1

3

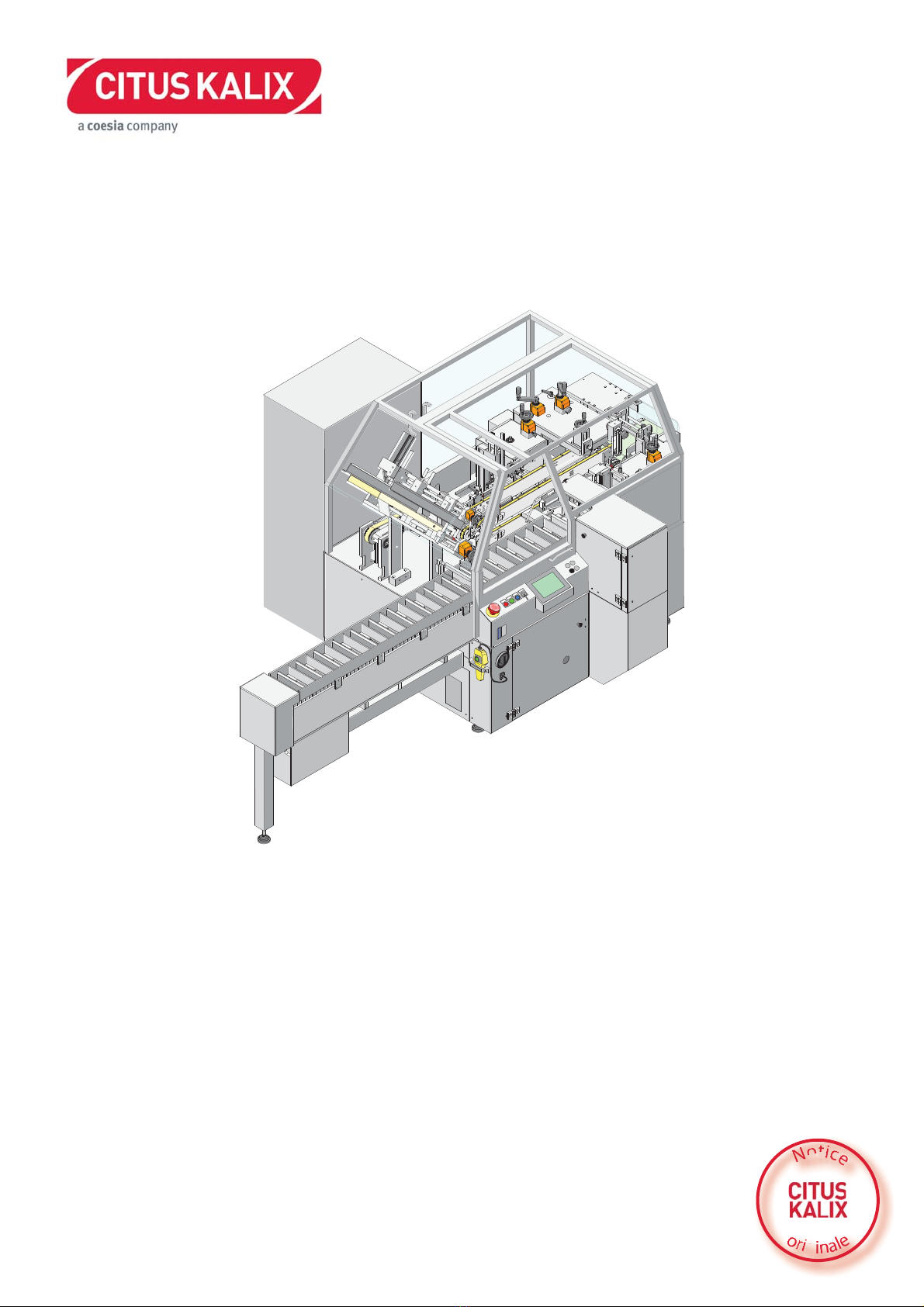

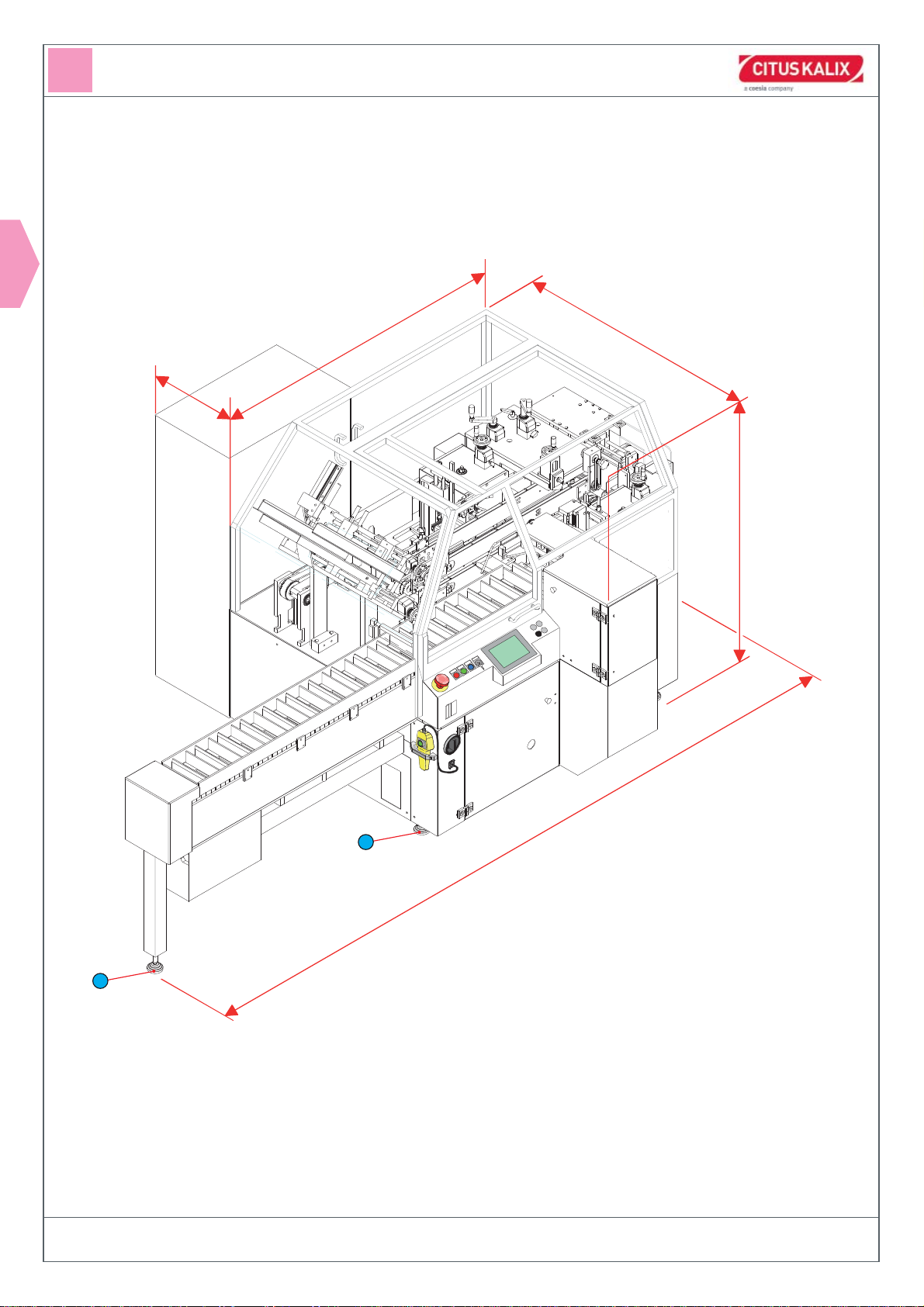

KP600 N°30314 SUSANNE LANG FRAGRANCE

• Safety devices relating to each machine must be completely checked once per year.

• Never use a machine if any of the safety mechanisms checked proves to be defective.

• Never deactivate any safety mechanisms.

• Ensure that xed and mobile safety guards are correctly in place. Replace or repair any damaged safety guards before

putting the machine into operation.

• Designate a person to be in charge of the machine settings. Section o the zone to third parties.

• Where work requiring the intervention of one or more persons cannot be carried out on a restricted-access machine,

those carrying out the work must observe the safety instructions in force in the establishment.

• Panels prohibit access to moving parts. Such panels should only be opened by maintenance workers who must take all

precautions deemed necessary to prevent accidents.

• Restrict access to the machine during maintenance work.

• Switch o the electricity supply upstream of the main breaker in the electrical cabinet before performing any form of arc

welding operations on the machine.

• Install the earth socket of the arc welding station on the area where you are carrying out your welding operations.

• Failure to observe these instructions may damage the machine in various ways, for example, its ltering capacity may be

destroyed.

• When the work is completed, ensure that no loose object remains inside the machine.

• For usual servicing requirements, always use CITUS KALIX parts.

• Do not wait for parts to become worn before replacing them.

YOU ARE RESPONSIBLE FOR ENSURING THE SAFE FUNCTIONING OF THE MACHINE.

CITUS KALIX shall not be held liable for the consequences of any incident or accident resulting from an act of negligence or

from the failure to observe the instructions and safety procedures contained in the instruction booklet.

Safety

GENERAL SAFETY INSTRUCTIONS

ALWAYS COMPLY WITH THE SAFETY MEASURES DETAILED IN ALL SECTIONS OF THE INSTRUCTION MANUAL.

Conduct a visual check of the machine before starting it to ensure that no undesirable element that may compromise the safety

of individuals or the machine is present.

Technical updates, adjustments, breakdown repair or maintenance must be carried out by authorized persons who are familiar

with the relevant instruction manual and precautions set out by CITUS KALIX, and who possess all necessary safety and

protective equipment.

Before work begins, the person responsible for carrying it out must ensure that the machine is not in use, that the motor power

has been switched o and that any residual electrical or mechanical energy has fully cleared.

CITUS KALIX will be happy to provide you with further information of a technical or commercial nature.

Should you face any diculty during use, or in the event of an incident, contact the CITUS KALIX after-sales technicians.