0 FOREWORD.............................................................................................................................. 4

0.1 How to read and use the instruction manual........................................................................... 4

0.1.1 Importance of the manual..................................................................................................... 4

0.1.2 Safe keeping the manual...................................................................................................... 4

0.1.3 Consulting the manual.......................................................................................................... 4

0.1.4 Copyright.............................................................................................................................. 4

0.1.5 Information on the images and contents.............................................................................. 5

0.1.6 Update of the instruction manual......................................................................................... 5

0.1.7 Symbols - Meaning and use................................................................................................ 5

0.2 Who the manual is for............................................................................................................. 6

1 SAFETY AND ACCIDENT PREVENTION................................................................................. 7

1.1 General safety warnings......................................................................................................... 7

1.2 Safety signs............................................................................................................................ 9

1.2.1 Warnings on residual risks..................................................................................................10

1.3 Safety devices....................................................................................................................... 11

1.4 Technical assistance............................................................................................................. 12

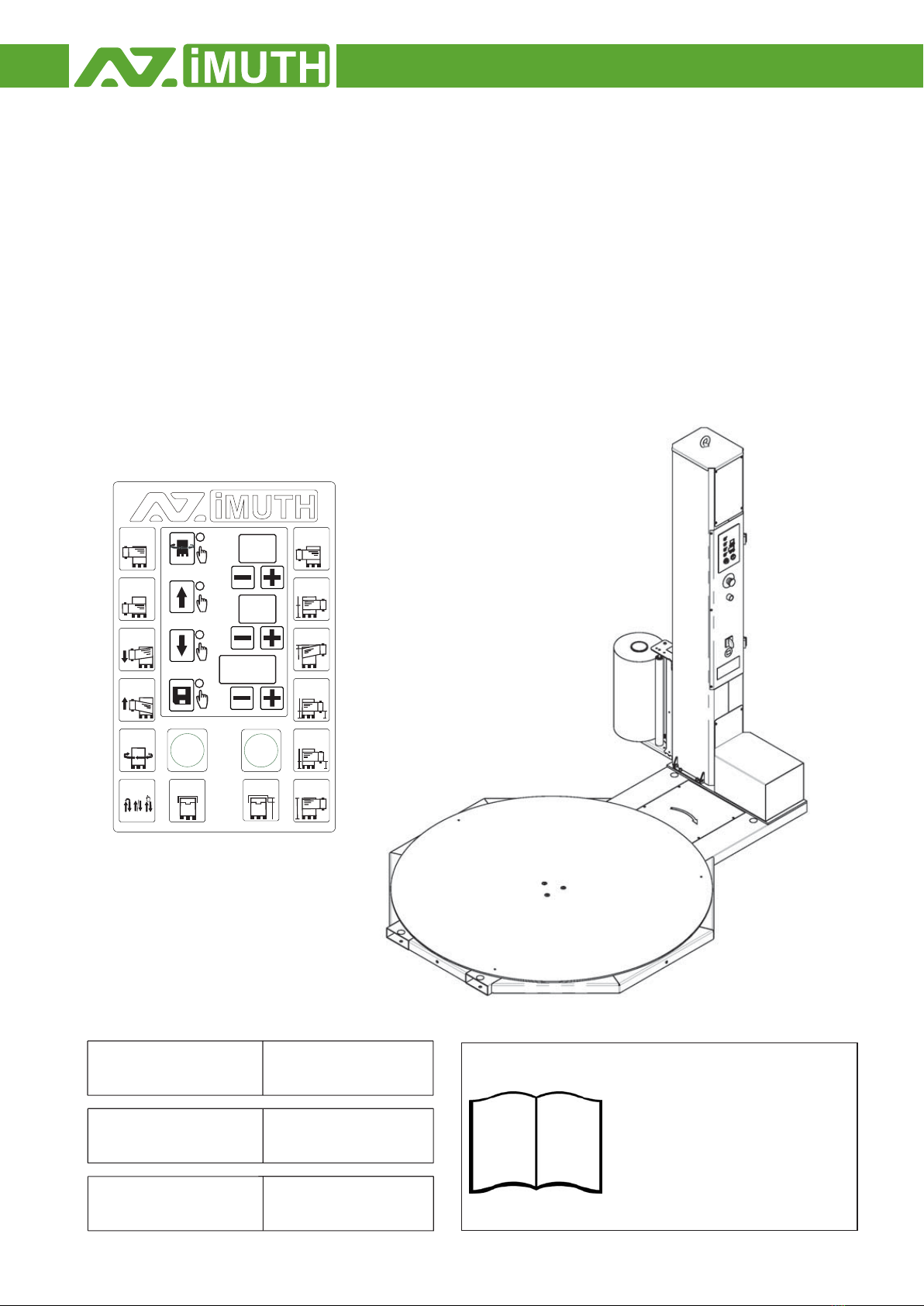

2 MACHINE DESCRIPTION....................................................................................................... 13

2.1 Manufacturer and machine identification data...................................................................... 13

2.2 General description............................................................................................................... 14

2.3 Intended use - Proper use - Purpose.................................................................................... 16

2.4 Unintended and unauthorised use - Foreseeable and unforeseeable improper use............ 17

2.5 Technical data and noise...................................................................................................... 17

2.6 Work and control stations..................................................................................................... 19

2.7 Roll-Holder carriages............................................................................................................ 20

3 TRANSPORT, HANDLING, STORAGE................................................................................... 21

3.1 Packing and unpacking......................................................................................................... 21

3.2 Transporting and handling the packed machine................................................................... 22

3.3 Transporting and handling the unpacked machine............................................................... 23

3.4 Storage of packed and unpacked machine........................................................................... 24

4 INSTALLATION....................................................................................................................... 24

4.1 Permitted ambient conditions................................................................................................ 24

4.2 Use and maintenance clearances......................................................................................... 25

4.3 Positioning the machine........................................................................................................ 25

4.3.1 Standard machine.............................................................................................................. 25

4.3.2 Machine recessed into the floor......................................................................................... 30

4.4 Electrical connection.............................................................................................................. 31

CONTENTS

2

Packaging Equipment