R7426A,B,C,D TEMPERATURE AND UNIVERSAL INPUT CONTROLLERS

63-2565 2

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 155 Gordon Baker Road, North York, Ontario M2H 3N7.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

SPECIFICATIONS

Models:

R7426A: Temperature Controller with floating, PWM, and 2 or

3-stage On/Off outputs.

R7426B: Temperature Controller for sequence control of

heating, energy recovery, and cooling. Floating, PWM, and

2,3,4,6, or 15-stage On/Off outputs.

R7426C: Temperature Controller for sequence control of

heating, energyrecovery or mixed-air damper, and cooling,

or to drive step controllers. Analog 0/2 to 10 Vdc output.

R7426D: Universal Input Controller with two transmitter inputs

for master/submaster cascade control, or main and

optional high or low limit control. One temperature

compensation input to provide main setpoint reset. One

analog output and one deviation signal output.

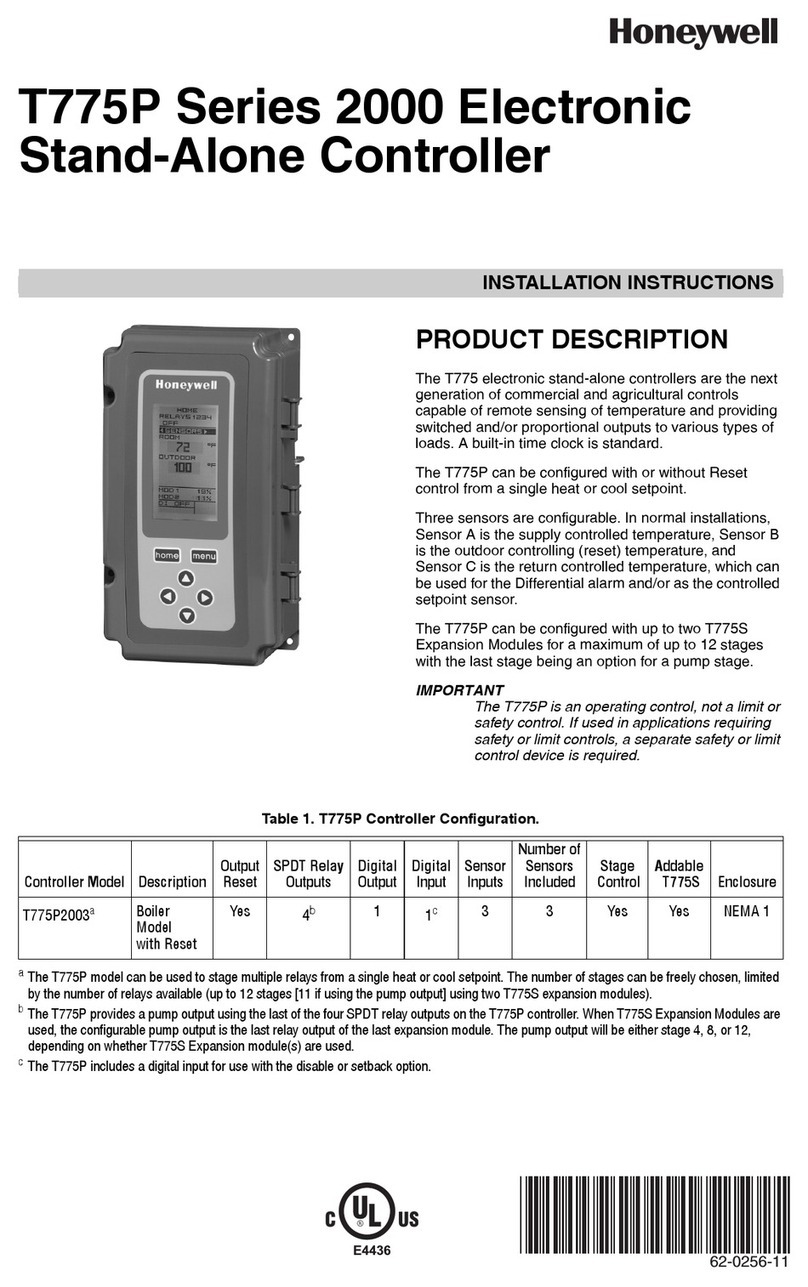

Dimensions: See Fig. 1.

Weight: 0.55 lb (250g).

Mounting: Back panel, wall, DIN rail, or (with panel mounting

accessory frame) front panel.

Electronic:

Microcontroller: 8-bit, 10-bit A/D converter, EEPROM and LCD.

Power supply: 24 Vac +10, -15%, 50/60Hz.

Power consumption: 3 VA.

Wiring:

Maximum Wiring Run from Controller to All Devices:

18 AWG: 328 ft (100m).

16 AWG: 492 ft (150m).

Offset Due to Wire Resistance: See Table 2.

Ambient Ratings:

Temperature:

Operating: 32°F to 122°F (0°C to 50°C).

Storage: -31°F to +158°F (-35°C to +70°C).

Humidity: 5 to 95% relative humidity, non-condensing.

Digital Inputs:

Occupancy (Summer/Winter Changeover) (R7426A,B,C only):

Operation Mode: Unoccupied (Winter), Occupied (Summer).

Potential Free Contact: open > 40kW, closed < 100W.

Freeze Protection (R7426A,B,C only):

Operation Mode: Freeze protection (normal).

Potential Free Contact: open > 40kW, closed < 100W.

Plant System On/Off:

Potential-Free Contact: open (off) greater than 40 kW,

closed (on) less than 100W.

Accuracy: ±0.9°F (±0.5K) (not including sensor inaccuracy).

Analog Inputs:

All Models: I03: Temperature compensation sensor.

R7426A,B,C Temperature Inputs:

I01: Main sensor.

I02: Limit or cascade sensor.

R7426D Universal Inputs (0 to100%, adjustable 0to 10 Vdc span):

I01: Main sensor.

I02: Limit or cascade sensor.

Outputs:

R7426A,B,C:

TRIAC (selectable) (Maximum Load: 450 mA at 24 Vac.):

Floating: Single-pole, double-throw (spdt) switching.

2,3,4,6 or 15-stage: On (24 Vac) / Off (0 Vac).

Pulse width modulation: 0 to 100% based on run time.

Humidity Deviation (optional): -5 to 5 Vdc, 200 mV/%rh.

Maximum Load: 450 mA at 24 Vac.

Analog (R7426C,D only):

Control Range: 0/2 to 10 Vdc (0 to 100%).

Full Range: 0 to 12 Vdc.

Maximum Load: 1.2 mA at 12 Vdc.

R7426D:

On/Off: Delay adjustable single-pole, single-throw (spst) switching.

Maximum Load: 450 mA at 24 Vac.

Deviation Signal:

Deviation Range: -5 to 5 Vdc (-25 to +25%), 200 mV/%.

Maximum Load: 0.5 mA at 5 Vdc.

Analog Output (O1):

Control Range: 0/2 to 10 Vdc (0 to 100%).

Full Range: 0 to 12 Vdc.

Maximum Load: 1.2 mA at 12 Vdc.

Sensor Ratings:

Temperature Range:

Pt 1000: -22°F to 266°F (-30°C to +130°C).

NTC 20K ohms (selectable):

-22°F to 185°F (-30°C to +85°C).

-22°F to 266°F (-30°C to +130°C).

Characteristics:

Pt 1000: 1000 ohms at 32°F (0°C).

NTC 20K ohms: 20K ohms at 77°F (25°C).

Control ranges:

R7426A,B,C: 32°F to 122°F (0°C to 50°C) or 32°F to 266°F

(0°C to 130°C).

R7426D: 0 to 100%.

Control Point Adjustments (CPA)/Setpoint Adjustments

(SPA): See Accessories and Table 1.