GENERAL INFORMATION

3

BAC cooling equipment is designed for the operating conditions

specified below, which must not be exceeded during operation.

Wind Load: For safe operation of unshielded equipment exposed to

wind speeds above 120 km/h installed at a height above 30 m from

the ground contact your local BAC-Balticare representative.

Standard electrical motors are suitable for an ambiant temperature

range from -25°C to +40°C.

CLOSED CIRCUIT COOLING TOWERS (VFL)

Design pressure : max. 16 bar

Fluid inlet temperature : max. 82°C

Fluid outlet temperature : min. 10°C

Fluids circulated through the inside of the coils must be compatible

with the coil construction material, ie.

- black steel, for hot dip galvanized coils

- stainless steel AISI 304L or 316L (options)

- galvanized steel for cleanable coil (option)

Maximum spray pressure : 14 kPa (If pump(s) are installed by

others, it is recommended to install a pressure gauge at the inlet of

the water distribution system.

EVAPORATIVE CONDENSERS (VCL)

Design pressure : 16 bar

Refrigerant inlet temperature : max. 120°C

Refrigerant outlet temperature : min. - 20°C

Suitable refrigerants : R-717, Halocarbon Refrigerants, HFC`s.

Standard condenser coils are manufactured from black steel and

hot dip galvanised after fabrication and may contain certain

contaminants, such as carbon, iron oxyde or welding particles. The

interior condition of the coil, including humid air must be

considered, when using halocarbon (or HFC) refrigerants and

sensitive system components, such as electronic expansion devices

or semi hermetic compressors. The installer must take the

necessary precautions on site to safeguard the operation of these

components in conjunction with the condenser coils.

Maximum spray pressure : 14 kPa (If pump(s) are installed by

others, it is recommended to install a pressure gauge at the inlet of

the water distribution system.)

At ambient temperatures above 40°C ensure spray water pump

remains running, even if condenser is idle. This prevents unwanted

discharge of refrigerant through safety valves (by others).

Note: Stand-by pump arrangements for evaporative fluid coolers and

condensers require alternating operation of each pump at least twice per

week to avoid stagnant water conditions and bacteriological growth.

Purge Requirements

The installer of BAC condensers must ensure proper system purging

of air prior to operation. Entrained air can obstruct free drainage of

refrigerant and reduce condensing capacity, resulting in higher

operating pressures than design. To verify absence of non

condensables in the system, follow the instructions of the BAC

Evaporative Condenser Manual E115.

Refrigerant connections on site :

All connections in the external refrigerant pipework (installed by

others) must be leak free and tested accordingly.

COOLING TOWERS (VTL)

Maximum inlet pressure : 0.5 bar

Water inlet temperature : max. 55°C (std. fill) or 65°C (high

temperature option)

For circulating water quality compatible with construction materials

refer to section ‘WATER CARE’ on page 4.

Note: Actual spray pressure is indicated on technical data sheet supplied with

order acknowledgement.

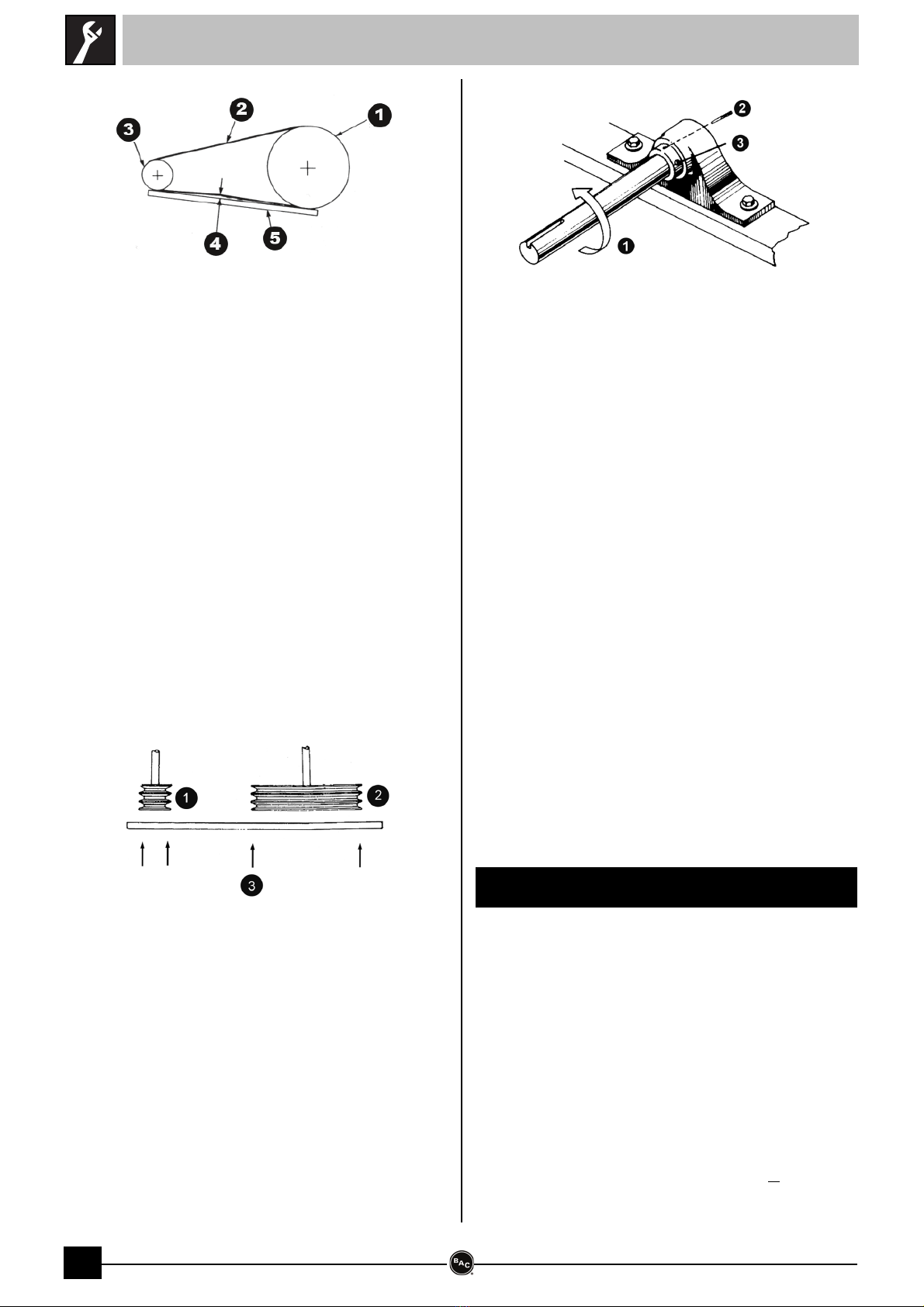

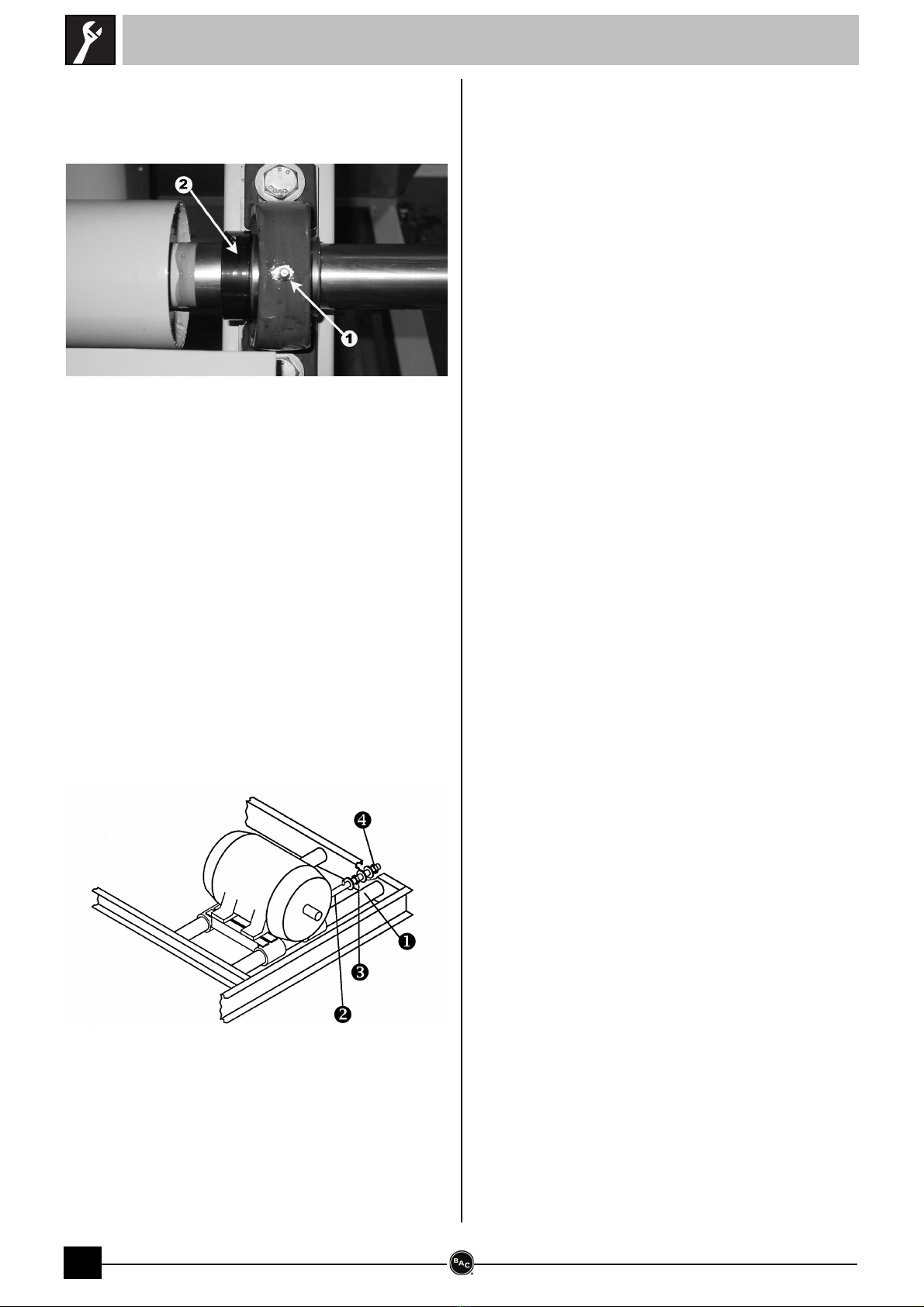

All piping external to BAC cooling equipment must be supported

separately. In case the equipment is installed on vibration rails or

springs, the piping must contain compensators to eliminate

vibrations carried through the external pipework.

All electrical, mechanical and rotating machinery constitute a

potential hazard, particularly for those not familiar with its design,

construction and operation. Accordingly adequate safeguards

(including use of protective enclosures where necessary) should be

taken with this equipment both to safeguard the public (including

minors) from injury and to prevent damage to the equipment, its

associated system and the premises.

If there is doubt about safe and proper rigging, installation,

operation or maintenance procedures, contact the equipment

manufacturer or his representative for advise.

AUTHORIZED PERSONNEL

The operation, maintenance and repair of this equipment should be

undertaken only by personnel authorized and qualified to do so. All

such personnel should be thoroughly familiar with the equipment,

the associated systems and controls and the procedures set forth in

this and other relevant manuals. Proper care, procedures and tools

must be used in handling, lifting, installing, operating and repairing

this equipment to prevent personal injury and/or property damage.

MECHANICAL SAFETY

Depending upon site conditions it also may be necessary to install

items such as bottom air inlet screens, ladders, safety cages,

stairways, access platforms, handrails and toe boards for the safety

and convenience of the authorized service and maintenance

personnel. At no time this equipment should be operated without all

fan screens, access panels and access doors in place.

When the equipment is operated with a variable fan speed control

device, steps must be taken to avoid operating at or near to the

fan’s «critical speed». For more information consult your local BAC

representative.

ELECTRICAL SAFETY

Each fan and pump motor associated with this equipment should be

installed with a lockable disconnect switch located within the sight

of the equipment. No service work should be performed on or near

the fans, motors, drives or inside the equipment unless fan and

pump motors, heaters etc. are electrically isolated.

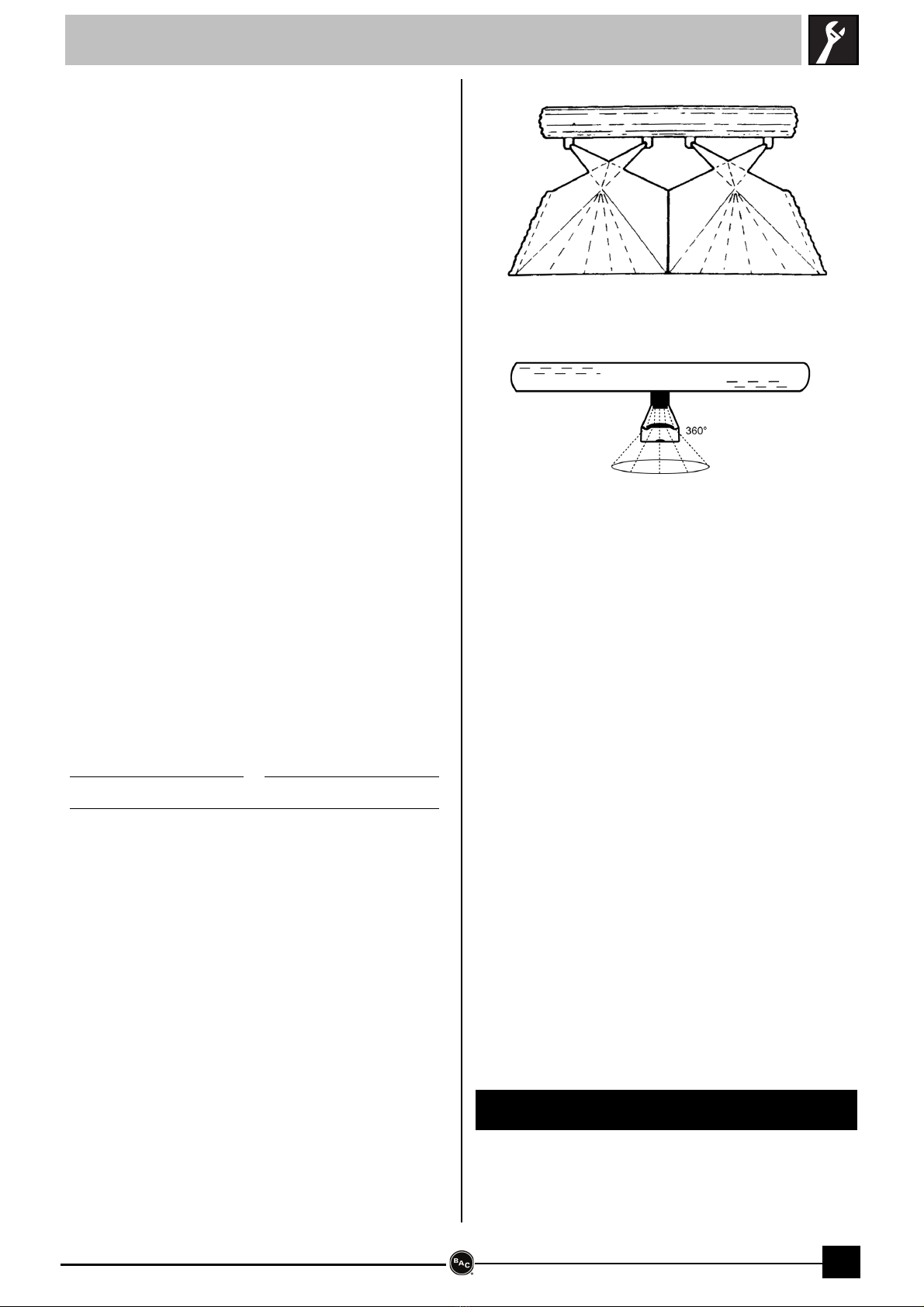

LOCATION

All cooling equipment should be located as far away as possible

from occupied areas, open windows or air intakes to buildings.

LOCAL REGULATIONS

Installation and operation of cooling equipment may be subject of

local regulations, such as establishment of risk analysis. Ensure

regulatory requirements are consistently met.

Operating Conditions Connecting Pipework

Safety Precautions