WWW.BALTIMOREAIRCOIL.COM.AU

2

MAR208-0

1RC SERIES

Introduction

Safety

Adequate precautions appropriate for the installation and location

of these products should be taken to safeguard the equipment and

the premises from damage and the public from possible injury. The

procedures listed in this manual must be thoroughly reviewed prior to

rigging and assembly. Read all warnings, cautions, and notes detailed

in the margins.

When the fan speed of the unit is to be changed from the factory set

speed, including the use of a variable speed device, steps must be

taken to avoid operating at or near the fan’s “critical speed” which

could result in fan failure and possible injury or damage. Consult with

your local BAC Representative on any such applications.

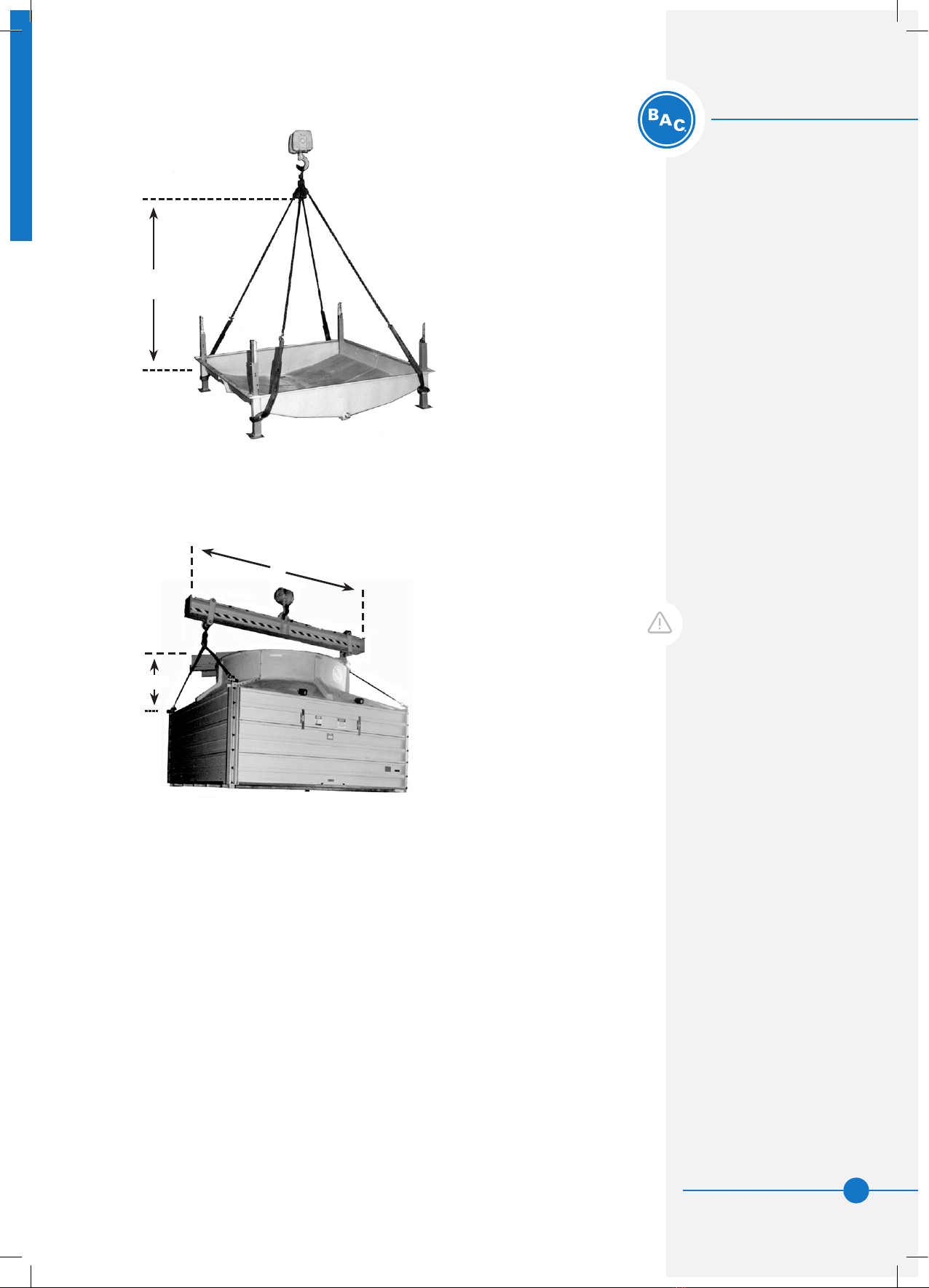

Shipping

BAC RC Series units are factory assembled to ensure uniform quality

with minimum eld assembly. As standard, models ship in two sections

per cell (lower and upper). Optional shipment of three sections per

cell and optional containerized shipments are available. Contact your

local BAC Representative for more information. For the dimensions and

weights of a specic unit or section, refer to the submittal drawings.

Pre-Rigging Checks

When the unit is delivered to the jobsite, it should be checked

thoroughly to ensure all required items have been received and are free

of any shipping damage prior to signing the bill of lading.

The following parts should be inspected:

WARNING: Failure to use

designated lifting points

can result in a dropped load

causing severe injury, death,

and/or property damage.

Lifts must be performed by

qualied riggers following BAC

published Rigging Instructions

and generally accepted

lifting practices. The use of

supplemental safety slings

may also be required if the

lift circumstances warrant

its use, as determined by the

rigging contractor.

WARNING: This equipment has

the potential to be a high risk

hazard! Do not handle, rig,

lift, install, assemble, operate,

maintain or enter this

equipment without assessing

the risks involved. control

measures must be developed

to eliminate or minimise the

potential risks.

Sheaves and Belts

Bearings

Bearing Supports

Fan Motor(s)

Fan Guard(s)

Fan(s) and Fan Shaft(s)

Float Valve Assembly(s)

Fill

Water Distribution System

Cold Water Basin Accessories

Interior Surfaces

Exterior Surfaces

Louvres

Mating Surfaces Between

Sections/Modules

Miscellaneous Items:

All bolts, nuts, washers,

and sealer tape required

to assemble sections

or component parts are

furnished by BAC and

shipped with the unit.

A checklist inside the

envelope marked “Customer

Information Packet”

indicates what miscellaneous

parts are included with the

shipment and where they are

packed. This envelope will

be attached to the side of

the unit or located in a box

inside the unit.