Curtis 1204M User manual

Other Curtis Controllers manuals

Curtis

Curtis 1239E User manual

Curtis

Curtis 1297 User manual

Curtis

Curtis 1226 User manual

Curtis

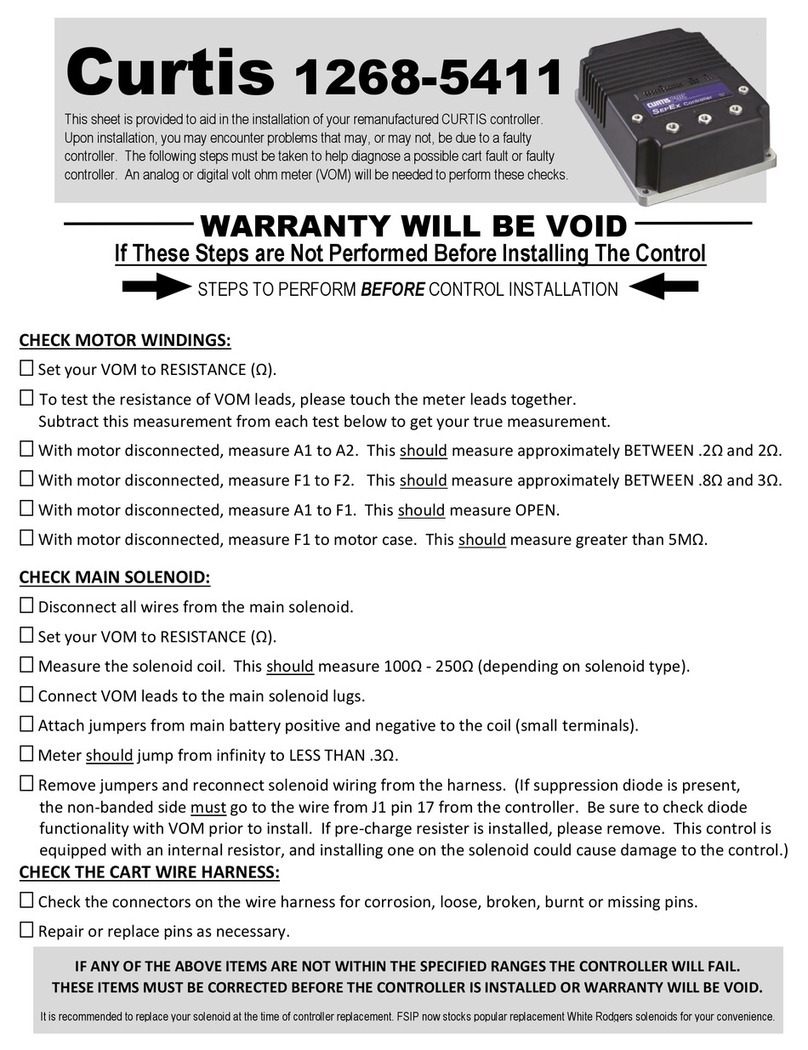

Curtis 1268 User manual

Curtis

Curtis PMC 1204 Series User manual

Curtis

Curtis 1232E User manual

Curtis

Curtis 1204 User manual

Curtis

Curtis 1220 User manual

Curtis

Curtis 1310 User manual

Curtis

Curtis 1244 User manual

Curtis

Curtis 1232E User manual

Curtis

Curtis 1298 User manual

Curtis

Curtis MultiMode 1214-8 User manual

Curtis

Curtis 1222 User manual

Curtis

Curtis 1232E User manual

Curtis

Curtis 1232E User manual

Curtis

Curtis MultiMode 1228 User manual

Curtis

Curtis 1268-5411 User manual

Curtis

Curtis 1355 User manual

Curtis

Curtis MultiMode 1207B User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions