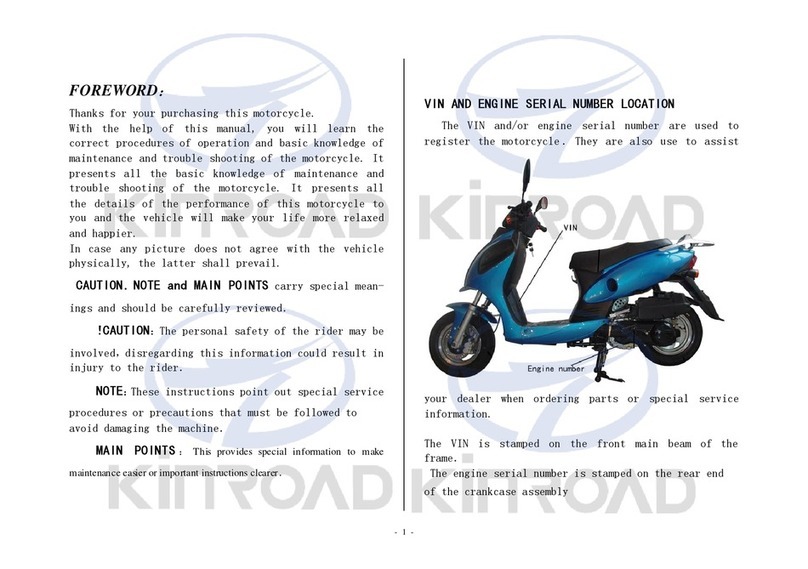

CHAPTER ONE MAINTENANCE OF THE MOTORCYCLE

Ⅰ

ⅠⅠ

Ⅰ. ITEMS OFMAINTENANCE

When the motorcycle is used, parts loose and mechanical wear inevitably occur to

varied extents. Neglecting of timely maintenance not only reduces its mechanical

function, economic performance, stability and durability, but also threatens the safety

of the motorcycle and the rider. Correct and timely maintenance of the motorcycle is

necessary. Items of maintenance refer to the parts and positions for maintenance.

Different items of maintenance are affected in different intervals and in different

manners.

1. Running-in Maintenance

This is the maintenance at the end of the first 1000km and is an all-round inspection

of motorcycle. A newly-bought motorcycle or a motorcycle fresh from an overhaul

might be severely overheated as a result of severe friction between the moving parts

which might be imperfect in finishing or fitting. Neglecting in use might lead to

damage of the friction surfaces and might threaten the performance, and the service

life of the motorcycle. Please observe the following points:

Restrict the speed in speed range specified in the instruction manual.

Restrict the load to 2/3 of the maximum load and ride in fairly good road

conditions.

Restrict the length of riding time to avoid long-time running of the engine.

Replace engine oil at short intervals so that metal chips caused in the running-

in period can be discharged. It is recommended to replace engine oil for 3 times

during the running-in period.

2. Routine Maintenance

Routine maintenance is the basis of all kinds of maintenances. It refers to the daily

maintenance, including cleaning, inspecting and common troubleshooting.

3. Periodic Maintenance

This maintenance is to restore normal performance of the motorcycle. The

maintenance is classified into first-grade periodic technical maintenance and second-

grade periodic technical maintenance (also known as items of maintenance) according

to different mileages. Generally speaking, a first-grade maintenance is effected after

the initial 4000km and a second-grade maintenance is effected every 8000km. As the

service time extends, maintenance intervals should be shortened accordingly.

Ⅱ

ⅡⅡ

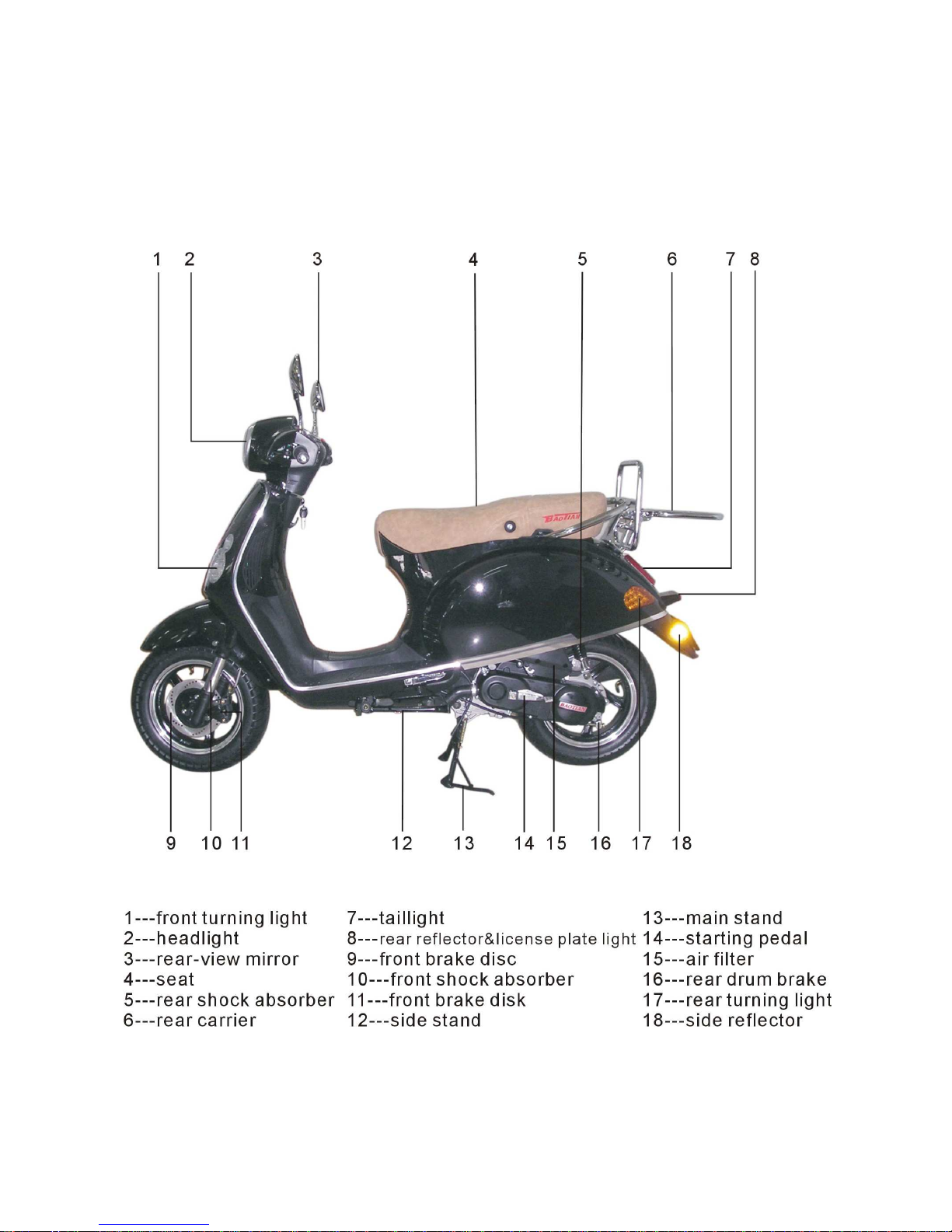

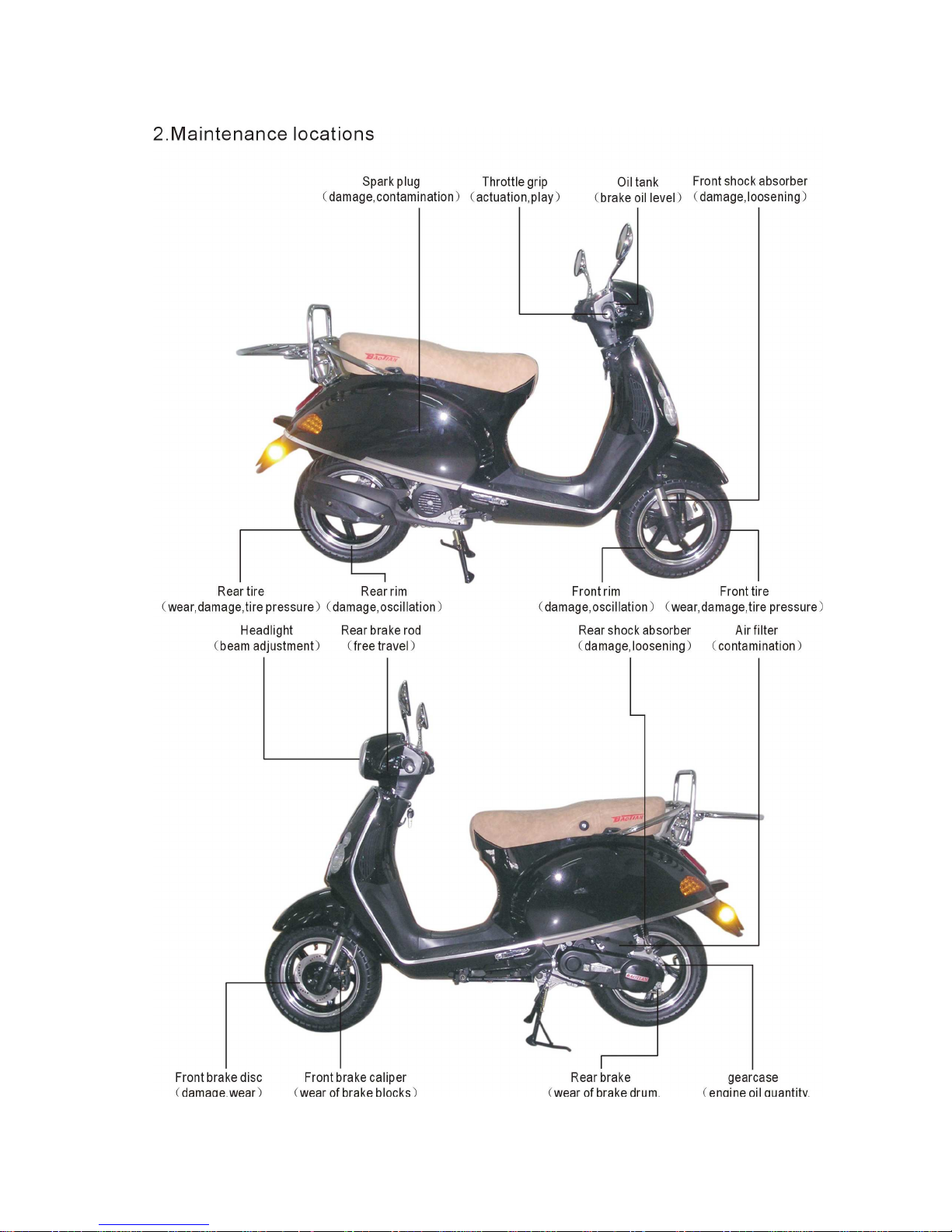

Ⅱ. PERIODIC MAINTENANCE SCHEDULE AND MAINTENANCE LOCATIONS

After a period of using (one day, one month or half a year, for example) or a certain

mileage (1000km, 4000km, 8000km, for example), an all-round maintenance

operation should be effected, including comprehensive inspection, adjustment,

tightening, lubrication, cleaning or replacement. The specific regulation made

according to time intervals or mileages is known as maintenance interval. The

motorcycle maintenance schedule is as follows.