Barco RLM W8 User manual

Other Barco Projector manuals

Barco

Barco Helios User manual

Barco

Barco GRAPHICS 808s User manual

Barco

Barco G60 Series User manual

Barco

Barco HDX W18 Owner's manual

Barco

Barco SP2K-C User manual

Barco

Barco Njord User manual

Barco

Barco Galaxy 4 Long Life+ R9040355 User manual

Barco

Barco CRPN-52B User manual

Barco

Barco DP-1500 User manual

Barco

Barco UDX 4K22 User manual

Barco

Barco UDX Series User manual

Barco

Barco HDX series User manual

Barco

Barco BarcoData 3300 User manual

Barco

Barco Graphics 9200 User manual

Barco

Barco G 6300 User manual

Barco

Barco ELM G10 User manual

Barco

Barco R9002180 User manual

Barco

Barco DP4K--32B Reference manual

Barco

Barco BarcoReality 909 Split Pack R9040040 User manual

Barco

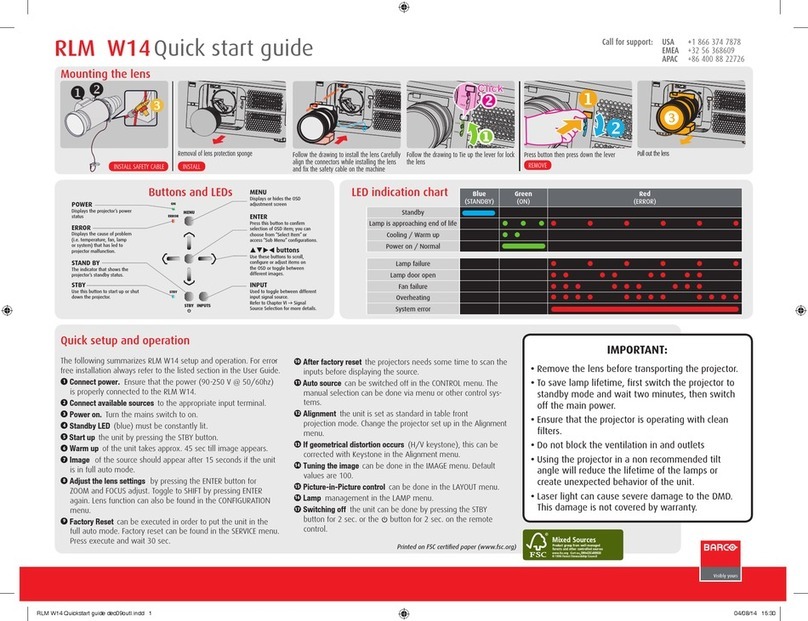

Barco RLM-W14 User manual