10015UK 01 -2004

Technical information: ES-525 Validator 4

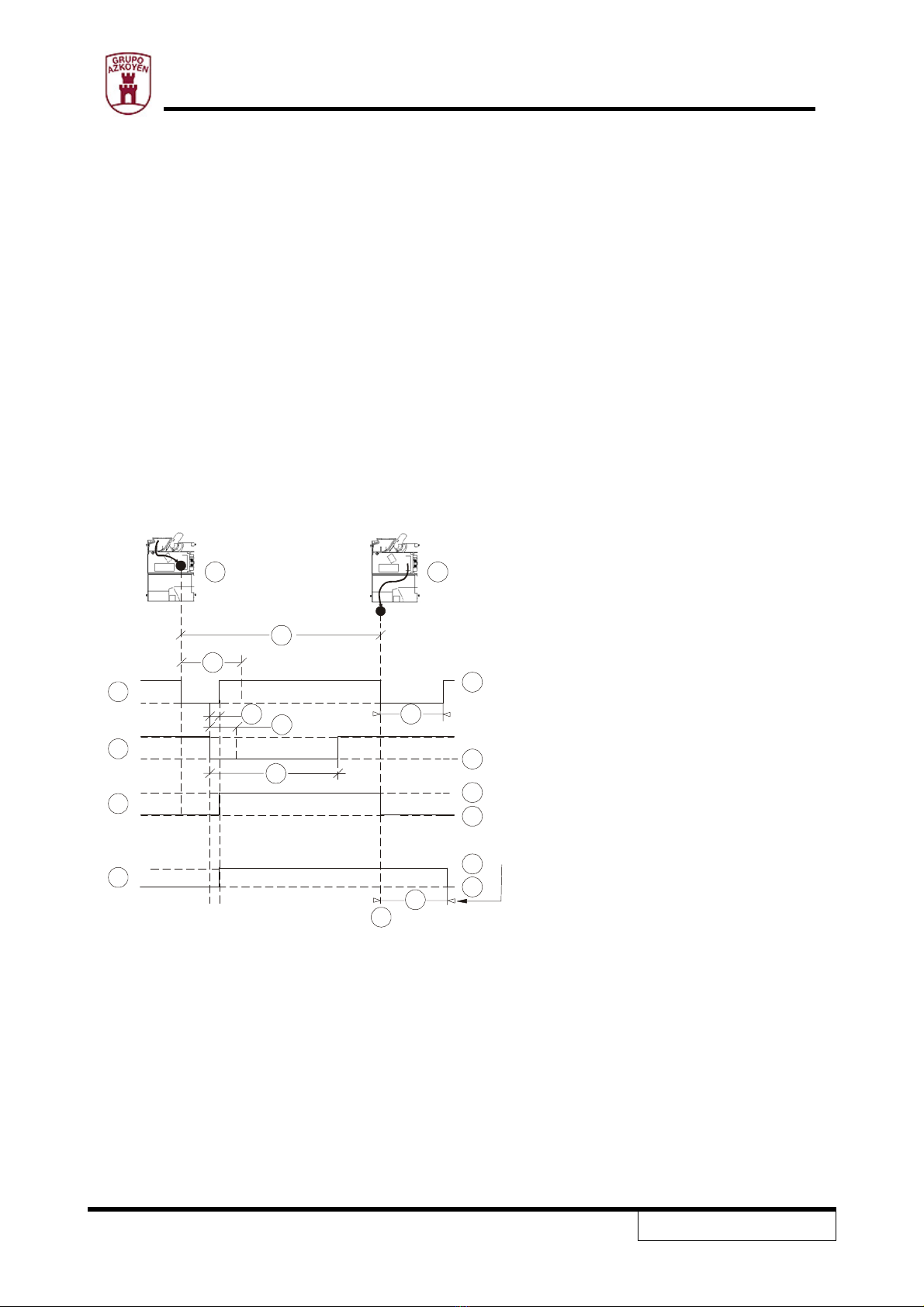

ÔThere are two protocols incorporated.

-Binary: The validator uses a combination of output lines to identify each coin.

-Dedicated: The validator uses one output line for each coin.

In this mode, the option of pulses can also be used. The same line can be used by

giving a different number of pulses to identify different coins.

Example:if an output line corresponds to a value “x” it gives 1 pulse, when a

different coin of double the value “2x” is inserted it gives 2 pulses, or 3 pulses if the

vale is “3x” and so on.

ÔYou can optionally work using Azkoyen protocol, which works the following way:

- With the validator at rest, without introducing a coin, the signals are:

xOutput lines: at rest.

xInhibition line: coins inhibited. The machine should control this line and maintain the

validator in inhibited state, high o low depending on how it is programmed. The line

that is used for this protocol to define which of the 8 inhibition lines of connector JP5

is programmed at the factory.

xOnce a coin is inserted, the validator looks at its characteristics and compares it to the

previously programmed coin tables. The result of the comparison can have two

values, valid coin (coin programmed), or coin not valid (coin not programmed). If the

coin is not valid, the validator rejects the coin and does not give a signal. If the coin is

valid, the coin acceptance process is initiated (figure 1).

xOnce the validator has recognised a valid coin, it sends a code through the output

lines informing the machine which coin it has. The duration of this pulse is between 1

millisecond minimum to 10 milliseconds maximum.

xAt this instant and within the 10 milliseconds of the pulse the machine confirms to the

validator that it wants to admit the coin, putting the inhibition line to the selected level

for at least 3 milliseconds. If the machine does not modify the inhibition line or does

not do it within the time limit, the validator will automatically reject the coin.