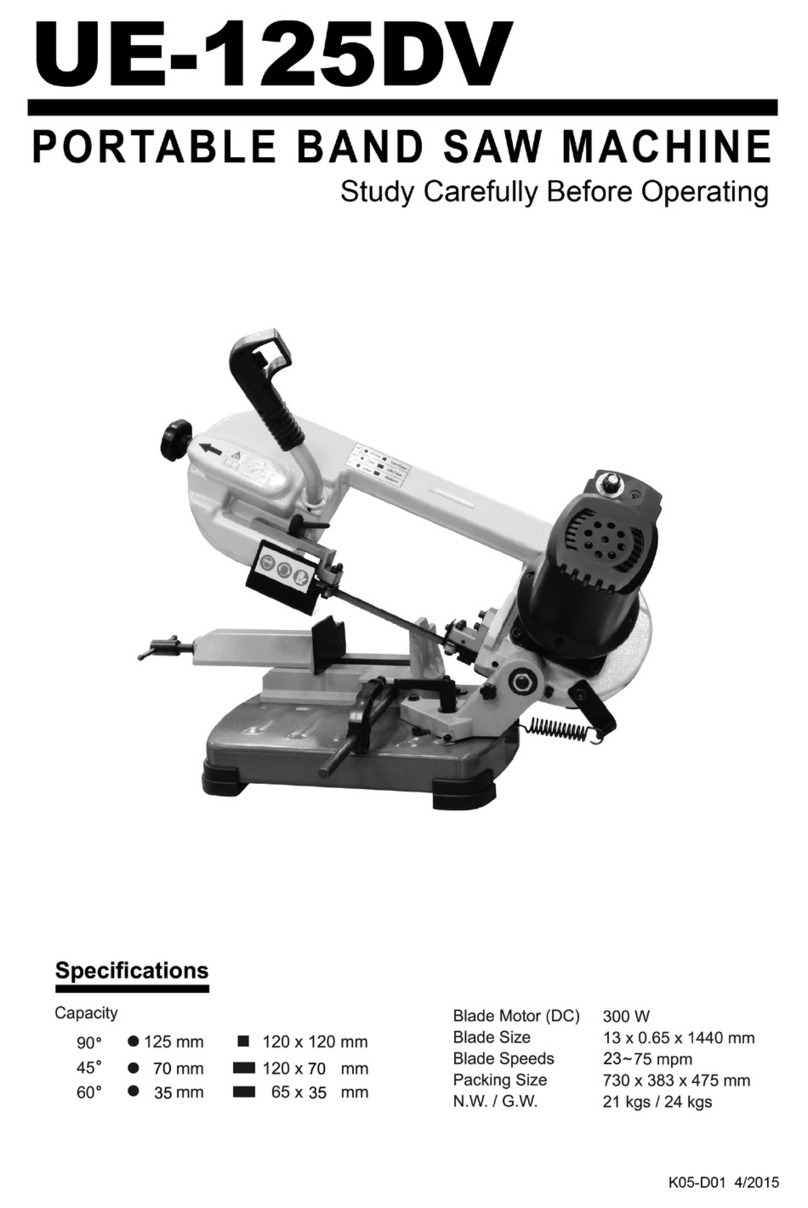

Specific Safety Instructions for Bandsaws

• Use only the correct size of blade for the machine.

Ensure that the blade is sharp and that the blade

support clearances, blade tension and tracking are all

correct. Blunt and/or in-correctly set blades require

more force and make control of the work more

difficult, leading to the possibility of accidents.

• Ensure that the blade guard and top bearing

assembly is as close to the top of the work as possible.

This will both support the blade correctly and ensure

that minimum amount of blade is exposed.

• Ensure that the table and fence, if used, are fully

tightened and cannot move under load.

• Push sticks or push pads should always be used when

cutting wood on a bandsaw. If necessary, one push

stick should be used to push the wood through the

blade and another used to hold the timber up against

the fence.

• Ensure that the blade has completely stopped before

removing small scraps of wood from the table.

• Only saw timber which is lying flat on the table; work

which is curved in the vertical plane should be fully

supported along its length in a suitable jig.

• When tight curves are being cut there is a risk of the

blade jamming in the slot in the timber. Use a narrow

blade when cutting tight curves.