Table of Contents

Page

I-E96-613A iii

SECTION 1 - INTRODUCTION....................................................................................................1-1

OVERVIEW ..................................................................................................................1-1

INTENDED USER.........................................................................................................1-1

INTERFACE DESCRIPTION ..........................................................................................1-1

MODULE DESCRIPTION ..............................................................................................1-2

INNIS01 Network Interface Slave Module................................................................1-2

INIPT02 INFI-NET to Plant Loop Transfer Module ...................................................1-2

IMMPI01 Multi-Function Processor Interface Module..............................................1-3

FEATURES...................................................................................................................1-3

INSTRUCTION CONTENT .............................................................................................1-4

HOW TO USE THIS INSTRUCTION ...............................................................................1-4

GLOSSARY OF TERMS AND ABBREVIATIONS .............................................................1-5

REFERENCE DOCUMENTS..........................................................................................1-5

NOMENCLATURE ........................................................................................................1-6

SPECIFICATIONS.........................................................................................................1-7

SECTION 2 - DESCRIPTION AND OPERATION........................................................................2-1

INTRODUCTION...........................................................................................................2-1

MODULE INTEGRITY ...................................................................................................2-1

INFI-NET to Plant Loop Messages ...........................................................................2-1

Plant Loop to INFI-NET Messages ...........................................................................2-2

INNIS01 NETWORK INTERFACE SLAVE MODULE .......................................................2-2

Messages ...............................................................................................................2-2

Broadcast ........................................................................................................2-2

Time Synchronization ......................................................................................2-2

Multicast .........................................................................................................2-2

NIS Poll ...........................................................................................................2-3

Message Format ..............................................................................................2-3

Message Transmission.....................................................................................2-3

Data Integrity.........................................................................................................2-3

Retry Logic ......................................................................................................2-3

Polling .............................................................................................................2-4

INIPT02 INFI-NET TO PLANT LOOP TRANSFER MODULE ............................................2-4

Exception Reporting...............................................................................................2-4

Control and Configuration Messages ......................................................................2-4

Status Reporting....................................................................................................2-5

Communication Protocol........................................................................................2-5

Framing...........................................................................................................2-5

Sequence Control ............................................................................................2-5

Line Control.....................................................................................................2-5

Error Detection and Recovery ..........................................................................2-6

Start-Up Control..............................................................................................2-6

Redundancy...........................................................................................................2-6

OPERATION OF SERIAL DATA CHANNELS ..................................................................2-6

SECTION 3 - INSTALLATION.....................................................................................................3-1

INTRODUCTION...........................................................................................................3-1

SPECIAL HANDLING ....................................................................................................3-1

UNPACKING AND INSPECTION ....................................................................................3-2

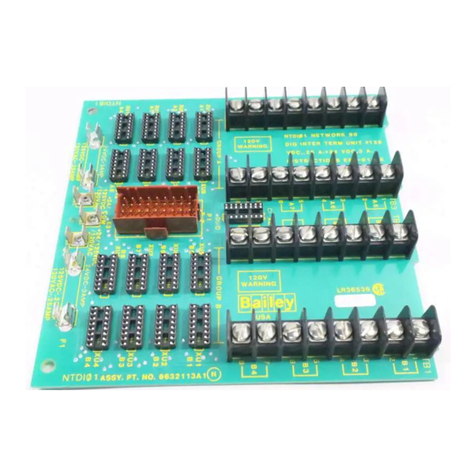

TERMINATION DEVICE CONFIGURATION AND INSTALLATION ...................................3-2