1USER INSTRUCTIONS 5

1.1 Introduction........................................................................................................... 5

1.2 Other applicable documents............................................................................... 5

1.3 Symbols and Conventions .................................................................................. 5

1.3.1 Bulleted Lists.................................................................................................... 5

1.3.2 Actions ............................................................................................................. 6

1.3.3 Numbers........................................................................................................... 6

1.3.4 Parameters....................................................................................................... 6

1.3.5 Directory paths................................................................................................. 6

1.3.6 ASCII code....................................................................................................... 6

1.4 Explanation of the warnings................................................................................ 6

1.5Used Technical Terms and Abbreviations......................................................... 7

1.6 Copyright............................................................................................................... 8

1.7 Legal requirements .............................................................................................. 8

1.8 Updates and upgrades......................................................................................... 8

1.9 Trademarks ........................................................................................................... 8

2SAFETY 9

2.1 Intended use ......................................................................................................... 9

2.2 General safety notes ............................................................................................ 9

2.2.1 Installation and startup..................................................................................... 9

2.2.2 Conformity........................................................................................................ 9

2.2.3 Operation ......................................................................................................... 9

2.2.4 Maintenance, inspection, repair....................................................................... 9

2.3 Disposal............................................................................................................... 10

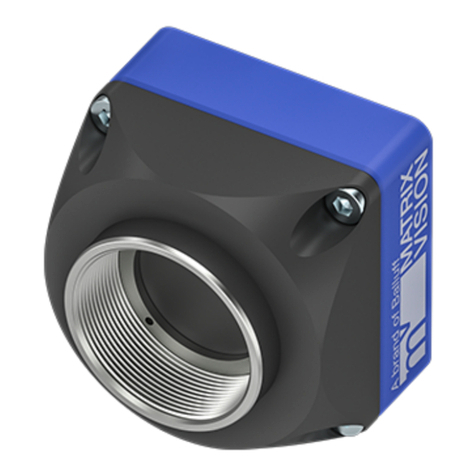

3PRODUCT DESCRIPTION 11

3.1 Product variants ................................................................................................. 11

3.2 Scope of delivery................................................................................................ 12

3.2.1 Assembly........................................................................................................ 13

3.3 Product specification......................................................................................... 14

3.3.1 Image sensor ................................................................................................. 14

3.3.2 Mechanical data............................................................................................. 14

3.3.3 Electrical data................................................................................................. 14

3.3.4 Operating conditions...................................................................................... 15

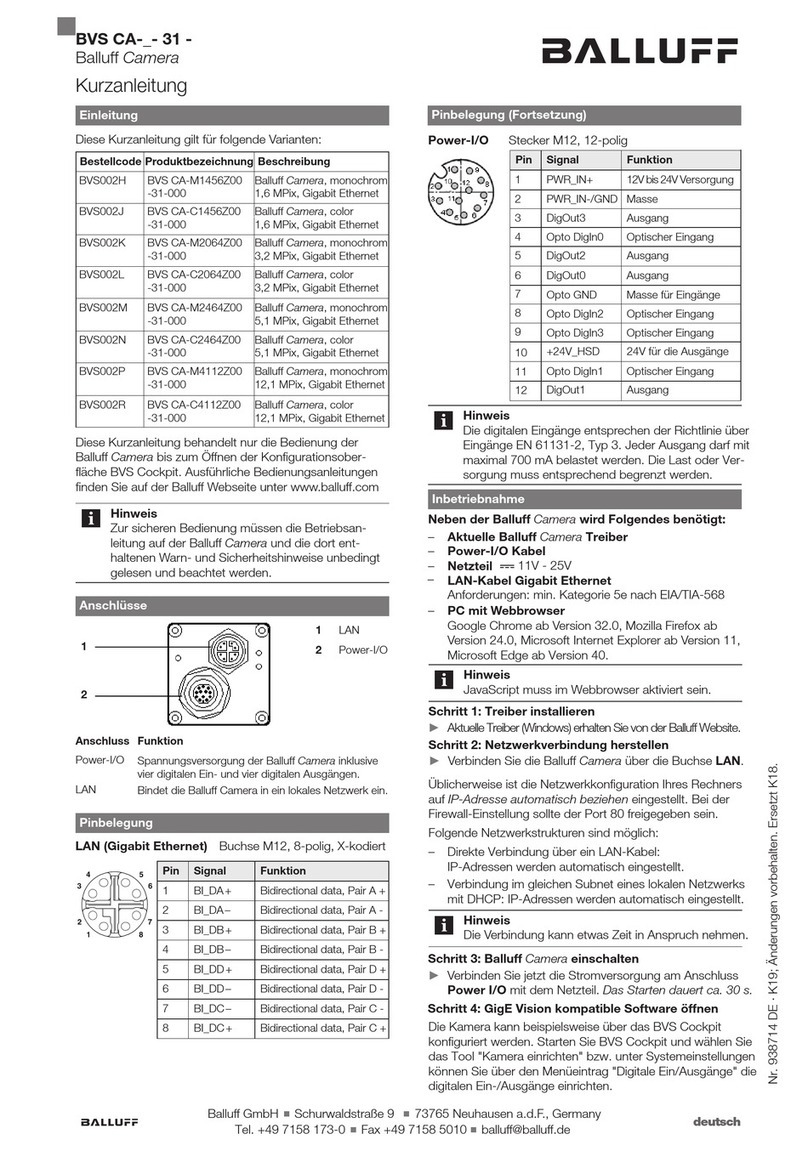

3.4 Connections and pin assignment..................................................................... 15

3.4.1 I/O variant....................................................................................................... 15

3.4.2 Power............................................................................................................. 18

3.4.3 LAN ................................................................................................................ 19

3.4.4 I/O light........................................................................................................... 20

3.4.5 I/O .................................................................................................................. 21

3.5 Display elements ................................................................................................ 24

3.5.1 Displays on the front / at the plug connectors................................................ 24

3.5.2 Displays on the front ...................................................................................... 24

3.5.3 Displays at the plug connectors..................................................................... 24

3.6 Cleaning............................................................................................................... 24

4FIRST STEPS 25

4.1 Step 1: Establishing a network connection with the SMARTCAMERA ........ 25

4.2 Step 2: Turn on SMARTCAMERA ..................................................................... 26

4.3 Step 3: Opening the BVS Cockpit web interface............................................. 26