24595_ins_BAPI_4_room_humidity

Installation & Operating Instructions

BA/B4-H200 Series

Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

T

el:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:

[email protected] • Web:www

.bapihvac.com

rev.01/26/11

Specications subject to change without notice.

Terminations

Note1: The termination screws should be turned fully Counter Clockwise (CCW) to open the jaws fully. Then insert the eld wire and turn

the screws Clock Wise (CW) to pinch the wire fully closed. If the jaws are left partially open, the inserted wire may be on bottom of, instead

of inside, the jaws causing a poor connection.

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger gauge wire may

be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or with wiring used

to supply highly inductive loads such as motors, contactors and relays.

BAPI recommends against wiring the sensor with power applied as accidental arcing may damage the product and void the warranty.

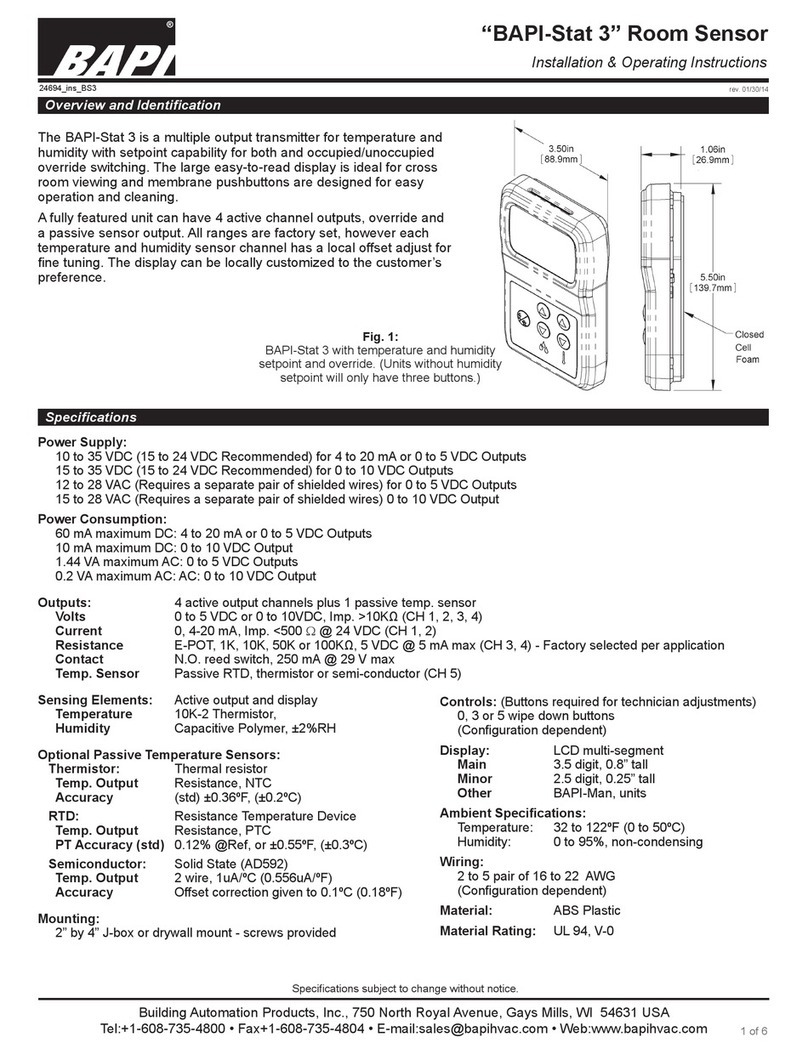

Fig 3: Circuit Board

NOTE: Common Ground Option (CG) OVR2, SEN2, and SET2 are connected together internally.

Differential Ground Option (DF) All terminals are independent.

4 to 20 mA Termination

Terminal Function

OVR1 & OVR2 Override Output (Dry Contact Switch). If unit is in common ground

(-CG), OVR2 is internally connected to SET2 & SEN2.

SET1 & SET2 Setpoint output. If unit is common ground (-CG), SET2 is internally con-

nected to OVR2 & SET2.

SEN1 & SEN2 Sensor Output (Resistive Output). If common ground (-CG), SEN2 is in-

ternally connected to OVR2 & SET2. (Semiconductor SEN1=+, SEN2=-)

EXT-OVR Allows remote control of the LCD indicator for occupancy, and is acti-

vated by logic LOW or power supply ground at this terminal.

VOUT Not Used

V+ Power, see specications section for details

GND 4 to 20 mA Humidity Signal [to analog input of controller]

0 to 5 VDC or 0 to 10 VDC or 2-10 VDC Termination

Terminal Function

OVR1 & OVR2 Override Output (Dry Contact Switch). If unit is common ground (-CG),

OVR2 is internally connected to SET2 & SEN2.

SET1 & SET2 Setpoint output. If unit is common ground (-CG), SET2 is internally

connected to OVR2 & SEN2.

SEN1 & SEN2 Sensor Output (Resistive Output). If common ground (-CG), SEN2 is

internally connected to OVR2 & SET2. (Semiconductor SEN1=+,SEN2=-)

EXT-OVR Allows remote control of the LCD indicaor for occupancy, and is activated

by logic LOW or power supply ground at this terminal.

VOUT Voltage Humidity Signal [to analog input of controller]

V+ Power, see specications section for details

GND To controller power supply ground [GND or Common]

2 of 5

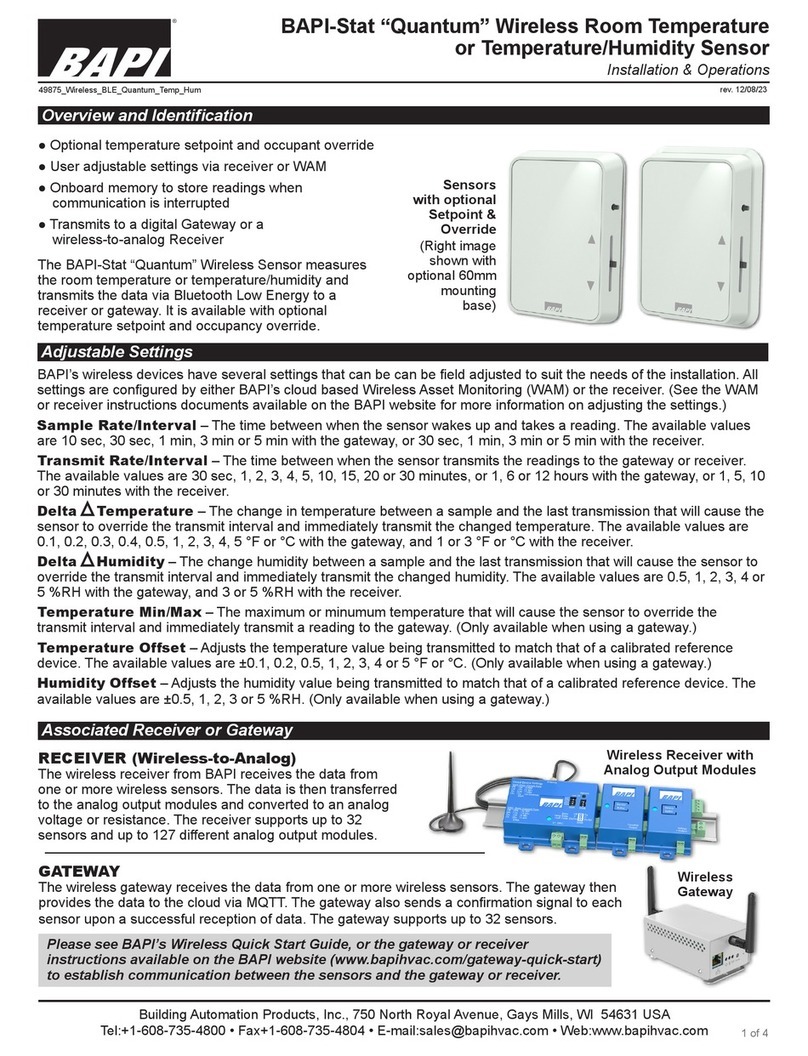

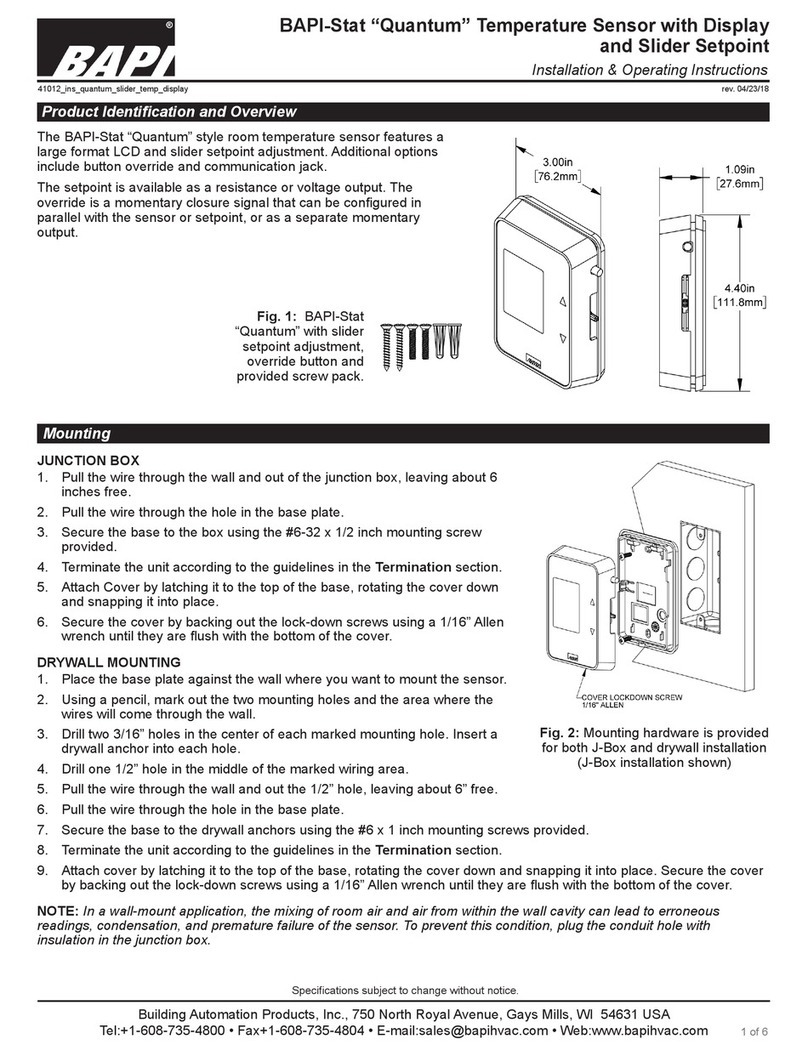

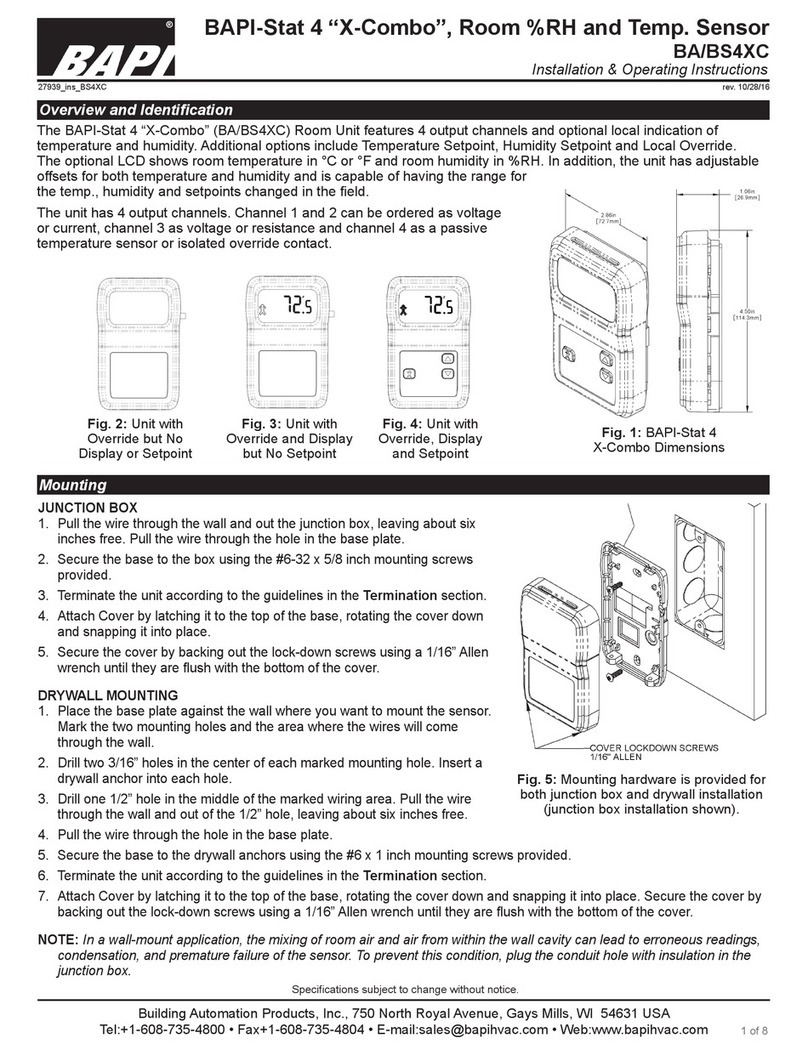

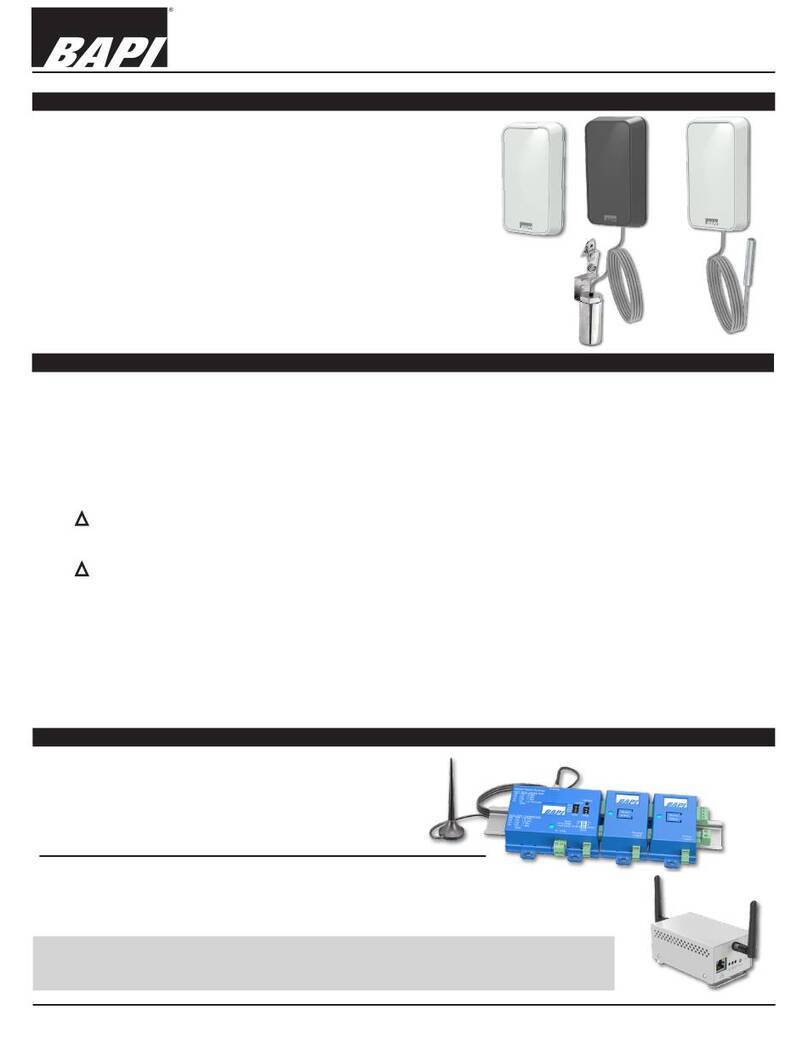

Mounting

Mounting hardware is provided for both junction box and drywall installation (junction box installation shown).

Junction Box

1. Pull the wire through the wall and out of the junction box, leaving about six inches free.

2. Pull the wire through the hole in the base plate.

3. Secure the plate to the box using the #6-32 x 1/2 inch mounting screws provided.

4. Terminate the unit according to the guidelines in the Termination section.

5. Attach Cover by latching it to the top of the base, rotating the cover down and snapping it into place.

6. Secure the cover by backing out the lock-down screws using a 1/16” Allen wrench

until they are ush with the bottom of the cover.

Drywall Mounting

1. Place the base plate against the wall where you want to mount the sensor.

2. Using a pencil mark out the two mounting holes and the area where the wires will

come through the wall.

3. Drill two 3/16” holes in the center of each marked mounting hole. Insert a drywall

anchor into each hole.

4. Drill one 1/2” hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out of the 1/2” hole, leaving about six inches free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

8. Terminate the unit according to the guidelines in the Termination section.

9. Attach cover by latching it to the top of the base, rotating the cover down and snapping it into place.

10. Secure the cover by backing out the lock-down screws using a 1/16” Allen wrench until they are ush with the bottom of the cover.

Fig 2: Mounting to a Junction Box

NOTE: In any wall-mount application, the wall temperature and the temperature of the air within thewall cavity can cause erroneous readings. The

mixing of room air and air from within the wall cavity can lead to condensation, erroneous readings and premature failure of the sensor. To prevent these

conditions, seal the conduit leading to the junction box or ll the box with insulation.