Table of Contents

Page

I-E96-621A iii

SECTION 1 - INTRODUCTION....................................................................................................1-1

OVERVIEW ..................................................................................................................1-1

INTENDED USER.........................................................................................................1-2

INTERFACE DESCRIPTION ..........................................................................................1-2

Plant Loop to Computer Transfer Module (INPCT01) ...............................................1-2

Bus Transfer Module (INBTM01) ............................................................................1-2

Loop Interface Module (INLIM03) ............................................................................1-2

FEATURES...................................................................................................................1-3

INSTRUCTION CONTENT .............................................................................................1-3

HOW TO USE THIS MANUAL .......................................................................................1-3

GLOSSARY OF TERMS AND ABBREVIATIONS .............................................................1-4

REFERENCE DOCUMENTS..........................................................................................1-4

SPECIFICATIONS.........................................................................................................1-5

NOMENCLATURE ........................................................................................................1-6

SECTION 2 - DESCRIPTION AND OPERATION........................................................................2-1

INTRODUCTION...........................................................................................................2-1

INTERFACE OPERATION..............................................................................................2-1

Loop Interface Module INLIM03..............................................................................2-1

Bus Transfer Module INBTM01 ..............................................................................2-2

Plant Loop to Computer Transfer Module INPCT01 .................................................2-2

SECTION 3 - INSTALLATION.....................................................................................................3-1

INTRODUCTION...........................................................................................................3-1

SPECIAL HANDLING ....................................................................................................3-1

UNPACKING AND INSPECTION ....................................................................................3-1

INPCT01 SWITCH SETTINGS .......................................................................................3-2

Option Switch (U72)...............................................................................................3-2

Serial Port Communication Rate (U73) ...................................................................3-2

Port Address (U75) .................................................................................................3-4

INLIM03 SWITCH SETTINGS ........................................................................................3-4

INBTM01 SWITCH SETTINGS.......................................................................................3-7

INPBS01 SWITCH SETTINGS .......................................................................................3-8

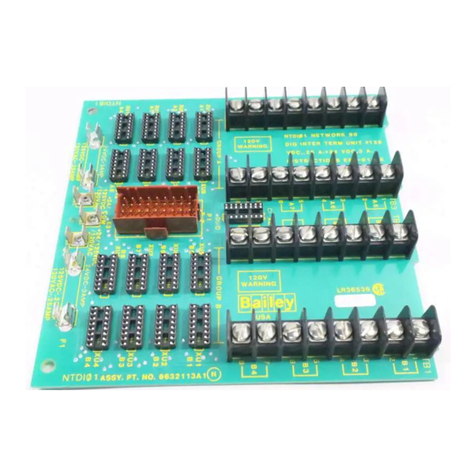

TERMINATION UNIT (MODULE) CONFIGURATION AND INSTALLATION .......................3-9

INSTALLING THE INTERFACE MODULES ....................................................................3-9

Installing the INPCT01 .........................................................................................3-10

Installing the INLIM03 and INBTM01 ...................................................................3-10

Installing the INPBS01 .........................................................................................3-11

SECTION 4 - OPERATING PROCEDURES................................................................................4-1

INTRODUCTION...........................................................................................................4-1

PLANT LOOP TO COMPUTER TRANSFER MODULE LEDs AND CONTROLS .................4-1

Status LED ............................................................................................................4-2

CPU LEDs..............................................................................................................4-2

Memory LEDs ........................................................................................................4-2

Stop Pushbutton....................................................................................................4-2

Reset Pushbutton ..................................................................................................4-2