baridi DH49 User manual

Baridi 5L Universal Beer Dispenser Tap

with Integrated Cooling

Model No. DH49

Thank you for purchasing a Baridi product from the Dellonda range. Manufactured to a high standard,

this product will, if used according to these instructions, and properly maintained, give you years of

trouble free performance.

DH49 v1 Issue 1 25/08/20

2

Important Information

Please read these instructions carefully and note any safe operational requirements, warnings &

cautions. Use the product correctly and with care for the purpose for which it is intended. Failure

to do so may cause damage and/or personal injury and will invalidate the warranty. Keep these

instructions safe for future use.

• ELECTRICAL SAFETY

• WARNING! It is the user’s responsibility to

check the following:

• Check all electrical equipment and appliances

to ensure that they are safe before using.

Inspect power supply leads, plugs and all

electrical connections for wear and damage.

Dellonda recommend that an RCD (Residual

Current Device) is used with all electrical

equipment.

You may obtain an RCD by contacting your

local domestic stockist. If the product is used

in the course of business duties, it must be

maintained in a safe condition and routinely

PAT (Portable Appliance Test) tested.

• Electrical safety information: It is important

that the following information is read and

understood.

• Ensure that the insulation on all cables and on

the appliance is safe before connecting it

to the power supply.

• Regularly inspect power supply cables and

plugs for wear or damage and check all

connections to ensure that they are secure.

• Important: Ensure that the voltage rating on

the appliance suits the power supply to be

used and that the plug is tted with the correct

fuse - see fuse rating in these instructions.

• DO NOT pull or carry the appliance by the

power cable.

• DO NOT pull the plug from the socket by the

cable.

• DO NOT use worn or damaged cables, plugs or

connectors.

• Ensure that any faulty item is repaired or

replaced immediately by a qualied electrician.

• This product is tted with a BS1363/A 13 Amp

3 pin plug. If the cable or plug is damaged

during use, switch off the electricity supply and

remove from use. Ensure that repairs are

carried out by a qualied electrician.

• Replace a damaged plug with a BS1363/A 13

amp 3 pin plug. If in doubt contact a qualied

electrician.

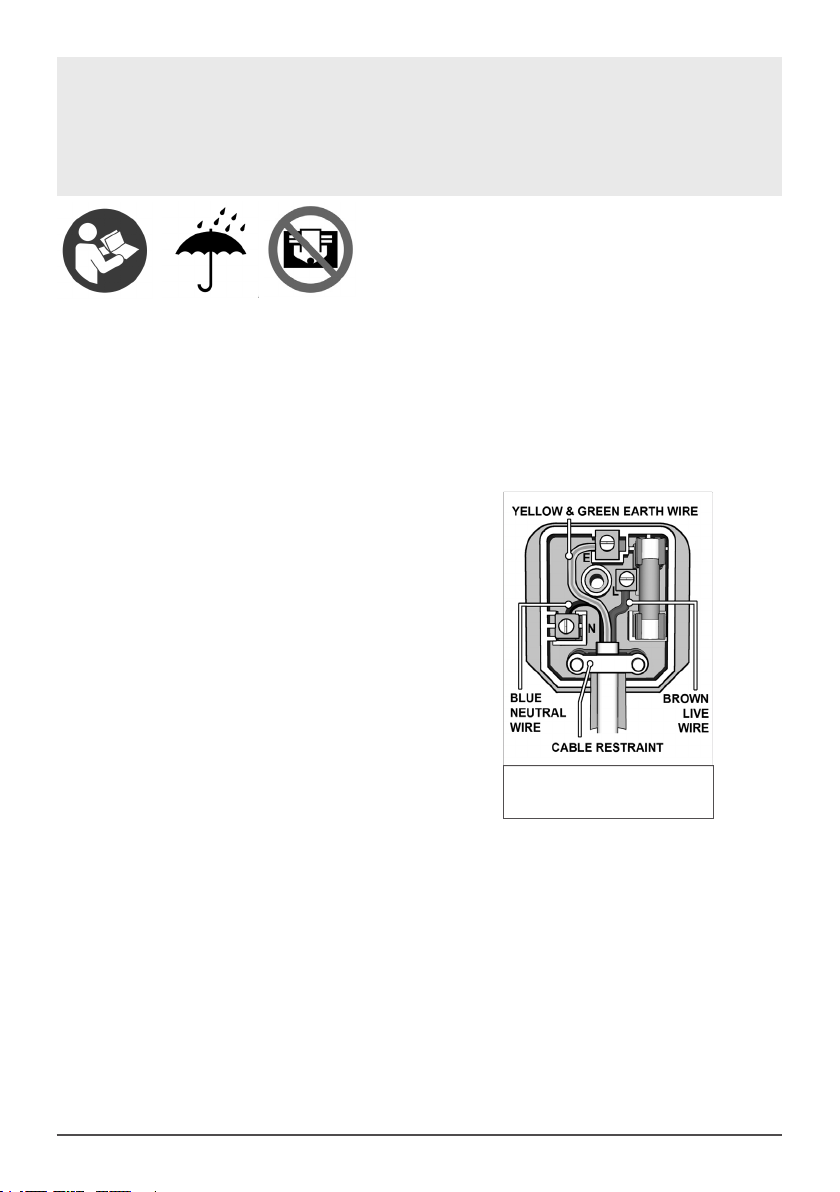

A) Connect the GREEN/YELLOW

earth wire to the earth terminal ‘E’.

B) Connect the BROWN live wire to the

live terminal ‘L’.

C) Connect the BLUE neutral wire to

the neutral terminal ‘N’.

• Ensure that the cable outer sheath extends

inside the cable restraint and that the restraint

is tight.

• Dellonda recommend that repairs are carried

out by a qualied electrician.

• GENERAL SAFETY

• DO NOT remove keg until fully empty.

Replacement fuse rating:

13A

Refer to

instructions

Keep out of

rain

Do not cover

3

• DO NOT remove CO2 cartridge until fully empty.

• DO NOT cover the unit while working.

• DO NOT place in direct sunlight.

• WARNING: Ensure the supply cord is not

trapped or damaged.

• WARNING: This appliance is intended

• This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of knowledge and

experience if they have been given supervision

or instruction concerning the use of the

appliance in a safe way and understand the

hazards involved. Children shall not play with

the appliance. Cleaning and user maintenance

shall not be made by children without

supervision.

• INTRODUCTION

• Universal tting for all 5L beer kegs.

Thermoelectric cooling technology chills beer

to as low as 4°C. Keeps beer fresh for up to 30

days. Removable drip tray with raised lip helps

prevent spillage. LED temperature gauge.

Operates using standard 16g CO2canisters.

Modern stainless steel and black design.

• SPECIFICATION

• Model no: DH49

• Lowest temperature: 4°C

• Rated current: 0.76A

• Voltage: 220-240V

• Frequency: 50Hz

• Noise level: ≤38dB(A); Ambient noise ≤25dB(A)

• Dimensions (W x D x H): 335 x 460 x 470mm

• Keg capacity: 5L

• INSTALLATION

• DO NOT locate the unit in a damp or moist

location.

• Operate unit on dry and level surface.

• NOTE: The unit is designed to be free-standing

and to ensure adequate ventilation, leave at

least 12 cm free space around the unit.

• Once in position allow the unit to rest for an

hour before turning it on.

• OPERATION

• Read this document thoroughly and assemble

the unit accordingly.

• Check that the unit is fully assembled and

installed in the appropriate location.

• Ensure that CO2valve is fully closed.

• Locate drip tray (g.1) into body and make

sure that the drain switch (g.1) is set in the

off (upright) position.

• Carefully pour 800 ml of clean tap water into

the cooling cavity.

• DO NOT exceed the ‘MAX’ mark inside the

chamber when lling.

• Select a temperature setting using the LED

interface on the top of the unit (g.1).

• NOTE: The LED display shows the current

temperature of the beer and pressing

and holding the ‘+’ key displays the set

temperature.

• Allow the unit time to reach the set

temperature before placing keg into the

cooling compartment.

• If using a ‘universal’ beer keg, open the

pressure control valve (g.1) and gently pull

the tap handle to begin ow.

• Use the pressure control valve to control the

beer’s ow rate and level of frothing.

• If serving Heineken beer, ensure the pressure

control valve is fully closed as the kegs have

their own internal pressurising device hence

there is no need to use the gas.

Pressure

Control

Drain

LED

Display

Drip tray

Latch

Fig.1

4

• CO2CARTRIDGE

• DO NOT attempt to remove a cartridge if it is

not empty.

• NOTE: Ensure that the pressure control

valve is set to fully closed before attempting

removal or replacement of a gas cylinder.

• NOTE: The cartridge mount has an ‘O’ ring

seal. If the seal is proven to be leaking,

replacement ‘O’ rings are supplied in the kit.

• NOTE: The cartridge used on this unit is NOT

the threaded type.

• Open the unit lid by pressing the button on the

lid (g.1).

• Unscrew the CO2 bottle housing from its

location within the lid and remove empty

cartridge from the unit (g.2).

• Check that the ‘O’ ring seal is in situ and in

good condition. Replace seal if in doubt.

• Place new cylinder into housing and relocate

into head.

• CARTRIDGE PIERCING CARE

• The cartridges used in this unit are of the blind

type i.e. they are NOT threaded. As such they

require piercing in order to operate.

• Should the piercing tool need replacement,

remove the empty gas cartridge.

• Carefully remove the ‘O’ ring seal from the

cartridge nest and lift out the installed piercing

tool (g.3).

• Insert the replacement piercing tool and ‘O’

ring noting that the orientation of the piercing

point is towards an inserted gas cartridge.

• BEER DISPENSING UNIT

• Assemble the dispensing unit by locating the

peg on the main body into the notch in the

clamp frame (g.4) NOTE: It can only t in one

direction.

• Screw the delivery tube onto the dispensing

unit making sure that the ‘O’ ring seal is in situ

and in good condition. Replace seal if in doubt.

• CONNECT DISPENSER TO TAP

• Assemble clear hose and connector as g.5.

• Lift the lid of the unit and press the release

mechanism on the tap body to release the

centre section of the tap body (g.5).

• Place the clear hose through the hole in the

removable centre section and while pushing

the tap handle down in the open position,

thread the clear hose down into the tap body.

CO2Cartridge housing

Pierce tool and ‘O’ ring

Fig.2

Fig.3

Fig.4

5

• NOTE: Ensure a rm leak proof location within

the tap body. Relocate centre section back to

original position.

• MOUNTING A UNIVERSAL KEG

• NOTE: Allow beer to fully settle before

attempting to t dispensing unit.

• NOTE: DO NOT leave keg standing in direct

sunlight or near a heat source.

• NOTE: It is recommended that you allow the

keg to cool for some time before use.

• NOTE: Carefully read any information

provided by the beer manufacturer that

relates to the keg and its operation.

• If tted, remove keg safety clasp according to

keg manufacturers instructions.

• Pierce keg seal with beer dispensing unit

probe (g.6).

• Push the tube down as far as it will go in

order to be able to t dispenser unit onto keg

rim.

• If the keg seal is of the type that is fully

removable, use the supplied tapered seal

(g.11) to make a leak proof seal.

• NOTE: The dispensing unit has a directional

arrow that indicates the direction of CO2 ow

through it.

• Ensuring directional ow as described above,

x dispensing unit into keg rim using the rim

of the keg to provide grip (g.7).

• Clip left side to keg rim and close opposite

side of clip under keg rim.

• Connect CO2 feed pipe and beer delivery tube

to either side of the unit by depressing white

tabs to allow full and leak proof engagement.

• MOUNTING A HEINEKEN KEG

• NOTE: Heineken kegs are pre-charged

with CO2 and DO NOT need the use of the

regulator.

• NOTE: Before connecting the keg ensure that

the tap is in the fully closed position.

• Remove the plastic cap from the keg using a

at head screwdriver.

• Using the Heineken adaptor (g.9) and before

tting it to the keg, attach the clear beer tube

to the Heineken adaptor and the other end to

the tap unit (g.8).

• Mount the adaptor into the keg by pressing it

into keg hole and clipping it in place.

• Carefully close the top cover.

• To remove the adaptor squeeze side tabs to

avoid damaging the adaptor (g.9).

Release

Button

Connection direct

To dispensing unit

Pierce keg seal

And push down

Clip unit under keg rim

Fig.5

Fig.7

Fig.6

Centre

section

Other baridi Kitchen Appliance manuals