H-63

Economical PID Control

(A)

Photoelectric

Sensors

(B)

Fiber

Optic

Sensors

(C)

Door/Area

Sensors

(D)

Proximity

Sensors

(E)

Pressure

Sensors

(F)

Rotary

Encoders

(G)

Connectors/

Sockets

(H)

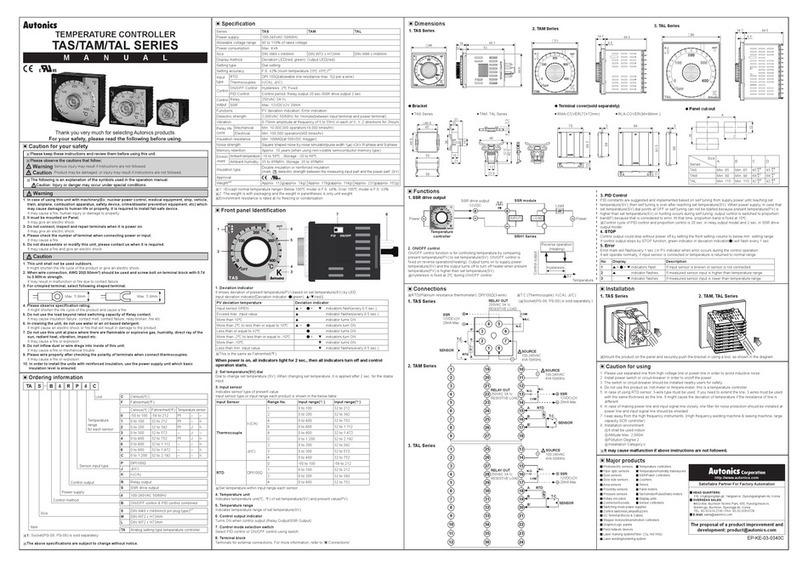

Temperature

Controllers

(I)

SSRs / Power

Controllers

(J)

Counters

(K)

Timers

(L)

Panel

Meters

(M)

Tacho /

Speed / Pulse

Meters

(N)

Display

Units

(O)

Sensor

Controllers

(P)

Switching

Mode Power

Supplies

(Q)

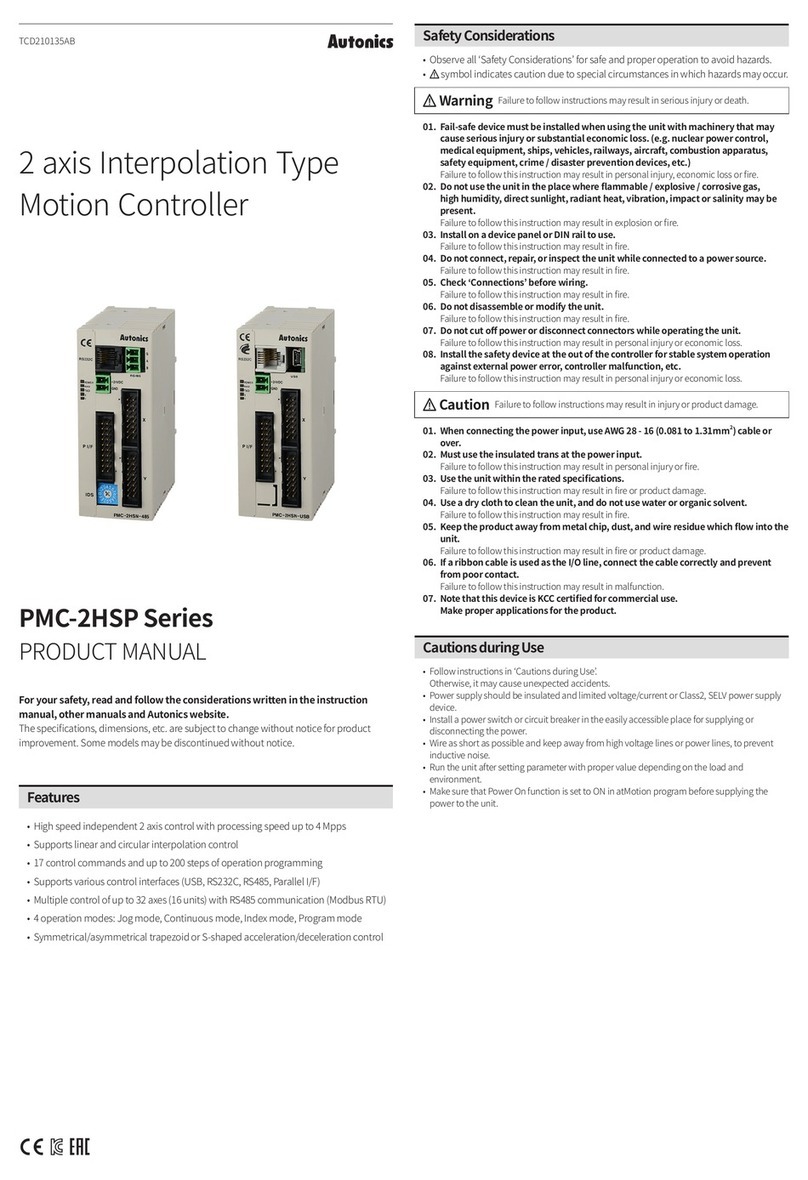

Stepper Motors

& Drivers

& Controllers

(R)

Graphic/

Logic

Panels

(S)

Field

Network

Devices

(T)

Software

Functions

Alarm operation

Alarm [AL-1 / AL-2]

Alarm

operation

Alarm

option

AM!A

Sensor break alarm

The function that alarm output will be ON when sensor is not connected or when sensor's disconnection is detected during temperature

controlling. You can check whether the sensor is connected with buzzer or other units using alarm output contact. It is selectable between

standard alarm [SBaA], or alarm latch [SBaB].

Alarm option

Mode Name Description

AM .A Standard alarm If it is an alarm condition, alarm output is ON. If it is a clear alarm condition, alarm output is OFF.

AM .B Alarm latch If it is an alarm condition, alarm output is ON and maintains ON status. (Alarm output HOLD)

AM .C Standby sequence 1

First alarm condition is ignored and from second alarm condition, standard alarm operates.

When power is supplied and it is an alarm condition, this rst alarm condition is ignored and from the

second alarm condition, standard alarm operates.

AM .D Alarm latch and

standby sequence 1

If it is an alarm condition, it operates both alarm latch and standby sequence. When power is supplied

and it is an alarm condition, this rst alarm condition is ignored and from the second alarm condition,

alarm latch operates.

AM .E Standby sequence 2

First alarm condition is ignored and from second alarm condition, standard alarm operates.

When re-applied standby sequence and if it is alarm condition, alarm output does not turn ON.

After clearing alarm condition, standard alarm operates.

AM .F Alarm latch and

standby sequence 2

Basic operation is same as alarm latch and standby sequence 1. It operates not only by power ON/OFF,

but also alarm setting value, or alarm option changing. When re-applied standby sequence and if it is

alarm condition, alarm output does not turn ON.

After clearing alarm condition, alarm latch operates.

Mode Name Alarm operation Description

AM)_

- -

No alarm output

AM!

Deviation

high-limit

alarm

SV

100℃

PV

110℃

OFF ONH

PV

90℃

SV

100℃

OFF ONH

If deviation between PV and SV as high-limit is

higher than set value of deviation temperature,

the alarm output will be ON.

High deviation: Set as 10℃ High deviation: Set as -10℃

AM@

Deviation

low-limit

alarm

PV

90℃

SV

100℃

OFFON H

SV

100℃

PV

110℃

OFFON H

If deviation between PV and SV as low-limit is

higher than set value of deviation temperature,

the alarm output will be ON.

Lower deviation: Set as 10℃ Lower deviation: Set as -10℃

AM#

Deviation

high/low-limit

alarm PV

90℃PV

110℃

SV

100℃

OFFON ONH H If deviation between PV and SV as high/low-limit

is higher than set value of deviation temperature,

the alarm output will be ON.

High/Lower deviation: Set as 10℃

AM$

Deviation

high/low-limit

reserve alarm PV

90℃PV

110℃

SV

100℃

OFFON ONH H If deviation between PV and SV as high/low-limit

is higher than set value of deviation temperature,

the alarm output will be OFF.

High/Lower deviation: Set as 10℃

AM%

Absolute

value high

limit alarm

PV

90℃

SV

100℃

OFF ONH

SV

100℃

PV

110℃

OFF ONH

If PV is higher than the absolute value,

the output will be ON.

Absolute-value Alarm:

Set as 90℃

Absolute-value Alarm:

Set as 110℃

AM^

Absolute

value low

limit alarm

PV

90℃

SV

100℃

OFFON H

SV

100℃

PV

110℃

OFFON H

If PV is lower than the absolute value,

the output will be ON.

Absolute-value Alarm:

Set as 90℃

Absolute-value Alarm:

Set as 110℃

SBa Sensor break Alarm

-

It will be ON when it detects sensor disconnection.

LBa Loop break Alarm

-

It will be ON when it detects loop break.

※H: Alarm output hysteresis [AHYS]

※Condition of re-applied standby sequence for standby sequence 1, alarm latch and standby sequence 1: Power ON

Condition of re-applied standby sequence for standby sequence 2, alarm latch and standby sequence 2: Power ON, changing set

temperature, alarm temperature [AL1, AL2] or alarm operation [AL-1, AL-2], switching STOP mode to RUN mode.

Set both alarm operation and alarm option by combining.

Each alarm operates individually in two alarm output models.

When the current temperature is out of alarm range, alarm clears

automatically. If alarm option is alarm latch or alarm latch and standby

sequence 1/2, press digital input key( + 3 sec., digital input

key[DI-K] of Parameter group 2 set as AlRE), or turn OFF the power

and turn ON to clear alarm.