1 Introduction

2 DHV0017 b2 EN © b2 electronic GmbH

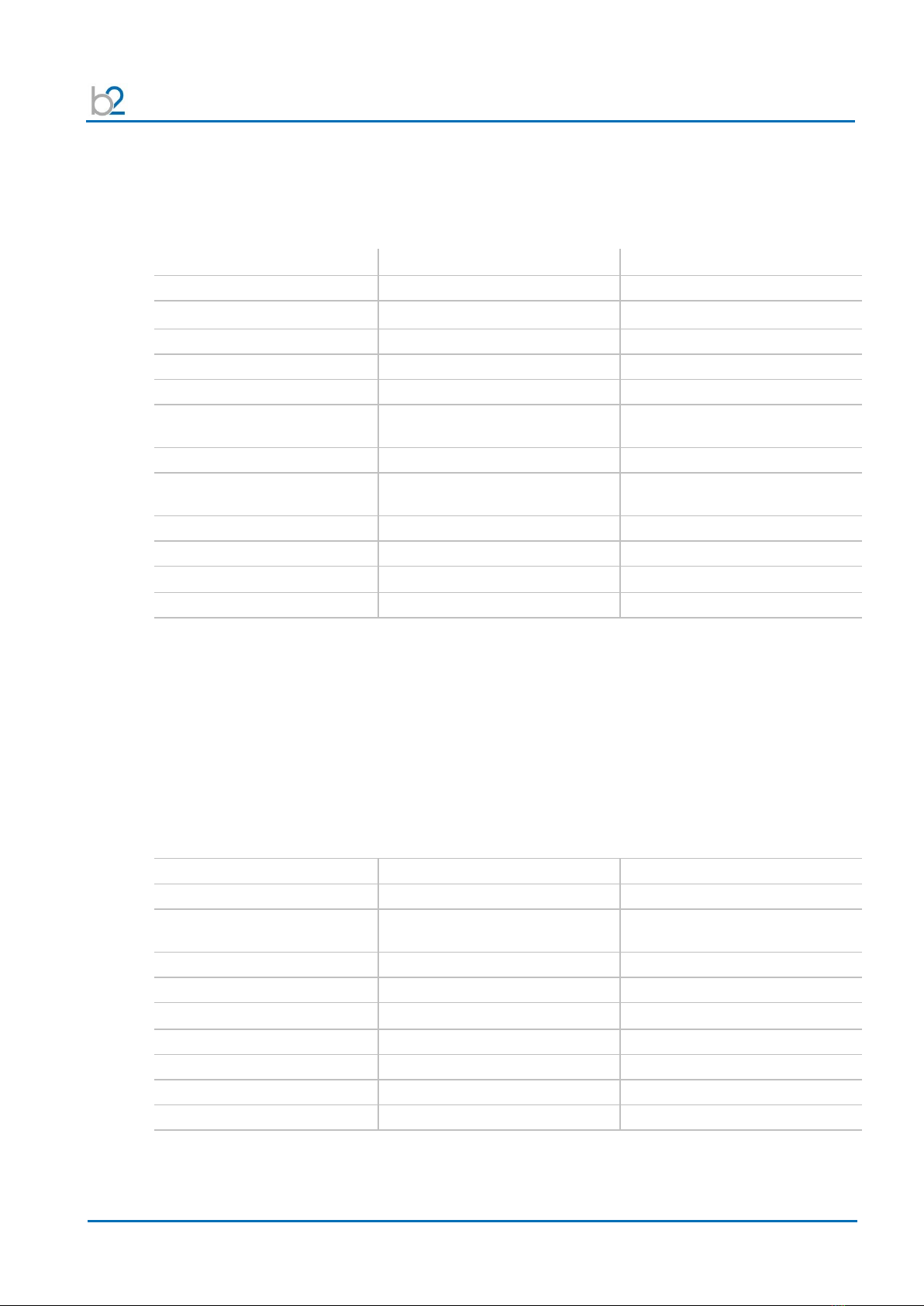

Table of Contents

1INTRODUCTION...................................................................... 3

1.1 Regarding this Document ..................................................................3

1.2 Documentation Conventions .............................................................4

1.3 Legal Considerations .........................................................................5

2SAFETY................................................................................... 7

2.1 Work Safety .........................................................................................7

2.2 Appropriate Applications ...................................................................8

3GENERAL DESCRIPTION ...................................................... 9

3.1 Technical Specifications ....................................................................9

3.2 Design Features ................................................................................11

3.3 Materials.............................................................................................12

4UNPACKING THE INSTRUMENT ......................................... 17

5DESIGN AND CONSTRUCTION ........................................... 18

5.1 Instrument Layout.............................................................................18

5.2 Instrument Set-up .............................................................................20

6SOFTWARE –REMOTE CONTROL ..................................... 25

7TEST PROCEDURE .............................................................. 26

7.1 Test Environment Criteria ................................................................26

7.2 Sample Selection and Handling ......................................................26

7.3 Instrument Connection.....................................................................27

7.4 Instrument Activation .......................................................................28

7.5Test Vessel Preparation ...................................................................28

7.6 Standard Test Execution ..................................................................29

7.7 Single Test Execution.......................................................................31

7.8 Withstand Test Execution ................................................................33

7.9 Error Messages .................................................................................35

7.10 Report.................................................................................................37

7.11 Instrument Disconnection and Termination ..................................40

8INSTRUMENT CARE............................................................. 41

8.1 Update ................................................................................................41

8.2 Installing Printer Paper Roll.............................................................41

8.3 Replacing Printer Ink Ribbon...........................................................43

8.4 Charging Internal Battery.................................................................45

8.5 Storage/Repairs.................................................................................45

9GLOSSARY AND ABBREVIATIONS .................................... 46

10 DECLARATION OF CONFORMITY....................................... 47