Table of Contents

Page

WBPEEUI240759A0 iii

SECTION 1 - INTRODUCTION....................................................................................................1-1

OVERVIEW ..................................................................................................................1-1

INTENDED USER .........................................................................................................1-2

COMPATIBILITY ...........................................................................................................1-2

HARDWARE REQUIREMENTS .....................................................................................1-2

FEATURES...................................................................................................................1-2

INSTRUCTION CONTENT .............................................................................................1-3

HOW TO USE THIS INSTRUCTION ...............................................................................1-3

DOCUMENT CONVENTIONS ........................................................................................1-4

GLOSSARY OF TERMS AND ABBREVIATIONS .............................................................1-4

REFERENCE DOCUMENTS..........................................................................................1-5

NOMENCLATURE ........................................................................................................1-5

SPECIFICATIONS .........................................................................................................1-5

SECTION 2 - DESCRIPTION AND OPERATION........................................................................2-1

INTRODUCTION...........................................................................................................2-1

MODULE OPERATION..................................................................................................2-1

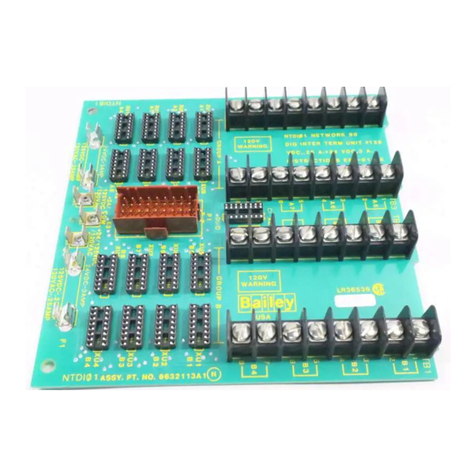

MODULE DESCRIPTION ..............................................................................................2-1

FUNCTION CODES ......................................................................................................2-3

SECTION 3 - INSTALLATION.....................................................................................................3-1

INTRODUCTION...........................................................................................................3-1

SPECIAL HANDLING ....................................................................................................3-1

UNPACKING AND INSPECTION ....................................................................................3-2

SWITCHES...................................................................................................................3-2

IP Address (S1, S2, S3, S4) .....................................................................................3-3

Hardware Options (S5) ...........................................................................................3-3

I/O Expander Bus Address (S6)..............................................................................3-4

JUMPERS (E1 TO E13) .................................................................................................3-5

MMU INSTALLATION....................................................................................................3-6

CABLE CONNECTIONS ................................................................................................3-6

FIRMWARE/PROTOCOL DOWNLOAD ..........................................................................3-7

SECTION 4 - FUNCTION CODE CONFIGURATION..................................................................4-1

INTRODUCTION...........................................................................................................4-1

FUNCTION CODES ......................................................................................................4-1

Factory Instrumentation Protocol Handler ..............................................................4-1

Digital Input Subscriber .........................................................................................4-1

Analog Input Subscriber ........................................................................................4-1

Analog Output Subscriber......................................................................................4-2

Digital Output Subscriber ......................................................................................4-2

PLC Support ..........................................................................................................4-2

Configuration.........................................................................................................4-2

PLC Performance ...................................................................................................4-2

EDI Performance....................................................................................................4-3

Data Output Options .............................................................................................4-4

CALCULATING IP ADDRESS SPECIFICATIONS ............................................................4-5

LINKING SUBSCRIBERS ..............................................................................................4-6

GROUPING SUBSCRIBERS ..........................................................................................4-6

EXAMPLE CONFIGURATION ........................................................................................4-6