4 | 36W. Baelz & Sohn GmbH & Co. · Koepstrasse 5 · 74076 Heilbronn · Germany · www.baelz.de Seite | Page

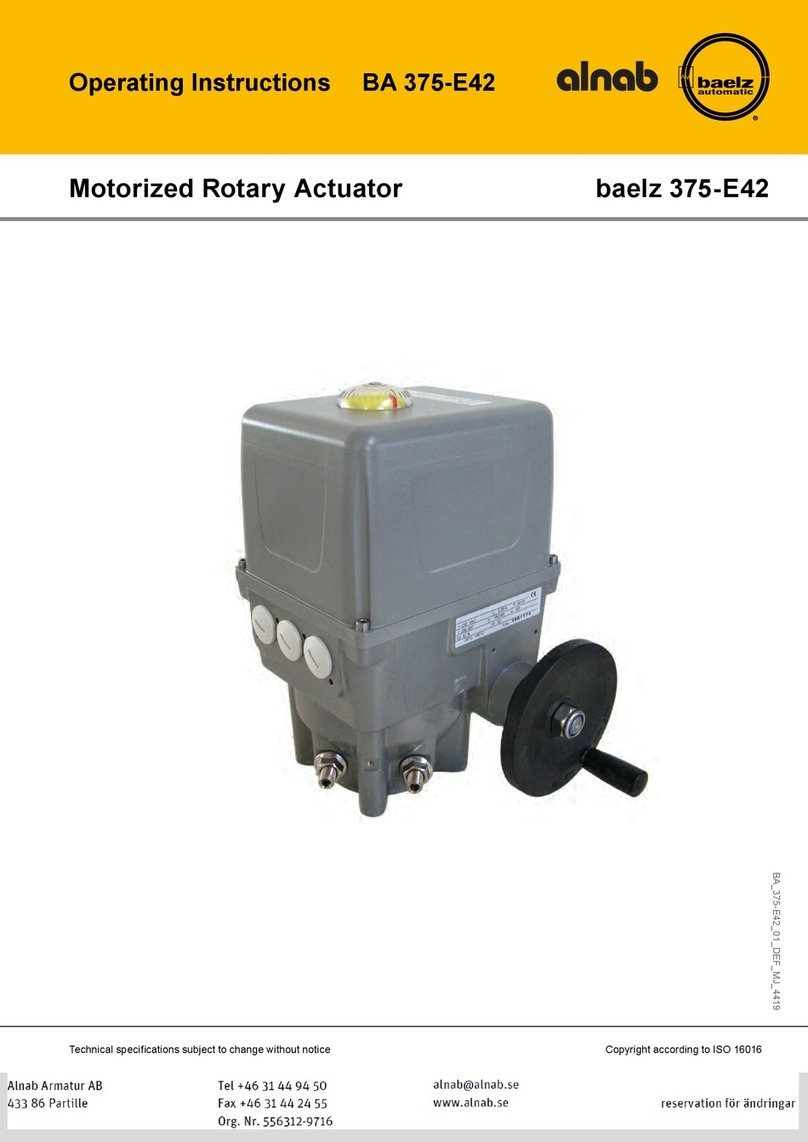

Motorized Linear Actuator baelz 373-E07

1. SAFETY

Read these operating instructions, in particular the following safety instructions, carefully

before installation and operation.

Beware

Potentially hazardous situation that could result in minor injury.

Also indicates a hazard that may result in property damage.

Beware

Caution

Potentially harmful situation in which the product or an object in its

vicinity may be damaged.

Caution

Danger

Imminent danger of death or serious injury.

Danger

Warning

Potentially hazardous situation that may result in death or serious injury.

Warning

Application instructions and other useful information.

1.1 Intended use

Baelz 373-E07 motorized linear actuators are controlled by three-point control or constant

control in combination the digital positioner baelz 7020. The linear actuators of the series

described in this document are intended for the stroke adjustment of valves.

Toensuretheirintendeduse,makesurethattheabovetypeidenticationcomplieswith

the nameplate of the linear actuators before starting any activities. The actual technical

specicationsofthelinearactuatorsandthepowersupplyrequirementsarethespecications

indicated on the nameplate.

Anyuseotherthantheintendedusementionedabove,dierenttasks,andoperationwithother

power sources than those permitted, is considered to be improper use. In case of improper

use, the operator shall be solely liable for the risk presented to persons and the device as well

as other property!

Intended use also includes compliance with accident prevention and DIN VDE regulations as

well as safe working practices for all measures described in these operating instructions, taking

into account the usual technical regulations.

1.2 Instructions for the operator

Always keep the operating instructions available at the place where the actuator is used!

During installation, operation and maintenance, observe the applicable occupational safety,

accident prevention and DIN VDE regulations. If necessary, observe additional regional, local

or internal safety regulations.

Make sure that every person entrusted with one of the measures described in these operating

instructions has read and understood these instructions.

Tip: